Table of Contents

Summary of Contents for Terex RMX Series

- Page 1 HI–RANGER RMX SERIES OPERATOR’S MANUAL This Operator’s Manual MUST BE READ prior to operating your RMX SERIES Non-Overcenter Material Handling Articulating Aerial Device. PRINTED IN THE USA Original Instructions in English 483018 03/2015...

- Page 2 RMX SERIES Terex South Dakota, Inc. 500 Oakwood Road Watertown, SD 57201 48 301 8 - 03 /15 T er ex S outh D ako ta RM X Se ri es...

-

Page 3: Table Of Contents

RMX SERIES TABLE OF CONTENTS INTRODUCTION ..............- I OWNERS, USERS AND OPERATORS . - Page 4 RMX SERIES JIB & WINCH OPERATION (OPTIONAL) ..........1 - 21 HYDRAULIC JIB EXTENSION (OPTIONAL) .

- Page 5 RMX SERIES LUBRICATION CHART ............2 - 4 END MOUNT .

- Page 6 RMX SERIES t o c - 4 4 8 3 0 1 8 - 3 / 1 5 T er ex S o u t h D ak o t a R MX S e r i e s...

-

Page 7: Introduction

INTRODUCTION OWNERS, USERS AND OPERATORS Thank you for choosing Terex South Dakota equipment for your application. User safety is our number one priority and this is best achieved by our joint efforts. As equipment users and operators, you make a major contribution to safety if you: 1. -

Page 8: Intended Use

Use of this product in any other way is prohibited and contrary to its intended use. BULLETIN DISTRIBUTION AND COMPLIANCE It is the owners responsibility to comply with all bulletins issued by Terex South Dakota or the vehicle manufacturer. Safety of product users is of paramount importance to Terex South Dakota. Various bulletins are used by Terex South Dakota to communicate important safety and product information to dealers and machine owners. -

Page 9: Safety

The operator is the single most important factor for safety when using any piece of equipment. Learn to operate your Terex South Dakota equipment in a safe manner. NOTE: The best method to protect yourself and others from injury or death is to use common sense. - Page 10 Terex South Dakota equipment, subjecting users to serious injury or death. Any such modification will void any remaining warranty. 3. Terex South Dakota reserves the right to change, improve, modify or expand features of its equipment at any time. Specifications, model or equipment are subject to change without notice and without incurring any obligations to change, improve, modify or expand features of previously delivered equipment.

-

Page 11: General Safety Guidelines

RMX SERIES GENERAL SAFETY GUIDELINES 1. The use of this Aerial Device is subject to certain potential dangers that cannot be protected against by mechanical means. Only the exercise of intelligence, care, and common sense can eliminate these dangers. It is essential to have competent, careful operators who are physically and mentally fit, and thoroughly trained in the safe operation of this Aerial Device. -

Page 12: Before Operation

RMX SERIES BEFORE OPERATION 1. Survey the conditions of the work area. Identify situations such as; soft ground, ditches, drop-offs, holes, debris, overhead obstructions, electrical conductors, and underground utilities. 2. Plan the job (tailgate session) and clear the area of bystanders. -

Page 13: During Operation

RMX SERIES DURING OPERATION 1. Never operate the Aerial Device unless you know the location, function, and operation of all the controls, including emergency and accessory operation. 2. Avoid abrupt starts, stops and reversal of direction. Operate all controls slowly for smooth motion. -

Page 14: Electrical Hazards

RMX SERIES ELECTRICAL HAZARDS ELECTRICITY OBEYS NO LAW, BUT ITS OWN. 1. Electricity is an ever-present danger when using an Aerial Device. Follow all OSHA, ANSI, state, federal and company rules and regulations when working on or near energized power lines. -

Page 15: Accessories

RMX SERIES 20. Use only non-metallic tool holders and tool trays. 21. Never use leather work gloves or bare hands on grounded conductors when energized conductors are on the same structure. Wear insulating rubber gloves with leather protectors. 22. Do not lift conductors with the boom tip or platform. Use lifting device with appropriate attachments. -

Page 16: Material Handling

RMX SERIES MATERIAL HANDLING 1. Use only a synthetic rope for the winch line. Do not use a wire rope. 2. Do not permit personnel to be under loads being lifted. 3. Do not use winch or load line to raise personnel off the ground. -

Page 17: Maintenance

RMX SERIES MAINTENANCE 1. Inspect, maintain, and repair this Aerial Device in accordance with the maintenance manual for this device and the maintenance section of this manual. 2. Only authorized and qualified personnel with complete knowledge of this Aerial Device shall be allowed to perform maintenance on this Aerial Device. -

Page 18: Overview Of Potential Hazards

The operators shall read and understand this manual and be trained to use the machine in an appropriate and safe manner. Should any questions arise concerning the maintenance or operation of the machine contact Terex South Dakota. Alert Symbol DANGER: Failure to follow will Your safety is involved. - Page 19 RMX SERIES Crushing WARNING: Will Cause Serious Do not operate outriggers unless you can verify all Crushing Injury. personnel and obstructions are clear. Operator must watch the outrigger while in motion. High Pressure WARNING: Can Cause Serious Relieve pressure on hydraulic and pneumatic systems Air or Fluid Injury or Death.

-

Page 20: Safety Related Decals

RMX SERIES SAFETY RELATED DECALS Safety signs are designed and fitted to the product to warn of possible dangers, and MUST be replaced immediately if they become unreadable or lost. If the product is repaired and parts have been replaced on which safety signs were fixed, be sure new safety signs are fitted before the product is put into service. - Page 21 RMX SERIES 2. & 3. THIS BASKET, WITHOUT AN INSULATING LINER, IS NOT CERTIFIED AS AN ELECTRICAL INSULATING BARRIER. NOT INSULATED 47988D BOOM IS BEYOND ARROWS AVOID CONTACT WITH ENERGIZED LINES. 402236A FAILURE TO OBEY THE FOLLOWING READ CAREFULLY WILL RESULT IN...

- Page 22 RMX SERIES ELECTROCUTION HAZARD DEATH OR SERIOUS INJURY WILL RESULT FROM CONTACT WITH OR INADEQUATE CLEARANCE TO ELECTRICAL POWER LINES AND APPARATUS Maintain safe clearances from electrical power lines in accordance with applicable government regulations. Allow for boom, platform, electrical line and load line sway.

- Page 23 RMX SERIES ELECTROCUTION HAZARD THIS MACHINE IS NOT INSULATED DEATH OR SERIOUS INJURY Will result from contact with or inadequate clearance to electrical power lines and apparatus Maintain safe clearance from electrical power lines in accordance with applicable government regulations. Allow for boom, platform, electrical line and load line sway.

- Page 24 RMX SERIES OUTRIGGER CONTACT AN UNTRAINED OPERATOR WILL CAUSE SUBJECTS HIMSELF AND OTHERS TO SERIOUS CRUSHING INJURY DEATH OR SERIOUS INJURY Do not operate any outrigger unless you or a signal person can see that personnel YOU MUST NOT OPERATE...

- Page 25 RMX SERIES OVERTURNING HAZARD DEATH OR SERIOUS INJURY May result from overturning machine This unit has been tested for stability on a maximum slope of 5 degrees. Working on slopes that exceed 5 degrees may result in truck tipping over.

- Page 26 RMX SERIES INSPECTION DATE RECORD Follow the Frequent and Periodic Inspection Intervals as required in the Operators and Maintenance Manuals. Maintain a record of all inspections. Stamp or engrave below when and who performed inspections. Follow component replacement intervals shown in your Maintenance Manual.

- Page 27 RMX SERIES FALL HAZARD FAILURE TO PROPERLY MAINTAIN THIS MACHINE CAN LEAD TO STRUCTURAL FAILURE AND RESULT IN DEATH OR SERIOUS INJURY Read and follow all inspection and maintenance schedules in the manual(s). Do not operate machine unless all deficiencies are corrected. Proper maintenance and inspection is required for safe and reliable operation.

- Page 28 RMX SERIES PINCH POINT KEEP HANDS CLEAR TO AVOID PERSONAL INJURY H23451 Escaping fluid under pressure penetrate skin causing serious injury. Relieve pressure before disconnecting hydraulic lines. Keep away from leaks and pin holes. Use a piece of cardboard or paper to search for leaks.

-

Page 29: What Is Insulated And What Is Not Insulated

RMX SERIES WHAT IS INSULATED AND WHAT IS NOT INSULATED The term insulated means separated from other conductive surfaces by a dielectric substance (including air space) offering a high resistance to the passage of current (from OSHA 1926.960). Area A. Upper Boom Insulation, provides an insulating area between area D and earth ground when in properly maintained condition. - Page 30 RMX SERIES The insulating boom section only prevents current from passing from the band of arrows at the boom tip to the lower band of arrows. All components above and below that area must be considered conductive. The boom tip is everything past the upper band of arrows.

-

Page 31: Electrical Insulation

RMX SERIES ELECTRICAL INSULATION Operation on or near energized lines is extremely hazardous unless proper OSHA and ANSI work rules are followed. The operation of this Aerial Device in proximity to high voltage electrical lines involves several hazards to the operator of the Aerial Device, ground personnel and bystanders on the ground. These hazards are as follows: 1. -

Page 32: Prevention Of Electrocution

RMX SERIES PREVENTION OF ELECTROCUTION 1. NEVER rely on fiberglass dielectric properties around power lines with moisture present on the platform(s) and booms. If the Aerial Device is stored outdoors, protect the platform(s) and booms from the weather with a cover when not in use. To preserve dielectric properties, fiberglass must be kept clean and dry. - Page 33 RMX SERIES The fiberglass boom and platform liners must be dielectrically tested periodically to insure the insulating properties are being maintained. Do not assume that it is so. Ground personnel must be warned to stay away from vehicle in case of accidental boom contact between conductor and metallic portion of boom, which will cause serious injury or death.

- Page 34 RMX SERIES READ CAREFULLY OCCUPANTS OF THE BASKETS OF THIS AERIAL DEVICE HAVE ABSOLUTELY NO ELECTRICAL PROTECTION FROM CONTACT BY THE HUMAN BODY WITH TWO ENERGIZED CONDUCTORS OR BETWEEN AN ENERGIZED CONDUCTOR AND A GROUNDED CONDUCTOR. It makes no difference if this contact is...

-

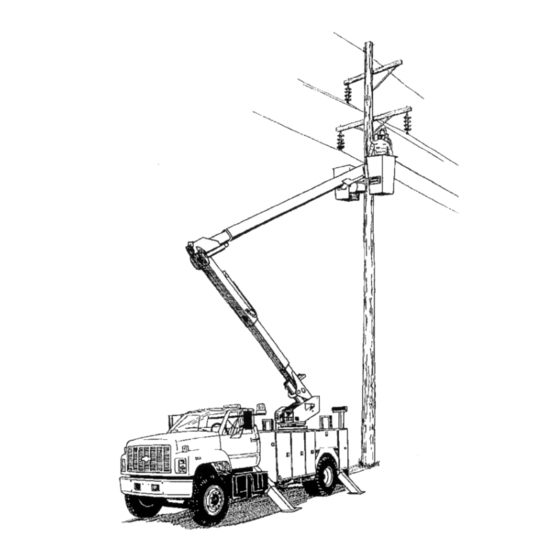

Page 35: Section 1

RMX SERIES SECTION 1 OPERATION GUIDELINES NOMENCLATURE Upper Controls Platform Upper Fiberglass Boom Boom Tip Elbow Elbow Cylinder Upper Boom Pivot Pin Fiberglass Insert Lower Boom (Steel) Main Boom Pivot Pin Lift Cylinder Turntable Lower Controls Platform Rest Boom Rest... -

Page 36: Cab Controls

RMX SERIES CAB CONTROLS MASTER CONTROL The master control is located in the cab of the vehicle and has a toggle switch on the dashboard. The toggle switch is used to energize the engine stop/start system and the throttle control options, which may be located in the cab, at the platform, or on the pedestal. - Page 37 RMX SERIES CAB CONTROLS OPERATION Master Power Push “ON” to activate remote electrical systems. Push “OFF” to deactivate remote electrical systems. May also engage PTO. O O N N M M A A S S T T E E R R...

-

Page 38: Controls Below Rotation

RMX SERIES CONTROLS BELOW ROTATION These controls are usually mounted at the rear of the vehicle chassis. The controls may include outriggers, hydraulic tools, control selector, engine stop/start, two-speed throttle, and auxiliary let down power. The controls shown are generic. The actual location and functions will vary depending on the purchasers requirements and options ordered. - Page 39 RMX SERIES CONTROLS BELOW ROTATION OPERATION Selector Move handle up to activate “UNIT” system. UNIT The Selector will function as an emergency stop by SELECTOR taking oil flow away from the active control O/R’S Move handle down to operate outrigger system “O/R’S”.

-

Page 40: Operator Controls And Descriptions

RMX SERIES OPERATOR CONTROLS AND DESCRIPTIONS Aerial Device functions may be controlled from either the upper controls at the platform or the lower controls station. The platform controls are used, in normal operation, by the operator to control the Aerial Device. The lower controls are used for inspection, maintenance, and in emergency situations. -

Page 41: Upper Controls

RMX SERIES LIFT LOCK HANDLES If a control lever at the upper controls operates a boom function, other than in the single stick, the control will have a lift lock handle. A spring-loaded lever on each boom function lever locks the levers in a neutral position and prevents accidental actuation. -

Page 42: Single Stick Operation

RMX SERIES The decals are an integral part of this Aerial Device. If the decals are illegible, they must be replaced. Always operate controls slowly and deliberately for smooth movements. Rough handling is never excusable and may cause damage to the Aerial Device and endanger the operator. - Page 43 RMX SERIES Upper Boom Squeeze the trigger and lift lever up to “UNFOLD” upper boom. UNFOLD Squeeze the trigger and push lever down to “FOLD” upper FOLD boom. Lower Boom Squeeze the trigger and push lever forward to unfold the lower boom “UP”.

- Page 44 RMX SERIES Platform Rotation Push to rotate clockwise “CW” to end position. (Optional) PLATFORM ROTATION Pull to rotate counterclockwise “CCW” to stowed position. 457490 NOTE: Directions are for side mount platform. Push to rotate clockwise “CW”. PLATFORM ROTATION Pull to rotate counterclockwise “CCW”.

- Page 45 RMX SERIES Jib Extension Push to extend jib boom “OUT”. (Optional) Always have one pin installed to prevent jib movement. EXTEND 457444 Pull to retract jib boom “IN”. Hydraulic Tools Push to select tool circuit number 1. TOOL 1 (Optional) Turn tool “OFF”...

-

Page 46: Lower Controls

RMX SERIES LOWER CONTROLS PRESS AND HOLD OPERATE TOWER ITEM CONTROL DESCRIPTION Rotation Controls rotation of booms. Upper Boom Controls articulation of upper boom. Lower Boom Controls lower boom articulation, upper maintains same angle to truck. Platform Leveling Allows the platform to be hydraulically tilted to level the platform. -

Page 47: Top Control And Option Shut Off

RMX SERIES TOP CONTROL AND OPTION SHUT OFF The Top Control and Option Shut Off is used to stop operation of the upper controls. It will stop all oil flow to the boom tip in case of an oil leak. It is also used to override the upper controls in case of an emergency. The upper controls are not operable when the Top Control and Option Shut Off is in the “OFF”... - Page 48 RMX SERIES Turntable Pull lever up to rotate “LEFT” or clockwise (CW). “Boom Rotation” LEFT Push lever down to rotate “RIGHT” or counterclockwise (CCW). TURNTABLE RIGHT Upper Boom Pull lever up to unfold upper boom “UP”. Push lever down to fold upper boom “DOWN”.

- Page 49 RMX SERIES Platform Leveling Pull lever up to tilt platform counterclockwise “CCW”. Do not operate when personnel are in the platform. PLATFORM LEVELING Push lever down to level platform clockwise “CW”. Winch Pull up to raise load or wind up winch line “UP”.

-

Page 50: Accessories

RMX SERIES ACCESSORIES DEMAND THROTTLE A demand throttle will increase the engine RPM automatically when a control is actuated. This signals the engine speed to increase therefore the pump output increases. The throttle activation used, electric or hydraulic, will depend on vehicle engine. -

Page 51: Hydraulic Tools (Optional)

RMX SERIES HYDRAULIC TOOLS (OPTIONAL) Hydraulic tool circuits are used to attach hydraulic powered hand tools to the hydraulic system of the Aerial Device. Quick-disconnect couplings are used to attach hydraulic tools. There may be one or two sets of tool couplers. -

Page 52: Platform Tilt

RMX SERIES PLATFORM TILT Do not allow anyone to tamper with the platform tilt device while occupants are in the platform. Serious personal injury or death could result from platform upsetting. The platform leveling system permits the platform to be tilted to clean out water and debris. It also allows the platform to be tilted for personnel rescue. -

Page 53: Platform Leveling

RMX SERIES PLATFORM LEVELING The platform leveling is through a master/slave cylinder combination. It can be used for platform clean out when no personnel are in the platform. It can also be used for rescue and removal of an injured operator. -

Page 54: Platform Rotator (Optional)

RMX SERIES PLATFORM ROTATOR (OPTIONAL) The platform rotator allows operator to rotate the platform from the stowed position to the rotated position (end position). When not in use the platform must be placed in the stowed position. Prior to platform rotation, observe all obstructions and hazards near the platform’s swing path to avoid collisions and contact with lines. -

Page 55: Jib & Winch Operation (Optional)

RMX SERIES JIB & WINCH OPERATION (OPTIONAL) When operating the winch under load, always use a smooth movement for lowering or raising loads to avoid shock loads and sudden changes in truck balance. These dynamic shocks can have an effect on the structural members of the Aerial Device. -

Page 56: Hydraulic Jib Extension (Optional)

RMX SERIES HYDRAULIC JIB EXTENSION (OPTIONAL) Refer to drawing below. 1. Install pin (1) and remove pin (2). 2. Extend or retract cylinder for desired direction to next hole and insert pin (2). 3. Remove pin (1). 4. Hydraulic extendable jib is now ready for use. -

Page 57: Determining Lift Capacities

RMX SERIES DETERMINING LIFT CAPACITIES The Aerial Device is equipped with an upper boom angle indicator and load chart on the side of the upper boom near the platform. The load capacity must be assured for the entire range of the boom motion throughout a lift. Must insure capacity is not exceeded at any point during load movement. -

Page 58: Avoid Trapped Loops

RMX SERIES AVOID TRAPPED LOOPS When winding a line with no load back to the winch drum, lower the boom so that a crewman with gloves can make sure that it is wound level. Trapped loops will damage the winch line or cause a load to drop on the next winch pay out operation. -

Page 59: Lower Boom Lifting Attachments

RMX SERIES LOWER BOOM LIFTING ATTACHMENTS The Aerial Device may be equipped with one of several optional lifting devices on the lower boom. When utilizing one of these lifting devices operate the Aerial Device from the lower controls with no one in the personnel platform(s). -

Page 60: Boom Lifting Eye Material Handling (Optional)

RMX SERIES BOOM LIFTING EYE MATERIAL HANDLING (OPTIONAL) A lifting eye may be provided to be used for limited material handling. For maximum lifting capacity, refer to the load chart installed on the Aerial Device. • Always extend the outriggers (if equipped). -

Page 61: Personnel And Training

RMX SERIES PERSONNEL AND TRAINING All personnel assigned to an Aerial Device shall be given an opportunity to become familiar with the operation of the equipment before they operate it on a job. The operator and all other personnel should be familiar with the operating procedures. -

Page 62: Pre-Operation

RMX SERIES PRE-OPERATION DAILY PRE-OPERATION CHECKS Before operating this Aerial Device, check the following: 1. Perform the frequent and periodic inspections and lubrications as outlined in the maintenance section of this manual. 2. Loose objects; store properly. 3. Under the vehicle for pools of liquid. - Page 63 RMX SERIES AERIAL DEVICE CHECKS ITEM DESCRIPTION ITEM DESCRIPTION Outriggers Upper Boom Outrigger Cylinders Upper Controls Outrigger Alarms Platform and Harness Outrigger Mounting Platform Step Return Line Filter Platform Mounting Main or Auxiliary Pump Hydraulic Plumbing Lower Controls Cylinder Holding Valves...

-

Page 64: Job Site Survey

RMX SERIES JOB SITE SURVEY Before locating the vehicle in position to work, make a complete survey of the job site. During the survey, some of the items to look for include the following: • Ambient conditions including temperature. • Consider the slope of the ground. Unit is tested on maximum 5 degree ground slope. -

Page 65: Job Site Setup

RMX SERIES JOB SITE SETUP Before locating the vehicle in position to work, make a complete survey of the job site. Select a truck position that has a ground slope of less than 5 degrees. This Aerial Device has been tested for stability on a flat firm surface with a maximum slope of 5 degrees. - Page 66 RMX SERIES • If unit is not equipped with outriggers, or only has one set of outriggers the tires and suspension on each side of each axle must uniformly support the truck and load because they are part of the stability system when operating the Aerial Device.

-

Page 67: Setting The Outriggers

RMX SERIES SETTING THE OUTRIGGERS Before lifting or rotating the Aerial Device, all outriggers (if equipped) must be lowered firmly to the ground on a surface that can support the load, and kept there until all work is complete and the Aerial Device is stowed for travel. -

Page 68: Setting Up On A Sloping Surface

RMX SERIES • Two sets of outriggers: The outriggers are extended to support the weight of the unit. The tires must remain in contact with the ground. • The vehicle can be leveled slightly with the outriggers. • The axles not located between the outriggers must equally support the load of the truck so the suspension on each side is equally loaded. -

Page 69: Setting Up On A Soft Surface

RMX SERIES If the vehicle must be set up with the slope, always keep the boom on the uphill side of the vehicle, chock the wheels, and always work off the rear of the vehicle. VEHICLE SETUP WITH THE SLOPE If the vehicle must be set up where an outrigger extends into a ditch or gutter and the full extension does not make firm contact, the outrigger must be blocked or cribbed up. -

Page 70: Setting Up For Operation On Snow And Ice

RMX SERIES SETTING UP FOR OPERATION ON SNOW AND ICE Operation on snow and ice adds an additional problem due to the slippery conditions. Normal traction is greatly reduced. Just as you need to maintain traction to walk and drive, it is required to keep Digger Derricks and Aerial Devices in a stable position. -

Page 71: Torsion Bars (Optional)

RMX SERIES TORSION BARS (OPTIONAL) Torsion bars may be installed on the rear axle, front axle, or both; alone or in addition to outriggers. If the vehicle has torsion bars, the tires, and suspension are important because they are providing the stability. -

Page 72: Operation

“feather” the controls for smooth operation. Lift the boom off the rest and elevate it high enough to clear all body obstructions before rotating. RMX Series Aerial Devices are equipped with a standard three port collector block oil distribution center in the mast which permits the continuous rotation of the boom in either direction without stops. -

Page 73: Aerial Operation

RMX SERIES AERIAL OPERATION Before using the Aerial Device, the operator should check through the pre-operational procedure to ensure the vehicle is properly positioned with outriggers (if equipped) firmly in place. Extreme care should always be exercised when lifting personnel. - Page 74 RMX SERIES FALLING FROM PLATFORM WILL RESULT IN DEATH OR SERIOUS INJURY Platform personnel must wear an OSHA approved fall protection system with lanyard attached to anchor provided. Platform doors, if provided, must be se- curely latched. 419264A ELECTROCUTION HAZARD...

- Page 75 RMX SERIES USE PROTECTIVE EQUIPMENT SUITABLE FOR THE WORK BEING PERFORMED: • Wear your rubber gloves and sleeves when working on or near electrical equipment. • Install hose, covers, and mats on all energized and grounded conductors. • Wear protective and insulated headgear.

-

Page 76: Emergency Operation

RMX SERIES EMERGENCY OPERATION Emergency operation may be required if an operator is injured or the equipment malfunctions. In any emergency, the first priority is always the safety of the personnel involved. It is always important to remember to follow the standard work practices and the safety regulations that apply. If the Aerial Device is operable, move the platform away from the danger and into the shortest, clear path of descent to get the operator on the ground. - Page 77 RMX SERIES STANDING ON GROUND CLOSE TO FALLEN POWER LINE You must shuffle keeping feet together, do not run. The voltage is highest where contact is made and decreases as you get farther away from the point of contact. The distance will depend on the ground conditions and conductivity of the ground.

-

Page 78: Top Control And Option Shut Off

RMX SERIES TOP CONTROL AND OPTION SHUT OFF When a situation requires use of lower controls to override the upper controls (such as, injured personnel in the platform). Move the Top Control and Option Shut Off control lever to the “off” position. This will make the upper controls inoperable. -

Page 79: Hydraulic Line Failure

RMX SERIES HYDRAULIC LINE FAILURE Hydraulic line failure during Aerial Device operation presents numerous hazards. Be aware that a hydraulic oil mist caused by a leak or hydraulic line failure is conductive even though nonconducting oil is used. A spray or mist produced by a hydraulic leak under pressure is very hazardous to personnel. - Page 80 RMX SERIES WHAT CAN HAPPEN WHEN HYDRAULIC LINES FAIL? Hydraulic oil, when confined within the hydraulic system and properly maintained, is non-conductive and not subject to being ignited. There are numerous hazards that develop when there is a hydraulic line separation: •...

-

Page 81: Engine Failure

RMX SERIES ENGINE FAILURE If the prime power source fails, the optional auxiliary let down power system can be used for emergency operation. If the auxiliary let down power system is not installed and the vehicle has a manual transmission, then use the engine stop/start control (if so equipped) to crank the engine. -

Page 82: Leaving The Job Site

RMX SERIES LEAVING THE JOB SITE 1. Articulate jib parallel with the upper boom before storing upper boom. Retract jib fully and pin for travel. 2. Rotate platform to stowed position. 3. Place upper and lower boom in the proper stored position for traveling. Upper boom must be locked in place with hold-down latch. -

Page 83: Section 2

A preventative maintenance program based on the manufacturer's recommendations shall be established. Dated and detailed inspection and repair records shall be maintained. It is recommended that the replacement parts for your Aerial Device be obtained from a Terex South Dakota distributor or Terex South Dakota. -

Page 84: Lubrication

Always remember, preventive maintenance can save much more than it costs. NOTE: The following check points listed are the minimum recommended by Terex South Dakota. They are subject to supplementation to conform with your own company regulations. -

Page 85: Frequent And Periodic Inspection Intervals

RMX SERIES FREQUENT AND PERIODIC INSPECTION INTERVALS DAILY 1. Check controls at platform and lower controls for proper operation. 2. Inspect fall protection equipment and attachments. 3. Inspect visual and audible devices. 4. Check cleanliness and dryness of fiberglass components. -

Page 86: Lubrication Chart

RMX SERIES LUBRICATION CHART END MOUNT HI-RANGER 6TC & 5TC SERIES 17 3 5,6,8 26,23 TYPE OF METHOD OF ITEM LUBRICATION POINT LUBRICATION APPLICATION CYLINDER BEARING BOOM PIVOT BEARING ELBOW PIVOT BEARING LINK BEARING ROTATION GEAR TEETH ROTATION DRIVE BEARING... -

Page 87: Side Mount

RMX SERIES SIDE MOUNT HI-RANGER TC SERIES 5,6,8 26,23 TYPE OF METHOD OF ITEM LUBRICATION POINT LUBRICATION APPLICATION CYLINDER BEARING BOOM PIVOT BEARING ELBOW PIVOT BEARING LINK BEARING ROTATION GEAR TEETH ROTATION DRIVE BEARING LITHIUM BASED BASKET SHAFT BEARING EP #2 GREASE... -

Page 88: Winch Rope Inspection

RMX SERIES WINCH ROPE INSPECTION All stable braid ropes in continuous service should be visually inspected once every working day. A thorough inspection of all ropes in use should be made at least once a month and a full written, dated and signed report of rope condition kept on file where readily available. -

Page 89: Daily Rope Inspection

RMX SERIES DAILY ROPE INSPECTION The synthetic rope must be inspected daily for any deterioration, resulting in appreciable loss of strength, such as described below. 1. Excessive external roughness. 2. Glossy or glazed areas, which indicates heat damage. 3. Look for flat areas, bumps, or lumps, which indicates core or internal damage. -

Page 90: Storage Procedure

RMX SERIES STORAGE PROCEDURE When a unit will not be used for a period of time, it should be prepared for storage to reduce the deteriorating effects of the environment. This includes the following: • Wash and clean to remove accumulated road grime. It can discolor the paint if left on for long periods of time. -

Page 91: Standards And Regulations

The information provided herein is accurate as of the date your Terex South Dakota, Inc. unit was manufactured. You must comply with the codes, standards and regulations as they are updated over time. It is your employer's responsibility to obtain copies and comply with all standards and regulations. -

Page 92: Osha Excerpts: (Clearance Distance)

APPENDIX A OSHA EXCERPTS: (CLEARANCE DISTANCE) The following are excerpts from OSHA Standards. They are not complete and do not cover all safety work rules. PARTIAL EXCERPT FROM SUBPART S - ELECTRICAL: (02-01-1998 EDITION) 1910.333 Selection and use of work practices. (c), (i) Unqualified person. - Page 93 APPENDIX A ALTERNATING CURRENT MINIMUM DISTANCES VOLTAGE RANGE MINIMUM WORKING AND (PHASE-TO-PHASE) KILOVOLT CLEAR HOT STICK DISTANCES 2.1 to 15 2 ft. 0 in. (0.61 m) 15.1 to 35 2 ft. 4 in. (0.71 m) 35.1 to 46 2 ft. 6 in. (0.76 m) 46.1 to 72.5 3 ft.

-

Page 94: Standard Hand Signals

APPENDIX A STANDARD HAND SIGNALS STOP. With arm extended EMERGENCY STOP. With both arms extended HOIST. With upper arm RAISE BOOM. With arm horizontally to the side, horizontally to the side, palms down, arms are swung back extended to the side, extended horizontally to the palm down, arm is swung and forth. -

Page 95: Responsibilities

APPENDIX B APPENDIX - B RESPONSIBILITIES ANSI A92.2-2009 (PARTIAL) Table of Contents: Responsibilities of Dealers and Installers. B - 1 Responsibilities of Owners. B - 2 Responsibility of Users. B - 5 Responsibilities of Operators. B - 7 Responsibilities of Lessors or Lessees. B - 9 Responsibilities of Brokers. - Page 96 APPENDIX B 7.8.1 Dealer or Installer as User. Whenever a dealer or installer directs personnel to operate an aerial device (inspecting, sales demonstrations, or any form of use), the dealer or installer shall assume the responsibilities of users as specified in Section 9 of this standard. All personnel authorized to operate the aerial device shall have been trained in a program that meets the requirements of this standard.

- Page 97 APPENDIX B 8.2.4 Periodic Inspection or Test. An inspection of the mobile unit shall be performed at the intervals defined in 8.2.2 depending upon its activity, severity of service, and environment, or as specifically indicated below. (These inspections shall include the requirements of 8.2.3): (1) Structural members for deformation, cracks or corrosion.

- Page 98 APPENDIX B 8.2.5 Post Event Inspection or Test. After any reported event during which structural members of an aerial device or mobile unit are suspected of being subjected to loading or stresses in excess of design stress such as after an accident involving overturning of the mobile unit or application of unintended external mechanical or electrical forces to the aerial device, the aerial device shall be removed from service and subjected to the applicable periodic inspection requirements in 8.2.4.

- Page 99 APPENDIX B 8.12.1 General Training. Only personnel who have received general instructions regarding the inspection, application and operation of aerial devices, including recognition and avoidance of hazards associated with their operation, shall operate an aerial device. Such items covered shall include, but not necessarily be limited to, the following issues and requirements: (1) The purpose and use of manuals.

- Page 100 APPENDIX B (6) The purpose of placards and decals. (7) Workplace inspection. (8) Applicable safety rules and regulations, such as Part 4, ANSI C2-2007, National Electrical Safety Code (applies to utility workers as defined in ANSI C2). The above standard is an example; other industries using aerial devices have safety rules pertinent to that industry.

- Page 101 APPENDIX B 10.4 Work Platform. The operator shall not use railing, planks, ladders or any other device in or on the work platform for achieving additional working height or reach. 10.5 Brakes. The vehicle parking brake(s) shall be set at all times that the boom is elevated except when the aerial device is being used in accordance with 10.11.

- Page 102 APPENDIX B 10.10 Precautions. Before and during each use the operator shall: (1) Check for overhead obstructions and electrical conductors. (2) Insure that the load on the platform and/or load lifting device is in accordance with the manufacturer's rated capacity. (3) Insure that outriggers and stabilizers are used if the manufacturer's instructions require their use.

- Page 103 APPENDIX B 10.13 Electrical Hazard. All applicable safety related work practices intended to protect personnel from electrical hazards shall be defined and explained to the operator by a qualified person. The operator shall maintain the appropriate Minimum Approach Distance (MAD) from energized conductors and apparatus commensurate with the operator’s qualification.

- Page 104 APPENDIX B (12) Electrical hazards and Minimum Approach distance to energized conductors and apparatus. See Appendix F. 11.4.2 Familiarization. When an operators are directed to operate an aerial device with which they are not familiar, they shall be instructed, prior to operating the aerial device, regarding the following items: (1) The location of the manuals.

-

Page 105: Survey Of Job Site

Construction and electrical workers are subject to certain hazards that cannot be eliminated by mechanical means and must be controlled by care, common sense and intelligence. Terex South Dakota, Inc. realizes the importance of safety and strongly recommends that prior to commencing any operation, the employer make a survey of the conditions of the site to determine the hazards and the kind and number of safeguards that the employer will install. - Page 106 APPENDIX B (c) Number of workers (d) Plans for maintaining interest in safety: (1) Safety bulletins, record charts and posters (2) Recognition for groups or individuals (3) Investigation and reporting on reportable accidents (4) Knowledge of safety orders (5) Safety meetings (6) Specific safety instructions for new employees (e) Establishment of provisions to take immediate action to correct unsafe conditions or acts (f) First aid and medical treatment of injuries...

Need help?

Do you have a question about the RMX Series and is the answer not in the manual?

Questions and answers