Table of Contents

Advertisement

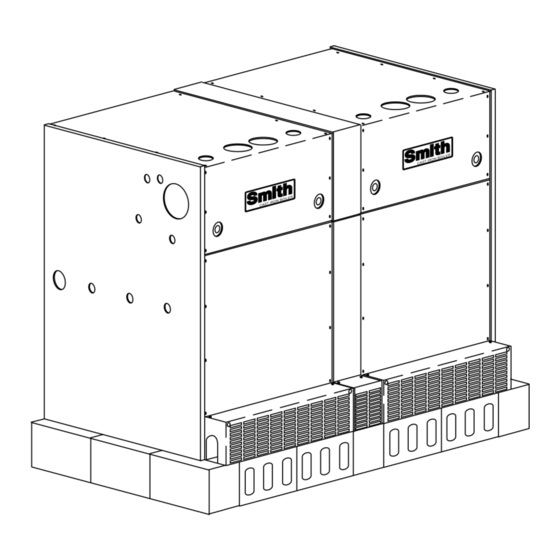

NATURAL OR PROPANE GAS BOILER

INSTALLATION & OPERATING MANUAL

Designed and tested according to A.S.M.E. Boiler and Pressure Vessel Code, Section

IV for a maximum allowable working pressure of 80 psi US, 50 psi Canada water,

15 psi steam.

CAUTION: Do not use automotive anti-freeze in the boiler waterways. If the use of

antifreeze is necessary an anti-freeze specifically formulated for hydronic heating

systems must be used!

Water treatment is not recommended. This boiler uses gaskets made from ethylene

propylene, EPT, to seal the section ports. Consult a water treatment professional before

adding any chemicals to the boiler water to ensure that they are compatible with the

gaskets. Failure to comply with this caution can result in failure of the gaskets voiding

the warranty.

Warning: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

• Do not try to light any appliance.

• Do not touch any electrical switch. Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

A qualified installer, service agency or the gas supplier, must perform installation

and service.

INSTALLER READ THESE INSTRUCTIONS CAREFULLY.

THEY WILL SAVE YOU VALUABLE TIME WHEN ASSEMBLING THE BOILER.

THESE INSTRUCTIONS TO BE AFFIXED ADJACENT TO THE BOILER.

CONSUMER, RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE PURPOSES.

GB300

WHAT TO DO IF YOU SMELL GAS:

WESTCAST, INC.

260 NORTH ELM STREET WESTFIELD, MA 01085

TEL. (413) 562-9631 FAX (413) 562-3799

www.smithboiler.com

GB300-IOM-4

Advertisement

Table of Contents

Summary of Contents for Smith Cast Iron Boilers GB300

- Page 1 EPT, to seal the section ports. Consult a water treatment professional before adding any chemicals to the boiler water to ensure that they are compatible with the gaskets. Failure to comply with this caution can result in failure of the gaskets voiding the warranty.

-

Page 2: Table Of Contents

Health Warnings ... back cover BEFORE YOU START This manual covers the application, installation, operation and maintenance of a GB300(S,W) low pressure steam or hot water boiler. To obtain the safe, dependable, efficient operation and long life for which this boiler was designed, these instructions must be read, understood and followed. -

Page 3: Boiler Ratings & Capacities

3. Ensure that the floor is structurally sound and will support the weight of the boiler. Never install a GB300(S,W) on a concrete floor that contains wires, cables, water pipes or hoses. This boiler is designed for non combustible floors only! Never install this boiler on... -

Page 4: Combustion Air & Ventilation

WARNING: Never operate a GB300 in an environment subjected to a negative pressure unless it is Direct Vented. Failure to comply with this warning can result in excessive levels of... -

Page 5: Chimney & Vent Pipe Connections

Ensure that the chimney is clean, properly constructed and properly sized. Table 2 lists the equivalent breeching and flue sizes required for the GB300 boilers. Table 2 Vent Outlet, Equivalent Breeching & Chimney Size... - Page 6 Page 6 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS COMMON VENT SYSTEMS If an existing boiler is removed from a common venting system, the common venting system may then be too large for the proper venting of the remaining appliances connected to it. At the time of removal of an existing...

- Page 7 Remettre les portes et les fenêtres, les ventilateurs, les registres de cheminées et les appareils au gaz à leur position originale. Figure 2A Vertical Venting Using A Metal Chimney System And Inside Air(GB300 Series) 2 FT 0.6 m 10 FT 3.4 m 3 FT 0.9 m 3 FT 0.9 m...

- Page 8 2 FT 0.6 m 10 FT 3.4 m 3 FT 0.9 m 5 FT 4.5 m Figure 2C Vertical Venting Using A Masonry Chimney And Inside Air (GB300 Series) 10 FT 3.1 m 3 FT 0.9 m 3 FT 0.9 m...

- Page 9 Page 9 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 2D Dual Flue Outlets Using A Masonry Chimney And Inside Air (GB300 Series) 10 FT 3.1 m 3 FT 0.9 m 3 FT 0.9 m Figure 2E Common Vents And Inside Air (GB300 Series) 10 FT 3.1 m...

- Page 10 Page 10 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 2F Dual Flue Outlets With Two Boilers Using A Masonry Chimney And Inside Air (GB300 Series) 10 FT 3.1 m Figure 2G 3 FT 0.9 m 1.5 FT 0.5m MINIMUM DISTANCE FROM EXHAUST TO MAXIMUM SNOW LINE.

-

Page 11: Boiler Assembly

Figure 1. Align the hollow blocks so air can flow through them. WARNING: Never install a GB300(S,W) boiler on top of combustible flooring! Failure to comply with this warning may result in a fire causing... - Page 12 Page 12 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Burner Base Assembly 5 through 12 Sections Loosely attach the base baffle to the side panels using 4 5/16 stainless steel nuts. Install the burner base front, side and rear panels as shown in Figures 6, 7, 8 and...

- Page 13 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Burner Base Assembly 13 through 21 Sections Box 72694, X7 Splice Channels, contains the burner base front, intermediate and rear channels and additional 5/16" nuts and bolts, Figure 10. Figure 10 The base baffles must be attached to the intermediate base channel before the side, front and rear panels are assembled, Figure 11.

- Page 14 Page 14 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Bolt the front and rear base panels in place, Figure 13. Center the factory installed refractory retention brackets on the rear base panel so that the bracket is in the middle of each refractory board Figure 13B.

- Page 15 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS NOTE: The base front panels bolt to the inside of the front base splice channel, Figure 15. Figures 15 Base Front Panel Detail Use a spirit level to plumb the front and rear panels before tightening the nuts and bolts, Figure 16.

- Page 16 Page 16 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Bolt the insulation splice panel bracket to the front base channel, Figure 21. Install the two insulation boards in the spaces between the two front and two rear burner base panels. Firmly but carefully press the insulation boards in place and insert the nails through the top and bottom holes, Figure 22A&B.

- Page 17 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Ceramic Blanket Installation Before installing the cast iron sections a ceramic blanket gasket must be installed on the burner base. Locate the roll of ceramic blanket and can of spray adhesive supplied in the X1 box. Spray two heavy coats of adhesive on the top of the burner base waiting for the adhesive to tack up between coats, Figure 23.

- Page 18 Page 18 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 26B Marking Burner Base Rear Midpoint Apply two coats of the spray adhesive supplied with the boiler to the rope seal grooves, Figure 27. Allow time for the first coat to become tacky before applying the second coat.

- Page 19 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS To ensure that the assembled sections will be centered on the burner base the cast iron sections should be assembled from the midpoint of the burner base outward. On boilers having an even number of sections the first intermediate section should be placed so it’s side surface...

- Page 20 Page 20 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 36 Lower Port Seal Placement Figure 37 Upper Port Seal Placement Table 3 Boiler Model GB300-5 GB300-6 GB300-7 GB300-8 GB300-9 GB300-10 FCB GB300-11 FCB GB300-12 FCB GB300-13 FCB GB300-14 FCB GB300-15 FCB...

- Page 21 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Make sure that the sections are square with the burner base. Align the bottom front edge of the sections so they’re flush with the face of the burner base front panel, Figure 39. Lift the next section into place being careful not to damage the ceramic blanket or hydronic seals and install the draw rods, washer and nuts.

- Page 22 Page 22 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 43 “J” Bolt Installation Figure 45 Top Jacket Splice Panel Bracket CAST IRON PRESSURE TEST NOTE: Before filling the sections with water temporarily set the flue collector(s) on top of the sections to locate the flue collector brackets, Figure 44.

- Page 23 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS NOTE: All assembled boiler sections shall pass the hydrostatic tests prescribed in Section IV of the ASME Boiler and Pressure Vessel Code. CAUTION: Do not connect any boiler controls during the pressure test or they will be damaged!

- Page 24 Page 24 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Position the flue collector(s) on the boiler sections with the draft hood opening(s) at the rear of the boiler. The sides of the flue collector(s) should lie along the center of each end section, Figure 48. Attach the flue collector(s) to the flue collector mounting brackets using the #10 sheet metal screws supplied, Figure 49.

- Page 25 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Clean Out Covers The clean out covers and mounting hardware are packaged in the Burner Box with a number from 72724 to 72731 on it, Figure 52 Figure 52 Clean Out Cover & Hardware Arrange the clean out cover(s) in front of the boiler so the mounting stud locations can be determined.

- Page 26 Page 26 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS MANIFOLD, BURNER AND PILOT INSTALLATION Box 63273, Base Panel Sides, contains the manifold brackets. Bolt the left and right manifold brackets to the front burner base side panel flanges, Figures 16 and 57.

- Page 27 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Install the supplied 1/8" stainless steel bleed line on continuous pilot boilers equipped with V88A gas valves. The bleed line must be located in a fixed position relative to the pilot burner and allowing for the escaping gases to be readily ignited by the pilot.

- Page 28 Page 28 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS When all of the burner tubes are in place adjust the manifold so the burner tube orifice brackets are positioned midway along the cylindrical portion of the orifice, Figure 65. Make sure all of the burner tubes are locked into the base rear panel as shown in Figure 64.

- Page 29 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS The jacket should be assembled using the black screws provided. On 5 through 12 section models slide the rear panel behind the draft hood flanges with the grill side on the floor, Figures 68, 69 & 70. On 13 to 21 section boilers open Box 55185, Jacket Splice Box, Figure 71.

- Page 30 Page 30 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Remove the left and right jacket side panels from Box 55175, Jacket Side Panels. Remove the knockouts necessary to attach the water or steam piping and controls. NOTE: All jacket panel joints must be made so the panels are metal to metal.

- Page 31 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 78 Rear Top Jacket Panel, 5 through 12 Figure 79 Rear Top Jacket Panel, 13 through 21 Install the front jacket top panel(s), Figures 80 and 81. Figures 80 Front Top Jacket Panel, 5 through 12...

- Page 32 Page 32 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS On 13-21 section models a splice kit is required to assemble the front jacket panels. The splice kit is shown in Figure 71. The splice panel sits on the splice panel brackets shown in Figure 45 and Figure 83.

- Page 33 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Install the front access panels as shown in Figure 86 5-12 sect and Figure 87 13-21 section using the supplied screws. Figure 86 Front Access Panel 5 - 12 Sect Figure 87 Front Access Panel 13 - 21 Sect Attach the front grill side panels to the grill top panels as shown in Figure 88.

- Page 34 This boiler is designed to allow for the installation of the gas train on either the left or right side of the boiler. Locate the gas train in the most ideal location, but ensure that the train and controls are protected from water and other possible damage.

-

Page 35: Heating System Piping

GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS HEATING SYSTEM PIPING NOTE: The boiler jacket must be installed before connecting the heating system piping and controls. All heating system piping must be installed by a qualified technician in accordance with the latest revision of the... - Page 36 Page 36 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Table 4 Supply & Return Pipe Sizing Boiler Model Supply Size (in) Return Size (in) 5 - 10 section 3" 11 - 21 section 4" Install the Pressure Relief Valve in the 1 1/2 NPT opening in the top of the end section opposite the gas controls.

- Page 37 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 97 Water Boilers in Battery Expansion Tank Pressure Reducing Valve Hi Limit Control Blowoff Valves Stop Valve Check Valve Air Vent Alternate Arrangement With Diaphragm Expansion Tank (Required On Each Boiler) Figure 97A Typical Single Boiler Steam Piping Pres.

- Page 38 Page 38 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 98 Typical Steam Piping - Gravity Return for Multiple Boilers Pres. Controls LWCO & Gage Stop Valve Glass Check Valve Blowoff Valves Figure 98A Typical Steam Piping - Pumped Return for Multiple Boilers F &...

-

Page 39: Gas Supply Piping

The GB300(S,W) boiler comes from the factory ready to be piped to the gas supply. If for any reason the boiler is not for the type of gas available at the installation site, call the nearest Smith Cast Iron Boiler distributor to resolve the problem. -

Page 40: Electrical Wiring

Page 40 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Figure 100 TO GAS SUPPLY MANUAL SHUTOFF VALVE INSTALL MANUAL SHUTOFF VALVE 5FT. ABOVE FLOOR WHERE REQUIRED BY LOCAL CODES. When applicable, provisions for vent, bleed and gas relief lines must be made in accordance with the latest revision of ANSI Z223.1. -

Page 41: Boiler Operation

GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Use the factory supplied wiring schematic booklet to connect power to the boiler. The schematic booklet also depicts how to interconnect the boiler controls, using the supplied wire harness. Before connecting any harnesses, the control panel and wire duct must be attached to the boiler using the supplied fasteners. -

Page 42: Lighting Instructions

Page 42 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS LIGHTING INSTRUCTIONS A. If this appliance is equipped with a continuous pilot it must be lit by hand. Follow the lighting instructions exactly when lighting the pilot. If this appliance is equipped with an intermittent pilot, the ignition control will automatically light the pilot. -

Page 43: Boiler Checking & Adjustment

14. A boiler designed for use with natural gas should have a manifold gas pressure of approximately 3.5" WC on high fire and 0.8" WC on low fire. For an LP boiler, the manifold pressure should be 10" WC. To adjust the... -

Page 44: Boiler Maintenance

Page 44 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS 1. Attach a 20" manometer to the tap on the manifold. 2. Remove the regulator adjustment screw cap from the gas regulator. On systems that do not use a separate gas regulator, remove the adjustment screw cap from the gas valve body on the valve closest to the gas supply piping. - Page 45 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Burner Installation 1. DO NOT install damaged or badly corroded burners, replace them. 2. Install the burners by sliding the rear of the burner tube into the slot located in the base rear panel. Slide the burner into the slot far enough so that the burner bracket clears the orifice on the manifold.

- Page 46 Page 46 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS...

- Page 47 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Ref # Name of Part — Jacket Less Sides Panels — Jacket Side Panels, Left & Right — Jacket Splice Panels, Front, Top, Rear & Grill — Jacket Screws Flue Collector Draft Hood —...

- Page 48 Page 48 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Ref # Name of Part Manifold Less Orifices Orifices, Natural Gas Orifices, LP Gas Burner Tubes Less Pilot Bracket w/Shutter NG Burner Tubes w/Pilot Bracket w/Shutter NG Burner Tubes Less Pilot Bracket LP Burner Tubes w/Pilot Bracket LP Robertshaw 7000 DERHC, Natural Gas, 1"...

- Page 49 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Ref # Name of Part — Manual Main Shut Off Valve, 1" Manual Main Shut Off Valve, 1-1/4" Manual Main Shut Off Valve, 1-1/2" — Manual Pilot Shut Off Valve, — Pilot Regulator RV12LT —...

- Page 50 Page 50 GB300 BOILER INSTALLATION AND OPERATION INSTRUCTIONS Ref # Name of Part Cast Iron Section, Left Side Gasket, Upper Port Gasket, Lower Port — 3/8" Rope, 42" length Draw Rod 1/2" x 7-1/2" 1/2 Flat Washer 1/2 Hex Nut...

- Page 51 Carbon Monoxide (CO) is a gas which is odorless, colorless and tasteless but is very toxic. If your Smith boiler is not working properly, or is not vented properly, dangerous levels of CO may accumulate. CO is lighter than air and thus may travel throughout the building. BRIEF EXPOSURE TO HIGH CONCENTRATIONS OF CO, OR PROLONGED EXPOSURE TO LESSER AMOUNTS OF CO MAY RESULT IN CARBON MONOXIDE POISONING.

- Page 52 WESTCAST, INC. 260 NORTH ELM STREET WESTFIELD, MA 01085 TEL. (413) 562-9631 FAX (413) 562-3799 www.smithboiler.com...

Need help?

Do you have a question about the GB300 and is the answer not in the manual?

Questions and answers