Table of Contents

Advertisement

Woody Equipment Inc., 205 rue Commercial, Saint-Odilon-de-Cranbourne, Quebec, Canada G0S3A0

T. (418) 464-2748 F. (418) 464-2746

Website: www.equipementswoody.com <http://www.equipementswoody.com/> Facebook:

Equipements Woody

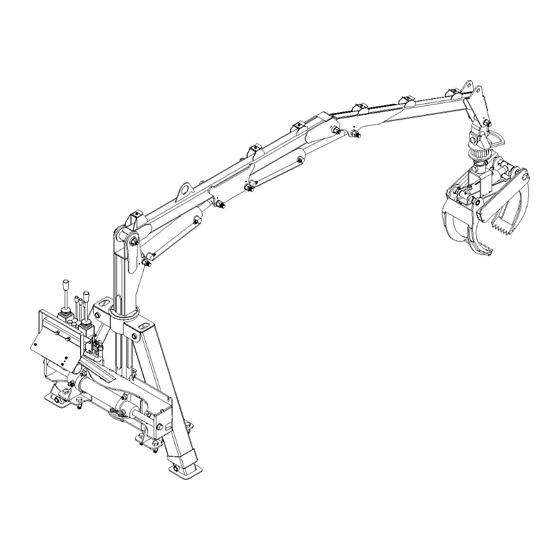

Woody Log Loader

Operator's Manual

Models 90 HD - 95 HD

- 105 HD

Email: ewoody@sogetel.net <mailto:ewoody@sogetel.net>

Advertisement

Table of Contents

Need help?

Do you have a question about the 90 HD and is the answer not in the manual?

Questions and answers