Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Ulma ENKOFORM VMK

- Page 1 INDICE INDICE User´s Guide ENKOFORM VMK E02FFR Construcción ...

- Page 2 Ni la totalidad ni parte de este documento puede reproducirse o trasmitirse por ningún procedimiento electrónico o mecánico, incluyendo fotocopia, grabación magnética, o cualquier almacenamiento de información y sistema de recuperación, sin permiso escrito de ULMA Construcción. © Copyright by ULMA C y E, S. Coop Construcción...

-

Page 3: Table Of Contents

General guidelines ............. 78 6.3.2 Inspection instructions of lifting appliances with CE 4.6.1 Outer solution. Outside corner head ......39 marking of ULMA Construcción ........... 78 4.6.2 Inner solution. Corner connector MK ......40 6.3.3 Inspection instructions with CE marking of equipment 4.7. - Page 4 INDICE ÍNDICE Construcción...

-

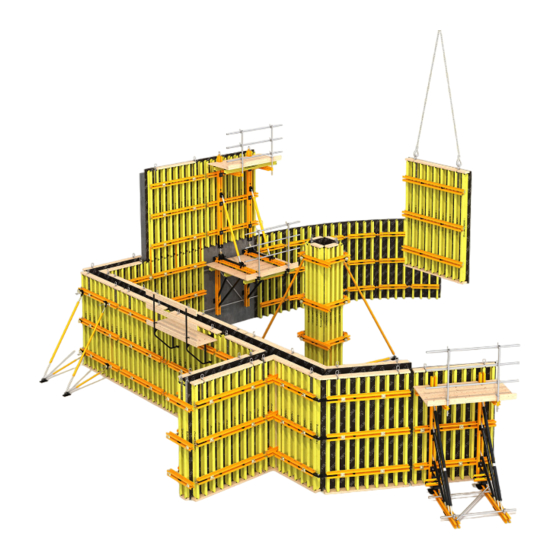

Page 5: Product Description

The component used in all these solutions is the WALER MK. Its design and the proper accessories make it possible for the system MK to give such different configurations. ENKOFORM VMK is a vertical formwork designed for vertical building (non-residential and residential building) and civil engineering (piers). -

Page 6: Concept Of The System

ENKOFORM VMK ENKOFORM VMK 1.1. CONCEPT OF THE SYSTEM The main feature of this system is its unlimited flexibility. This system offers to assemble the PANELS depending on the: Shape: This system enables assemble customized PANELS with the needed dimensions, always with standard components. - Page 7 Configuration of a PANEL for a 30 kN/m2 concrete pressure. In contrast to modular PANELS such as ORMA, ENKOFORM VMK PANELS of both sides do not need The main advantage of this system is that PANELS to be the same. Therefore, the solutions for corners, will be assembled with the required shape.

-

Page 8: Components And Accessories

ENKOFORM VMK ENKOFORM VMK 2. Components and accessories 2.1. GRAPHIC DESCRIPTION Weight Weight Code Name Code Name MK-120 WALERS AND PROFILES CONNECTION AND LIFTING COMPONENTS 1990104 PROFILE MK-120 / 0,5 1960220 10,2 LIFTING BRACKET E V-100 1990105 PROFILE MK-120 / 0,625... - Page 9 ENKOFORM VMK ENKOFORM VMK Weight Weight Code Name Code Name 1990895 10,35 POSTIZO RIOSTRA MK 1960375 0,95 WALER-VM20 CLAMP 2T 1960345 1,30 WALER-VM20 ANGULAR CLAMP 1990730 15,7 ARTICULATED ADJUS. CONNECTOR MK 1960450 TOOLKIT CASE 1990830 12,9 ARTICULATED CONNECTOR MK...

- Page 10 ENKOFORM VMK ENKOFORM VMK Weight Weight Code Name Code Name 1960172 2,20 RIGHT ANGLE HEAD 1940157 19,1 PLYWOOD 2,5x1,25x0,009 BIRCH 1940161 25,5 PLYWOOD 2,5x1,25x0,012 BIRCH 1940155 38,2 PLYWOOD 2,5x1,25x0,018 BIRCH 1940151 44,6 PLYWOOD 2,5x1,25x0,021 BIRCH 1940198 34,9 PLYWOOD 1,25x2,5x0,018 BETO...

- Page 11 ENKOFORM VMK ENKOFORM VMK Weight Weight Code Name Code Name 1900256 1,40 PLATE WASHER NUT 15 0122001 2,08 TUBE 40x40x3 L=600 (D18) 0122002 1,39 TUBE 40x40x3 L=400 (D18) 7238000 0,73 PLATE NUT 15 1861033 0,60 SHORT PIN 0,35...

- Page 12 ENKOFORM VMK ENKOFORM VMK Weight Weight Code Name Code Name 0121004 HANDRAIL SOCKET D50 SAFETY PLATFORMS 1960255 16,2 WALKWAY BRACKET E V-100 2211165 VM HANDRAIL SUPPORT 0241200 0,02 NUT M12 DIN-934-5.6 1861122 0,39 PANEL BOLT 0241201 0,01 WASHER A12 DIN-125...

- Page 13 ENKOFORM VMK ENKOFORM VMK Weight Code Name 7230264 0,006 CONE 22(250 units) 7238048 0,007 CONE 26(250 units) 9371967 0,03 CONE 32 7238049 0,009 WATER STOP CAP 26 (250 units) 7230455 0,16 SPACER TUBE 22/25 (75 ml) 7238047 0,23...

-

Page 14: Elements Description

ENKOFORM VMK ENKOFORM VMK 2.2. ELEMENTS DESCRIPTION 2.2.1 PANEL IN DETAIL The unit element of the system is the PANEL. Although this system formed many components, the unit of the system will be the PANEL. The placement of some PANELS next to each other will make possible to adjust to the required geometry of the wall. - Page 15 ENKOFORM VMK ENKOFORM VMK WALERS MK-120: LIFTING BRACKET E V-100: The real length is 12 mm shorter than the one indicated in the name. They have long and round holes along the profiles. In vertical formwork, the mainly used holes (with WEDGES MK) are the long ones (125 mm gap It makes possible to shift the PANELS.

- Page 16 ENKOFORM VMK ENKOFORM VMK Other components of the system: ADJUSTABLE CONNECTOR MK: WALER CONNECTOR MK: It joins 2 MK-120 WALERS to form a third one: It joins 2 MK-120 WALERS lengthwise to form a third similar function to the WALER CONNECTOR, but with one.

- Page 17 ENKOFORM VMK ENKOFORM VMK ARTICULATED CONNECTOR MK: PUSH-PULL PROP HEAD: It joins 2 PANELS that form a non 90º angle between them. It allows the joint of PUSH-PULL PROPS to MK-120 WALERS to plumb and stabilise PANELS. ARTICULATED ADJUS. CONNECTOR MK: PUSH-PULL PROP: It joins 2 WALERS that form a non 90º...

- Page 18 ENKOFORM VMK ENKOFORM VMK PUSH-PULL PROPS E: TIE RODS: They stand higher loads than the PUSH-PULL PROPS They are used to join two PANELS both in front of (if necessary). each other (with the BOARD face to face).

-

Page 19: Assembly, Use And Disassembly

ENKOFORM VMK ENKOFORM VMK 3. Assembly, Use and Disassembly 3.1. PROP: BASIC ASSEMBLY INSTRUCTIONS The steps for assembling a standard PANEL are: Prepare a flat surface and place the needed BIRA Protect the working area. trestles for each case. - Page 20 ENKOFORM VMK ENKOFORM VMK Place 2 VM 20 BEAMS of both corners as indicated in Place the E V-100 LIFTING BRACKETS to the VM 20 the drawing. BEAMS. The joint between VM 20 BEAMS and MK-120 WALERS will be carried out by means of the WALER- VM20 CLAMP.

- Page 21 ENKOFORM VMK ENKOFORM VMK Place the planks of the E V-100 LIFTING BRACKETS. Place the ASSEMBLY SQUARE. Cover the PANELS with BOARD. Screw the BOARD to the VM20 BEAMS. Construcción...

-

Page 22: Lifting Bracket E V-100

ENKOFORM VMK 3.2. LIFTING BRACKET E V-100 This component is part of the PANEL of the system ENKOFORM VMK. I.e., it is not a removable bracket, but each PANEL will have two brackets. E V-100 LIFTING BRACKETS will be placed when assembling the PANEL. -

Page 23: Assembly Of Lifting Bracket E V-100

ENKOFORM VMK ENKOFORM VMK 3.2.1 Assembly of LIFTING BRACKET E V-100: 1. Make 4 holes of 17 mm diameter in the centre to the BEAM VM20 (in case the BEAM VM20 has no holes). The gap between the holes is 160 mm, and the gap from the 1st hole to the corner of the BEAM VM 20 will be 115 mm. - Page 24 ENKOFORM VMK ENKOFORM VMK 3. Continue assembling the PANEL according to what it is indicated in the assembly draft. Place the VM20 BEAMS that have the E V-100 LIFTING BRACKETS included in the indicated position. Take into account that the VM20 BEAMS that have the E V-100 LIFTING BRACKETS will have to be placed in such a way that the plates with rings will be in the outwards on both sides.

- Page 25 ENKOFORM VMK ENKOFORM VMK 5. Place the BOARD on the VM20 BEAMS. Screw type: D6x50 mm with countersinking head. Completed PANEL. 6. The slings that go to the E V-100 LIFTING BRACKETS should form a maximum angle of 60º between them.

-

Page 26: Solutions

ENKOFORM VMK ENKOFORM VMK 4. Solutions 4.15 4.6.1 4.13 4.1.- WALER MK-120 4.2.- BOARD PLACEMENT IN PANELS 4.3.- TIE ROD PLACING 4.4.- JOINT BETWEEN PANELS (WITH NO FILLER) 4.5.- JOINT BETWEEN PANELS (WITH FILLER) 4.5.1.- COMPENSATION BY MEANS OF BOARD AND VM20 BEAMS 4.5.2.- COMPENSATION BY MEANS OF THE COMPENSATION PLATE... - Page 27 ENKOFORM VMK ENKOFORM VMK 4.9.- PIERS OR LIFT SHAFTS 4.10.- PILASTERS 4.11.- COLUMN SOLUTION 4.12.- BEAM VM20 CONNECTION PLATE 4.13.- PANEL STABILIZATION 4.14.- WALKWAY BRACKET 4.15.- SHIFTING OF PANEL 4.16.- WALER-VM20 CLAMP 2T 4.11 4.14 4.12 4.6.2 ...

-

Page 28: Waler Mk-120

ENKOFORM VMK ENKOFORM VMK 4.1. WALER MK-120 The range of MK-120 WALERS is: 1.125 / 1.25 / 1,375 / 1.625 / 1,875 / 2.125 / 2.375 / 2.625 / 3.125 / 3.625 / 4.125 / 4.625 / 4.875 / 5.625 / 4.1.2... -

Page 29: Criterion To Be Followed

ENKOFORM VMK ENKOFORM VMK 4.1.4 Criterion to be followed Whenever PANELS are assembled by means of WALER CONNECTORS MK or ADJUSTABLE CONNECTORS MK, the BOARD must be placed before shifting the PANEL. Whenever it is possible, MK-120 WALERS will be assembled in zigzag, always trying to be different in length, i.e.: it is better a... -

Page 30: Board Placement In Panels

ENKOFORM VMK ENKOFORM VMK 4.2. BOARD PLACEMENT IN PANELS The width of the PANEL is delimited by the width of the BOARD. When a PANEL is 5 m wide, that means that its BOARD is 5 m wide. -

Page 31: Tie Rod Placing

ENKOFORM VMK ENKOFORM VMK 4.3. TIE ROD PLACING The TIE RODS used in ENKOFORM VMK are mainly TIE RODS 15. Spacer tube 22/25 or 22/26 Plate washer nut 15 Cone 22 Waler MK-120 Tie rod 15 Detail of the joint of two face-to-face-PANELS with SPACER TUBES 22 and CONES 22 between them. -

Page 32: Joint Between Panels (With No Filler)

ENKOFORM VMK ENKOFORM VMK 4.4. JOINT BETWEEN PANELS (WITH NO FILLER) The component used to join two PANELS together (with no filler between them) is the PANEL CONNECTOR MK. Joint between 2 PANELS by means of the PANEL CONNECTOR MK. -

Page 33: Bring Panels Over. Tightness

ENKOFORM VMK ENKOFORM VMK If there is a gap of some millimetres between the two 4.4.1 Bring panels over. Tightness BOARDS, it will go diminishing every time one of the The easiest way of using the PANEL CONNECTOR MK WEDGES MK of each side is introduced more. -

Page 34: Correction Of Errors When Placing The Board

ENKOFORM VMK ENKOFORM VMK 4.4.2 Correction of errors when placing the 4.4.3 Correction of errors when assembling Board walers in panels. The position of the WALER MK-120 inside a PANEL It may happen that PANELS have an assembling error can change from its theoretical position (centralized in the position of MK-120 WALERS. -

Page 35: Joint Between Panels (With Filler)

ENKOFORM VMK ENKOFORM VMK 4.5. JOINT BETWEEN PANELS (WITH FILLER) 4.5.1 By means of BOARD and VM20 BEAMS The component used to join two PANELS with a filler between them is the ADJUSTABLE CONNECTOR MK. Two PANELS joined with a FILLER PANEL between them. - Page 36 ENKOFORM VMK ENKOFORM VMK 4.5.1.2 Correction of the assembling errors of 4.5.1.1 Making filler panels the walers in panels FILLER PANELS formed ADJUSTABLE Some errors could be made when assembling CONNECTOR MK, WALER-VM20 CLAMPS, VM20 PANELS (for example, misplacing the WALER MK- BEAMS and BOARD.

-

Page 37: By Means Of The Compensation Plate

ENKOFORM VMK ENKOFORM VMK The main functions of the ADJUS. COMPENSATION 4.5.2 By means of the compensation plate CONNECTOR MK with the ADJUS. COMPENSATION Components used to connect two PANELS with a HEAD MK and the PUSH-PULL PROPS are: COMPENSATION PLATE between them are: ADJUS. - Page 38 ENKOFORM VMK ENKOFORM VMK 4.5.2.1 To connect PANELS with 4.5.2.2 To correct assembly errors of walers in COMPENSATION PLATE between them PANELS PANELS on both sides do not need to have the edges Some errors could be made when assembling cut in chamfer.

-

Page 39: Corners

ENKOFORM VMK ENKOFORM VMK 4.6. 90º CORNERS 4.6.1 Outer solution. Outside corner head The outer part of the joint of two PANELS is solved In 90º corners, the outer and inner parts will be solved with the OUTSIDE CORNER HEAD MK. -

Page 40: Inner Solution. Corner Connector Mk

ENKOFORM VMK ENKOFORM VMK 4.6.2 Inner solution. Corner connector MK 4.6.2.1 Corner connector MK The CORNER CONNECTOR MK makes it possible to connect 2 different MK-120 WALERS perpendicular to each other. Waler MK-120 Corner connector MK The CORNER CONNECTOR MK connects 2 PANELS perpendicular to each other. -

Page 41: Bulkheads

ENKOFORM VMK ENKOFORM VMK 4.7. BULKHEADS 4.7.1 Wide walls ENKOFORM VMK offers an easy and useful solution to bulkheads. Plate nut 15 The BULKHEAD PANEL will be placed perpendicular to Tie rod 15 the other 2 PANELS. Bulkhead head... -

Page 42: Round Formwork

ENKOFORM VMK ENKOFORM VMK 4.8. ROUND FORMWORK Timber stud This type of formwork will be used in walls with radius bigger than 20 m. Pin e20x70 Articulated adjustable different CONNECTORS used round connector MK formwork. ARTICULATED ADJUSTABLE CONNECTOR MK is used for connecting 2 WALERS MK inside a round PANEL. -

Page 43: Outer Solution

ENKOFORM VMK ENKOFORM VMK 4.8.2 Outer solution Timber stud Articulated adjustable Pin e20x70 connector MK The ARTICULATED ADJUSTABLE CONNECTOR MK connects 2 different WALERS MK-120 inside 1 PANEL. Where necessary, TIMBER STUDS placed between the BEAM VM20 and WALER MK-120. This General view an outer circular formwork. -

Page 44: Lift Shafts Or Piers

ENKOFORM VMK ENKOFORM VMK 4.9. LIFT SHAFTS OR PIERS Lift shafts and piers are solved in a similar way. 4.9.2 Solution of the outer part Whenever it is possible, the outer part will be solved with one PANEL on each side. In case it were not 4.9.1... -

Page 45: Pilasters

ENKOFORM VMK ENKOFORM VMK 4.10. PILASTERS The side of the wall with no bulkhead will be solved 4.10.2 Solution with the CORNER CONNECTOR by means of any PANEL (differing from the modular formwork ORMA). In other words, when solving one... -

Page 46: Column Solution

ENKOFORM VMK ENKOFORM VMK 4.11. COLUMN SOLUTION ENKOFORM VMK also allows solving formwork Outside corner head MK columns. Tie rod 15 Plate nut 15 Top view of a column by means of the formwork ENKOFORM VMK. On the other hand, column PANELS are formed by... -

Page 47: Beam Vm20 Connection Plate

ENKOFORM VMK ENKOFORM VMK 4.12. BEAM VM20 CONNECTION PLATE The BEAM VM20 CONNECTION PLATE makes possible to connect two VM20 BEAMS lengthways. BEAM VM20 CONNECTION PLATE. The joint is carried out by means of 4 BOLTS M16, using the holes of the BEAMS VM20. -

Page 48: Panel Stabilization

ENKOFORM VMK ENKOFORM VMK 4.13. PANEL STABILIZATION The PUSH-PULL PROPS HEAD is joined to MK-120 The use of PUSH-PULL PROPS to stabilize the PANELS WALERS with one E20x190 PIN (each pin will carry at provides: the same time a COTTER PIN R 5) or with no PIN at ... -

Page 49: Walkway Bracket E V-100

ENKOFORM VMK ENKOFORM VMK 4.14. WALKWAY BRACKET E V-100 4.14.1 Walkway bracket in beam VM 20: The WALKWAY BRACKET E V-100 will be placed in one of the holes used to place the BEAM VM 20 CONNECTOR. It will be fixed by means of a screw. -

Page 50: Shifting Of Panel

ENKOFORM VMK ENKOFORM VMK Each PANEL will have 2 E V-100 LIFTING BRACKETS; 4.15. SHIFTING OF PANEL i.e., the E V-100 LIFTING BRACKETS are part of the PANEL. The LIFTING BRACKET E V-100 is fixed to the VM 20 BEAM with 4 M16 screws. -

Page 51: Waler-Vm20 Beam Clamp Types

ENKOFORM VMK ENKOFORM VMK 4.16. WALER-VM20 BEAM CLAMP TYPES Steps for assembling WALER-VM20 CLAMPS 2T: There are 2 CLAMPS that make possible to fix the 1.- The BEAMS VM20 are placed on the MK-120 WALER MK-120 to the BEAM VM20: WALERS. - Page 52 ENKOFORM VMK ENKOFORM VMK 5.- The arms are inserted in the section of the WALER MK-120. 6.- The SCREWER will be used to tie up the nuts electrically. General view of the assembly of the WALER-VM20 CLAMP 2T.

-

Page 53: Waler-Vm20 Angular Clamp

ENKOFORM VMK ENKOFORM VMK 4.16.2 WALER-VM20 ANGULAR CLAMP General view of the WALER-VM20 ANGULAR CLAMP. General view of the assembly of the WALER-VM20 ANGULAR CLAMP. The features of this component are: Steps assembling WALER-VM20 ANGULAR The angle of the joint between the BEAM VM20 CLAMPS: and the WALER MK-120 is between 74º... -

Page 54: Features

ENKOFORM VMK ENKOFORM VMK 5. FEATURES 5.1. FEATURES OF THE MAIN COMPONENTS 5.1.1 WALER MK-120 The properties of the WALER MK-120 are: m = 27,5 kg/m mass/m A = 27 10 area of the net section =12,32 10... -

Page 55: Waler Connector Mk

ENKOFORM VMK ENKOFORM VMK 5.1.2 WALER CONNECTOR MK The properties of the WALER CONNECTOR MK are: A = 17,95 10 area of the net section = 33,99 10 shear area I = 220 10 moment of inertia = 58 10... -

Page 56: Beam Vm20

ENKOFORM VMK ENKOFORM VMK 5.1.4 BEAM VM20 The technical properties of the BEAM VM20 are (in SLS): Maximum bending moment = 11 Maximum shear force EI = 450 kN m Rigidity (EI) 5.1.5 PIN E20x70 + PUSH-PULL PROP E... -

Page 57: Lifting Bracket E V-100

ENKOFORM VMK ENKOFORM VMK 5.1.7 LIFTING BRACKET E V-100 The fact that the LIFTING BRACKET E V-100 has a 13 kN working load, does not mean that PANELS of 26 kN (2 brackets/PANEL) can be raised: The 13 kN working load is the maximum working load of the LIFTING BRACKET E V-100, but the geometry of this PANEL can limit this value, dropping it until 5.5 kN. -

Page 58: Tables

ENKOFORM VMK ENKOFORM VMK 5.2. TABLES 5.2.1 WALER MK-120 When placing the PANELS, TIE RODS are used to join a PANEL with the one in front of it. The maximum working load of the TIE RODS is 90 kN (tension axis). - Page 59 ENKOFORM VMK ENKOFORM VMK 3.625 0.23 0.91 88.1 4.125 0.23 0.74 84.9 4.625 0.30 0.44 74.4 4.875 0.79 0.55 65.9 4.875 0.20 0.80 5.625 0.30 0.56 73.5 Construcción...

-

Page 60: Vm20 Beams

ENKOFORM VMK ENKOFORM VMK 5.2.2 VM20 BEAMS a [m] b [m] z [m] h = 2.55[m] 0.45 1.25 0.85 Concrete pressure [kN/m Beam spacing [mm] Maximum deflection in span [mm] Maximum deflection in cantilever -0.3 -0.4 -0.3... - Page 61 ENKOFORM VMK ENKOFORM VMK a [m] b [m] c [m] z [m] h = 3.7[m] 0.45 1.25 1.25 0.75 Concrete pressure [kN/m Beam spacing [mm] Maximum deflection in span [mm] Maximum deflection in cantilever -0.3 -0.3 -0.2 -0.1 -0.1...

- Page 62 ENKOFORM VMK ENKOFORM VMK a [m] b [m] c [m] d [m] z [m] h = 5[m] 0.45 1.25 1.25 1.25 Concrete pressure [kN/m Beam spacing [mm] Maximum deflection in span [mm] Maximum deflection in cantilever -0.2 -0.3 -0.2...

-

Page 63: Betofilm Boards

ENKOFORM VMK ENKOFORM VMK 5.2.3 BETOFILM BOARDS 4.2.3.1 Plywood Betofilm (18mm) 4.2.3.2 Plywood Betofilm (21mm) Construcción... -

Page 64: Columns

ENKOFORM VMK ENKOFORM VMK 5.2.4 COLUMNS 4.2.4.1 Up to 70x70 cm From 20 x 20 cm to 52 x 52 cm _____________________________________________________________________________________ From 50 x 50 cm to 70 x 70 cm Components pro waler row: Dimensions of the column [cm] 20/20 30/30 40/40 50/50 60/60 70/70 Profile MK‐120 / 0,875 4 4 4 ... - Page 65 ENKOFORM VMK ENKOFORM VMK 80 kN/m Column dimensions [cm] 20/20 30/30 40/40 50/50 60/60 70/70 Number of beams VM20 on each side Column Gap between WALERS [m] height [m] 1,35 1,35 1,35 1,35 1,10 1,10 1,10 1,10 1,05...

- Page 66 ENKOFORM VMK ENKOFORM VMK 90 kN/m y 100 kN/m Column dimensions [cm] 20/20 30/30 40/40 50/50 60/60 70/70 Number of beams VM20 on each side Column Gap between WALERS [m] height [m] 1,35 1,35 1,35 1,35 1,10 1,10...

- Page 67 ENKOFORM VMK ENKOFORM VMK 4.2.4.2 Up to 120x120 cm From 65 x 65 cm to 92 x 92 cm _____________________________________________________________________________________ From 90 x 90 cm to 120 x 120 cm Components pro waler row: Dimensions of the column [cm] 70/70 80/80 90/90 100/100 110/110 120/120 Waler MK‐120 / 1,625 2 2 ...

- Page 68 ENKOFORM VMK ENKOFORM VMK 80 kN/m Column dimensions [cm] 70/70 80/80 90/90 100/100 110/110 120/120 Number of beams on each side Column Gap between WALERS [m] height [m] 1,10 1,10 1,15 1,35 1,35 1,35 1,00 1,00...

- Page 69 ENKOFORM VMK ENKOFORM VMK 90 kN/m Column dimensions [cm] 70/70 80/80 90/90 100/100 110/110 120/120 Number of beams VM20 on each side Column Gap between WALERS [m] height [m] 1,20 1,10 1,10 1,15 1,35 1,35...

- Page 70 ENKOFORM VMK ENKOFORM VMK 100 kN/m Column dimension [cm] 70/70 80/80 90/90 100/100 110/110 120/120 Number of beams VM20 on each side Column Gap between WALERS [m] height [m] 1,15 1,15 1,10 1,15 1,15 1,35 1,00...

-

Page 71: Push-Pull Props

ENKOFORM VMK ENKOFORM VMK 5.2.5 PUSH-PULL PROPS The working loads of the PUSH-PULL PROPS will be represented depending on the extension. WORKING LOAD OF PUSH-PULL PROPS PUSH-PULL PROP 1.1- PUSH-PULL PROP 2.4- PUSH-PULL PROP 3.6- PUSH-PULL PROP 5-6... -

Page 72: Push-Pull Props E

ENKOFORM VMK ENKOFORM VMK 5.3. PUSH-PULL PROPS E Table and diagram of working loads in PUSH-PULL PROPS E: WORKING LOADS OF PUSH-PULL PROPS E PUSH-PULL PROP E PUSH-PULL PROP E PUSH-PULL PROP E 1.00- PUSH-PULL PROP E 1.51- 0.51-0.75... -

Page 73: Terms And Conditions Of Use

ENKOFORM VMK ENKOFORM VMK 6. TERMS AND CONDITIONS OF USE Before starting stripping/dismantling procedure, check that all structural components 6.1. SAFE OPERATING GUIDELINES (e.g. ties) are in place. If not, revise the assembly before proceeding with stripping/dismantling. -

Page 74: Guidelines For Formwork

ENKOFORM VMK ENKOFORM VMK For storage, the panels should be stacked one on 6.1.2 Guidelines for formwork top of the other, placing wood runners between 4.1.2.1 Formwork them. Use some sort of support to separate them Place some sort of support to store or move the from the ground, and provide shelter. - Page 75 PANELS of the system ENKOFORM V-100 Never allow the vibrator to touch the formwork to of ULMA. It will never be used for other prevent exceeding the considered loads. applications or other formwork systems.

-

Page 76: Transport, Handling And Storage

ENKOFORM VMK ENKOFORM VMK 2. Make sure that the used wire rope slings to raise 6.2. TRANSPORT, HANDLING AND the PANELS are placed in a symmetric way. Make STORAGE a previous study of the area where the E V-100 6.2.1 General guidelines... -

Page 77: Handling

ENKOFORM VMK ENKOFORM VMK Keep your distance when opening the containers communication with the crane operator by means of a previously agreed sign code. after transport to prevent injuries from falling objects. If necessary, use tag lines to control the load from distance. -

Page 78: Inspection And Maintenance

ULMA Construcción 6.3.1 General guidelines Equipment with CE marking marketed by ULMA ULMA is responsible for the delivery of the Constucción is checked following the instructions products, for sale or rent, in good working stipulated in the User´s Guide of the respective condition. -

Page 79: Legal References

ENKOFORM VMK ENKOFORM VMK 7. Legal references Council Directive 89/391/EEC of 12 June 1989 on the introduction of measures to encourage improvements in the safety and health of workers at work. Council Directive 89/654/EEC of 30 November 1989 concerning the minimum safety and health requirements for the workplace. -

Page 80: Appendix

AGREEMENT STATEMENT According to Directive 98/37/CE concerning machines Hereby ULMA C y E, S. Coop., located in Paseo Otadui 3, 20560 Oñati, declares that the product whose code and name are mentioned below complies with the design and manufacturing aspects concerning people’s safety required by the corresponding European directive, being this the valid... - Page 81 ULMA Construcción around the world www.ulma-c.com PRODUCTION PLANT Poland AND HEADQUARTERS ULMA Construccion Polska S.A. WARSAW ULMA C y E, S. Coop. www.ulma-c.pl Ps. Otadui, 3 - P.O. Box 13 WSCHÓD REGION 20560 OÑATI (Guipúzcoa) SPAIN WARSZAWA Branch Phone: + 34 943 034900...

- Page 82 Bolton - ONTARIO P.R. China www.ulma-c.ca ULMA Formworks China R.O. LEVANTE Branch SHANGHAI NÁQUERA (Valencia) www.ulma-c.cn Chile MOLINA DE SEGURA (Murcia) ULMA Chile - Andamios y Moldajes, S.A. SANTIAGO www.ulma-c.cl ULMA Formworks UAE L.L.C. DUBAI Norte Branch www.ulma-c.ae ANTOFAGASTA Sur Branch India CONCEPCIÓN...

Need help?

Do you have a question about the ENKOFORM VMK and is the answer not in the manual?

Questions and answers