Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Oerlikon S16A2

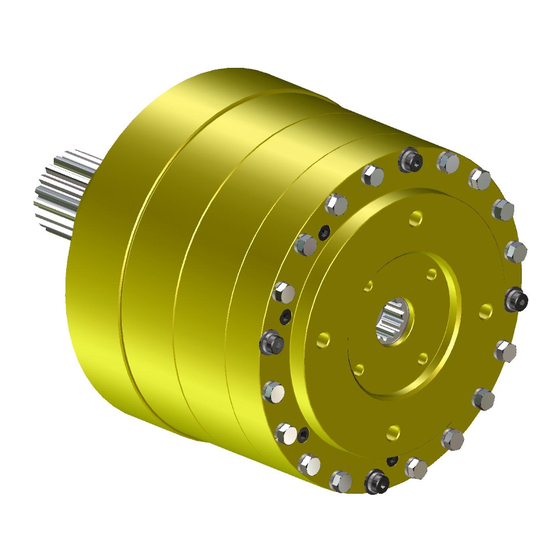

- Page 1 ® Torque-Hub Planetary Final Drive S16A1 & 2 Series Service Manual Rev 9/3/13...

- Page 2 While every precaution has been taken in the preparation of this document, Fairfield Manufacturing Co. Inc. assumes no liability with respect to the use of the documentation described herein, or for any act or omission of Fairfield Manufacturing ® Co. Inc. concerning this documentation. Torque-Hub is a registered trademark of Fairfield Manufacturing Co.

-

Page 3: Table Of Contents

Planetary Final Drive Service Manual Content Introduction Roll and Leak Test Tightening and Torquing Bolts Lubrication Information Disassembly Instructions Main Disassembly Cover Disassembly Output Carrier Disassembly Input Carrier Disassembly Housing-Spindle Disassembly Assembly Instructions Cover Subassembly Input Carrier Subassembly Output Carrier Subassembly Housing Spindle Subassembly Main Assembly Assembly Drawing... -

Page 4: Introduction

Planetary Final Drive Service Manual Introduction This manual is a step-by-step guide to the disassembly and ® assembly of the S12 Series Torque-Hub units. It is designed for the customer or mechanic who is repairing this particular Torque- ® model. Users of this manual should note that each part mentioned is followed by an identification number enclosed in parentheses. -

Page 5: Roll And Leak Test

Planetary Final Drive Service Manual Roll and Leak Test ® Torque-Hub units should always be roll and leak tested before disassembly (if possible) and after assembly to make sure the unit’s gears, bearings, and seals are working properly. The following information briefly outlines what to look for when performing these tests. - Page 6 The Leak Test The purpose of a leak test is to make sure the unit is airtight. To perform a leak test use the leak test fixture from the table below. If the tool is not available, the gearbox must be sealed to perform the test.

-

Page 7: Tightening And Torquing Bolts

Planetary Final Drive Service Manual Tightening and Torquing Bolts If an air impact wrench is used to tighten bolts, extreme care should be taken to ensure the bolts are not tightened beyond their specified torque. The following steps describe how to tighten and torque bolts or socket head cap screws in a bolt circle. -

Page 8: Lubrication Information

The lubricant should have a minimum viscosity index of 95cst and maintain a minimum viscosity of 40cst under normal operating conditions. Some applications require special considerations; consult the machine manufacturer and Oerlikon Fairfield for more additional information. The table below lists the recommended viscosities for various ambient operating temperatures. - Page 9 Oil temperatures should be not higher than 160° to 180°F for continuous operation, and no higher than 200°F for intermittent operation. For special applications, high horsepower, high speeds or wide temperature changes, please consult Oerlikon Fairfield. ® Oil Fill Level...

- Page 10 DISASSEMBLY...

-

Page 11: Main Disassembly

Planetary Final Drive Service Manual Main Disassembly Figure 1 refers to SAE “C” motor mount NOTE: Figure 2 refers to SAE “D” motor mount NOTE: Continued on Next Page... - Page 12 Perform roll check and leak check prior to disassembling the unit. Remove the magnetic Pipe Plug (20) from Input Cover (17) and drain the oil out of the gearbox. NOTE: Record the condition and volume of the oil. Remove four of Shoulder Bolts (18) followed by sixteen of Hexagonal Bolts (15) from Cover Subassembly.

- Page 13 NOTE: Figure 2 refers to 20 : 1 Ratio Remove two Thrust Washers (10) and a Thrust Bearing (9) from the hub of Input Carrier Subassembly. Remove the Sun Gear (4) from Output Carrier Subassembly. Lift out the Ring Gear (2) from Housing Spindle Subassembly. Remove Output Carrier Subassembly from the unit from the Housing Spindle Subassembly.

-

Page 14: Cover Disassembly

Planetary Final Drive Service Manual Cover Disassembly Figure 1 refers to SAE “C” motor mount NOTE: Figure 2 refers to SAE “D” motor mount NOTE: Continued on Next Page... - Page 15 Remove the O-Ring (5) from counter-bore in Cover (17) and Discard O-Ring. Remove two Thrust Washers (10) and Thrust Bearing (9) from Cover (17). Remove Thrust Washer (8) from the Cover (17). Remove Thrust Washer (19) from counter-bore in Cover (17). For SAE “C”...

-

Page 16: Output Carrier Disassembly

Planetary Final Drive Service Manual Output Carrier Disassembly Unbend tang of Tanged lock-Washer (6N) from the Bearing Nut (6P) and remove Bearing Nut (6P) and Tanged Lock-Washer (6N) from the Planet Shaft (6E). Remove Planet Shaft (6E) from the Carrier (6A). Remove Lock Pin (6Q) from slot of Carrier (6A). -

Page 17: Input Carrier Disassembly

Planetary Final Drive Service Manual Input Carrier Disassembly 29 & 40 to 1 Unbend tang of Tanged Lock-Washer (3H) from the Bearing Nut (3G) and remove Bearing Nut (3G) and Tanged Lock-Washer (3H) from the Planet Shaft (3E). Remove Planet Shaft (3E) from the Carrier (3A). Remove Lock Pin (3D) from slot of Carrier (3A). - Page 18 Planetary Final Drive Service Manual Input Carrier Disassembly 20 to 1 Unbend tang of Tanged Lock-Washer (3H) from the Bearing Nut (3G) and remove Bearing Nut (3G) and Tanged Lock-Washer (3H) from the Planet Shaft (3E). Remove Planet Shaft (3E) from the Carrier (3A). Remove Lock Pin (3D) from slot of Carrier (3A).

- Page 19 CAUTION: Safety glasses must be worn during these next steps. Remove Retaining Ring (11) from Coupling (12). Slide coupling from Sun Gear (3J). Remove Retaining Ring (25) from Coupling (12). Remove Sun Gear (3J) from Carrier (3A) through one of the planet carrier windows. This concludes the Input Carrier Disassembly 20 TO 1.

-

Page 20: Housing-Spindle Disassembly

Planetary Final Drive Service Manual Housing-Spindle Disassembly Set the unit on bench such that Housing (1G) small diameter end is facing down. Continued on Next Page... - Page 21 CAUTION: Safety glasses must be worn during these next steps. Remove Retaining Ring (1I) from the groove of Spindle (1A). Remove Thrust Washer (1H) from the Spindle (1A). Remove two Pipe Plugs (1P) from the Housing (1G). Remove Pipe Plug (1Q) from Housing (1G). Turn the unit over and carefully place the unit on a support base until the Shaft (1A) rests on it.

- Page 22 THIS PAGE INTENTIONALLY LEFT BLANK...

- Page 23 ASSEMBLY...

-

Page 24: Cover Subassembly

Planetary Final Drive Service Manual Cover Subassembly Figure 1 refers to SAE “C” motor mount cover. NOTE: Figure 2 refers to SAE “D” motor mount cover. NOTE: Continued on Next Page... - Page 25 Install Pipe Plug (20) onto Cover (17). Grease and Install O-Ring (5) into groove on Cover (17). Ensure that O-Ring is fully seated against the inner diameter. Grease and install Thrust Washer (10) onto Cover (17). Grease and install Bearing (9) on top of Thrust Washer (10). Grease and install Thrust Washer (10) on top of Bearing (9).

-

Page 26: Input Carrier Subassembly

Planetary Final Drive Service Manual Input Carrier Subassembly 29 & 40 to 1 CAUTION: Safety glasses must be worn during these next steps. NOTE: Bearing (3C) is a matched set and must stay as a set. Place Planet Gear (3F) with part number up onto press table. Install Internal Retaining Ring (3C) into the groove of Planet Gear (3F). - Page 27 Align planet shaft bore in Planet Gear (3F) with Thrust Washer (3B) bore and Carrier (3A) planet shaft bore Install Planet Shaft (3E) through the large diameter in the Carrier (3A) hole and through Planet Gear (3F) bearing inner race by aligning the lock pin slot in both the Carrier (3A) and Planet Shaft (3E).

- Page 28 Planetary Final Drive Service Manual Input Carrier Subassembly 20 to 1 1. Install Sun Gear (3J) through a planet gear window in the carrier and to the center of the Carrier (3A). CAUTION: Safety glasses must be worn during these next steps. NOTE: Bearing (3C) is a matched set and must stay as a set.

- Page 29 Align planet shaft bore in Planet Gear (3F) with Thrust Washer (3B) bore and Carrier (3A) planet shaft bore Install Planet Shaft (3E) through the large diameter in the Carrier (3A) hole and through Planet Gear (3F) bearing inner race by aligning the lock pin slot in both the Carrier (3A) and Planet Shaft (3E).

-

Page 30: Output Carrier Subassembly

Planetary Final Drive Service Manual Output Carrier Subassembly CAUTION: Safety glasses must be worn during these next steps. Install Internal Retaining Ring (6T) into Planet Gear (6F) bore. Place Spacer (6U) against Retaining Ring (6T) in deep end of Planet Gear (6F). Press first Bearing Cup (6C) against Spacer (6U) using tool T158150. - Page 31 Clean Planet Shaft (6E) and Locknut (6P) threads using ethanol. Apply Loctite 263 to the Bearing Nut (6P) and planet shaft threads. Tighten Bearing Nut (6P) and tap end of Planet Shaft (6E) to make sure Bearings (6D) are properly seated. Measure Rolling torque of Planet Gear (6F) using Fish Scale. Using tool T- 119240 tighten Bearing Nut (6P) until a torque of 1.5 –...

-

Page 32: Housing Spindle Subassembly

Planetary Final Drive Service Manual Housing Spindle Subassembly Install Pipe Plug (1Q, 1P) into Housing (1G) using Thread Sealant. Press Bearing Cone (1F) onto Output Shaft (1A) using pressing tool T136184. Press Bearing Cup (1E) into Housing (1G) using pressing tool T154563. Make sure the cup is pressed in squarely and to the housing counter-bore. -

Page 33: Main Assembly

Planetary Final Drive Service Manual Main Assembly NOTE: Figure 1 refers to 20 : 1 Ratio NOTE: Figure 2 refers to 29 and 40 : 1 Ratio Continued on Next Page... - Page 34 With Housing Spindle Subassembly standing on the Output Shaft (1A), mark the four counter-bore holes. Grease and install O-Ring (5) into Housing (1G). Lower Output Carrier Subassembly into Housing (1G) and onto Output Shaft (1A). Install Ring gear (2) into Housing (1G), and align the hole marked “X” with a counter bore in Housing (1G).

- Page 35 Figure 2 refers to SAE “D” motor mount NOTE: Install Cover Subassembly onto the Ring Gear (2). Install four Shoulder Bolts (18) with Flat Washers (22) and Lock Washers (14) in these bolts by hand, then torque to 35 – 45 ft-lbs. Install sixteen Hexagonal Head Bolts (15) with Lock Washers (14) into Housing (1G).

-

Page 36: Assembly Drawing

Planetary Final Drive Service Manual Assembly Drawing... -

Page 37: Parts List

Planetary Final Drive Repair Instructions Parts List Number Description OUTPUT SHAFT LIP SEAL TAPERED BEARING TAPERED BEARING TAPERED BEARING TAPERED BEARING HOUSING THRUST WASHER EXTERNAL RETAINING RING PIPE PLUG PIPE PLUG RING GEAR CARRIER THRUST WASHER TAPERED BEARING ASSY LOCK PIN PLANET SHAFT PLANET GEAR BEARING NUT... - Page 38 Number Description COUPLING LOCK WASHER HEXAGONAL BOLT INPUT COVER SHOULDER BOLT THRUST WASHER PIPE PLUG FLAT WASHER EXTERNAL RETAINING RING SUN GEAR O-RING...

-

Page 39: Assembly Tools

Planetary Final Drive Repair Instructions Assembly Tools T158150 – LOADING PLUG AND BASE FOR ASSEMBLY... - Page 40 T158149 – LOADING PLUG AND BASE...

- Page 41 T160764 – BEARING CUP ASSEMBLY PRESSING TOOL...

- Page 42 T223131 – LOCKNUT WRENCH...

- Page 43 T119240 – LOCKNUT WRENCH...

- Page 44 T154563 – ASSEMBLY PRESSING TOOL...

- Page 45 T139345 – ASSEMBLY PRESSING TOOL...

- Page 46 T137786 – TOOL TO PRESS IN SEAL...

- Page 47 T158049 – BEARING CONE PRESSING TOOL...

- Page 48 T136184 – TOOL TO PRESS BEARING ON SHAFT...

- Page 49 T159173 – PRESSING TOOL TO INSTALL BEARING CONE...

- Page 50 T173814-LEAK TEST FIXTURE...

- Page 51 T220225 – LEAK TEST TOOL...

- Page 52 T224477 – ROLL TEST TOOL...

- Page 53 T223989 – ROLL TEST TOOL...

- Page 54 T158149 – LOADING PLUG AND BASE FOR ASSEMBLY...

-

Page 55: Contact Information

Planetary Final Drive Repair Instructions Contact Information With over 80 years of experience, Fairfield Manufacturing has become the largest U.S. non-captive producer of gears, custom gear assemblies, planetary final drives, and related gear products. Fairfield Manufacturing, headquartered in Lafayette, Indiana, is distinguished by our extensive design, manufacturing, and applications engineering capabilities. - Page 56 Oerlikon Fairfield U.S. 52 South / P.O. Box 7940 Lafayette, IN 47903 USA 765-772-4000 www.oerlikon.com/fairfield...

Need help?

Do you have a question about the S16A2 and is the answer not in the manual?

Questions and answers