Table of Contents

Advertisement

Quick Links

Parker Hannifin Corporation

Porter Instrument Division

245 Township Line Road

Hatfield, PA 19440

Office 215 723 4000

Fax 215 723 5106

The Quality System for Porter Instrument is certified to ISO 13485. The scope of our registration is:

"The design, manufacture, distribution and servicing of Nitrous Oxide – Oxygen Sedation Flowmeters, Gas

Scavenging Systems, Gas Distribution Systems and Office Communication Systems for use by a physician, dentist or

licensed healthcare Profession."

Check our website: www.porterinstrument.com for additional information.

To register your product:

To download a User's Manual: www.porterinstrument.com/resources-dental choose Manuals tab

www.porterinstrument.com/resources-dental

PORTER DIGITAL MDM

Operations and Installation

Manual

choose Warranty tab.

FM-1286

12/13/2013

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Porter DIGITAL MDM

- Page 1 Operations and Installation Manual The Quality System for Porter Instrument is certified to ISO 13485. The scope of our registration is: “The design, manufacture, distribution and servicing of Nitrous Oxide – Oxygen Sedation Flowmeters, Gas Scavenging Systems, Gas Distribution Systems and Office Communication Systems for use by a physician, dentist or licensed healthcare Profession.”...

-

Page 2: Warnings And Precautions

WARNINGS AND PRECAUTIONS These warnings and precautions are to help you to guidelines established by the National Fire Protection understand how to safely operate the PORTER Digital Association for Nonflammable Medical Gas Systems, MDM Flowmeter. A WARNING alerts you to a NFPA 99. - Page 3 Symbol Description MEDICAL EQUIPMENT WITH RESPECT TO ELECTRIC SHOCK, FIRE AND MECHANICAL HAZARDS IN ACCORDANCE WITH UL 2601-1, AND CAN/CSA C22.2 NO. 601.1 Alternating Current Protective Earth (ground) Attention, consult the accompanying documents WARNINGS and PRECAUTIONS ELECTRICAL CONNECTIONS & GROUNDING INSTRUCTIONS The unit must be grounded.

- Page 4 Machine Diagnostics The DIGITAL MDM mixer performs self checks at start up and during operation. If any errors are detected, the unit displays EE on the %O...

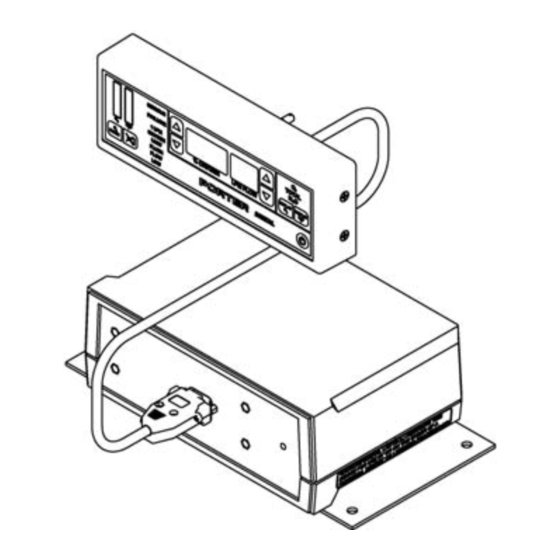

- Page 5 Description of Unit: The DIGITAL MDM mixer consists of a Control Unit attached to a Base Unit via an Interface cable. Note - Control and Base Units are calibrated together and must remain together match serial numbers on each unit).

-

Page 6: Key Pad Controls

SAFETY ALARM SYSTEM There are four alarm conditions on the DIGITAL MDM mixer. They appear in the safety alarm display (see Figure 1, item 2) only when conditions warrant. Otherwise, they are not visible. The alarm conditions Both the OXYGEN FAILURE and NITROUS FAILURE are: are self-canceling alarms. - Page 7 Machine Diagnostics The DIGITAL MDM mixer performs self checks at start up and during operation. If any errors are detected, the unit displays EE on the % OXYGEN display and an error code on the LPM FLOW display. If an error code...

- Page 8 PORTER DIGITAL MDM SYSTEM ILLUSTRATION...

- Page 9 PORTER DIGITAL MDM SYSTEM COMPONENTS & ACCESSORIES Item Part Number Description 40152601 PORTER DIGITAL MDM AVS-5000 AVS optional 5501-RK Vacuum Block Kit optional 5155-1 Adult Rubber Gds (w/ Vacuum Block) 5155-3 Adult Rubber Gds (no Vacuum Block) P1407A Bag Tee...

-

Page 10: General Installation

Base Unit horizontally, but in an (Bracket B-5485) under cabinet orientation. (Kit B-5555-002, “Z” bracket) Control Unit Figure 3. Control Unit mount directly to wall. Figure 5. Porter Digital MDM connected with interface cable. - Page 11 Base Unit and the other end to the Control the nitrous oxide hose to the male DISS, N Unit. Note - Be sure to use the Porter INLET, fitting on the back of the mixer head cable that came with the unit and that the (see Figure 6).

- Page 12 O DISS Power Cord DISS Figure 6. Connection to the back of unit. Figure 7 Installation of Power Cord. Figure 8. Connections Schematic (some components may not be part of your installation).

-

Page 13: Flowmeter Accessories

FLOWMETER ACCESSORIES Three or Two Liter Reservoir Bag Install the reservoir bag by sliding the opening over the outside of the bag tee downspout. The bag moves in and out with each inhalation and exhalation and becomes a visual barometer for monitoring the patient’s respiration rate. - Page 14 Porter recommends that effective scavenging can be achieved with the ball float in the green bar area of the acrylic sight glass, however NIOSH publications conclude that higher vacuum flows of up to 45 L/min are most effective. To meet the NIOSH recommendation of 45 L/min adjust the ball above the green bar area.

- Page 15 ACCESSORY MONTHLY CHECKS Non-Rebreathing Valve - Check Monthly Place the On / Standby switch in the STANDBY (Off) position. Disconnect the corrugated rubber tubing from the Rubber Goods and breathe into the corrugated tubing connected to the bag tee. You should not be able to fill the bag with exhalation gas.

-

Page 16: Side Effects & Contraindications

SIDE EFFECTS & CONTRAINDICATIONS Note: This is not an exhaustive list. The list was prepared from published articles. Possible Side Effects of Nitrous Oxide – Oxygen Conscious Sedation: May experience nausea, vomiting, excessive sweating, euphoria, excitement, deep sedation, drowsiness, sleep, dizziness, lightheadedness, dysphoria, amnesia, and headaches. - Page 17 PREPARATION FOR USE: TESTS, TECHNIQUES, MAINTENANCE CAUTION: Before using the DIGITAL MDM mixer, check the operation of the unit by performing the following tests. Performance Checks: These preliminary tests must be conducted to ensure that your analgesia mixer is performing correctly. If the unit fails any one of the following performance checks, the unit must be returned for service.

- Page 18 -While cleaning the outside of the unit, observe ] flow key and hold, as shown in Figure 1. The caution so that liquid does not get inside. Porter flow rate should decrease to 1.0 LPM. An audible recommends using a damp (wrung toward dry) alarm sounds at the lower limit while the key is ...

-

Page 19: Specifications

SPECIFICATIONS Base Unit Physical Dimensions: 10” W x 5.5” H x 14” D with hoses and Nitrous Oxide Inlet interface cable connected Pressure Requirements: 50 to 55 psi Weight: 6 lbs. Flow Requirements: 10 LPM minimum flow Control Unit Physical Gas Delivery Dimensions: 3.5”...

Need help?

Do you have a question about the DIGITAL MDM and is the answer not in the manual?

Questions and answers