Summary of Contents for Eletta S2

- Page 1 Eletta Flow Monitor Installation Operations Manual Models S2, S25, S02 and 5041D2E18...

- Page 2 These data are disclosed to you under the permission that you use it with limits within your company only, not including manufacture or processing uses. Any other use is strictly prohibited without prior written permission from Eletta Flow AB, Sweden.

- Page 3 In the unlikely event of such an This to save valuable time for any of us involved in the Eletta Products, as it is incident, we kindly ask you to make sure that you go trough the manual care- sometimes easy to overlook a specific sentence in the manual.

-

Page 4: Table Of Contents

Operation ..................19 Principle of operation, DP-Flow Measurement ...... 19 Change of Flow Range ............19 Adjustment of switch point, S2 and S25 ....... 21 Change of Flow Direction ............22 3.4.1 Flow Direction Selector (from January 2013) ......22 3.4.2 Flow Direction Selector (until December 2012) ..... -

Page 5: General Information

The Flow Monitors are working with two different differential pressure ranges, i.e. 50 – 200 mbar for the S2/S02 and 22 – 550 mbar for the S25/S05, depending on the desired and ordered flow range. The same goes for our models;... -

Page 6: Specifications

The only flow difference between the S2/S02 and S25/S05 is the turn down of the flow range i.e. the S2/S02 has a 1:2 turn down (for example; 50 –100 l/min) and the S25/S05 has a turn down of 1:5 (for example; 20 – 100 l/min). - Page 7 ” – 20”) for FSS-models Alarm/ Contacts: S2 and S25 have 2 (two) micro switch SPDT contacts, inde- pendently adjustable within the ordered Flow range. S02 and S05 has no micro switch contacts included; only a dial for local indication of Flow.

- Page 8 The spacer holds the orifice plate inside the pipes section and Intrinsically Safe they are made of Polyamide plastic (PA) as a standard. Max.li- (Ex i): The Eletta Flow Monitor contains only SPDT quid/gas temperature is 150°C (300°F). Intrinsically Safe 5041A2E4...

- Page 9 Proof: The Flow Monitor itself is not approved as a complete instru- approvals: The Eletta Flow Monitors conforms with the EU directive for ment according to EU Hazardous Area EX-regulations. ment according to EU Hazardous Area EX-regulations. low voltage no: 72/23/EEC ( EN 60 204-1, Part 1.) We refer to the certificates issued, which will be sent to you upon request.

-

Page 10: Installation

Stainless Steel Pipe Sections (FSS/GSS) is not possible in the field without ordering a new Pipe Section and we kindly ask you to contact your local re- presentative or Eletta Flow AB, Sweden for help. Check that the pipe section has the right threads or the right flange standard to match your piping or counter flange. -

Page 11: Installation Of The Pipe Section

mages or holes that can prevent proper function. The plastic hoses should not be used in temperatures over 90ºC (194 ºF). If your application temperature exceeds this temperature/pressure, we recommend to use copper or stainless steel tubing, depending on the compatibility to the measured gas or liquid (see section 2.4) Installation of the Pipe Section Note!!! Before starting to install the Pipe Section, please make sure... -

Page 12: Separate Mounting Of The Pipe Section And Control Unit

Control Unit Sometimes separate mounting of the Pipe Section and the Control Unit is re- quested due to vibrations, high temperature or lack of space. As the Eletta Flow Monitor is using the differential pressure caused by the orifice plate... - Page 13 ports up to the Control Unit, it is also possible to separate the Monitor (Fig. 2) from the Pipe Section -GL/FA into two parts. The pressure is then lead through either plastic hoses or metallic tubing depending on the liquid, pressure and temperature.

-

Page 14: Installation And Changing The Control Unit

Installation and changing of the Control Unit As all Eletta Flow Monitors are designed in sections to achieve a modular and versatile Flow Monitor, there is a possibility to upgrade/rebuild them and ad- ding other features to your already installed Monitor, by changing the Control Unit or Pipe Section. - Page 15 Pipe Section, without any on-site adjustments or calibration. All reading scale. When you order, you will get the Control Unit with the diaphragm Eletta DP Flow Monitors are working with the same differential pressure wit- housing included. Make sure you order the right material in the diaphragm hou- hin their specific range (Pls.

-

Page 16: Pressure Drop

0.96 ∆ρ and 0.51 ∆ρ can be expected. Example: For the Eletta Flow Monitor S2-GL15 with a flow range of 10 - 20 l/min, the following example can be used for how to calculate the ∆ρ... - Page 17 10,2 mm 16,0 mm ⇒ This gives β = 10,2/16,00 β = 0,6375 and (1-β ) = 0.594 Furthermore, in order to use this β−value in the above formula, we need to de- termine the ∆ρ . We can either use the ”Actual Pressure Drop Graph” (fig. (apd) 4) for an approximate value or for intermediate values we can use the formula below the graph (fig.

-

Page 18: Electrical Installation

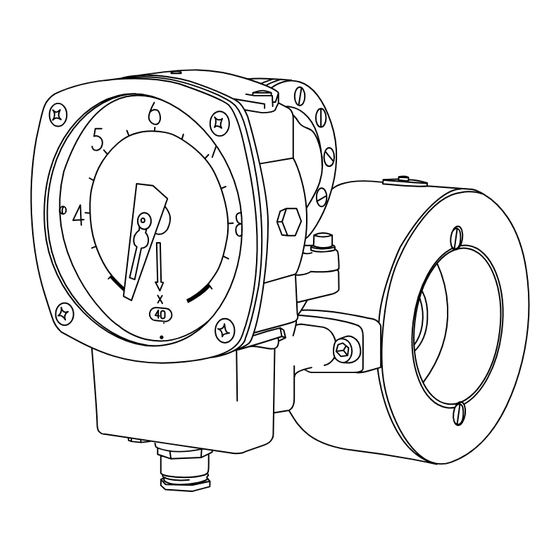

A grounding screw is to be found at the side of the terminal block. Before any circuit is connected/disconnected, make sure that all power is off! Setting of high/low flow alarm for the S2/S25 (tool normally placed under top lid) Figure 5 5041A2E4... -

Page 19: Operation

This mechanism transforms the movement into a Flow rate value shown on the dial. All the Eletta Flow Monitors are tested and ap- proved according to the European CE-mark regulations. (Pls. contact your Distributor or Eletta Sweden for copy of certificate or go to www.eletta.com). - Page 20 For threaded model -GL: For threaded model -GL: Untighten the bolts that hold the Pipe Section between the flanges in the pi- For threaded model -GL: Untighten the bolts that hold the Pipe Section between the flanges in the piping ping (do not remove the threaded parts from the piping).

-

Page 21: Adjustment Of Switch Point, S2 And S25

Adjustment of switch point, S2 and S25 must be specified and ordered with the new orifice plate. All the Eletta Flow Monitors are tested and calibrated according to the custo- Adjustment of switch point, S2 and S25 mers’ orders before shipping. If the customer does not specify a desired switch point for the flow alarm, the S-series Monitor’s micro switches are preset to... -

Page 22: 3.4 Change Of Flow Direction

3.4 Change of Flow Direction Empty the pipe system so that it is un-pressurized and has no flow! At the time of ordering, you must specify in which direction the Flow Monitor shall be mounted i.e. from which side is the flow entering the Pipe Section and how you would like to read the scale. -

Page 23: Flow Direction Selector (Until December 2012)

3.4.2 Flow Direction Selector (until December 2012) Change of Flow Direction For GL and FA models there are two flow direction selectors to choose from, the ”R” and the ”L” selector. For GL-models, first empty the pipe system so that it is un-pressurized and For mounting directions according to alternative A, C and F (see fig. -

Page 24: Change Of Dial Orientation

Change of Dial Orientation As the Eletta Flow Monitors are not limited to a certain mounting position in the piping system, the large visible dial can be mounted in several positions to suit the application. (please refer to fig. 7). If you need to change the orienta- tion in the field, please do as follows;... -

Page 25: Trouble Shooting

Eletta Flow Monitors work with two different ∆ρ’s i.e. on the V1 and S2 units the ∆ρ is always maximum 2000 mm H2O (196 mbar) and for the V15 and S25 units, the ∆ρ is always maximum 5500 mm H2O (539 mbar). -

Page 26: Electrical Connections

2000 mmH2O (196 mbar) on the S2/S02series with a blocked orifice, the pointer should reach the last digit (8 for the S2/S02) on the front scale and if you have a direct reading scale installed, the pointer should reach the end value. -

Page 27: Spares

We refer to section 7 where you can find an exploded drawing showing all replaceable components included in the Flow Monitor. If you have installed the Eletta S-series Flow Monitor in a very critical appli- cation, we recommend you to have a complete identically precalibrated Control Unit on stock, as it will only take removal of four bolts to change this. -

Page 28: Distributors

Distributors Eletta has appointed distributors around the world. You find more information about which distributor to contact on our website www.eletta.com or call our customer service. Phone: +46 8 603 07 80 5041A2E4 5041D2E18... -

Page 29: Tables

Tables Measuring Ranges S2 and S02 S25 and S05 5041A2E4 5041D2E18... -

Page 30: Weight And Dimensions

Weight and Dimensions 5041A2E4 5041D2E18... -

Page 31: Spare Parts

Exploded drawing S-GL/FA 5041A2E4 5041D2E18... -

Page 32: Exploded Drawing S-Gl/Fa

5041D2E18... - Page 33 7.2 S-GSS/FSS 5041A2E4 5041D2E18...

-

Page 34: Exploded Drawing S-Gss/Fss

5041A2E4 5041D2E18...

Need help?

Do you have a question about the S2 and is the answer not in the manual?

Questions and answers