Woody 130 HD Operator's Manual

Log loader

Hide thumbs

Also See for 130 HD:

- Operator's manual (33 pages) ,

- Operator and maintenance manual (66 pages)

Table of Contents

Advertisement

Quick Links

Woody Equipment Inc., 205 rue Commercial, Saint-Odilon-de-Cranbourne, Quebec, Canada G0S3A0

T. (418) 464-2748 F. (418) 464-2746

Website: www.equipementswoody.com <http://www.equipementswoody.com/> Facebook: Equipements Woody

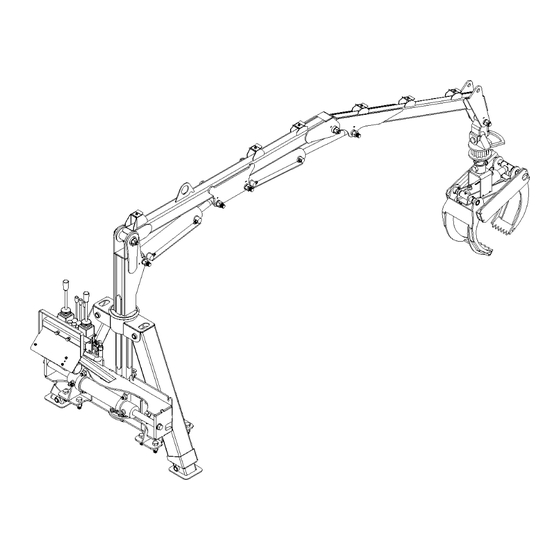

Woody Log Loader

Operator's Manual

Models: 130 HD - 150

HD - 170 HD

Email: ewoody@sogetel.net <mailto:ewoody@sogetel.net>

Advertisement

Table of Contents

Summary of Contents for Woody 130 HD

- Page 1 Woody Log Loader Operator’s Manual Models: 130 HD - 150 HD - 170 HD Woody Equipment Inc., 205 rue Commercial, Saint-Odilon-de-Cranbourne, Quebec, Canada G0S3A0 T. (418) 464-2748 F. (418) 464-2746 Email: ewoody@sogetel.net <mailto:ewoody@sogetel.net> Website: www.equipementswoody.com <http://www.equipementswoody.com/> Facebook: Equipements Woody...

- Page 2 Email: ewoody@sogetel.net <mailto:ewoody@sogetel.net> Website: www.equipementswoody.com <http://www.equipementswoody.com/> Facebook: Les Equipements Woody Woody Equipment Inc. C All Rights Reserved: Woody Equipment Inc. of Saint-Odilon-de-Cranbourne. No part of this manual may be reproduced in any form without the written permission of Woody Equipment Inc.

-

Page 3: Table Of Contents

Table of Contents Introduction................1 Warning................2 Caracteristic of the loader 130HD........3 130HD Loader parts list............4 Caracteristic of the loader 130HDT........5 130HDT Loader parts list............6 Caracteristic of the loader 150HD........7 150HD Loader parts list.............8 Caracteristic of the loader 150HDT.........9 150HDT Loader parts list..........10 Caracteristic of the loader 170HD.........11 170HD Loader parts list...........12 Caracteristic of the loader 170HDT.......13... -

Page 4: Introduction

Woody Equipment reserves the right to modify and / or improve its equipment and maintenance instructions, as well as to revise data without notice. Write down the serial number, model number, purchased date, dealer name, and sales representative’s name. -

Page 5: Warning

Warning The following symbols used in this manual are to warn the operator of the dangers connected to the use of this machinery. Follow the safety instructions to avoid any risk of serious injury or death. -

Page 6: 130Hd Loader Parts List

130-HD Loader Parts List DETAIL AW DETAIL BA DETAIL BB DETAIL BC DETAIL BD SCALE 1 : 16 SCALE 1 : 16 SCALE 1 : 16 SCALE 1 : 16 SCALE 1 : 16... - Page 7 Loader telescopic stabilizers 130,150 & 170 60-018-05 Loader stabilizer 60-018-04 Loader stick boom 130 HD 60-018-03 Loader main boom 130 HD 60-018-02 Loader column 130 HD & HDT 60-018-14 Loader A-Frame 130 HD 60-004-08 Rotation chain 130 & 150 60-000-060 Hose lock 200010...

- Page 8 130 HDT Loader Parts List DETAIL BJ DETAIL BH DETAIL BG DETAIL BF DETAIL BE SCALE 1 : 16 SCALE 1 : 16 SCALE 1 : 16 SCALE 1 : 16 SCALE 1 : 16...

-

Page 9: 130Hdt Loader Parts List

Loader telescopic stabilizer 60-030-01 Loader stick boom 130 HDT 120230 Hydraulic cylinder 2" x 36" stroke 60-030-02 Loader main boom 130 HDT 60-018-02 Loader column 130 HD & HDT 60-018-14 Loader A-Frame 130 HD 60-000-060 Hose lock 200010 Rotation plastic sleeve 89-24-20-44-D22-00 Plastic tubing 1 1/2"... -

Page 10: 150Hd Loader Parts List

150-HD Loader Parts List DETAIL BP DETAIL BN DETAIL BM DETAIL BL DETAIL BK SCALE 1 : 18 SCALE 1 : 18 SCALE 1 : 18 SCALE 1 : 18 SCALE 1 : 18... - Page 11 150-HD Loader Parts List Item Description Part # 60-006-08 Loader stick boom pin 130,150 & 170 60-006-09 Loader main boom pin 130,150 & 170 60-020-30 Loader swing slider 130,150 & 170 60-019-11 Loader A-Frame 150 HD 60-010-04 Loader control valve support 115, 125, 130,150 & 170 60-019-02 Loader column 150 HD 60-019-03...

-

Page 12: Hdt Loader Parts List

150 HDT Loader Parts List DETAIL CA DETAIL BW DETAIL BV DETAIL BU DETAIL BY SCALE 1 : 19 SCALE 1 : 19 SCALE 1 : 19 SCALE 1 : 19 SCALE 1 : 19... -

Page 13: 150Hdt Loader Parts List

150 HDT Loader Parts List Item Description Part # 60-019-11 Loader A-Frame 150 HD Loader control valve support 115, 125, 60-010-04 130,150 & 170 60-019-02 Loader column 150 HDT 60-031-02 Loader Main boom 150 HDT 60-031-01 Loader Stick boom 150 HDT 60-031-06 Telescope 60-018-05... -

Page 14: Hd Loader Parts List

170 HD Loader Parts List DETAIL CB DETAIL CC DETAIL CE DETAIL CD DETAIL CF SCALE 1 : 20 SCALE 1 : 20 SCALE 1 : 20 SCALE 1 : 20 SCALE 1 : 20... -

Page 15: 170Hd Loader Parts List

170 HD Loader Parts List Item Description Part # 60-020-03 Loader main boom 170 HD 60-020-02 Loader column 170 HD 60-020-10 Loader A-Frame 170 60-010-04 Loader control valve support 115, 125, 130,150 & 170 60-024-04 Loader stick boom 170 HD 60-006-08 Loader stick boom pin 130,150 &... -

Page 16: Hdt Loader Parts List

170 HDT Loader Parts List DETAIL CJ DETAIL CL DETAIL CK DETAIL CH DETAIL CG SCALE 2 : 39 SCALE 2 : 39 SCALE 2 : 39 SCALE 2 : 39 SCALE 2 : 39... -

Page 17: 170Hdt Loader Parts List

170 HDT Loader Parts List Item Part # Description 60-032-02 Loader main boom 170 HDT 60-020-02 Loader column 170 HD 60-020-10 Loader A-Frame 170 60-018-06 Loader telescopic stabilizer 130,150 & 170 60-010-04 Loader control valve support 115, 125, 130,150 & 170 60-032-01 Loader stick boom 170 HDT 60-032-07... - Page 18 Parts list Grapple 52'' Item Description Parts # 140030-009-100700-101820 Hose 3/8'' 140030-010-100700-101820 Hose 3/8'' 57-004-04 Side plate grapple 57-004-01 Grapple 52'' center 57-004-13 Wide finger grapple 57-004-12 Little finger grapple 86-20-152 Rod 1 1/4" O.D. 86-24-166-E18-00-E148-00 Rod 1 1/2" O.D. 86-24-177-E14-00-E163-00 Rod 1 1/2"...

- Page 19 Parts list Winch 6000lbs Item Description Part# 58-007-02 Winch head 58-000-04 Swivel head fixation- large, medium, small 58-000-05 Winch roller- large, Medium 58-007-03 Cable tensioner pin 58-000-06 Winch fixed cluth- Large, Medium, Small 58-000-07 Winch fixed cluth- Large, Medium, Small 58-000-08 Clutch arm- Large, Medium 58-000-01...

-

Page 20: Parts List Double Hydraulic Directional

Parts list Double directional Item Description Parts # 59-076-23 Double directional frame 59-003-08 Hitch 59-076-09 Deck span 9.5 59-076-08 Pivot lock 59-076-04 Pivot lock 59-076-034 Washer 59-076-035 Washer 59-076-06 Pivot double directional CU3008-0453 Hydraulic cylinder 3" Dia. x 8" Stroke 307063 Snap-Ring 1 1/4"... -

Page 21: Operation

Stop all operations immediately if any bystanders enter the work zone (20 Woody loaders are intended for normal use in the agricultural and forestry sectors. They must be used only by persons trained in the handling of this type of machinery. -

Page 22: Safety Instructions

Safety Instructions If the overload protection of the hydraulic system is not properly adjusted or certain system functions are altered, safety cannot be ensured. . Always lower the hydraulic stabilizers before each operation to avoid overturning. . Always check that any unauthorized personnel remains outside the work risk area. . - Page 23 Safety Instructions Driving on the Road Observe the following instructions to avoid any risk of accident. Position during Transport . If there is no load, position the loader boom as low as possible on the trailer. Make sure that the grapple and the rotator are firmly attached to the trailer, so that there is no risk of the loader rolling over during transport.

- Page 24 Safety Instructions Welding Repair . If a repair or modification requires the welding of certain parts, you must first contact your dealer for necessary instructions. Improper welding or negligence during welding can cause sudden machine breakdowns. Working in Extreme Conditions The recommended ambient temperature for the operation of this machine is between -20 °...

-

Page 25: Safety Instructions

Safety Instructions Maintenance and Servicing Safety Instructions . Hot oil can cause burns. Inhalation of hot oil vapor can cause breathing difficulties. . If a hose bursts and you get oil on your skin, it is not dangerous. However, avoid oil contact with eyes and nose. If you get oil in your eyes or in your respiratory tract, contact a doctor immediately. -

Page 26: Safety Instructions

Safety Instructions Greasing points and intervals DETAIL AG SCALE 2 : 21 By prevention, remove the cap once a year, tighten the castellated nut, fill the cap with grease and replace the cap! Greasing Interval Item Greasing point Lubricating oil hourly / yearly Telescopic stabilizer Bushing grease... - Page 27 Trailer Parts List Axle tandem Tires # Assembly # Trailer # Assembly Axle Tires tandem 11-74 59-013 59-024-03 5000lbs 12.5L15 11-74 59-150 59-081-02 8000lbs 385-65-22.5 11-74 59-151 59-082-07 8000lbs 400-60-15.5 13-78 59-014 59-024-03 5000lbs 12.5L15 13-78 59-125 59-082-07 8000lbs 12.5L15 13-78 59-161 59-082-07...

- Page 28 Regularly monitor tire pressure and increase air pressure as needed based on written tire specifications. By prevention, remove the cap once a year, tighten the castellated nut, fill the cap with grease and replace the cap! Greasing Interval Item Greasing point Lubricating oil hourly / yearly Posts...

- Page 29 Maintenance and safety instructions for proper use of the 6000 lb. hydraulic winch Grease every 4 hours of use with bushing grease. Caution: Risk of crushing your finger or hand and could even lead to death!!!

- Page 30 Maintenance and safety instructions for proper use of a double drawbar Grease every 4 hours of use with bushing grease Make sure that no one is standing in the perimeter and also make sure no one is standing on the step!

- Page 31 Safety Instructions Storage If you plan to stop using the loader for a long period of time, it should be cleaned carefully. Note that high pressure cleaning is not recommended! After cleaning, make a visual inspection for any cracks (if you find any, you must have them repaired before the next use of the loader) all grease nipples must be lubricated.

Need help?

Do you have a question about the 130 HD and is the answer not in the manual?

Questions and answers