Table of Contents

Advertisement

www.farmiforest.fi

CH 260 CHIPPER

OPERATION, MAINTENANCE AND

SPARE PARTS MANUAL

CHIPPER CH 260

From machine: 329 2525

It is very important to read this instruction hand-

book thoroughly before using the machine!

03299770

FARMI Forest

Ahmolantie 6

FIN --- 74510 PELTOSALMI

FINLAND

Tel. +358 (0) 17 83 241

Fax +358 (0) 17 823 606

A- -USA- -221002- -JaK

03485700

Advertisement

Table of Contents

Summary of Contents for Farmi Forest Corporation VALBY CH 260

- Page 1 www.farmiforest.fi 03299770 A- -USA- -221002- -JaK CH 260 CHIPPER OPERATION, MAINTENANCE AND 03485700 SPARE PARTS MANUAL CHIPPER CH 260 From machine: 329 2525 It is very important to read this instruction hand- book thoroughly before using the machine! FARMI Forest Ahmolantie 6 FIN --- 74510 PELTOSALMI FINLAND...

-

Page 3: To The Owner

www.farmiforest.fi CH 260 CHIPPER OPERATION,MAINTENANCE AND SPARE PARTS 1. TO THE OWNER---OPERATOR Thank you for purchasing a Normet Corporation product. Before we begin this manual, the people at Normet Corporation want you, the owner-- operator , to know this piece of equipment can be very dangerous if safety procedures and warnings are ignored. -

Page 4: Safety Instructions

www.farmiforest.fi CH 260 CHIPPER SAFETY INSTRUCTIONS 2. SAFETY INSTRUCTIONS 2.1.TERMS AND SYMBOLS USED IN INSTRUCTIONS Safety is a combination of operator com- THINK mon sense and alertness at all times SAFETY! when the machine is being operated or serviced. This message is used for general remind- CAUTION! ers of good safety practices or to direct attention to unsafe practices. -

Page 5: General Safety

www.farmiforest.fi CH 260 CHIPPER SAFETY INSTRUCTIONS 3.GENERAL SAFETY Do not operate this machine until you have read and IMPORTANT! understood the manual page by page. The owner of this machine is responsible for instructing all operators and support personnel in the operation and safety precautions of this chipper. -

Page 6: Rotating Knives

www.farmiforest.fi CH 260 CHIPPER SAFETY INSTRUCTIONS Disengage the PTO, cut the engine and remove the keys before any mainte- D D D D nance. Use only original parts replacements. IMPORTANT! Do not make any modifica- D D D D tions. D D D D Check all moving parts. -

Page 7: Safety Instructions For The Hydraulic Unit

www.farmiforest.fi CH 260 CHIPPER SAFETY INSTRUCTIONS 3.3.SAFETY INSTRUCTIONS FOR THE HYDRAULIC UNIT D D D D Before performing lubrication work on any equipment, consult the manufac- turer’s instruction manual and follow the recommended procedures. D D D D Before lubricating the machine, shut down the engine and stop the ma- chine. -

Page 8: Table Of Contents

www.farmiforest.fi CH 260 CHIPPER TABLE OF CONTENTS 1.TO THE OWNER ---OPERATOR ..........2.SAFETY INSTRUCTIONS . - Page 9 www.farmiforest.fi CH 260 CHIPPER TABLE OF CONTENTS SPARE PARTS ............03485700 CH 260 Chipper .

-

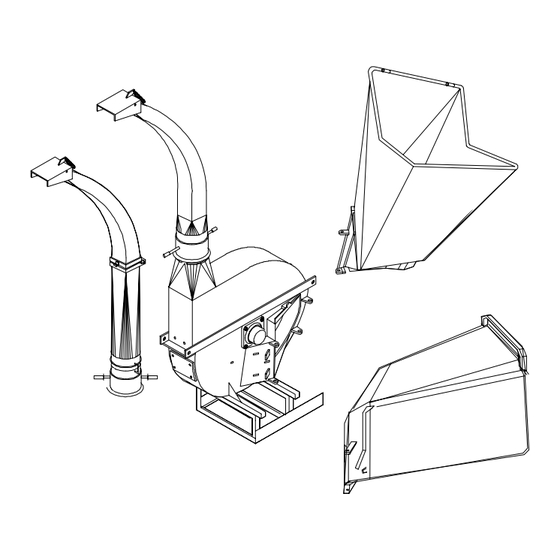

Page 10: Presentation

www.farmiforest.fi CH 260 CHIPPER CHIPPER PRESENTATION 4.PRESENTATION 5.MAIN COMPONENTS 1.UPPER CHAMBER The Farmi CH 260 is a double-- or triple--knife disk cutter for chipping wood up to Æ260 mm, and 2.LOWER CHAMBER plastic. The adjustable chip size enables creation 3.DISK chips for, e.g.,... -

Page 11: Dimensions

www.farmiforest.fi CH 260 CHIPPER CHIPPER PRESENTATION 6.DIMENSIONS 965 (38”) 1,150 (46”) 990–1,092 (39”–43”) Fig 2.CH 260 dimensionss. 7.TECHNICAL DATA CH 260 Type Disk chipper 10--40 m /h wood, 2--- 3 ton/h paper Output Chip lenght 7--12 mm wood, 13--15 mm paper ”--1”... -

Page 12: Plates And Stickers

www.farmiforest.fi CH 260 CHIPPER PLATES AND STICKERS 8.PLATES AND STICKERS These decals and stickers must be found from chipper. Missing ones must be renewed immediately. 30140602 30140602 CH 260 20 __ __ 40142080 40142080 41011750 4101750 41014310 41014310 --- 12 ---... - Page 13 www.farmiforest.fi CH 260 CHIPPER PLATES AND STICKERS 41014170 41014170 41015500 41015500 41014270 41014270 40141160 8. 40141160 41014110 9. 41014190 41014110 41014190 --- 13 ---...

- Page 14 www.farmiforest.fi CH 260 CHIPPER PLATES AND STICKERS Plates and stickers for chipper CH 222 Part Order no. Description Remarks Qty..30140602 ..VALBY---sticker ........... .

-

Page 15: Lifting

www.farmiforest.fi CH 260 CHIPPER ASSEMBLY AND MOUNTING D Tighten the nuts (M20) to 340 Nm. 9.LIFTING D The hydraulic feeder and mechanical feeders include fitting blocks that are Lifting points for each machi- installed between the chipper and feeder. ne are marked with hook sym- The fitting blocks are installed so that the bols. -

Page 16: Cutting The Pto Shaft To The Correct Length

www.farmiforest.fi CH 260 CHIPPER ASSEMBLY AND MOUNTING 10.2.CUTTING THE PTO SHAFT TO THE CORRECT LENGTH If the PTO shaft is too long, Damage might be caused to the bearings of the chipper or to the PTO of the tractor. If the PTO CAUTION! shaft is too long it must be cut. -

Page 17: Installing The Screen And Breaker

www.farmiforest.fi CH 260 CHIPPER ASSEMBLY AND MOUNTING 10.3.INSTALLING THE SCREEN AND The screen may only be used for screening thin plastic BREAKER pieces. The chipper can be equipped with a twig or The screen must be removed CAUTION! high--power breaker, or alternatively a screen. before chipping other material! The screen cannot be installed in conjunction... -

Page 18: Operating The Chipper

www.farmiforest.fi CH 260 CHIPPER OPERATION Never disconnect the hydrau- 11.OPERATING THE CHIPPER lics from high rpm. This will cause a risk of cavitation and may damage the hydraulic mo- CAUTION! 11.1.INSPECTIONS PRIOR TO tor. Check that no sounds indica- OPERATION ting cavitation can be heard from the hydraulic motor. -

Page 19: Adjusting The Discharge Pipe And Lid

www.farmiforest.fi CH 260 CHIPPER OPERATION FIRE HAZARD! 12.STORAGE Always keep adequate fire -- fighting equipment on hand when using the chipper. Check D Ensure that the chipper is on solid ground WARNING the outside temperature of the and that it cannot tip over. chipper regularly. -

Page 20: Periodic Maintenance

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE 13.PERIODIC MAINTENANCE Always disengage the PTO and stop the tractor and chip- per fully before maintenance or repair work. WARNING! Ensure that the disk is fully stopped before inserting anything inside the feed chute. Lock the disk before maintenance or re- pairs. -

Page 21: Periodic Inspections

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE 13.3. PERIODIC INSPECTIONS D Check the mounting bolts for tightness once a week. D With new machines, check the mounting D The knife---to--- anvil clearance is adjusted to bolts for tightness after the first operating ho- the specified values. -

Page 22: Knife And Anvil Maintenance

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE 14.2. REMOVING THE KNIVES 14.KNIFE AND ANVIL MAINTE- FROM THE KNIFE BRACKETS NANCE Read the safety instructions. Lock bolt The disk continues rotating like a flywheel after the PTO is dis- engaged. DANGER! Wear protective gloves when handling knives or anvils. -

Page 23: Sharpening The Knives

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE 14.3. SHARPENING THE Fig. 20.A knife with a flat profile KNIVES The hone angle is ground to a 45° angle with two to three longitudinal strokes, using level sharpening stone. Sharpen all knives equally. Burrs are removed from the knife fastening bolt This ensures disk balance. -

Page 24: Sharpening The Anvils

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE 14.5. SHARPENING THE ANVILS D Measure the knife--- to--- anvil clearance; ad- just if necessary. If you notice wear or rounding of the inner edge 1. Loosen the vertical anvil fastening bolts of the vertical anvil, sharpen the anvil so that (M16) (A). -

Page 25: Adjusting The Chip Length

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE 14.8. ADJUSTING THE CHIP LENGTH 4. Loosen the knife bracket fastening nuts (M20). See Fig. 28. Adjust so that the The chip length is determined by the distance bet- distance from both ends of the knife to the ween the knife and disk (Fig. -

Page 26: Replacing The Splined Shaft

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE 15.REPLACING THE SPLINED SHAFT 1. Remove the upper chamber. 2. Remove the bearings (see Chapter 13). Welding damages the bearings. 3. Lift the disk up using a hoist. 4. Grind an 15 mm--deep groove about 2 mm from the edge of the shaft. -

Page 27: Installing The Bearings

www.farmiforest.fi CH 260 CHIPPER MAINTENANCE Knife to chamber distance 1,5mm Disk Lower chamber Knife bracket Anvil Fig. 32.The knife- -to- - anvil clearances. 16.INSTALLING THE BEARINGS Fig. 33.Installing the bearings. --- 27 ---... -

Page 28: Spare Parts

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03485700 CH 260 Chipper 26.6 26.3 26.5 26.1 26.2 26.4 --- 28 ---... - Page 29 www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03485700 CH 260 Chipper Part Order no. Description Remarks Qty..13297010 ..Lower chamber ...........

- Page 30 www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03485700 CH 260 Chipper 26.6 26.3 26.5 26.1 26.2 26.4 --- 30 ---...

- Page 31 www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03485700 CH 260 Chipper Part Order no. Description Remarks Qty..52060233 ..Screw ......M10x30 DIN933 .

- Page 32 www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03485700 CH 260 Chipper 26.6 26.3 26.5 26.1 26.2 26.4 --- 32 ---...

- Page 33 www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03485700 CH 260 Chipper Part Order no. Description Remarks Qty... . . 52060126 ..Screw ......M8x20 DIN933 .

-

Page 34: Disk, 2---Knife, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03298110 Disk, 2---knife, complete Part Order no. Description Remarks Qty..33297760 ..Disk ............. -

Page 35: Disk, 3---Knife, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03297130 Disk, 3---knife, complete Part Order no. Description Remarks Qty..13297210 ..Disk ............. -

Page 36: Short Discharge Pipe, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03296450 Short discharge pipe, complete Part Order no. Description Remarks Qty..23296430 ..Discharge pipe ........... . -

Page 37: Long Discharge Pipe, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03297370 Long discharge pipe, complete Part Order no. Description Remarks Qty..33297360 ..Vertical pipe ............ -

Page 38: Plastic Sheddering Screen, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03297630 Plastic sheddering screen, complete Part Order no. Description Remarks Qty..43297640 ..Plastic shredding screen .......... -

Page 39: Twig Crusher, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03297650 Twig crusher, complete Part Order no. Description Remarks Qty..43297560 ..Twig crusher ............ -

Page 40: Cross Braker For Slab, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03298150 Cross braker for slab, complete Part Order no. Description Remarks Qty..43298140 ..Cross braker for slap .......... -

Page 41: F250 Feed Chute, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03297520 F250 feed chute, complete Part Order no. Description Remarks Qty..03291242 ..Feed chute ............ -

Page 42: Df250 Sh Drop Spout, Complete

www.farmiforest.fi CH 260 CHIPPER 03485700 SPARE PARTS 03295086 DF250 SH Drop spout, complete Part Order no. Description Remarks Qty..33295098 ..Drop spout ............ - Page 43 --- 43 ---...

- Page 44 --- 44 ---...

- Page 45 LIMITED WARRANTY Valby products are warranted to be free from defects in materials and wormanship for 12 months from the date of purchace, or one month from in---service, whichever is longer. The warranty covers parts replacement only. The free replacement of parts is exclusive. The manufacturer is not liable for any incidental or consequential damages.

- Page 46 Date of delivery: ____ /____ 20____ Dealer: Dealer’s address: Dealer’s tel: Product: Serial number: Return to the manufacturer Date of delivery: ____ /____ 20____ Dealer: Dealer’s address: Dealer’s tel: Customer: Customer’s address: Customer’s tel: Product: Serial number: Notes:...

Need help?

Do you have a question about the VALBY CH 260 and is the answer not in the manual?

Questions and answers