Table of Contents

Advertisement

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

DANGER

Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

When servicing the unit, the internal components may

be hot enough to cause pain or injury. Allow time for

cooling before servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

®

Energy Recovery & Make-Up Air Technical Support

Call 1-800-240-0870, press 1 for Service

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. All moving parts must be free to rotate without

striking or rubbing any stationary objects.

3. Unit must be securely and adequately grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan RPM. Adjustments to fan speed

significantly effects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to the unit while it is

running.

Document 480955

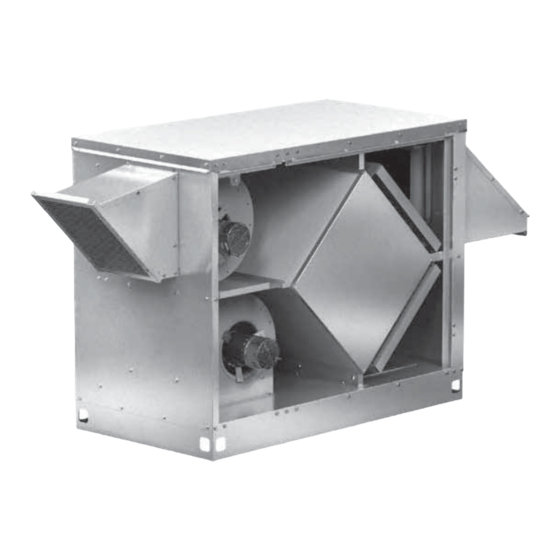

Model ECV

Energy Core Ventilator

Energy Core Ventilator

1

Advertisement

Table of Contents

Summary of Contents for Greenheck ECV Series

- Page 1 Document 480955 Model ECV Energy Core Ventilator ® Installation, Operation and Maintenance Manual Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with these instructions will result in voiding of the product warranty and may result in personal injury and/or property damage.

-

Page 2: Table Of Contents

Table of Contents Unit Overview Unit Overview ....2 Basic Unit Receiving, Handling and Storage ..3 The unit is prewired such that when a call for outside air Installation is made (via field-supplied 24 VAC control signal wired... -

Page 3: Receiving, Handling And Storage

Receiving The unit should be stored at least 3½ in. (89 mm) off the floor. Clearance should be provided to permit air This product may have been subject to road salt circulation and space for inspection. during transit. If so, immediately wash off all visible Outdoor white reside from all exterior surfaces. -

Page 4: Installation

Installation Outdoor Mounting Options EXHAUST AIR EXHAUST AIR DISCHARGE DISCHARGE SUPPLY AIR DISCHARGE SUPPLY AIR DISCHARGE OUTDOOR OUTDOOR AIR INTAKE AIR INTAKE RETURN AIR INTAKE RETURN AIR INTAKE Outdoor Air Discharge Bottom Outdoor Air Discharge End Indoor Mounting Options EXHAUST AIR EXHAUST AIR DISCHARGE DISCHARGE... -

Page 5: Service Clearances

Service Clearances The ECV unit requires minimum clearances to perform routine maintenance, such as filter replacement and energy core inspection. Blower and motor assemblies, energy recovery core and filter sections are always provided with a service door or panel for proper component access. Clearances for component removal may be greater than the service clearances, refer to drawing below for these dimensions. -

Page 6: Handling

Handling Lifting While this unit was constructed with quality and WARNING dependability in mind, damage still may occur during All factory provided lifting lugs must be used when handling of the unit for installation. lifting the unit. Failure to comply with this safety The system design and installation should follow precaution could result in property damage, serious accepted industry practice, such as described in the... -

Page 7: Roof Curb Mounting

Roof Curb Mounting Curb Outside Dimensions and Weights Rooftop units require curbs to be mounted first. The duct connections must be located so they will be clear of structural members of the building. 1. Factory Supplied Roof Curbs: Roof curbs are Model GKD. -

Page 8: Ductwork Connections

Rail Mounting / Layout Ductwork Connections • Rails designed to handle the weight of the unit Examples of poor and good fan-to-duct connections should be positioned as shown on the diagram are shown. Airflow out of the fan should (rails by others). be directed straight or curve the same direction as the •... -

Page 9: Electrical Information

Electrical Information WARNING The unit must be electrically grounded in accordance To prevent injury or death due to electrocution or with the current National Electrical Code, contact with moving parts, lock disconnect switch ANSI/NFPA 70. In Canada, use current CSA Standard open. -

Page 10: Control Center Components

Typical Control Center Components Optional Accessory Wiring Schematics Remote Panel 1. Main Disconnect (nonfusible, lockable) The remote panel is available with a number of different 2. Motor Starter – Exhaust Air Fan 3. Motor Starter – Outdoor Air Fan alarm lights and switches to control the unit. The remote 4. -

Page 11: Unit Overview Basic Unit

Dirty Filter Indicator (powered by others) Motor Potentiometer/0-10 VDC Fan Motor Control Model ECV-10-VG (reference unit wiring diagram) CLOSED 115-120V OPEN 208-230/277V BLACK 2CBL-M1 2CBL-M1 BLACK BLACK 0-10VDC WHITE ORANGE SUPPLY FAN MOTOR CLOSED 115-120V OPEN 208-230/277V BLACK 2CBL-M2 2CBL-M2 BLACK BLACK 0-10VDC... -

Page 12: Optional Component Overview Economizer

Optional Component Overview Variable Frequency Drives (VFD) VFDs are used to control the speed of the fan as either Economizer multi-speed or modulating control. Multi-speed VFDs The energy core operation can be altered to take reference a contact which can be made by a switch or advantage of economizer operation (free cooling). -

Page 13: Start-Up

Start-Up Pre Start-Up Checklist – check as items are completed. DANGER Disconnect and lock-out all power switches Remove any foreign objects that are located in the Electric shock hazard. Can cause injury or death. energy recovery unit. Before attempting to perform any service or maintenance, turn the electrical power to unit to OFF Check all fasteners, set-screws, and locking collars at disconnect switch(es). -

Page 14: Optional Accessories Checklist

Optional Accessories Checklist Refer to the respective sections in this Installation, Operation and Maintenance Manual for detailed information. Refer to wiring diagram in unit control center to determine what electrical accessories were provided. Provided with Unit? Frost Control Application / Operation section: Setting Factory Default Frost Control set point... -

Page 15: Start-Up Components Fans

When operating conditions of the fan are to be changed (speed, pressure, temperature, etc.), consult Direction of Fan Wheel Rotation Greenheck to determine if the unit can operate safely Blower access is labeled on unit. Check for proper at the new conditions. -

Page 16: Optional Start-Up Components Dirty Filter Switch

Optional Start-Up Components Economizer Relevant Set Points Dirty Filter Switch 1. MAT SET The outdoor air temperature set point Setscrew (on front of switch) must after the energy core. The control will open/close be manually adjusted after the the bypass damper to maintain temperature as system is in operation. -

Page 17: Frost Control

® Frost Control Test Procedure Vari-Green Electronically Commutated (EC) Motor Timed Exhaust 1. Remove power from unit. Features 2. Jumper the temperature indicating sensor in the unit Soft Start – All motors control center. Thermostat controller has a pre-set feature soft-start technology temperature of 35ºF. -

Page 18: Variable Frequency Drives

Most of the set points in the VFDs are Yaskawa factory defaults. However, USER TO PROVIDE ISOLATION AS REQUIRED a few set points are changed at Greenheck and are 0-10 VDC CONTROL SIGNAL (BY OTHERS) A1 AC shown in the tables. - Page 19 MODULATING CONTROL FOR FAN SPEED PROPORTIONAL CONTROL (0-10 VDC) Setting Setting Parameter Parameter V1000 J1000 V1000 J1000 A1-01 Access Level B1-17 VFD Start-Up Setting B1-17 VFD Start-Up Setting C6-02 Carrier Frequency C6-02 Carrier Frequency D2-02 Ref Lower Limit D2-02 Ref Lower Limit E2-01 Motor Rated FLA Motor...

-

Page 20: Routine Maintenance

Maintenance Procedures: Routine Maintenance Lubrication DANGER Check all moving components for proper lubrication. Electric shock hazard. Can cause injury or death. Apply lubrication where required. Any components Before attempting to perform any service or showing excessive wear should be replaced to maintain maintenance, turn the electrical power to unit to OFF the integrity of the unit and ensure proper operation. - Page 21 Fan Wheel & Fasteners Exhaust Air Filters: Access to the exhaust air filters is through the door labeled as “Filter Access” on the sides Wheels require very little attention when moving clean of the unit. air. Occasionally oil and dust may accumulate on the Refer to Access Panel Location section for additional wheel causing imbalance.

-

Page 22: Troubleshooting Economizer Alarms

Troubleshooting - Economizer Alarms Addressing Alarms Alarms will signify a faulty sensor. When this occurs, verify all connections to the sensor and controller are secure. Press enter twice to clear the alarm. If the issue persists, consult the factory. Clearing Alarms Once the alarm has been identified and the cause has been removed (e.g. -

Page 23: Airflow

Troubleshooting – Airflow Test and Balance Report The Test and Balance Report (TAB) is utilized to determine whether the appropriate amount of outdoor air and exhaust air is being supplied and removed from a building, respectively. There are no set rules on what information must be included in a TAB report. - Page 24 Troubleshooting – Unit Symptom Possible Cause Corrective Action Replace fuse or reset circuit breaker and check Blown fuse or open circuit breaker. amps. Defective motor or capacitor. Replace. Blower fails Motor starter overloaded. Reset starter and check amps. to operate Check for On/Off switches.

- Page 25 Troubleshooting – Unit Symptom Possible Cause Corrective Action Adjust wheel and/or inlet cone. Tighten wheel hub Fan wheel rubbing on inlet. or bearing collars on shaft. Replace defective bearing(s). Lubricate bearings. Bearings. Tighten collars and fasteners. Motor base or blower loose. Tighten mounting bolts.

-

Page 26: Maintenance Log

Maintenance Log Date ___________________Time _____________ AM/PM Date ___________________Time _____________ AM/PM Notes: ___________________________________________ Notes: ___________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ Date ___________________Time _____________ AM/PM Date ___________________Time _____________ AM/PM Notes: ___________________________________________ Notes: ___________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ Date ___________________Time _____________ AM/PM... -

Page 27: Maintenance Log

Maintenance Log Date ___________________Time _____________ AM/PM Date ___________________Time _____________ AM/PM Notes: ___________________________________________ Notes: ___________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ Date ___________________Time _____________ AM/PM Date ___________________Time _____________ AM/PM Notes: ___________________________________________ Notes: ___________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ _________________________________________________ Date ___________________Time _____________ AM/PM... -

Page 28: Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice. Product warranties can be found online at Greenheck.com, either on the specific product page or in the literature section of the website at Greenheck.com/Resources/Library/Literature.

Need help?

Do you have a question about the ECV Series and is the answer not in the manual?

Questions and answers