Summary of Contents for Neptune MP7100

- Page 1 INSTALLATION OPERATION & MAINTENANCE NEPTUNE Series 7000 Non-Controlled Mechanical “dia-PUMP” Models MP7100, MP7120, MP7130, MP7150, MP7180 NEP-ZL129306 03.2018_REV 1...

-

Page 2: Safety Instructions

ZL129306 03.2018_REV 2 WARNING LOCKOUTS ARE REQUIRED BEFORE SERVICING THIS EQUIPMENT. SAFETY INSTRUCTIONS: Shut off/Lockout Pump Power before Servicing. Be certain pump isolation valves are Closed and chemical is shut off. Bleed pressure before servicing. - Page 3 WARNING Please read thoroughly before installation, operation or maintenance of any Neptune pump EQUIPMENT MISUSE HAZARD Equipment misuse can cause the equipment to rupture, malfunction and result in serious injury. This equipment is for professional use only. • Read all instruction manuals, tags, and labels before operating the equipment.

- Page 4 Ground the equipment. See motor installation instruction for grounding procedure. • Do not pump non recommended flammable or explosive fluids. • Static electricity may generate by fluid moving through pipes and hoses. A static spark could • be produced by high fluid flow rate. Earthling of the pump is a must. Provide fresh air ventilation to avoid the possible buildup of flammable fumes from the •...

-

Page 5: Table Of Contents

SECTION PARAGRAPH TABLE OF CONTENTS PAGE GENERAL DESCRIPTION LIMITED WARRANTY PARTS ORDERING INSTRUCTIONS INSTALLATION INSTRUCTIONS GENERAL SUCTION PIPING DISCHARGE PIPING INSTALLATION OUTDOORS STARTUP PROCEDURE NORMAL MAINTENANCE MAINTENANCE PARTS LIST COMMON PARTS LIST GEAR BOX PARTS LIST PER MODEL LIQUID HEAD PARTS LIST PER MODEL 18,19 MOTOR OPERATING CONDITIONS TROUBLE SHOOTING CHART... -

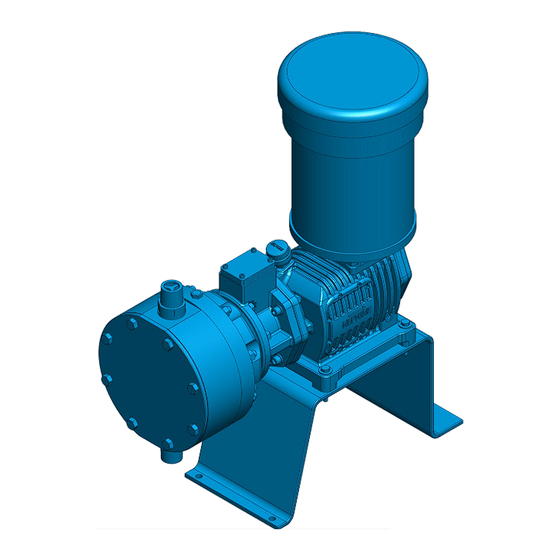

Page 6: Igeneral Description

SECTION I GENERAL DESCRIPTION The Neptune MP7000 Mechanical Diaphragm metering pump is a reliable metering pump of the low-pressure diaphragm type. Under constant conditions of temperature, pressure, and capacity setting, a +/- 2% metered discharge volume is maintained. Rugged contoured composite diaphragm designed for high metering accuracy. -

Page 7: Limited Warranty

NEPTUNE CHEMICAL PUMP COMPANY LIMITED WARRANTY All Neptune Pumps are tested at the factory prior to shipment. Each part used in their construction has been carefully checked for workmanship. If the pump is installed properly, Neptune Chemical Pump Company warrants to the purchaser of this product for a period... -

Page 8: Parts Ordering Instructions

CHEMICAL PUMP CO. North Wales PA 19454 DOVER COMPANY TEL: 215-699-8700 Send all orders or inquiries for parts to: Parts Department Neptune Chemical Pump Company, Inc. 295 DeKalb Pike North Wales, PA 19454 Tel.: 215-699-8700 1 -888-3NEPTUNE (888-363-7886) FAX: 215-699-0370 Web: www.neptune1.com... -

Page 9: Installation Instructions

When unpacking a pump or chemical feed system, be certain that no parts are thrown away. Examine the equipment for possible damage. If damage has occurred, file claim with the common carrier within 24 hours. Neptune will assist in estimating the repair costs. 1.0.2 The Mechanically Actuated Diaphragm metering pumps should be located on a level surface. -

Page 10: Suction Piping

20 feet (6 meters) of water suction lift. Neptune Mechanically Actuated Diaphragm metering pumps are designed for continuous service at the rated discharge pressure. The discharge pressure must exceed suction pressure by at least 25 psiA (or 1.75 Bar). -

Page 11: Discharge Piping

3.0.3 To protect the pump, it is recommended that an external relief valve as manufactured by Neptune Chemical Pump Company, or equal, be placed in the discharge line of the pump to avoid over pressure. - Page 12 significant amount of maintenance. It is advised that periodic visual observations be made of the oil level to make sure that it is over the worm gear. The liquid end of the pump should also be inspected for leakage and check the liquid head bolt torque.

- Page 13 6.3.0 LIQUID HEAD REMOVAL, INSPECTION, AND REINSTALLATION CAUTION: If the diaphragm failed, process fluid will pass through the bleed hole located behind the diaphragm. Handle any liquid with appropriate care. (Refer to liquid manufacturer’s MSDS) Mechanical diaphragms should operate for approximately 2000+ hours under normal operating conditions;...

-

Page 14: Model Mp7120-3N5 Mechanically Actuated Pump

MODEL MP7120-3N5 MECHANICALLY ACTUATED PUMP (SHOWN WITH PVC #3 LIQUID HEAD) HORIZONTAL CROSS SECTION... - Page 15 VERTICAL CROSS SECTION...

- Page 16 PUMP SIDE VIEW (LEFT SIDE)

- Page 17 PUMP SIDE VIEW (TOP VIEW)

-

Page 18: Parts List

BACK COVER MECH DIAPH PUMP 004793 PIPE PLUG 100196 MOTOR PIPE PLUG 100332 BREATHER VENT 104447 GEAR BOX PARTS LIST PER MODEL PUMPS MP7100, 120, 130, 150, 180-2NX PUMPS MP120, 130, 150, 180-2NX ITEM PART ITEM PART DESCRIPTION QTY. DESCRIPTION QTY. -

Page 19: Liquid Head Parts List Per Model

CROSS SECTION (HEAD AREA) MP7120-2N5,-2N8 LIQUID HEAD PARTS LIST PER MODEL FOR PUMPS: MP7100, 120, 130, 150, 180 -2N3 -2N5 -2N8 ITEM NO DESCRIPTION QTY. PART NO. PART NO. PART NO. PLATE, HEAD, #2 004858 004858 LIQUID HEAD #2 316SS... -

Page 20: Liquid Head Parts List Per Model

LIQUID HEAD PARTS LIST PER MODEL FOR PUMPS: MP7100, 120, 130, 150, 180 -3N3 -3N5 -3N8 ITEM NO DESCRIPTION QTY. PART NO. PART NO. PART NO. PLATE, HEAD, #3 004859 004859 LIQUID HEAD #3 316SS 004799 LIQUID HEAD, #3, PVC... -

Page 21: Motor Operating Conditions

SECTION IV MOTOR OPERATING CONDITIONS The normal temperature rise for standard motors is 40°C above ambient temperature and, thus, it might appear that the motor is operating at a higher than normal temperature. This situation is normal. As a precaution against motor overheating, it is recommended that the pump be located where adequate ventilation is available, It is also recommended that a MOTOR STARTER WITH THE PROPER OVERLOAD PROTECTION BE SUPPLIED AS AN ADDITIONAL SAFETY DEVICE. -

Page 22: Spare Parts Kits

SPARE PARTS KITS ITEM PART DESCRIPTION QTY. NUMBER KIT NUMBER 005178 DIAPHRAGM #2 ASSEMBLY 104743 46, 47 CHECK VALVE ASSEMBLY 1/2” NPT 005011 MP71XX-2N3 ITEM PART DESCRIPTION QTY. NUMBER DIAPHRAGM #2 ASSEMBLY 104743 KIT NUMBER 005179 46, 47 CHECK VALVE ASSEMBLY 1/2” NPT 003279 MP71XX-2N5 ITEM... -

Page 23: Msds For Hypoid Gear Oil Sae 80W-90

MSDS FOR GEAR OIL SAE 80W-90... -

Page 36: Pump Data / Maintenance Log

PUMP DATA / MAINTENANCE LOG Serial #_______________________________ Pump Model___________________________ Maximum Flow________________________ Strokes per Minute______________________ Maximum Pressure_____________________ Diaphragm diameter ____________________ Spare Parts Kit #____________________________________________________________ NEPTUNE CHEMICAL PUMP CO. Tel.: 215-699-8700 • FAX: 215-699-0370 DATE SERVICED BY MAINTENANCE PERFORMED...

Need help?

Do you have a question about the MP7100 and is the answer not in the manual?

Questions and answers