Table of Contents

Advertisement

TECHNICAL GUIDE

TOUGH GUN™

TT REAMER

For Serial #TT-11300 and higher

SAFETY & WARRANTY

INSTALLATION

MAINTENANCE GUIDE

TECHNICAL DATA

OPTIONS

EXPLODED VIEW & PARTS LIST

TROUBLESHOOTING

ORDERING INFORMATION

Certified ISO 9001:2008

Please read instructions prior to use.

Save this manual for future reference.

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Tregaskiss TOUGH GUN TT REAMER

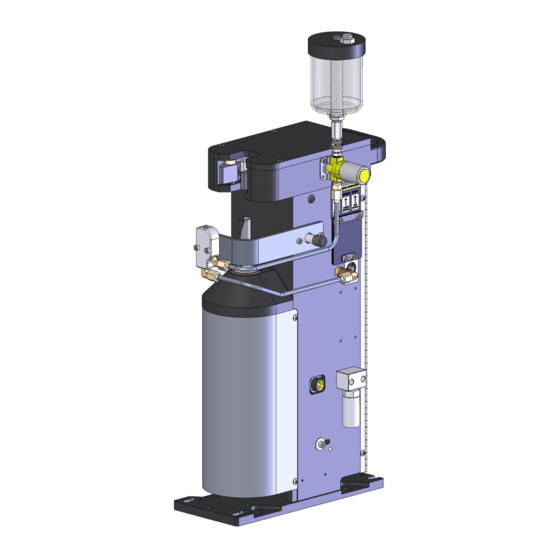

- Page 1 TECHNICAL GUIDE TOUGH GUN™ TT REAMER For Serial #TT-11300 and higher SAFETY & WARRANTY INSTALLATION MAINTENANCE GUIDE TECHNICAL DATA OPTIONS EXPLODED VIEW & PARTS LIST TROUBLESHOOTING ORDERING INFORMATION Certified ISO 9001:2008 Please read instructions prior to use. Save this manual for future reference.

-

Page 2: Table Of Contents

TABLE OF CONTENTS WARRANTY ..........................2 THANK YOU… ..........................3 GENERAL SAFETY ........................3 1.0 – INSTALLATION / SETUP ....................4 1.1 INSTALLING TOUGH GUN REAMER ......................4 1.2 AIR MOTOR LUBRICATION ........................... 5 1.3 WIRING INTERFACE CONNECTIONS ......................5 1.4 ACCESS TO ELECTRICAL AND PNEUMATIC CONTROLS ................ -

Page 3: Thank You

Buyer after notification by Customer Service. Tregaskiss makes no other warranty of any kind, expressed or implied, including, but not limited to the warranties of merchantability or fitness for any purpose. Tregaskiss shall not be liable under any circumstances to Buyer, or... -

Page 4: Installation / Setup

CALIFORNIA PROPOSITION 65 WARNING This product, when used for welding or cutting, produces fumes or gases which contain chemicals known to the State of California to cause birth defects and, in some cases, cancer. This product contains chemicals, including lead, known to the State of California to cause cancer, and birth defects or other reproductive harm. -

Page 5: Air Motor Lubrication

1.2 AIR MOTOR LUBRICATION An air line lubricator (not supplied) must be mounted in the air line of the TOUGH GUN Reamer. The Lubricator should be set to feed one drop of oil for every 50-75 CFM of air going through the motor (approximately every 3-5 cycles). -

Page 6: Led Indicators

To switch from sourcing to sinking, the switches located inside the motor shroud must be accessed. See Section 1.4 ACCESS TO ELECTRICAL AND PNEUMATIC CONTROLS above for directions. Although the circuit board is protected, Tregaskiss suggests disconnecting the power before moving the switches. ... -

Page 7: Programming Events Sequence

1.8 PROGRAMMING EVENTS SEQUENCE 1. Verify the TOUGH GUN Reamer input showing “Clamps Open”. 2. Position the robot to place the MIG gun at a right angle to the unit and to insert the gun to the proper depth, centered and pressed against the v-block (See Section 1.7 NOZZLE INSERTION HEIGHTS). 3. -

Page 8: Maintenance

ADJUSTING THE FLOW CONTROL VALVE(S) There is a flow control valve for adjustment of the up speed of the feed head. The down (retract) speed is fixed. The feed rate may require adjusting for different applications. The valve controls the rate at which air is released on the exhaust side of the cylinder. -

Page 9: Cutter Blade Replacement

2.3 CUTTER BLADE REPLACEMENT Remove cutter blade using a 5/8” wrench and the supplied 9/16” wrench. The cutter blade is removed by turning counterclockwise when viewed from above. CUTTER Considerable force may be required to loosen the BLADE cutter since it tightens naturally as the Reamer operates. -

Page 10: Scheduled Maintenance Program

2.6 SCHEDULED MAINTENANCE PROGRAM The TOUGH GUN Reamer will require a periodic maintenance program to ensure a reliable service life. The following schedule is recommended. DAILY Ensure spindle cover area is clear of spatter. Visually check oil level in lubricator reservoir. ... -

Page 11: Electrical Schematic

3.2 ELECTRICAL SCHEMATIC... -

Page 12: Cutter Blade And V-Block Chart

3.3 CUTTER BLADE AND V-BLOCK CHART NOZZLE OUTSIDE CUTTER BLADE NOZZLE PART # REAMER MODEL V-BLOCK PART # DIAMETER PART # 401-4-38 0.938” TT-0938-06 TR-2150 RC-06 0.938” 401-45-38 TT-0938-06 TR-2150 RC-06 0.938” 401-45-38 TT-0938-06 TR-2150 RC-06 0.938” 401-46-38 TT-0938-06 TR-2150 RC-06 0.938”... -

Page 13: Exploded View And Parts List

4.0 – EXPLODED VIEW AND PARTS LIST COMMON COMMON WITH WITH PART # DESCRIPTION PART # DESCRIPTION PREVIOUS PREVIOUS MODEL MODEL R-2110 CLAMP COVER TR-2530 MUFFLER TR-2120 JAW ASSEMBLY TR-2632 TENSION LOCK WASHER TR-2130 CLAMP CYLINDER TR-2662 RUBBER GASKET V-BLOCK SEE PAGES 12 FOR CHART TR-2661 SPINDLE CAP SEAL... -

Page 14: Troubleshooting

5.0 – TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LED SIGNALS CIRCUIT BOARD DAMAGED REPLACE BOARD LIMIT SWITCH MALFUNCTIONING REPLACE SWITCH ACTIVATING INPUT VOLTAGE IS INCORRECT CHECK INPUT VOLTAGE AND MAKE ADJUSTMENTS AS REQUIRED MOTOR STOPS AIR SUPPLY IS INCORRECT SET AT 80-100 PSI AT 16 CFM... -

Page 15: Sprayer Programming Events Sequence

Adjust timer to increase or decrease quantity of anti-spatter compound as required by process. ● NOTE: If using Tregaskiss TOUGH GARD™ Anti- Spatter Compound, spray time can be as low as 0.2 seconds. Anti-spatter compound should be enough to coat inside of nozzle with no drippage. -

Page 16: Sprayer Parts List - Sr-500

6.5 SPRAYER PARTS LIST – SR-500 TECHNICAL DATA Electrical: 24 volts DC 2.5 watts Pneumatic: 80-100 psi at 16 CFM (Uses Reamer Air Supply) ITEM PART # DESCRIPTION SR-500-1 SPRAY HEAD BRACKET TS-500-15 SPRAY HEAD SR-500-20 CHECK VALVE - SMC RR-1320 RESERVOIR SR-500-50... -

Page 17: Flow Control

7.2 FLOW CONTROL Reamer Reamer with standard sprayer with optional flow control for the sprayer NOTE: Choosing Reamer option ‘C’ - Flow Control adds an adjustable check valve, giving users the ability to control the amount of TOUGH GARD Anti-Spatter applied in each spray. Also available: the retrofitable flow control kit (Part #SR-500-55). -

Page 18: Multi-Feed Ready Reamer

Multi-Feed System. A diagram below shows one of many Multi-Feed RR-1320 configurations. Refer to our website or your local (REMOVED) Tregaskiss representative for more information. NOTE: Multi-Feed Systems are sold separately. MULTI-FEED MALE QUICK CONNECT IS INCLUDED WITH ALL REAMERS. -

Page 19: Ordering Information

9.0 – ORDERING INFORMATION Building a TOUGH GUN Reamer part number TT – XXXX – XX –XX – XX Optional Reamer Stand – ‘10’ Stand only – ‘12’ Stand with FRL (filter-regulator-lubricator) S – Sprayer C – Sprayer with Flow Control (‘S’ not required) W –... - Page 20 NOTES TREGASKISS is an industry leader in the development and manufacture of semi-automatic and robotic MIG welding guns and robotic peripherals. TREGASKISS™, TOUGH GUN™, TOUGH LOCK™, and other names are trademarks of Tregaskiss, a division of ITW Canada Inc. M064 REV I...

Need help?

Do you have a question about the TOUGH GUN TT REAMER and is the answer not in the manual?

Questions and answers