Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Auto Crane 6006EH

- Page 1 6006EH OWNERS MANUAL Manual No. 366904000 Rev. 09/12/05 Serial No. __________________ Mailing Address: P.O. Box 580697 Tulsa, OK 74158-0697 Physical Address: Phone (918) 836-0463 4707 N. Mingo Rd. Fax (918) 834-5979 Tulsa, OK 74117-5904 http://www.autocrane.com...

- Page 3 Serial No.: Date Product Delivered: Date Processed:* VIN # * For Auto Crane use only ONE REGISTRATION FORM PER UNIT (CRANE OR BODY) Registration form must be mailed or faxed within 15 days of customer installation. Mail to: Warranty Department Auto Crane Company P.O.

- Page 5 1. The information contained in this manual is in effect at the time of this printing. It does not cover all instructions, configurations, accessories, etc. If you require additional information, please contact Auto Crane Company at (918) 836-0463. 2. Auto Crane Company reserves the right to update this material without notice or obligation.

- Page 7 ♦ Attempt to lift or drag a load from the side! The boom can fail far below its rated capacity. ♦ Weld, modify, or use unauthorized components on any Auto Crane unit! This will void any warranty or liability. Also failure of the crane may result.

-

Page 9: Table Of Contents

6006EH TABLE OF CONTENTS INTRODUCTION 1-1.0 GENERAL SPECIFICATIONS 1-2.0 SAFETY TIPS AND PRECAUTIONS 2-1.0 OPERATING PRACTICES & WARNINGS 2-3.0 QUALIFICATIONS FOR OPERATORS 2-4.0 OPERATION OF UNIT / OUTRIGGERS 2-7.0 CONTROLLER OPERATIONS 2-8.0 INSPECTION 3-1.0 TESTING 3-4.0 MAINTENANCE 3-5.0 BATTERIES 3-7.0 LUBRICATION AND MAINTENANCE SCHEDULE 3-9.0... -

Page 11: Introduction

The payload of the vehicle is reduced by the If, through no fault of Auto Crane Company, it weight of the crane. The operator should is necessary to send an experienced factory exercise care when loading the vehicle. - Page 12 Auto Crane Company at the following telephone number: (918) 836-0463. The information contained in the manual is in effect at the time of this printing. Auto Crane Company reserves the right to update this material without notice or obligation. 1-2.0...

-

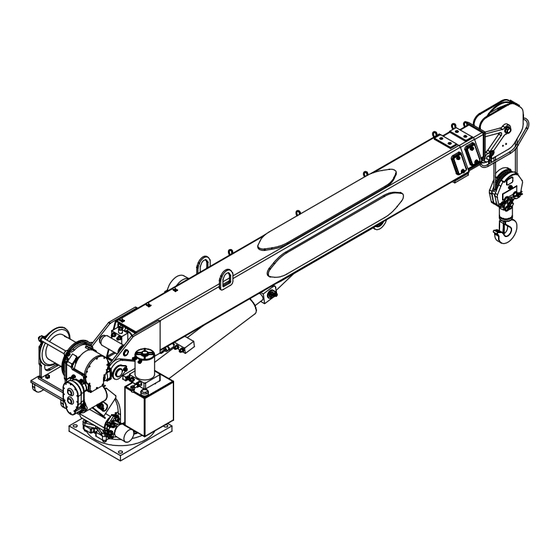

Page 13: General Specifications

6006EH GENERAL SPECIFICATIONS DIMENSIONS REACH Width: 21.75 in (0.55 m) Second boom will reach from 10 feet 4 inches to 16 feet 4 inches. Height: 35.88 in (0.91 m) Third boom will reach from 16 feet 4 inches to 20 feet 4 inches. -

Page 14: Safety Tips And Precautions

30. Always store outriggers before transportation. WARNING! Auto Crane Company cranes are not designed or intended for use in lifting or moving persons. Any such use shall be considered to be improper and the seller shall not be responsible for any claims arising there from. - Page 15 --- IMPORTANT --- SAFETY TIPS AND PRECAUTIONS 31. Always store the crane in its stowed position 41. Do not push down on anything with boom for transportation. extensions; similarly do not lift anything with boom extensions. 32. Remember the overall height of the entire unit for garage door clearance or when 42.

-

Page 16: Operating Practices & Warnings

NEVER hold any Control Select Switch on that will cause unsafe operating conditions! WARNING! Auto Crane Company remote controlled, stiff boom cranes are not designed or intended for use on any applications involving the lifting or moving of personnel. 2-3.0... -

Page 17: Qualifications For Operators

QUALIFICATIONS FOR AND CONDUCT OF OPERATORS AND OPERATING PRACTICES REFERENCE ASME B30.5a AND OSHA 1910.180 FOR COMPLETE QUALIFICATION REQUIREMENTS tests may be required to determine these OPERATORS conditions. 1. Crane operation shall be limited to personnel 5. Operators and operator trainees should have with the following minimum qualifications: normal depth perception, coordination, and no tendencies to dizziness or similar undesirable... - Page 18 QUALIFICATIONS FOR AND CONDUCT OF OPERATORS AND OPERATING PRACTICES or neutral position and all personnel are in the C. Means are provided to hold the vehicle clear. stationary while operating the crane. 6. If power fails during operation, the operator shall: D.

- Page 19 QUALIFICATIONS FOR AND CONDUCT OF OPERATORS AND OPERATING PRACTICES N. No person should be permitted to stand or 3. Caution shall be exercised when working near pass under a suspended load. overhead lines, because they can move horizontally or vertically due to wind, moving the 4.

-

Page 20: Operation Of Unit / Outriggers

--- IMPORTANT --- OPERATION OF UNIT 1. Make sure this manual has been thoroughly 8. Always boom up before rotating so the boom will read by all crane operating personnel and clear the required boom support. supervisors. 9. When extending the boom, always maintain 2. - Page 21 FM CONTROL SYSTEM OPERATION TRANSMITTER LAYOUT The red light to the left of the Power On/Off button indicates low transmitter battery. As the battery runs down, the light will begin to flash. It will flash increasingly faster as the battery power decreases (see “Charging the Transmitter”).

- Page 22 FM CONTROL SYSTEM OPERATION AUXILLARY BUTTONS Functions described in this paragraph will not worked if not properly connected to the vehicle at the time of installation. Press the Engine Slow/Fast button to provide a maintained voltage to a throttle control. To stop the engine, press the Engine Start/Stop button. To start the engine, press the Engine Start/Stop button a second time within five (5) seconds of releasing it.

-

Page 23: Inspection

INSPECTION REQUIREMENTS REFERENCE ASME B30.5a AND OSHA 1910.180 FOR COMPLETE INSPECTION REQUIREMENTS INSPECTION CLASSIFICATION 3. Inspect safety devices for malfunction. 4. Visually inspect all hydraulic hoses, particularly 1. Initial inspection. those that flex in normal operation of crane functions. Prior to initial use, all new, altered, modified or extensively repaired cranes shall be inspected by a 5. - Page 24 INSPECTION REQUIREMENTS PERIODIC INSPECTION B. Improper return of spool to neutral position. C. Leaks at spools or joints. Any deficiencies, such as those listed below, shall be D. Sticking spools. carefully examined and determination made as to E. Failure of relief valves to attain or maintain whether they constitute a hazard: correct pressure setting.

- Page 25 INSPECTION REQUIREMENTS A. Reduction of rope diameter below nominal diameter due to loss of core support. B. Internal or external corrosion. C. Wear of outside wires. D. Severely corroded, cracked, bent, worn, or improperly applied connections. CRANES NOT IN REGULAR USE A crane, which has been idle for a period of over one month or more, shall be given an inspection conforming to the “initial”...

-

Page 26: Testing

TESTING REQUIREMENTS REFERENCE ASME B30.5a AND OSHA 1910.180 FOR COMPLETE TESTING REQUIREMENTS TESTING SHALL BE PERFORMED BY DESIGNATED PERSONNEL ONLY. Prior to initial use, all new, altered, modified, or extensively repaired cranes shall be tested for compliance with the operational requirements of this crane. Test requirements: 1. - Page 27 GENERAL REPAIRS AND MAINTENANCE REFERENCE ASME B30.5a AND OSHA 1910.180 FOR COMPLETE MAINTENANCE AND REPAIR REQUIREMENTS A preventative maintenance program should be B. Critical parts of the crane structure which are established based on this section and all replacement cracked, bent, broken, or excessively corroded. parts should be obtained from AutoCrane Company.

- Page 28 GENERAL REPAIRS AND MAINTENANCE (2.4 mm) for diameters 11/4 in. (32 mm) to and side of the cut are required, and for non-preformed including 11/2 in. (38 mm). rope 1 in. (25 mm) diameter or larger, three seizings on each side of the cut are required. G.

-

Page 29: Maintenance

MAINTENANCE OF BATTERIES Maintenance of Auto Crane unit batteries differs deterioration of the remaining parts of the very little from the generally prescribed battery. maintenance of any lead acid battery. All batteries Keep A Relatively Clean Battery must be kept properly charged, properly filled with water, and relatively clean. - Page 30 MAINTENANCE OF BATTERIES If, after charging, it is noted that the specific gravity 2. Place the battery on charge according to the reading of one cell is 30 points less than any of the manufacturer's instructions. other cells, it may be assumed that the cell is bad and that the battery should be replaced.

- Page 31 6006EH LUBRICATION & MAINTENANCE SCHEDULE SERVICE DAY WKLY 3 MOS 6 MOS YEAR NOTES PERFORMED INSPECT HOOK & LATCH FOR DEFORMATION, LOAD HOOK CRACKS, & CORROSION MAKE SURE CABLE IS WOUND EVENLY ON CABLE DRUM DRUM HOIST / BOOM CHECK FOR FLATTENING, KINKS, & BROKEN...

- Page 32 2. Once a bolt has been torqued to its rated capacity and then removed; the bolt should be replaced with a new one. 3. Auto Crane Company recommends that this crane be serviced per “Crane Inspection Log” P/N 999978. These logs should be filled in at the intervals noted and kept as a permanent record.

- Page 33 6006EH SAFETY DECAL SECTION PART NO.: 040579000 DECAL: OPERATING INSTRUCTIONS FUNCTION: To inform the operator of the proper procedure to follow for safe operation of the crane. USED ON: All Cranes QUANTITY: PLACEMENT: Right side plate PART NO.: 040580000 DECAL:...

- Page 34 6006EH SAFETY DECAL SECTION PART NO.: 040529000 DECAL: ELECTROCUTION HAZARD FUNCTION: To inform the operator of the hazard involved with contacting electrical power lines with crane boom. USED ON: All Cranes QUANTITY: PLACEMENT: Both sides of end of lower boom PART NO.:...

- Page 35 6006EH SAFETY DECAL SECTION PART NO.: 040587000 USED ON: All cranes equipped with a load sensor. DECAL: LOAD SENSOR, DON'T TAMPER QUANTITY: FUNCTION: To inform the operator that the load PLACEMENT: Both sides of the lift cylinder near sensor is pre-set and that tampering...

- Page 36 6006EH DECAL LAYOUT P/N: 366704000 4-4.0 9/12//05...

- Page 37 DECAL AUTO CRANE 040579000 DECAL OPERATION INSTRUCTIONS 360034000 DECAL AUTO CRANE LOGO 040580000 DECAL TRAINED OPERATOR 366710000 DECAL, LOAD CHART 6006EH 330622000 DECAL SERIAL NO 366804000 DECAL 6006 EH 366036100 DECAL, TRAVELING BLOCK 6006H (SHORT) 040518000 DECAL STAY CLEAR OF LOAD 4-5.0...

- Page 38 NOTES...

- Page 39 6006EH GENERAL DIMENSIONS NOTE: CG IS APPROXIMATE 5-1.0 9/12/05...

- Page 40 9. Load test the crane to ensure proper functioning and truck stability 10. Make certain the owner’s manual is delivered to the customer. 11. For additional help: call the service department at the Auto Crane Company. (918) 836-0463 (Tulsa, Oklahoma)

- Page 41 6006EH MOUNTING AND INSTALLATION W/O SLIP RING 1/4-20NC x 1" LG BOLTS (P/N 005604000) w/ NUTS (P/N 015900000) AND LOCKWASHERS (P/N 020200000) 3 PIN PLUG VOLTAGE SWITCHING UNIT P/N 366692000 TWECO CONNECTOR QUICK DISCONNECT (OPTIONAL) BATTERY P/N 360830000 VENTED BATTERY BOX...

- Page 42 NOTES...

- Page 43 6006EH MOUNTING AND INSTALLATION WITH SLIP RING ATTACH GROUND WIRE TO THIS BOLT 3/8 X 1NC BOLT (P/N 330371000) FLATWASHER 3/8 (P/N 320976000) LOCKWASHER 3/8 (P/N 021100000) 4 AWG CONNECTOR FROM SLIP RING (INSERT SLEEVE (P/N 366703000) OVER BARE WIRE BEFORE INSERTING CONNECTOR)

- Page 44 6006EH GENERAL ASSEMBLY HARDWIRED W/SLIP RING – P/N: 366600000 6 3 4 5 APPLY LOCTITE 242 TO THREADS BEFORE INSTALLATION EXTEND RETRACT 14 15 PORT #7 PORT #8 ELECTRICAL SCHEMATIC P/N: 366684000 HYDRAULIC SCHEMATIC P/N: 366785000 6-1.0 9/12/05...

- Page 45 PIN, CYLINDER 360675000 PIN, BOOM PIVOT 239300000 ZERK, GREASE 366063000 TRAVELING BLOCK 480031000 WIRE ROPE ASSEMBLY 3/8" 366697000 SHIP KIT 6006EH CRANE 366704000 DECAL LAYOUT 6006EH 366688000 COVER, REAR 020601000 WASHER 5/16 LOCK 007807000 SCW HEX 5/16-18 3/4LG GR5 360678000...

- Page 46 6006EH GENERAL ASSEMBLY HARDWIRED W/O SLIP RING – P/N: 366780000 10 9 6 7 APPLY LOCTITE 242 TO THREADS BEFORE INSTALLATION RETRACT PORT #8 EXTEND PORT #7 ELECTRICAL SCHEMATIC P/N: 366783000 HYDRAULIC SCHEMATIC P/N: 366785000 6-3.0 9/12/05...

- Page 47 6006EH GENERAL ASSEMBLY HARDWIRED W/O SLIP RING – P/N: 366780000 ITEM NO. QTY. PART NO. DESCRIPTION 366781000 PEDESTAL ASSEMBLY, 6006EH 366630000 BOOM ASSEMBLY 360675000 PIN, BOOM PIVOT 360677000 PIN, 1/4 COTTERLESS RING 366688000 COVER, REAR 008702000 SCREW HX HD 3/8-16UNC X 1 1/4 LG GR5...

- Page 48 6006EH PEDESTAL ASSEMBLY W/SLIP RING - P/N: 366640000 HYDRAULICS: PORT B-1 RETRACT PORT B-2 BOOM UP PORT B-3 CCW REAR MOTOR PORT A-1 EXTEND PORT A-2 BOOM DOWN PORT A-3 CC FRONT MOTOR CYLINDER SEAL KIT: 366342001 C’BAL CARTRIDGE: 480188000 6-5.0...

- Page 49 6006EH PEDESTAL ASSEMBLY W/SLIP RING - P/N: 366640000 32,26,33 27 30 15 13 6-6.0 9/12/05...

- Page 50 6006EH PEDESTAL ASSEMBLY W/SLIP RING - P/N: 366640000 ITEM NO. QTY. PART NO. DESCRIPTION 366641000 BASE PLATE WELDMENT 366642000 PEDESTAL WELDMENT 360678000 PIN, 3/16 COTTERLESS RING 360676000 PIN, CYLINDER 366652000 CYLINDER, LIFT 320976000 WASHER, FLAT, 3/8 SAE HARDENED 021100000 WASHER SP LK 3/8...

- Page 51 6006EH PEDESTAL ASSEMBLY W/SLIP RING - P/N: 366640000 ITEM NO. QTY. PART NO. DESCRIPTION 366698000 CORD GRIP .375-.500 3/4" HUB 360493000 SCW WHIZ-LK 1/4NCX 1/2 007400000 SCW HEX 5/16-18 X 1 GR5 366687000 COVER, RELAY PANEL 366682000 RELAY PANEL ASSY...

- Page 52 6006EH PEDESTAL ASSEMBLY W/O SLIP RING – P/N: 366781000 17 42 13 14 HYDRAULICS: PORT B-1 RETRACT PORT B-2 BOOM UP PORT B-3 CCW REAR MOTOR PORT A-1 EXTEND PORT A-2 BOOM DOWN PORT A-3 CC FRONT MOTOR CYLINDER SEAL KIT: 366342001 C’BAL CARTRIDGE: 480188000...

- Page 53 6006EH PEDESTAL ASSEMBLY W/O SLIP RING – P/N: 366781000 32, 20, 23 13 15 6-10.0 9/12/05...

- Page 54 6006EH PEDESTAL ASSEMBLY W/O SLIP RING – P/N: 366781000 ITEM NO. QTY. PART NO. DESCRIPTION 366721000 BASE PLATE WELDMENT 366642000 PEDESTAL WELDMENT 360678000 PIN, 3/16 COTTERLESS RING 360676000 PIN, CYLINDER 366652000 CYLINDER, LIFT 320976000 WASHER, FLAT, 3/8 SAE HARDENED 021100000 WASHER SP LK 3/8...

- Page 55 CORD GRIP .375-.500 3/4" HUB 360493000 SCW WHIZ-LK 1/4NCX 1/2 007400000 SCW HEX 5/16-18 X 1 GR5 366687000 COVER, RELAY PANEL 366782000 MAIN WIRING HARNESS, 6006EH 642908000 CORD CONNECTOR 366653000 BRACKET, VALVE MOUNT 330252000 SCW HX 5/16 NC X 3/4 GR5 320826000...

- Page 56 6006EH BOOM ASSEMBLY P/N: 366630000 NOTES: APPLY LOCTITE 609 TO BOLT THREADS, 12 PLCS BEFORE INSTALLING. APPLY LOCTITE 242 TO BOLT THREADS, 4 PLCS BEFORE INSTALLING. CYL SEAL KIT P/N: 366331001 C’BAL P/N: 360153001 6-13.0 9/12/05...

- Page 57 6006EH BOOM ASSEMBLY P/N: 366630000 ITEM NO. QTY. PART NO. DESCRIPTION 366631000 LOWER BOOM WELDMENT 366632000 MID BOOM WELDMENT 366633000 UPPER BOOM WELDMENT 366331000 CYLINDER EXTENSION 366669000 WEAR PAD, BOTTOM MID 366696000 COVER, SIDE WEAR PAD 021100000 WASHER SP LK 3/8...

- Page 58 6006EH ROTATION GEARBOX P/N: 160407 6-15.0 9/12/05...

- Page 59 6006EH ROTATION GEARBOX P/N: 160407 ITEM NO. QTY. PART NO. DESCRIPTION 300058 ADAPTER 308085 BUSHING 316092 CAP BEARING 328126 COVER 334016 GEAR R.H. 338261 HOUSING GEAR 342120 357139 SHAFT OUTPUT 366019 WASHER THRUST 368183 WORM R.H. 402044 BEARING BALL 402105...

- Page 60 6006EH ACTUATOR ASSEMBLY P/N: 297025 6-17.0 09/12/05...

- Page 61 6006EH ACTUATOR ASSEMBLY P/N: 297025 ITEM NO. QTY. PART NO. DESCRIPTION 306034 SPRING - FLAT 314008 PLATE - CAM 328106 COVER - SPUR GEAR HSG. 328128 COVER - BRAKE 328134 COVER - WORM GEAR HSG. 334001 IDLER GEAR 334003 SPUR GEAR...

- Page 62 6006EH ACTUATOR ASSEMBLY P/N: 297025 ITEM NO. QTY. PART NO. DESCRIPTION 442184 GASKET 442185 GASKET 442189 GASKET 442205 GASKET 450001 KEY - WOODRUFF 450016 KEY - BARTH 456008 RELIEF FITTING 458005 MOTOR - 24V 462015 O-RING 468002 REDUCER 468011 PIPE PLUG SQ HD...

- Page 63 6006EH TRAVELING BLOCK ASSEMBLY P/N: 366063000 ITEM NO. QTY. PART NO. DESCRIPTION 480362000 SHORT BLOCK SIDE PL WDMT 480130000 SHEAVE ASSY 480364000 TACKLE LOWER 480372000 BOLT, SHEAVE W/ ZERK FITTING 480367000 PIN BLOCK 480371000 HOOK SWIVEL 3 METRIC TON 480368000...

- Page 64 6006EH ELECTRICAL SCHEMATIC, W/SLIP RING – P/N:366684000 VSU (WHT/BLK) PUMP (WHT/BLK) PUMP BOOM DOWN (BLU) BOOM DOWN BATT. VOLTAGE (BLU/WHT) RETRACT (ORG/BLK) RETRACT BOOM UP (BLU/BLK) DIODE BOOM UP HOIST UP (GRN) HOIST UP (H1) (RED/ BLANK PROG. PIN PLUG...

- Page 65 6006EH ELECTRICAL SCHEMATIC, W/SLIP RING – P/N:366684000 LEFT SIDE OF SCHEMATIC ON PREVIOUS PAGE PUMP PUMP HOIST RELAY CASE ARMATURE +24V RELAYS (BLK 4 GA) HOIST +24V TO SLIP RING (BLK 4 GA) +12V TO SLIP RING (16 GA) TRUCK...

- Page 66 6006EH ELECTRICAL SCHEMATIC W/O SLIP RING - P/N: 366783000 VSU (WHT/BLK) PUMP (WHT/BLK) PUMP BOOM DOWN (BLU) BOOM DOWN BATT. VOLTAGE (BLU/WHT) RETRACT (ORG/BLK) RETRACT BOOM UP (BLU/BLK) DIODE BOOM UP HOIST UP (GRN) HOIST UP (H1) (RED/ BLANK PROG. PIN...

- Page 67 6006EH ELECTRICAL SCHEMATIC W/O SLIP RING - P/N: 366783000 LEFT SIDE OF SCHEMATIC CONTINUED ON PREVIOUS PAGE PUMP PUMP HOIST RELAY CASE ARMATURE HOIST +24 V RELAYS (BLK 4 GA) SIGNAL TO +12V TO CRANE TRUCK (RED 16 GA) BATTERY...

- Page 68 6006EH PENDANT 8 FUNCTION W/ ON/OFF SWITCH - P/N: 366709000 PENDANT HEAD CW (ORG) CCW (WHT/RED) EXTEND (GRN/BLK) RETRACT (ORG/BLK) PUMP (WHT/BLK) BOOM UP (WHT) BOOM DN (BLU) HOIST UP (GRN) HOIST DN (RED/BLK) VOLTAGE SWITCHING UNIT (WHT/RED) + (RED)

- Page 69 6006EH VOLTAGE SWITCHING UNIT P/N: 366692000 RELAY RELAY OUTSIDE INSULATION OF CORD SHOULD EXTEND 1" PAST GROMMET AND ZIP TIE INSTALLED TO RETAIN CORD. RELAY LOCATE DECAL IN CENTER OF LID INSTALL SCHEMATIC DECAL (ITEM-14) TO UNDERSIDE OF LID. DECAL SHOULD BE RIGHT SIDE UP WHEN LID IS OPENED DOWNWARD.

- Page 70 6006EH VOLTAGE SWITCHING UNIT P/N: 366692000 POWER SWITCH RELAY - 1 RELAY - 2 POWER LIGHT RELAY - 3 RELAY - 3 RELAY - 1 RELAY - 2 AUX. BATTERY 16/3 CONDUCTOR CORD TRUCK BATTERY PANEL GROUND A B C...

- Page 71 6006EH VOLTAGE SWITCHING UNIT P/N: 366692000 ITEM NO. QTY. PART NO. DESCRIPTION 366693000 ENCLOSURE, VOLTAGE SWITCHING UNIT 367242001 DECAL, THIS END UP 736272000 NUTSERT .25UNC X .027-.165 GRIP 001900000 SCREW RD HD #10 x 3/8NF 320355000 RELAY, BOSCH 360493000 SCW WHIZ-LK 1/4NCX 1/2...

- Page 72 6006EH HYDRAULIC SCHEMATIC P/N: 366785000 8-1.0 9/12/05...

- Page 73 6006EH HYDRAULIC CONTROL VALVE P/N: 320826000 INSIDE PORT ON POWER UNIT (PRESSURE) EXTEND PORT RETRACT PORT (EXT) (RET) EXTEND COIL RETRACT COIL BOOM DOWN COL BOOM UP COIL ROTATE CCW ROTATE CW COIL COIL B OOM DOWN BOOM UP PORT (RET)

- Page 74 6006EH HYDRAULIC POWER UNIT P/N: 366650000 8-3.0 9/12/05...

- Page 75 6006EH HYDRAULIC POWER UNIT P/N: 366650000 NOTE: SOME PARTS AVAILABLE ONLY IN THEIR RESPECTIVE KITS. ITEM PART NO. DESCRIPTION QTY. 360808001 PUMP AND PARTS PUMP ASSEMBLY O-RING O-RING O-RING SCREW SCREW LOCKING SPRING RETAINER COUPLING 366650001 RELIEF VALVE KIT GASKET...

- Page 76 6006EH GENERAL ASSEMBLY FM - W/SLIP RING - P/N: 366600001 5 6 7 APPLY LOCTITE 242 TO THREADS BEFORE INSTALLATION 21 22 15 16 RETRACT 4 5 6 3 PORT #8 EXTEND ELECTRICAL SCHEMATIC P/N: 366783000 PORT #7 HYDRAULIC SCHEMATIC P/N: 366785000 9-1.0...

- Page 77 SCW HX 3/8-16 X 1 1/4 GR5 360676000 PIN, CYLINDER 239300000 ZERK, GREASE 366063000 TRAVELING BLOCK 480031000 WIRE ROPE ASSEMBLY 3/8" 366697001 SHIP KIT 6006EH FM CRANE 366704000 DECAL LAYOUT 6006EH 366715000 BRACKET ASSEMBLY, RECEIVER MOUNT 366711000 RECEIVER, KAR-TECH 020200000 WASHER SP LK 1/4 005500000...

- Page 78 6006EH GENERAL ASSEMBLY FM W/O SLIP RING - P/N: 366790000 4 5 6 7 APPLY LOCTITE 242 TO THREADS BEFORE INSTALLATION 4 5 6 3 15 16 EXTEND RETRACT PORT # 7 PORT # 8 ELECTRICAL SCHEMATIC P/N: 366783000 HYDRAULIC SCHEMATIC P/N: 366785000 9-3.0...

- Page 79 SCREW HX HD 3/8-16UNC X 1 1/4 LG GR5 360676000 PIN, CYLINDER 239300000 ZERK, GREASE 366063000 TRAVELING BLOCK 480031000 WIRE ROPE ASSEMBLY 3/8" 366697002 KIT-SHIP 6006EH FM CRANE 366704000 DECAL LAYOUT 6006EH 366715000 BRACKET ASSEMBLY, RECEIVER MOUNT 366711000 RECEIVER, KAR-TECH 020200000 WASHER SP LK 1/4 005500000...

- Page 80 6006EH ELECTRICAL SCHEMATIC FM - P/N: 366712000 (BLK) (GRY) (PUR) P1 (GREY PLUG) GROUND RS-232 (GRN) CAN H CAN L RS-232 TX (WHT) RS-232 RX (BRN) BOOM LMT SW PRESS. SW. (BLU) BAT. VOLTAGE (WHT) ATB SWITCH (ORG) PROGRAM ID...

- Page 81 REMOTE / PENDANT PARTS AND ACCESSORIES Component Part Number Receiver 366711000 Transmitter 320920002 Pendant Cable 366500008 Antenna 366500005 Cigarette Lighter Charger 366504000 A/C Charger 366505000 Palm Diagnostic Unit 366510000 Receiver Harness 366712000 Hard Wired Pendant 366709000 Receiver Transmitter 10-2.0 9/12/05...

-

Page 82: Power(+)

TRANSMITTER / RECEIVER SYNCHRONIZATION 1. Power on the transmitter and receiver. 2. Locate the program plug on the crane. This will be the unused plug near where the cord reel plugs into the wire harness. 3. Using a jumper wire, as shown below, connect the two contacts in the plug. 4. - Page 83 6006EH CONTROLLER DIAGNOSTICS On the receiver the green light indicates that a signal is being received, the red indicates the status of error. Below is a list of the error codes both as they would be displayed on a Palm handheld and on a receiver.

-

Page 84: Boom Up

6006EH CONTROLLER DIAGNOSTICS CODE: 6 Flashes/EC10 DESCRIPTION: Incorrect ID POSSIBLE CAUSE(S): Signal received from transmitter with incorrect ID code. POSSIBLE SOLUTION(S): Confirm that transmitter being used is for use with this unit. Follow ‘New Transmitter’ procedure in the transmitter operation section of this manual. -

Page 85: Hoist Up

6006EH CONTROLLER DIAGNOSTICS CODE: 13 Flashes/EC08 DESCRIPTION: Hoist up POSSIBLE CAUSE(S): Short or open connection on hoist up output. POSSIBLE SOLUTION(S): Check plug in hoist up solenoid on hydraulic control valve. Check wire for damage that could cause break or short. - Page 87 6006EH LOAD CHART P/N: 366710000 6000 NOTE: 1. DISTANCE FROM BASE OF CRANE 3627 6000 TO CENTER OF BOOM PIVOT 6000 4111 IS 22" 2528 4641 6000 2860 5328 6000 3222 6000 6000 2051 3689 75° 6000 2318 60° 4314...

- Page 88 NOTES...

- Page 89 2 YEAR PARTS AND LABOR Auto Crane will warranty to the consumer for a period of (2) years parts and labor from the date of purchase. Each new Auto Crane unit they sell will be free under normal use and service from defects in material and workmanship.

Need help?

Do you have a question about the 6006EH and is the answer not in the manual?

Questions and answers