Table of Contents

Advertisement

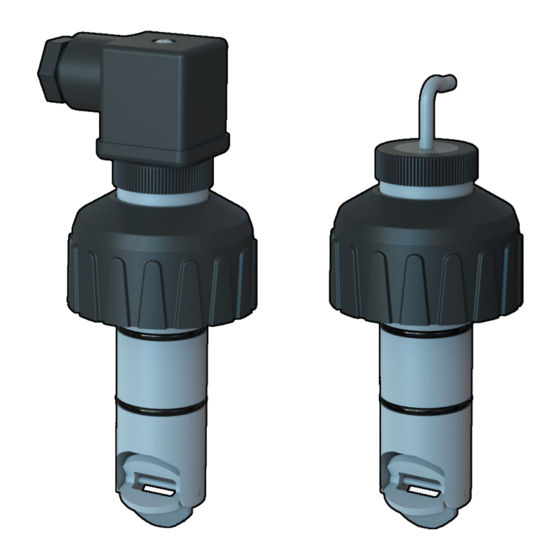

FLS F3.00

PADDLEWHEEL

FLOW SENSOR

SAFETY INSTRUCTIONS

General Statements

• Do not install and service the product without following the Instruction

Manual.

• This item is designed to be connected to other instruments which can be

hazardous if used improperly. Read and follow all associated instrument

manuals before using with it.

• Product installation and wiring connections should only be performed by

qualified staff.

• Do not modify product construction.

Installation and Commissioning Statements

• Remove power to the instrument before wiring input and output connections.

• Depressurize and vent the system before installing or removing the sensor.

• Check and confirm the chemical compatibility of the materials in contact

with the liquid.

• Do not exceed maximum specifications using the instrument.

• To clean the unit, use only chemical compatible products.

1

Advertisement

Table of Contents

Summary of Contents for FIP FLS F3.00

-

Page 1: Safety Instructions

FLS F3.00 PADDLEWHEEL FLOW SENSOR SAFETY INSTRUCTIONS General Statements • Do not install and service the product without following the Instruction Manual. • This item is designed to be connected to other instruments which can be hazardous if used improperly. Read and follow all associated instrument manuals before using with it. -

Page 2: Packing List

PACKING LIST Please verify that the product is complete and without any damage. The following items must be included: • F3.00 Paddlewheel Flow Sensor • Instruction Manual for F3.00 Paddlewheel Flow Sensor DESCRIPTION The simple and reliable paddlewheel flow sensor type F3.00 is designed for use with every kind of solid-free liquids. -

Page 3: Standards And Approvals

Specific for F3.00.C • Supply voltage: 3 to 5 VDC regulated or 3.6 Volt Lithium battery • Supply current: < 10 µA max • Output signal: - square wave - frequency: 45 Hz per m/s nominal (13.7 Hz per ft/s nominal) - min. - Page 4 Maximum Operating Pressure / Temperature (25 years lifetime) F3.00.H or F3.00.P Sensor F3.00.C Sensor • CPVC body: • CPVC body: - 10 bar (145 psi) @ 25°C (77°F) - 10 bar (145 psi) @ 25°C (77°F) - 1,5 bar (22 psi) @ 80° C (176°F) - 1,5 bar (22 psi) @ 80°...

- Page 5 DIMENSIONS...

-

Page 6: Installation

INSTALLATION Pipe Location • The six most common installation configurations shown in fig. 1 help in selecting the best location in the pipeline for paddlewheel flow sensor as well for magmeter flow sensor. • The three configurations in fig. 2 ensure that the pipe is always full: for a correct measurement the sensor can NOT be exposed to air bubbles at any time. -

Page 7: Mounting Position

Fig.2 Fig.3 Fig.4 Mounting position Measuring part of sensor (rotor for paddlewheel and pins for magmeter) should be positioned at 12% of ID where, basing on insertion theory, average velocity can be measured. The reading accuracy of insertion flow sensors can be affected by: •... -

Page 8: Process Connection

Process connection 1. Lubricate the sensor O-rings with a silicone lubricant. Do not use any petroleum based lubricant that may damage the O-rings. 2. Lower the sensor into the fitting making sure the alignment tab is seated in the fitting notch. 3. - Page 9 F3.00.H IP65 Sensor Connection to FLS Instruments (except M9.20) F3.00.C IP68 Sensor Connection to FLS Instruments (only for M9.20) F3.00.C IP65 Sensor Connection to FLS Instruments (only for M9.20)

- Page 10 F3.00.P IP68 Sensor Connection to PLC with NPN Input F3.00.P IP68 Sensor Connection to PLC with PNP Input F3.00.P IP65 Sensor Connection to PLC with NPN Input...

- Page 11 F3.00.P IP65 Sensor Connection to PLC with PNP Input F3.00.H IP68 Sensor Connection to Other Brand Instruments 2.7Kohm Pull-up resistor may be F3.00.H IP65 Sensor Connection to Other Brand Instruments 2.7Kohm Pull-up resistor may be...

- Page 12 F3.00.C IP68 Sensor Connection to Other Brand Instruments F3.00.C IP65 Sensor Connection to Other Brand Instruments 2.7Kohm Pull-up resistor may be...

-

Page 13: Installation Fittings

INSTALLATION FITTINGS Type Description • Size: d20 to d50 (0.5” to 1.5”) Plastic Tees • Materials: PVC, C-PVC, PP, PVDF • Size: d63 to d225 (2” to 8”) PVC-U Clamp Saddles • Insert Materials: C-PVC, PVDF • Size: d63 to d315 316L SS Tees •... -

Page 14: K-Factor Tables

K-FACTOR TABLES K-Factor is the number of pulses which a sensor produces for one liter of measured fluid. Here below all K-Factors for water at room temperature are listed. K-Factor values can depend on the installation conditions. K-Factor has to divide the frequency generated by F3.00 in order to achieve the flow rate (l/s). - Page 15 NPT Female Threaded PVC Tee Fittings ASTM SCH. 80 PVC Tee Fittings for ASTM SCH. 80 pipes for ASTM SCH. 80 pipes (NPT threaded female ends) (female ends for solvent welding) Part No. SIZE K-Factor Part No. SIZE K-Factor TFNV20B 0.50"...

- Page 16 Installation on C-PVC pipes ISO Metric CPVC Tee Fitings for ISO SDR 21 ISO Clamp Saddles for ISO SDR 21 pipes pipes (female ends for solvent welding) Part No. K-Factor Part No. K-Factor TFIC20B 235,45 SVIC063BVC 21,69 TFIC25B 142,46 SVIC075BVC 14,98 SVIC090BVC 9,88...

- Page 17 NPT Female Threaded PP Tee Fittings for ASTM SCH.80 pipes ISO Clamp Saddles for ISO SDR 21 pipes (NPT threaded female ends) Part No. K-Factor Part No. K-Factor TFNM20B 0.50" 1/2" 212,17 SVIC063BME 27,50 TFNM25B 0.75" 3/4" 135,32 SVIC075BME 18,56 TFNM32B 1.00"...

- Page 18 Installation on PVDF pipes ISO Metric PVDF Tee Fittings for ISO SDR 33 ISO Clamp Saddles for ISO SDR 33 pipes pipes (female ends for socket welding) Part No. K-Factor Part No. K-Factor TFIF20B 225,06 SVIF063BF 20,58 TFIF25B 139,38 SVIF 075BF 14,09 SVIF 090BF 9,29...

- Page 19 Installation on Metal pipes 316L SS Threaded Tees (BSP Female Threads) Part No. K-Factor TFFX20 1/2" TFFX25 157,06 TFFX32 1" 92,84 TFFX40 1" 1/4 51,52 Metal Strap-on Saddles Metal Strap-on Saddles mounted on Cast Iron pipes mounted on Other Metal pipes Part No.

-

Page 20: Ordering Data

Correction formula for K-Factor calculation according to real internal diameter: K-Factor_NEW = (K-Factor x ID²) / ID_NEW² ID = Value in the table for the internal diameter (in mm) ID_NEW = New value for the real internal diameter (always in mm) K-Factor = Value in the table K-Factor_NEW = New K-Factor value for the specified internal diameter Example:... - Page 21 0.15 to 8 m/s F3.00.H.14 Hall 5 - 24 VDC CPVC/FPM IP65 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.00.H.15 Hall 5 - 24 VDC CPVC/EPDM IP65 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.00.H.16 Hall 5 - 24 VDC CPVC/FPM IP65 (0.5 to 25 ft./s.)

- Page 22 F3.00.C.XX Paddlewheel Flow Sensors (Remote version) Main Power Flow Rate Weight Part No. Version Length wetted Enclosure supply Range (gr.) materials 0.15 to 8 m/s F3.00.C.01 Coil 3 - 5 VDC CPVC/EPDM IP68 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.00.C.02 Coil 3 - 5 VDC...

- Page 23 0.15 to 8 m/s F3.00.C.22 Coil 3 - 5 VDC 316SS/FPM IP65 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.00.C.23 Coil 3 - 5 VDC 316SS/EPDM IP65 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.00.C.24 Coil 3 - 5 VDC 316SS/FPM IP65 (0.5 to 25 ft./s.)

- Page 24 0.15 to 8 m/s F3.00.P.18 Push-Pull 12 - 24 VDC PVDF/FPM IP65 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.00.P.19 Push-Pull 12 - 24 VDC PVDF/EPDM IP65 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.00.P.20 Push-Pull 12 - 24 VDC PVDF/FPM IP65 (0.5 to 25 ft./s.)

- Page 25 F3.01.X.XX Paddlewheel Flow Sensors (Compact version) Power Main wetted Flow Rate Weight Part No. Version Length Enclosure supply materials Range (gr.) 0.15 to 8 m/s F3.01.H.01 Hall 5 - 24 VDC CPVC/EPDM IP68 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.01.H.02 Hall 5 - 24 VDC...

- Page 26 0.15 to 8 m/s F3.01.C.10 Coil 3 - 5 VDC 316SS/FPM IP68 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.01.C.11 Coil 3 - 5 VDC 316SS/EPDM IP68 (0.5 to 25 ft./s.) 0.15 to 8 m/s F3.01.C.12 Coil 3 - 5 VDC 316SS/FPM IP68 (0.5 to 25 ft./s.)

-

Page 27: Spare Parts

SPARE PARTS Weight Part No. Name Description (gr.) F3.SP1 4 pole Cable Plug Cable Plug according to DIN 43650 F3.SP2.1 Sensor Cap Black Sensor Cap, for Hall version F3.SP2.2 Sensor Cap Red Sensor Cap, for Coil version F3.SP2.4 Sensor Cap Yellow Sensor Cap, for push-pull version F3.SP2.6 Sensor Cap... - Page 28 4-pole Cable Plug Sensor Cap O-Rings Rotor KIT...

- Page 29 NOTE...

- Page 30 NOTE...

- Page 31 NOTE...

- Page 32 FIP - Formatura Iniezione Polimeri S.p.A. Loc. Pian di Parata 16015 Casella Genova - Italy Tel. +39 010 96211 Fax +39 010 9621209 www.flsnet.it...

Need help?

Do you have a question about the FLS F3.00 and is the answer not in the manual?

Questions and answers

Pelo manual da Danieli, necessito ter no estoque F3.00.H ?

If a FLS F3.00 Paddlewheel Flow Sensor is wired incorrectly to the FLS M9.00 Flow Monitor, will damage to either component occur ?