Advertisement

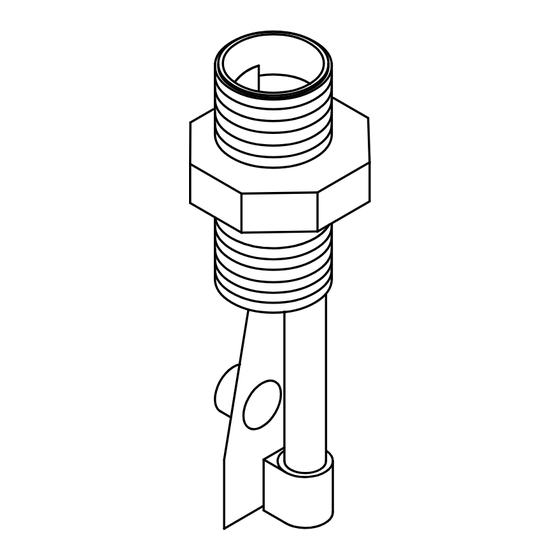

MODEL Q-12

Q-12N, Q-12CR, Q-12DS (TEMPERATURE: QT-12)

½" OR ¾" NPT

APPLY TEFLON

SEALING TAPE

AS REQUIRED

(2-3 LAYERS)

ENCAPSULATED

MAGNET

ONE PIECE

BENDING BEAM

TARGET AND

MAGNET

OPTION 1

BASIC UNIT SUPPLIED WITH

TWO 0.187 x 0.020 MALE

SPADE TERMINALS RECESSED

IN ½" NPT NIPPLE SECTION.

INSTALLATION INSTRUCTION SHEET

SIDE VIEW

0.5"

0.65"

1.1" SMALL BODY

1.4" MEDIUM BODY

1.8" LARGE BODY

ENCAPSULATED

REED SWITCH

OPTION 2

BASIC UNIT WITH TWO-

CONDUCTOR INSTRUMENT

CABLE POTTED IN PLACE.

PVC TEE OPTIONAL.

FLUID FLOW SWITCH

ULTRA RELIABLE SINCE 1956

HARWIL CORPORATION

•

Pressure drop typically less than 1.0 psi

at rated flow.

•

Mount in any position.

OPTION 3 GROMMET SELECTION CHART

Grommet

Cable OD

Size

A

AA

OPTION 3

BASIC UNIT W/ DMP TAPERED

RUBBER GROMMET ATTACHMENT

FOR WATERTIGHT SEAL & STRAIN

RELIEF. PVC TEE OPTIONAL.

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

TOP VIEW

1.2"

Grommet

Cable OD

Size

0.25"

B

0.33"

C

OPTION 4

BASIC UNIT WITH ½" FLEXIBLE

SPIRADUCT PLASTIC CONDUIT &

FITTINGS. ELECTRICAL CABLE NOT

SUPPLIED. PVC TEE OPTIONAL.

TURBULENT

2D

FLOW REDUCTION

5D

MOUNT IN

THREE POSITIONS

0.375"

0.50"

P. 1

Advertisement

Table of Contents

Summary of Contents for Harwil Q-12

-

Page 1: Top View

MODEL Q-12 HARWIL CORPORATION 541 KINETIC DRIVE, OXNARD, CA 93030 TEL: (805) 988-6800 FAX: (805) 988-6804 EMAIL: HARWIL@HARWIL.COM Q-12N, Q-12CR, Q-12DS (TEMPERATURE: QT-12) INSTALLATION INSTRUCTION SHEET TOP VIEW SIDE VIEW 1.2” 0.5” ½” OR ¾” NPT 0.65” APPLY TEFLON SEALING TAPE •... -

Page 2: Installation Instructions

MODEL Q-12 HARWIL CORPORATION 541 KINETIC DRIVE, OXNARD, CA 93030 TEL: (805) 988-6800 FAX: (805) 988-6804 EMAIL: HARWIL@HARWIL.COM Q-12N, Q-12CR, Q-12DS (TEMPERATURE: QT-12) INSTALLATION INSTRUCTIONS Flow switch should be mounted at least 5 pipe diameters insure threads are not crossed and the bending beam... - Page 3 Inasmuch as these data are based on tests by entities over which HARWIL has no control, HARWIL DOES NOT GUARANTEE AND DOES NOT ACCEPT ANY RESPONSIBILITY FOR THE ACCURACY OF SUCH THIRD PARTY TESTING.

Need help?

Do you have a question about the Q-12 and is the answer not in the manual?

Questions and answers