Summary of Contents for WPI UltraMicroPump II

- Page 1 UMP2 Microsyringe Injector and Micro4 Controller INSTRUCTION MANUAL serial no._____________________ 071807 World Precision Instruments, Inc.

-

Page 2: Table Of Contents

Contents introduction ..................1 Parts list .................... 2 set-up and operation ................ 2 setting Parameters ................6 ultramicroPump ii operation ............13 defining other syringes ..............14 computer control ................18 General maintenance ..............25 troubleshooting ................25 specifications .................. 22 syringes ................... -

Page 3: Introduction

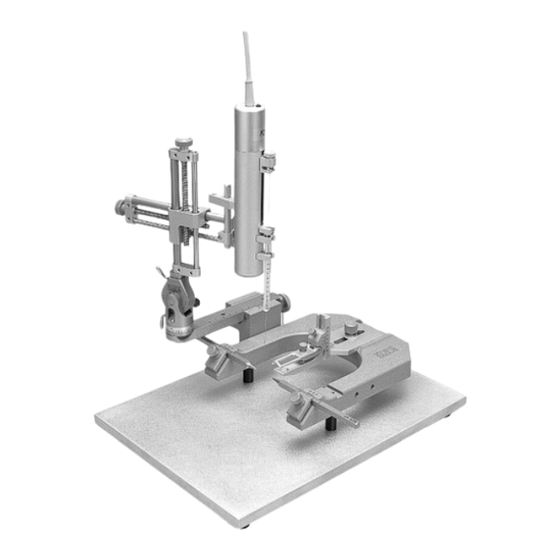

Fig. 1 — UltraMicroPump II and Micro4 controller. The pump above is mounted on WPI’s M3301 micromanipulator and TB-1 stand (not included); and syringe with luer µTip (not included). At left, pump is shown with TAXIC900 stereotaxic frame (not included). -

Page 4: Parts List

Power cable Allen key instruction manual For a list of microsyringes available from WPi, see page 23. Set-up and Operation these instructions will help you put the ultramicroPump to immediate use. We recommend that you read the entire manual and familiarize yourself with the various operating procedures of the ultramicroPump and micro4. - Page 5 UltraMicroPump II Axial Needle Alignment in order to maintain a good syringe needle alignment particularly along the same axis of the supporting bar, rotate the syringe body while placing in the two clamps to allow the syringe to seat properly and align along the body of the pump for minimal slant offset.

- Page 6 UltraMicroPump II Mounting to Stereotaxic Frames WPi’s umP2 fits directly into most standard stereotaxic frames. the umP2 mounting bar diameter is 7.90 mm (0.311 in.). For example, umP2 fits directly into Kopf standard 900 series frames (in place of 1770 electrode holder).

- Page 7 UltraMicroPump II Choosing a Syringe the syringe should be chosen to inject no less than 5% of the volume of any given syringe. Example: A 100 µl syringe may be used for injections on the umPii to volumes of 5 µl (5000 nl) and higher with high precision and repeatability. expecting this 100 µl syringe to inject lower than 1 µl may be difficult if the syringe is not calibrated...

-

Page 8: Setting Parameters

UltraMicroPump II Setting Parameters Parameters are entered using the membrane keys on the front panel of the micro4. keys move the cursor on the lcd display to the desired left right arrow position. the keys select the channel (corresponding to the down arrow output channels on the rear of the instrument). - Page 9 UltraMicroPump II Setting Infuse/Withdraw the character displayed in the first field indicates the operating mode — I for infuse, W for Withdraw. to change modes, use the to position the arrow keys cursor in this field, then press select I = Infuse...

- Page 10 UltraMicroPump II Volume Set to select the desired volume to be infused or withdrawn, position the cursor in the volume set field and enter the numbers with the numeric keypad. the values shown on the lcd display are in nanoliters. (Note: For 10 µL enter “10000”; for 1.0 µL enter “1000.”—including decimal point.)

- Page 11 UltraMicroPump II Injections beyond 99,999 nL (5 digits in the volume field) example: You want to inject 150,000 nl from a 500 µl liquid tight syringe, but the volume counter can not accept 150,000 as a number. 1. take the value 150000 / 500000 = 0.3 or 30% of the syringe volume.

- Page 12 UltraMicroPump II Rate Units two rate units are available — nanoliters per second and nanoliters per minute. Position the cursor in this field and use the key to choose either S (nl/sec) select or M (nl/min). S = nl/sec M = nl/min...

- Page 13 † These are defined as 60 mm in Rev. H firmware. † † WPI’s Nanoliter 2000, a nanoliter injector for the 2-70 nL range, comes with its own simple controller but may also be driven by the Micro4. For more information, enquire about WPI # B203XVY.

- Page 14 UltraMicroPump II Grouped/Non-grouped/Disabled For convenience in operating multiple pumps (whether of identical or various vol- umes), pumps may be grouped or non-grouped. Pressing the key while the select cursor is in this field will toggle through three operating modes: Grouped mode: syringe channels with “G” in this field are started or...

-

Page 15: Ultramicropump Ii Operation

UltraMicroPump II UltraMicroPump II Operation When the pump runs, a series of beeps indicates that the pump is running. At the end of the program, the controller also beeps. A lamp on the back of the ultramicroPump indicates a signal from the controller. As the pump runs, the counter increments as an indication of the plunger’s motion. -

Page 16: Defining Other Syringes

UltraMicroPump II Defining Other Syringes eleven microsyringes with volumes ranging from 0.5 µl to 1000 µl are already preset in the micro4 (syringe types A through L — see table on page 11). A mi- crosyringe with a volume other than those preset may be entered as device type M. - Page 17 UltraMicroPump II note that this does not yet affect the action of any channel since M has not been selected as the device type for any channel. Before proceeding, move the cur- sor back to the Volume set field and re-enter the correct volume for the syringe on output channel 1 (which may be any type —...

- Page 18 UltraMicroPump II Volume Set Actual volume delivered 0-0.9999 nl 1 nl-1.999 nl 1 nl 2 nl-2.999 nl 2 nl and so on... Using Teflon Tipped syringes carefully remove the plunger and its teflon tip by drawing it out of the syringe barrel.

- Page 19 UltraMicroPump II Calibration Every syringe should be calibrated on the pump that it is being used with. this gives the user two things, verification of the error involved in the injection and the confidence that injection is correct. micro volume syringes are rated at 1% to 3% of the full-scale volume.

-

Page 20: Computer Control

UltraMicroPump II Computer Control rs232 commands are used to control the micro4 via the serial port of a Pc or macintosh computer. RS232 Commands All commands are case sensitive. the settings for the rs232 port are baud rate 9600, 8 data bits, 1 start bit, 1 stop bit. microsoft Hyperterminal setting: Flow con- trol must be set to none. - Page 21 UltraMicroPump II ?M returns a G for grouped mode, n for nongrouped mode, and d for disabled mode. returns the letter of the syringe type. ?D returns the syringe pump direction: i=infuse, W=Withdraw. ?U returns the rate units: s=nl/second, m=nl/minute.

- Page 22 UltraMicroPump II Format of the C counter command the character field of c is a maximum of five numerals; a 6th character can be the decimal point (.). this field should be entered as c0.0; to begin with as this is the counter that determines how much more the sryinge needs to move before it stops.

- Page 23 Ground Micro4 controller umc data in micro4 cable with 9- umc data out pin connector is WPi run/ stop #40500. +5V pull up Footswitch Connections since the footswitch produces run and stop signals by connecting +5 volts (from pin 4) to pin 6, this port may also be used for ttl signals from other sources.

-

Page 24: General Maintenance

UltraMicroPump II General Maintenance ultramicroPump requires minimal maintenance; regular laboratory cleaning will keep this instrument in optimum operating condition. do not apply solvents or oils to any part of the ultramicroPump. this instrument is not autoclavable. do not disassemble—there are no serviceable parts inside either the umPii or the micro 4 controller. - Page 25 4. mechanical damage. if the umP2 plunger carrier is loose (a condition which can be caused by overtravel), the pump must be returned to WPi for repair. World Precision instruments...

-

Page 26: Specifications

UltraMicroPump II Specifications UltraMicroPump II total number of steps (end to end) ..20,000 (63 mm travel) minimum dispensing Volume ....0.58 nl/step linear motion .......... 3.175 µ/step Plunger Position error ......< 0.5% Pump Force ..........400 g syringe diameters ........5.5 mm to 9.0 mm maximum step rate ....... -

Page 27: Syringes

UltraMicroPump II Syringes UltraMicroPump II is designed to be used with glass syringes having barrel diameters from 5.5 mm to 9 mm. WPi stocks the following syringes (with replaceable beveled needles): SGE0005RN* 0.5 µl 23 gauge (0.63 mm) 70 mm long (s) †... - Page 28 B203XVY nanoliter 2000 injector (usA 110V power adapter included) Replacement parts 65134 mounting Bar 65085 mounting Bar locking nut 65015 collar stop nut For special connections: 6-pin miniature din plug (digi-Key # cP-20600-nd) Not available from WPI. World Precision instruments...

-

Page 29: References

UltraMicroPump II References S.B. Mazzone, D.P. Geraghty “respiratory actions of tachykinins in the nucleus of the solitary tract: effect of neonatal capsaicin pretreatment” (2000) British Journal of Pharmacology 129:6 pp1132-1139. B.L. Davidson, C.S. Stein, J.A. Heth, I. Martins, R.M. Kotin, T.A. Derksen, J. -

Page 30: Appendix: Nanoliter 2000 / Micro4 Volume Settings

UltraMicroPump II APPENDIX: Nanoliter 2000 / Micro4 Volume Settings When using the micro4 to control injections with the nanoliter 2000, take care when entering the injection volume. the nanoliter 2000 injector’s volume per step is based on the movement of the plunger wire inside a pulled glass pipette. this plunger moves 0.0005"... -

Page 31: Warranty

WPi shall not be liable for any damage to data or property that may be caused directly or indirectly by use of this product.

Need help?

Do you have a question about the UltraMicroPump II and is the answer not in the manual?

Questions and answers