Table of Contents

Advertisement

Quick Links

O

P

O

P

S

E

M

I

-

M

S

E

M

I

-

M

Farmet a.s.

Jiřinková 276

552 03 Česká Skalice

Czech Republic

Tel:

00420 491 450 140

00420 491 450 122

Fax:

00420 491 450 136

E-mail: farmet@farmet.cz

obchod@farmet.cz

http:

www.farmet.cz

E

R

A

T

I

N

E

R

A

T

I

N

O

U

N

T

E

D

O

U

N

T

E

D

K

-

K

-

Edition No.6, effective from 5th January 2009

G

M

A

N

G

M

A

N

K

O

M

P

A

K

O

M

P

A

3

0

0

P

3

0

0

P

U

A

L

U

A

L

K

T

O

M

A

T

K

T

O

M

A

T

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Farmet K-300P

- Page 1 Farmet a.s. Jiřinková 276 552 03 Česká Skalice Czech Republic Tel: 00420 491 450 140 00420 491 450 122 Fax: 00420 491 450 136 E-mail: farmet@farmet.cz obchod@farmet.cz http: www.farmet.cz Edition No.6, effective from 5th January 2009...

- Page 2 This serial number should be mentioned for reference when ordering spare parts. The index plate is located on the central frame near the shaft. All spare parts should be ordered according to the official Spare Part Catalogue issued by Farmet a.s., Česká Skalice, Czech Republic.

-

Page 3: Table Of Contents

K-300P - TABLE OF CONTENTS Page 3 - A. LIMITING PARAMETERS Page 4 - B. TRANSPORTATION Page 4-5 Page 5 - C. LIFTING DEVICE OPERATION - D. ASSEMBLY AT THE CUSTOMER'S PLACE Page 5 - E. AGGREGATION WITH THE TRACTOR... -

Page 4: Limiting Parameters

K-300P LIMITING PARAMETERS Operator(s) may use the machine for agricultural purposes only as an exchangeable implement aggregated with a tractor. (25) A.1.1 Operator(s) may use the machine only for soil preparation before sowing as a follow-up operation after ploughing or stubble ploughing in the field. -

Page 5: Lifting Device Operation

The operator may hitch up the machine solely to such a tractor that is provided with a rear three-point suspension and a functional undamaged hydraulic system. Towing vehicle requirements: Tractor Engine Output Requirements for Towing the K-300P Machine 60-75 kW Lower suspension joints spacing... -

Page 6: Road Transportation

K-300P (14) The minimum pressure in the circuit: 125 bar; the (11) Axle lifting circuit maximum pressure in the circuit: 160 bar, two ISO 12.5 quick coupler sockets Before aggregating the machine with the tractor (especially with those not provided with a quick suspension device), the operator must secure the tractor against undesirable movement. -

Page 7: Machine Adjustments

K-300P Before setting the machine to work, please read the Operating manual carefully. Pay attention to labour protection, safe operation and transportation, environmental protection, setting machine maintenance. The operator is responsible for all damages incurred by improper operation of the tractor and the coupled machine. -

Page 8: Replacement Of Worn-And-Torn Shares

K-300P Any machine repairs should be made in service shops. (12) Before repairing the machine hydraulic circuits , the repairman must eliminate pressure in the hydraulic circuits with the control levers in the tractor cab. This should be done by moving the levers to their extreme positions back and forth (approx. - Page 9 K-300P Transportation on the machine is P 37 H strictly forbidden. Do not step between the tractor and the machine when coupling or uncoupling. P 2 H Do not step between the tractor and the machine until they are at rest and the engine turned off.

- Page 10 K-300P Fig. 1 - Labour-protection stickers locations on the machine P37H, P53H P37H P37H, P53H P13H P52H P2H, P6H P1H, P13H P52H P37H, P53H P37H P37H, P53H Fig.2 – position of self-adhesive label for lubrication of house bearings - 10 -...

-

Page 11: Machine Description

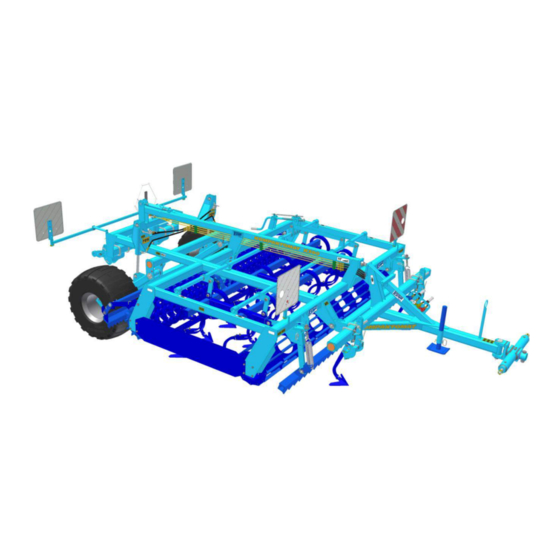

K-300P MACHINE DESCRIPTION The machine is designed as semi-mounted. The basic model consists of a three-point-suspension bar, of a shaft (towing bar) with tractor track looseners and a supporting frame. The supporting frame bears the machine working tools, the transport axle and the rear three-point suspension for aggregation with attachments such as an air-operated sowing machine, the Nocken or Crosskill crumbling rollers, etc. -

Page 12: Operational Safety Rules

K-300P OPERATIONAL SAFETY RULES Before you take over the machine, please check that is has not been damaged during transportation and that all its parts have been supplied according to the delivery note. Before setting the machine to work, please read these Operating manual carefully. Pay attention to labour protection, safe operation and transportation, setting the machine and its maintenance. -

Page 13: Setting To Work

K-300P Fig.4 – maximum axle load permitted Max.load-see tab.4 *The values given in Tab. 4 for K-300P are the maximum possible ones. According to the Czech Traffic Rules, the maximum permissible axle road is 3000 kg. SETTING TO WORK 5.1 When aggregating the machine with the tractor and setting it to work, the steps given in Chapter E /Page 5 to 6 should be followed. -

Page 14: Aggregation With The Tractor

K-300P 5.7 The track looseners should be placed in such a manner that they can loosen the earth compacted by the tractor tires. See Fig. 7 for adjustment options. The loosening depth should be selected according to actual needs but it should not exceed 100 mm below the tractor track level (See Fig 8). -

Page 15: Exchanging The Working Tools

K-300P with the surface, lock this position with the stop (close to the tractor hydraulics) as the lowest one. The M30 supporting screw should then be locked with a locknut. 8.2 SETTING THE "V" HEIGHT OF THE FRONT DRAG (SEE FIG. 9/PAGE 14) The front drag is to be set by driving out PIN 20 and shifting the welded lever. -

Page 16: Maintenance And Repairs

K-300P MAINTENANCE AND REPAIRS When making any repairs, strictly observe the labour-protection rules mentioned in Chapters A through N / Pages 4 through 10. After the first 20 hours of operation, check all the mechanical parts connected with bolts. -

Page 17: Aggregation With An Attachment

K-300P AGGREGATION WITH AN ATTACHMENT An attachment is understood e.g. an air-operated sower, the NOCKEN or CROSSKILL crumbling rollers. For aggregating the machine with an air-operated sower, the Cultivator can be provided with a SOWER DRIVE. Only such attachments that allow continuos terrain copying may be aggregated with the machine. - Page 18 (see point 14.2.3). 14.2.8 The warranty is conditioned by using original spare parts of the manufacturer. Issued by: Farmet a.s., Technical Department, Jiřinková Str. 276, 552 03 Česka Skalice, Pages: 19, Date: 25th February 2009, All amendments reserved. - 18 -...

-

Page 19: Letter Of Guarantee

K-300P Farmet a. s. Tel.: 00420 491 45 01 40 Jiřinková 276 45 01 22 ČESKÁ SKALICE 552 03 Fax.: 00420 491 45 01 36 Machine Model: ……………………….. YEAR OF PRODUCTION/SERIAL NUMBER: TECHNICAL INSPECTION: BUYER (ADDRESS): SELLER (ADDRESS): WARRANTY: The manufacturer gives a 24-month warranty for the following machine parts: The main frame, the axle and the shaft (tow bar). -

Page 20: Ce Certificate Of Conformity

CE CERTIFICATE OF CONFORMITY EG-KONFORMITÄTSERKLÄRUNG DÉCLARATION CE DE CONFORMITÉ СЕРТИФИКАТ СООТВЕТСТВИЯ ЕС DEKLARACJA ZGODNOŚCI WE Мы Nous Farmet a.s. Jiřinková 276 552 03 Česká Skalice Czech Republic DIČ: CZ46504931 Tel/Fax: 00420 491 450136 Vydáváme na vlastní zodpovědnost toto prohlášení. Hereby issue, on our responsibility, this Certificate.

Need help?

Do you have a question about the K-300P and is the answer not in the manual?

Questions and answers