Table of Contents

Advertisement

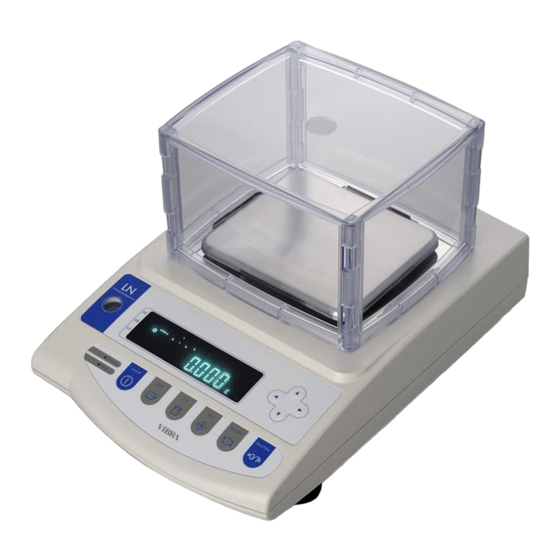

High-Precision Advanced Tuning Fork Balance

L N

Operation

To ensure safe and proper use of the balance, please read this

manual carefully.

After reading this manual, store it in a safe place near the balance, so

you can review it as needed.

SHINKO DENSHI CO., LTD.

S e r i e s

Manual

IMPORTANT

360002M21

Advertisement

Table of Contents

Summary of Contents for Shinko Denshi LN 423

- Page 1 To ensure safe and proper use of the balance, please read this manual carefully. After reading this manual, store it in a safe place near the balance, so you can review it as needed. SHINKO DENSHI CO., LTD. 360002M21...

- Page 2 PREFACE Thank you for purchasing an LN Series electronic balance. This balance is equipped with a high precision mechanism. It provides parts counting, percentage weighing, and limit functions helpful in weighing a certain amount, and has various other functions. This advanced balance employs a user-friendly program, and the key arrangement is also easy to operate.

-

Page 3: Table Of Contents

Contents 1 Precautions Relating to Use ......2 9 Calibration and Span Test for the Balance Span Adjustment ........43 2 Names of Component Parts ......5 Span Test ..........44 Calibration of Built-in Weight ....45 3 Installation of the Balance and Operation Check 10 Date and Time Setup ........ -

Page 4: Precautions Relating To Use

1 Precautions Relating to Use This Section "Precautions Relating to Use" sets forth precautionary notes that the user should observe in order to prevent physical injury to the user and/or damage to property. The nature of problems that may result in the event of improper operation, and consequential effects on the quality and performance of the balance, are indicated under the two categories of "Caution"... - Page 5 Do not place the balance on an unstable base or use the balance in a location where it may be subjected to shock. • The loaded sample may fall off the pan. Do Not Use • Accurate measurement may be rendered impossible.

- Page 6 Avoid applying excess force or impact to the balance. • Place the sample to be measured on the balance carefully to prevent breakage or malfunction. Do Not Apply Force Do not use the balance in a location were it may be subjected to abrupt changes in ambient temperature or humidity.

-

Page 7: Names Of Component Parts

2 Names of Component Parts Main Unit Wind shield 220g~620g capacity models Adjuster Fixed legs 1200g~15kg capacity models kg,31kg capacity model Display Adjuster Level Operation key D-SUB9P RS232C Rear output connector (male) DIN8P connector for peripheral device output Jack for the AC adapter Antitheft hole (Use a wire, etc., through the hole for preventing to... - Page 8 Displayed Signs and Operation Keys 2.2.1 Displayed signs Display Description kg g Kilogram, gram →0← Zero-point − Minus Tare sign Gross weight Indication of stable balance (If this light is off, the balance is unstable.) ∗ Indicates that the addition function is enabled for accepting an additional load. Parts counting Grain unit Percentage weighing...

- Page 9 2.2.2 Operation keys and their functions Operation key Function On/Off key Turns the balance on or off. Starts output. Print key Also used to cancel the operation to set date/time. [Short press] Starts the setting a count or a percent. Set key [Continuous press] Starts the setting of a limit value when the limit function is enabled.

-

Page 10: Installation Of The Balance And Operation Check

3 Installation of the Balance and Operation Check Installation 1 Attach the pan base and pan Attach the pan base to the main unit. Be sure that the "FRONT" indication is on the to the main unit. display side when attaching the pan base. Align the bosses on the body with the holes on the pan base before fastening the screws. -

Page 11: Operation Check

Operation Check 3.3.1 Turn the power on and off and check the display Connect the AC adapter. The balance enters standby mode, and the Stand by lamp (LED) lights up. On/Off Press the On/Off key. When the display is turned on, check it for any missing signs. - Page 12 Weigh additional samples 4 Reset the display to 0. Press the Zero/Tare key. The gross weight of the sample on the pan is reset to →0← g Zero/Tare 5 Put an additional sample on the balance. The weight of the additional sample is displayed.

- Page 13 Hints The following description applies commonly to the weighing machine, parts counting, percentage weighing, unit converting, and gravimeter functions. A small amount of current is still flowing after the balance is turned off. In a standby state, the Stand by lamp (LED) is lit. When the balance is turned on, the LED goes out.

-

Page 14: Function1

4 Function1 Setting and Check 1. Call Function1. Keep pressing the Function key. When the display is changed to [] , release the key. Now you can set Function1. The first setting item is ]. displayed [... -

Page 15: Description Of Function1

Description of Function1 Item Set Value Description Weighing machine (only supports weight measuring) Parts counting (parts counting and weight measuring) Percentage weighing (weight percent measuring and weight measuring) Weighing Mode Unit converting (coefficient multiplying and weight measuring) ... - Page 16 Item Set Value Description No display Bar Graph Displays the bar graph Disable (for continuous use) Available only when Auto Power Off operated on Enable (the power is turned off 3 minutes batteries.

- Page 17 Item Set Value Description 1 Disable Advice CAL 2 Enable Disable Compliance with ISO/GLP/GMP Enable Output of Disable CAL and span test Enable results Data Disable compliant ...

-

Page 18: Additional Functions

Additional Functions Displayed when [ ] is other than []. Item Set Value Description Always judge (even when the balance is unstable). Condition Judge only when the balance is stable. Above +5 ticks is covered in the judgment. ... -

Page 19: Interface

Interface Displayed when [ ] is [~]. Item Set Value Description Stop output Output continuously at all times Output continuously if stable (Stop output if unstable) Output once when the Print key is pressed (regardless of whether ... -

Page 20: Function2

5 Function2 Setting and Check 1 Call Function2. Press the Function key while holding down the Zero/Tare key. Press the Function key while holding down the Zero/Tare key. When [] is displayed, release the key. ]. The display will be changed to show [ ... -

Page 21: Weighing Mode

6 Weighing Mode You can select a weighing mode from the five types in Function1: a weighing machine, a parts counting, a percentage weighing, a unit converting, and a gravimeter. All the weighing modes except for the gravimeter support additional functions (the addition function and the limit function) depending on the display unit. -

Page 22: Parts Counting

Parts Counting The parts counting function employs an automatic memory update method, also referred to as a Self Counting System. When you put a specified number of samples on the balance, and put additional samples, the balance automatically updates the average unit weight of the samples. However, you cannot add more than two times as many samples as the first reading. - Page 23 5 Put additional samples on the balance. Add no more than two times as many samples as the displayed number and wait until it is stable again. A beep will sound and the memory is updated. Pcs Repeating this operation will improve the resolution of ...

-

Page 24: Percentage Weighing

Percentage Weighing 6.4.1 Set a reference weight by weighing an actual sample You can make the display indicate the weight percentage (%) of a sample with respect to a reference sample weight. 1 Select the percentage weighing function. Select the percentage weighing function [... - Page 25 6.4.2 Set a reference weight by entering a value You can enter a reference weight in the balance, and then make the display indicate the weight percentage (%) of a sample with respect to the reference. 1 Set a reference weight. Press the Function key for a few seconds.

-

Page 26: Unit Converting

Unit Converting The unit converting function multiplies the weight of a sample on the balance by a saved coefficient, and displays the result. 1 Select the unit converting function. Select the unit converting function in Function1 [ ]. Then, press the Set key to return to the measurement mode. -

Page 27: Gravimeter

Gravimeter When the balance is used as a gravimeter, specific gravity is measured by hanging a sample, thus requiring an optional hooking device. Any net or cage, hanging strings, or containers that may be required to hang the sample on the balance should be prepared by the user for the particular sample to be subjected to the measurement. - Page 28 6. Measure the weight of the sample in the air. Measure the weight of the sample put in a cage or on a pan, in the air. After the weight display is stable, press the Set key to ...

- Page 29 6.6.2 Entering water temperature or the specific gravity of the media This is for entering correction data for the liquid media to be used for the measurement. Enter water temperature if the media is water. Otherwise, enter the specific gravity value of the liquid. Use Function1 for selecting the media as follows: Correction data input procedures 1 Set the balance for gravimeter and select the...

- Page 30 6.6.3 Gravimeter measurement data output (1) Output before gravimeter measurement With the gravimeter function, the operation is with the [ ] (output once when Print key is pressed after it is stabilized) mode, regardless of the setting by []. (2) Output while specific gravity is displayed [...

-

Page 31: Statistics Function

Statistics Function This is a function to collect weight data and display statistics such as the maximum and average values. Regardless of which function is selected, the measurement unit is set to “g,” and the minimum value is displayed to the maximum number of decimal places available. 6.7.1 Calculation items The statistics displayed by the statistics function (calculation items) are as follows:... - Page 32 6.7.2 Operational procedure Set Function1 to [ ]. 1. Start the statistics function. Then, press the Set key to switch to the statistics function. Place a tare container on the balance as appropriate. g Zero-setting and tare are important in order to ensure that statistics are accurately calculated.

- Page 33 Caution In step 2, press the Print key only when the output control is set to [ ]. If the output control is set to [ ], the data is automatically output once when the balance is stable. If the statistics function is selected, only or can be enabled. If the output control is set to anything other than these three settings, [...

- Page 34 6.7.3 Printing out all of the statistical calculation results Using an output device, you can print out all of the statistical calculation results at once. Switch to the statistical calculation display before 1. Switch to the statistical calculation display. collecting the next data point. ...

- Page 35 6.7.4 Cancelling the last collected data point You can cancel the last collected data point only once. Switch to the statistical calculation display before 1. Switch to the statistical calculation display. collecting the next data point. g ...

-

Page 36: Addition Function

7 Addition Function The addition function allows you to find the cumulative weight of samples put on the balance one after another. Except for the gravimeter function, all other functions, i.e., weighing machine, parts counting, percentage weighing, and unit converting functions support the addition function. Cumulate Function With the cumulate function, a cumulative weight can be obtained while samples are reloaded. -

Page 37: Net Addition Function

Net Addition Function The net addition function automatically performs tare range after an addition, so additions can be performed without having to replace samples. Set Function1 from [ ] to 1 Set Function1. [ ]. Then, press the Set key to return to the measurement mode. -

Page 38: Limit Function

8 Limit Function The limit function judges a weight based on limit values that you have stored on the balance. The limit judgment result will be indicated by the position where the triangle [] is lit. When one or two points are set, the resulting display will be either HI (high), OK (proper), or LO (low). With a 3 or 4 point setting, 5 triangles [] are used to provide more detailed judgments. -

Page 39: Judge By Absolute Values

Judge by Absolute Values 8.4.1 Set two limit values by putting actual samples on the balance 1 Start the limit function. Press the Set key for a few seconds. When the display indicates [ ], release the key. The current lower limit is displayed next to [LO ]. Continuous press 2 Put the lower limit sample on the balance. - Page 40 8.4.2 Set two limit values by entering values 1 Start the limit function. Press the Set key until the display indicates [ ]. The current lower limit is displayed next to [LO ]. Continuous press 2 Switch to the value input screen. Press the Zero/Tare key.

-

Page 41: Judge By Deviation Values

Judge by Deviation Values 8.5.1 Set two limit values by putting actual samples on the balance 1 Start the limit function. Press the Set key for a few seconds. When [] is displayed, release the key. The current reference weight blinks in the display. Key released ... - Page 42 8.5.2 Set two limit values by entering values 1 Start the limit function. Press the Set key for a few seconds. When [] is displayed, release the key. The current reference weight blinks in the display. Continuous press 2 Switch to the value input screen. Press the Zero/Tare key.

- Page 43 Caution: The initial limit values are all zero. You can set separate limit values for the weighing machine, parts counting, percentage weighing, and unit converting functions. However, absolute values and deviation values are saved in the same storage area. So if you switch between absolute values and deviation values, limit values are deleted.

-

Page 44: Bar Graph For The 2-Point Scale

Bar Graph for the 2-point Scale You can set two points for the limit function, and display a bar graph to indicate the result in a range specified by the two points. Except for the gravimeter function, all other functions, i.e., weighing machine, parts counting, percentage weighing, and unit converting functions can support this function. -

Page 45: Calibration And Span Test For The Balance

9 Calibration and Span Test for the Balance Span Adjustment An electronic balance, which is influenced by the acceleration of gravity, indicates different values depending on the location it is used. For this reason, you should calibrate your balance every time you relocate it. -

Page 46: Span Test

Span Test The purpose of the span test is to check for any offset in the span of the balance with respect to a reference weight. Performing this function will not calibrate the balance. 9.2.1 Span Test with Built-in Weight * Only supported by the LN**R series 1 Set Function1. -

Page 47: Calibration Of Built-In Weight

Calibration of Built-in Weight * Only for the LN**R series This is a function to calibrate the built-in weight with an external weight. 1 Set Function2. Set Function2 with nothing put on the pan. Enable the calibration of built-in weight function in Function2 [ ... -

Page 48: Date And Time Setup

10 Date and Time Setup 10.1 Time Setup The time is displayed with a clock [] symbol. Set the time in Hour-Minute-Second format on a 24- hour basis. 1 Display the time. Press the Function key for a few seconds. When the display is changed from [] to [], release the key. -

Page 49: Various Functions

11 Various Functions 11.1 Auto Sleep Function This is a function to turn off the display when the balance is left to stand in measurement mode for about 3 minutes. This function can only be used when the balance is operated on the AC adapter. To use the auto sleep function, enable it in Function1 [... -

Page 50: Advice Cal

11.5 Advice CAL Advice CAL blinks the CAL sign in the display to inform you when span adjustment is to be made. The timing to perform span adjustment depends on changes in ambient temperature and used hours. To use this function, set Function1 to [ ]. When the CAL sign starts to blink, perform span adjustment as soon as possible. -

Page 51: Interval Output Function

11.10 Interval Output Function This function outputs data at regular intervals. You can also output data time stamped. Set an interval in Hour-Minute-Second format. To use the interval output function, enable it in Function1 to [ ] or [ ]. * If it is desired to output time stamp data at the same time, refer to Section 11.7. -

Page 52: Id Number Entry

11.11 ID Number Entry An ID number is used when data is printed in compliance with ISO/GLP/GMP. Set an ID number when you print data. When an ID number is displayed, two triangles, [] and [▲] are displayed in the upper left part of the display. -

Page 53: Entry Of Weight Error

11.12 Entry of Weight Error By entering the weight error of an external reference weight to be used in span adjustment or span test, a more accurate calibration can be performed. Enter the weight error obtained from the following equation: (Weight errors are entered in the unit of mg.) Weight Error = Actual Weight - Nominal Value = 1000.00012 −... -

Page 54: Input/Output Functions

12 Input/Output Functions 12.1 RS232C Output 12.1.1 Connector pin numbers and functions Signal Pin No. Input/Output Function & Remarks Name Input Receiving data Output Transmitting data HIGH Output (When the balance is powered ON) Signal ground 1 2 3 4 5 6 ... - Page 55 12.1.2 Connecting the balance to a PC Sample connection with an IBM-PC/AT compatible machine Balance IBM-PC/AT compatible machine D-SUB9P D-SUB9P Sample wire connection with PC9801 Balance PC9801 D-SUB9P D-SUB25P...

- Page 56 12.1.3 Interface specifications (1) Transmission system Serial transmission, Start-stop synchronization (2) Transmission rate 1200/2400/4800/9600/19200 bps (3) Transmission codes ASCII codes (8/7 bits) (4) Signal level Compliant with EIA RS-232C. HIGH level (data logic 0) +5 to +15 V Low level (data logic 1) -5 to -15 V (5) Bit configuration Start bit 1 bit...

-

Page 57: Output To Peripherals

12.2 Output to Peripherals Our standard peripheral units can be connected to the balance. These peripheral units include: CSP-160, CSP-240 12.2.1 Connector pin numbers and functions Signal Pin No. Input/Output Function & Remarks Name Tare setting from an EXT.TARE Input external device Output Transmitting data... -

Page 58: Type Of Communication Texts

12.3 Type of Communication Texts This interface function uses the following three types of communication texts: (1) Output data Data, such as weight values, that is output from the balance to an external unit (2) Input commands Commands to control the balance from an external unit (3) Response Response that is output from the balance to an input command Caution:... - Page 59 12.4.3 Numeric data 6-digit numeric format: (D1-D7: 7 characters) 7-digit numeric format: (D1-D8: 8 characters) D1 to D7(D8) Code Description 0 – 9 30H to 39H Digits 0 – 9 Decimal point (floating) Omitted when numeric data does not contain decimal places.

- Page 60 12.4.5 Judgment result when the limit function is enabled (S1: 1 character) Code Description Too little (LO) Proper (OK) 1- or 2-point scale Too much (HI) Rank 1 Rank 2 Rank 3 3- or 4-point scale Rank 4 Rank 5 Cumulative value Unit weight Data type...

-

Page 61: Input Commands

12.5 Input Commands The following 7 input commands are supported: (1) Tare range command (2) Set output control command (3) Set measurement mode command (4) Request date output command (5) Request time output command (6) Set interval command (7) Span adjustment/test command 12.5.1 Procedure for transmission (1) An input command is sent from an external device. - Page 62 12.5.2 Response You can select the response format of either the A00/Exx format or the ACK/NAK format in Function1. (1) A00/Exx format Consists of 5 characters including terminators (CR, LF). Response types Code Meaning Successful completion * Command error (when an errant command is received) (Errors other than E01) * Numeric format error...

- Page 63 12.5.3 Command format (1) Tare range (zero-setting) command Code Description Value Response A00: Successful completion E01: Command error • Set Tare E04: A tare range cannot be Range set or the zero-point (SP) None • cannot be adjusted Adjust the (because of a range zero-point violation or a weight...

- Page 64 12.5.4 Set measurement mode command Command Main Body Description Value Response Code character character A00: Successful Set to Mode 1 completion Set to Mode 2 None E01: Command Set to Mode 3 error Set to Mode 4 E02: (error) The measurement mode to be activated by the above mode settings 1 to 4 depends on the weighing mode currently in use.

- Page 65 12.5.6 Setting intervals Command Main Body Description Value Response Code character character A00: Successful completion E01: Command Interval time setup Interval time error E02: Interval time error * Upon setting the time interval, mark off between the entries of command, hour, minute, and second using a comma, ","...

- Page 66 12.5.8 Setting limit values Command Main Body Description Value Response first second ASCII code character character First setting point/lower limit A00: Successful Second setting completion Limit point/upper limit values E01:Command error Reference value E02:Set value error Third setting point Forth setting point Caution 1.

-

Page 67: Special Format Output

12.6 Special Format Output 12.6.1 Special format 1 This output format is applied when [ ] is selected in Function1 Measurement data (including decimal point) Unit Terminator P1 (One character): Set value error Polarity plus/zero: [+] (2BH), Minus: [-] (2DH) SP (One character): Space [ ] (20H) D1~D8 (Eight character): Measurement data, numerical value [0 to 9] (30H–39H), and decimal point (2EH) - Page 68 12.6.2 Special format 2 This output format is applied when [ ] is selected in Function1. Unit Stability Measurement data (including polarity and decimal Termi- (One to three information point) nator characters) S1~S3 (three character): Stable: [S S] (53H) (20H) (53H), Unstable: [S D]: (53H) (20H) (44H) SP (One character): Space [ ](20H)...

-

Page 69: Use Printers

13 Use Printers 13.1 Printer Setting (1) Use CSP-160 or CSP-240 with the balance. (2) Set proper print functions (print control) with the balance referring to the instruction manual for your printer. The factory default of our printer is manual printing (printer control). (3) Make the baud rate and other settings compatible between the balance and the printer. -

Page 70: Output In Compliance With Iso/Glp/Gmp

14 Output in Compliance with ISO/GLP/GMP When a span adjustment or span test is successfully completed, the balance presents the results according to the following format. If span adjustment or a span test is not completed successfully, no data will be printed. The "X" entries in the following tables will vary with the model or the weight used. - Page 71 (3) Span test with the built-in weight English Japanese (Katakana) テ ス ト ヒ ツ " ケ シ " コ ク カ タ シ キ セ イ ハ " ン テ ス ト ナ イ フ " フ ン ト "...

- Page 72 (5) Printing of measurement data Header English Japanese (Katakana) N K O D E N S H N K O D E N S H カ タ シ キ X X X X X X X X X X X X X X X X X X X X X X X X X X セ...

-

Page 73: Operate On Batteries

15 Operate on Batteries This function can only be used with a balance equipped with optional batteries. The battery option is unavailable for LN**R series units. 15.1 Specifications • Built-in batteries • Charge time: About 15 hours • Operation time: About 6 hours of continuous operation •... -

Page 74: Troubleshooting

16 Troubleshooting * Parentheses contain a page to refer to. Symptom Cause Measures to Take • → Ensure that the AC adapter No display The AC adapter is not connected. is connected. • The batteries are exhausted. → Recharge the batteries (page 71). -

Page 75: Specifications

17 Specifications 17.1 Basic Specifications Model 1202 2202 3202 4202 Item 223R 323R 423R 623R 1202R 2202R 3202R 4202R Weighing 220g 320g 420g 620g 1200g 2200g 3200 4200 capacity [g] Minimum 0.001g 0.001g 0.001g 0.001g 0.01g 0.01g 0.01g 0.01g readability [g] Parts counting Minimum unit 0.001g... - Page 76 17.2 Common Specifications (1) Weight measurement method: ············ Tuning fork system (2) Tare range ······································ Full capacity (3) Display: ········································· The FIP segment can display up to 8 digits. The segment is 12.5 mm high, and displays 8 digits for a weight. Can display a bar graph of up to 40 bars and various messages.

- Page 77 17.3 Minimum Display by Unit of Measurement Model LN223 LN323 LN423 LN623 LN1202 LN2202 LN3202 LN4202 Unit_of LN223R LN323R LN423R LN623R LN1202R LN2202R LN3202R LN4202R measuremant 1200 2200 3200 4200 0.001 0.001 0.001 0.001 0.01 0.01 0.01 0.01 0.22 0.32 0.42 0.62 0.000001...

- Page 78 Model LN6202 LN8202 LN12001 LN15001 LN21001 LN31001 Unit_of measuremant 6200 8200 12000 15000 21000 31000 0.01 0.00001 0.0001 0.0001 0.0001 0.0001 0.0001 31000 41000 60000 75000 100000 150000 (ct) 0.05 1000 (oz) 0.0005 0.005 0.005 0.005 0.005 0.005 (lb) 0.00005 0.0005 0.0005 0.0005...

-

Page 79: Conversion Table Of Units

18 Conversion Table of Units Penny Unit Gram carat Ounce Pound troy ounce Weight 0.03527 0.00220 0.03215 0.64301 0.00705 0.00044 0.00643 0.12860 28.34952 141.74762 0.06250 0.91146 18.22917 453.59237 2267.96185 14.58333 291.66667 1ozt 31.10348 155.51738 1.09714 0.06857 1dwt 1.55517 7.77587 0.05486 0.00343 0.05 0.06480...

Need help?

Do you have a question about the LN 423 and is the answer not in the manual?

Questions and answers