Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for THM Clavicula M3

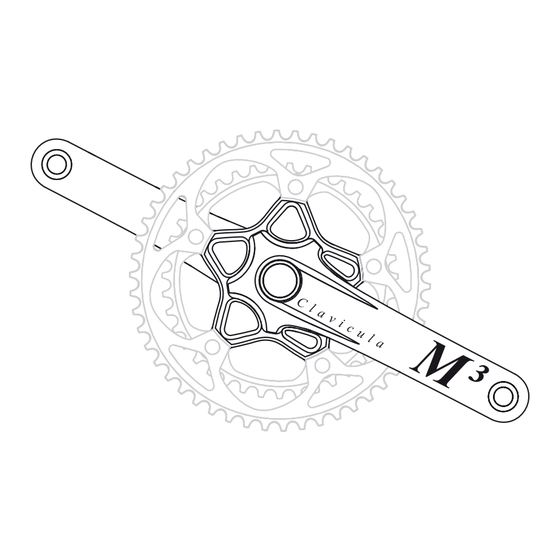

- Page 1 C l a v i c u l a M ³ Road Instruction book THM Clavicula M³_3_en, 2013-02...

- Page 2 Don't forget that your THM component is a lightweight carbon design. Be aware of this when carrying out assemly and maintenance work and when handling the component. Proceed with utmost care!

- Page 3 Instruction book...

-

Page 4: Table Of Contents

Contents INTRODUCTION Preface ....... . 5 SAFETY Intended use ......6 Fundamental safety precautions . -

Page 5: Introduction

Introduction Preface This manual is an integral part of your THM component and it provides you with infor- mation regarding the safe operation of your THM-Clavicula crank system. Read this manual carefully prior to assembling your THM component. Always read and... -

Page 6: Safety

The following warnings for the THM-Clavicula component apply to all Clavicula models (Clavicula Road, Clavicula MTB etc.), unless otherwise specified. For the time being we limit the service life of your THM-Clavicula crank system to 100,000 km or 10 years. It is imperative you contact us before continuing to use your... -

Page 7: On The Road

-If you are involved in a heavy fall you should not continue riding your bicycle. If such a case occurs, send us your THM components for inspection, even if no external damage is visible! In your own interest you should treat all components on your bicycle which are produced by other manufacturers in the same way. -

Page 8: Specifications

(6) Bearing cup, left (marked by groove) (7) Spacer, 2.5mm (8) Bearing cup, right (13) THM adjusting tool (14) THM bottom bracket tool (optional) (15) THM lockring tool (MTB) These items must be ordered separately if necessary. without chainwheels and chainwheel bolts... -

Page 9: Bottom Bracket

Specifications Bottom bracket (a) Road (BSA/ITA): Bearing cup left/right (b) MTB (BSA): Bearing cup left/right, 3× spacer ring (2.5mm) (c) BB30 Road: Bearing cup left/right (d) BB30 MTB: Bearing cup left/right, 2× spacer ring (2.5mm) (e) PressFit 30 Road: Bearing cup left/right (f) PressFit 30 MTB: Bearing cup left/right (g) BBright™... -

Page 10: Size

Total weight, max.*** kg(lb) Technical specifications, dimensions and weights are to be understood with the corresponding tolerances and can differ slightly from your THM components. BSA (1.37"×24 tpi) / ITA (36×24 tpi) Total weight = rider + bicycle + luggage... -

Page 11: Tightening Torques

Specifications Tightening torques WARNING Risk of accident caused by a malfunctioning crank system due to loose screw connections. -Check the required tightening torque of all screw connections after the first 100 km - re- tighten the connections if necessary. Repeat this check every 2500km! N·m(lbf·in) max. -

Page 12: Assembly

Assembly Installing the Clavicula WARNING If not properly performed, assembly and maintenance work can cause accidents resulting in serious or fatal injury. -Do not overestimate your technical ability. All assembly and maintenance work should be performed by a specialist workshop for bicycles. This is the only way to ensure that work is conducted in a professional manner. -

Page 13: Spacers

Assembly E-TYPE, Chain- guide, … E-TYPE, Chain- guide, … Spacers Spacers Bottom bracket Front derail- Bottom bracket Fig. housing leur type Anticlockwise Clockwise Road BSA (ITA); BB30 Road; PressFit Clip-on/ 30 Road braze-on 2× 2.5mm 68.0mm (70.0mm) MTB BSA 1× 2.5mm 1×... -

Page 14: Installing The Bottom Bracket

Installing the bottom bracket Do not use the Clavicula Road in combination with an E-TYPE front derailleur! The THM socket wrench(1)(fig. 3), which can be used as a torque wrench, can be ob- tained from us or from your specialised dealer. -

Page 15: Bb30/Pressfit 30/Bbright™ Pressfit

Tighten the bearing cup (3) or (4) using a tightening torque of 40N·m (354lbf·in). This torque corresponds to a manual force of approx. 20kg (44lb) at the end of the THM bottom 20 kg bracket tool. (44 lb) (fig. 6) 40 N·m (354 lbf·in) -

Page 16: Press-Fit/Evo386

Risk of accident caused by a malfunctioning spider due to the use of hollow screws that are too long or too short. -Only ever use original THM hollow screws when attaching the spider. Make sure that the hollow screw threads are provid- ed with fresh, medium-strength thread lock. - Page 17 Make sure the thread of the lockring is provided with fresh, medium-strength thread lock. Use the THM lockring tool to tighten the lockring with a tightening torque of 30N·m (266lbf·in). (fig. 12) SRM PowerMeter If you have an SRM PowerMeter that you would like to use, please contact SRM directly to inquire whether it is compatible with your Clavicula M³.

-

Page 18: Assembling The Chainwheels

Assembly Assembling the chainwheels NOTICE Danger of damage to the chainwheel mount or axle crank. -The number of chainwheel teeth must never be below the minimum number required – see Size, page 10. -Always mount 2 chainwheels on the outer chainwheel mount for the corresponding spi- ders (Road, Road Compact, MTB 3-104/64) (fig. - Page 19 Assembly Insert the axle crank through the bottom bracket up to its stop. (fig. 17) Thoroughly degrease the axle and crank multi-tooth segment. Insert the spacer ring onto the axle. Road: 2.5mm MTB: 9.7mm (fig. 18) Road ...

-

Page 20: Adjusting The Bottom Bracket

0.3–1N·m (3–9lbf·in). Screw the adjusting screw into the axis – when doing this use the THM adjusting tool, the end of the THM bottom bracket tool or, if necessary, a suitable coin (such as a 1 Euro piece). -

Page 21: Assembling The Pedals

Danger of damage to the carbon structure around the pedal threads. -It is essential you do not confuse the RH and LH pedal! -Do not exceed the maximum tightening torque for the pedals prescribed by THM – max. 20N·m (177lbf·in)! -

Page 22: Maintenance

Never use caustic solvents (such as paint thinners, acetone, nitro compounds, etc.) as they can attack the surface of your THM components. Only use commercially available paint care products and water to clean your THM com- ponents. Spirit or petrol should be used carefully - when using such products avoid excessive wiping and prolonged exposure times. -

Page 23: Disposal

Disposal If THM components are defective or no longer in use, you can dispose of them with your non-recyclable waste or domestic refuse, or ask a local waste disposal company for other disposal methods (e.g. recycling). -

Page 24: Before Each Trip

WARNING Risk of accident due to material damage or assembly error. -Check your THM components before each journey to ensure the bonded joints are com- pletely undamaged. Send us your THM components for inspection before further use if damage is visible (cracks, fractures, clicking sounds, wobbling, etc.) or if you are in any doubt about their functionality. -

Page 25: Regular Maintenance

When cleaning your THM components always check for signs of damage (dents, cracks, scratches, large abrasions, worn areas, etc.). Periodically preserve the surface of your THM com- ponents using a high quality protecting wax or other similar agent. Clavicula M³... -

Page 26: Dismantling The Bottom Bracket

Maintenance Dismantling the bottom bracket BB30/PressFit 30 When dealing with BB30, PressFit 30 and BBright™ PressFit bottom brackets the bearing cup with internal thread (1) or (3) is always located to the right, while the bearing cup with external thread (2) or (4) is al- ways located to the left. - Page 27 Maintenance Use a rubber mallet to carefully tap the bearing cup(2) or (3) until the bearing cup(1) or (4) is freed from the bottom bracket housing. (fig. 6, 7) Now twist the bearing cups apart by hand and re- move these from the bottom bracket housing.

-

Page 28: Legal

Liability does not extend to any kind of damage caused by normal wear and tear, accidents, unauthorised modifications, negligence or improper handling and use. Liability shall expire if repair work or any other work on the THM product has been conducted by unauthorised persons. - Page 29 The company THM Faserverbund-Technologie GmbH is constantly striving to improve product designs as technical developments continue. We therefore reserve the right to make alterations which must not correspond to the text and illustration contained in this manual, and without incurring obligation to alter any products previously delivered.

- Page 32 THM Faserverbund-Technologie GmbH Am Sportplatz 3 D - 24791 Alt Duvenstedt +49 4338 99 94-123 +49 4338 99 94-122 info@thm-carbones.com www.thm-carbones.com...

Need help?

Do you have a question about the Clavicula M3 and is the answer not in the manual?

Questions and answers