Advertisement

T3 Control Set Installation Guide

1. General

1.1 This T3 control set has been designed for

control of flow and water temperature in

an underfloor heating system. It is pre-

assembled and tested to ensure that it can

be fitted with the minimum of on-site labour

and commissioned immediately once fitted.

1.2 As supplied it is designed to connect to the

left hand side of an Emmeti manifold with

210mm between the centres of the flow

and return arms. It can also be used with

any other manifold built on this dimension.

The control set can also be altered to fit to

the right hand side of a manifold simply by

removing the bracket clips and turning the

control set elbows through 180 degrees

using the union fittings at the top and bottom

of the pump. The pump motor may need to

be rotated through 180 degrees to minimise

the space occupied by the control set and

allow access to the electrical connection box.

2. Connections & Dimensions

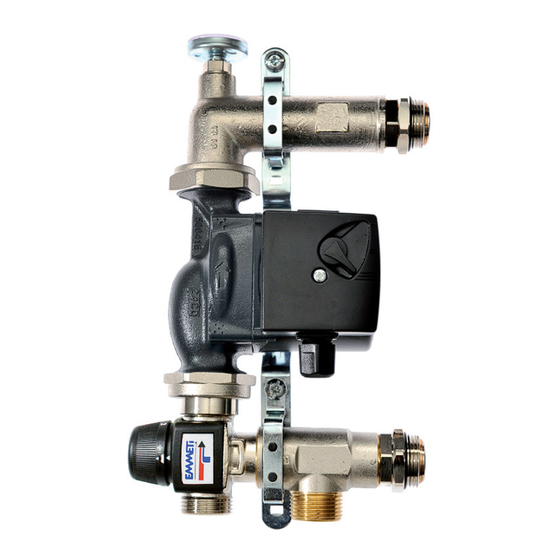

Fig.1 Overall Connections and Dimensions

Please note the overall dimensions of the control set and allow reasonable access at either side and the

front for installation and maintenance

1.3 There are other manifold sets to cater for

applications with different control needs or

higher flow rates for larger residential and

commercial applications:

•

U9700020 - Control set with thermostatic

valve (concealed dial) and pump, kvs 3.4

•

U9700060 - Control set with thermostatic

valve and variable speed class A pump, kvs 3.4

•

U9700030 - Control set with Thermostatic mixing

valve, thermal actuator and pump, kvs 3.4

•

U9700040* - Control set with motorised

mixing valve and pump, kvs 6.3

•

U9700050* - Control set with motorised

mixing valve and pump, kvs 8.0

* available with 3-point actuator, temperature

controller or weather compensator for mounting

on control set.

For a full description of each control set, please

consult our website www.emmeti.co.uk.

Fig. 2 Mounting Bracket Dimensions

T3 Control Set Installation Guide

3. Technical Data

Maximum static pressure

Maximum differential pressure

Maximum temperature

Operating temperature Range

Inlet connections

Outlet connections

Overall dimensions mm

Kvs

4. Control Set Contents

Pre-assembled control set including:

•

'L' pattern thermostatic mixing valve –

operating temperature range 35

C to 60

o

•

Grundfos UPS 25-60 circulating pump

•

Inlet tee assembly with 1"M swivel connector

to the underfloor return rail

•

Outlet elbow assembly with built-in

temperature gauge and 1"M swivel connector

to the underfloor flow rail

•

Mounting bracket with rubber supports

5. Installation

5.1 Remove the control set assembly carefully

from the packaging and check to ensure that

all components are in place and that there is no

damage to them.

5.2 The control set is supplied for connection to the

left hand side of the manifold but can be altered

very simply for connection to the right hand side.

(i) Remove the mounting bracket clips from the

control set by unscrewing the two screws

shown in Fig. 3 and rotating the upper and lower

elbows through 180

using the pump union nuts.

o

Fig. 3

Remove mounting

bracket clips

5.3 Re-fit the mounting bracket and rotate the

pump to an upright position as shown in Fig. 4.

10 bar

3 bar

95

o

C

Adjustable between 35

o

C and 60

2 x 1"M (G1)

2 x 1" M (G1) – swivel joint

311h x 189w x 132h

3.4

C

o

5.4 If the pump needs to be lowered into the

gap in the mounting bracket for space-saving

reasons, it will be necessary to remove the

Allen screws securing the pump motor and

rotate the motor so that the junction box is at

the front.

5.5 The control set can be attached to the

manifold either before or after the manifold

is secured to the wall. The control set should

be secured to a flat vertical surface able to

support the weight of the control set and

manifold. Using the dimensions shown in

Figs. 1 and 2, ensure that there is sufficient

space for installation and maintenance at the

intended position for the control set. The fixing

hole positions of the mounting bracket can be

marked through the mounting bracket itself.

5.6 A swivel joint is fitted to each side of the

control set for connecting to the 1" F manifold

tappings. The inlet tee swivel joint should be

connected to the return rail and the outlet

elbow swivel joint to the flow rail of the

manifold. Carefully offer up and screw the

swivel joint threads evenly into the manifold

using a 37mm A/F spanner: the use of a

31mm A/F spanner will also ensure that the

connection to the control set is kept tight – see

o

C

Fig. 4

Re-fit mounting

bracket

Advertisement

Table of Contents

Summary of Contents for emmeti T3

- Page 1 T3 Control Set Installation Guide T3 Control Set Installation Guide 1. General 3. Technical Data 1.1 This T3 control set has been designed for 1.3 There are other manifold sets to cater for Maximum static pressure 10 bar control of flow and water temperature in...

- Page 2 Emmeti literature for the 5.8 The primary flow and return pipework can now manifold. A pair of male blanking plugs, code be connected to the 2 x 1”M connections...

Need help?

Do you have a question about the T3 and is the answer not in the manual?

Questions and answers