Summary of Contents for MAK M43C

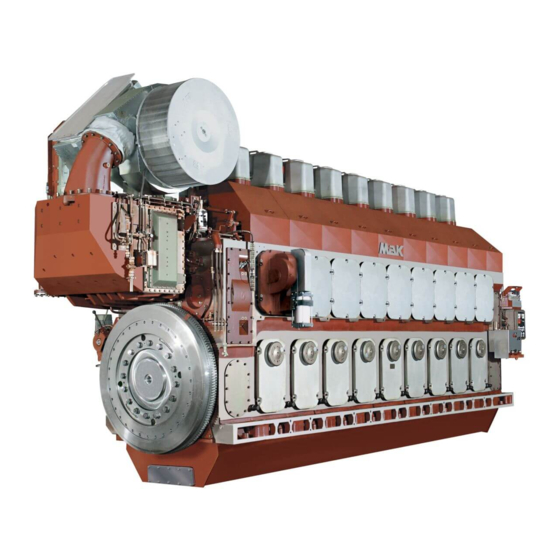

- Page 1 Engine Operating Instructions M43C Engine Operating Instructions Type M43C Engine No.: Record No.: 68 280 281717 68 281 en / 26.05.2009 AA000643...

- Page 2 Engine Operating Instructions M43C Please note the copyright notice pursuant to ISO 16016 "All documents such as drawings, data and programmes, etc. and models, templates etc. shall remain our exclusive property. They are only handed over to the agreed purpose and must not be used for any other purpose.

-

Page 3: Table Of Contents

Total Index A0.01 Book A, B and C Engine Operating Instructions Total Index Book A, B and C A0.01 Introduction A0.02 Safety instructions A0.03 Emergency Stop Safety System A0.04 Technical Engine Data Governor Data A1.04 Working pressures of auxiliary equipment A1.05 Temperatures of operating media A1.06... -

Page 4: Table Of Contents

Total Index A0.01 Book A, B and C Spare Parts Catalogue Total Index Book A, B and C B0.01 Introduction B0.02 Spare Parts Table of contents B1.01 Safety instructions B1.03 Stand-by parts External Documentation Total Index Book A, B and C C0.01 Introduction Electrical Equipment C0.02... -

Page 5: Introduction

Since the type of fuel used considerably influences the service life of the components, the Caterpillar / MaK after-sales service has to be consulted when it is required to change from destillate fuel operation to heavy fuel oil operation, in order to ensure an expert retrofit of the engine plant and to exchange the necessary documentation. -

Page 6: Safety Instructions

Safety instructions A0.03 M20-M601C Personnel entrusted with work on the engine/plant must have read the operating instructions and in particular the pages on safety instructions which precede the chapters before beginning work. In order to eliminate danger which may constitute a risk of life and limb of the user or of third ~ ~ ~ ~ parties, all safety regulations which are marked with the symbol have... - Page 7 Safety instructions A0.03 M20-M601C Our engine is equipped with a monitoring system and an emergency stop system to prevent damage caused to the operators' health as well as damages to the engine. Within the scope of commissioning all mechanical, electric and pneumatic equipment and systems allowing the engine to be stopped for safety reasons will be demonstrated and explained by our commissioning personnel.

- Page 8 Actions that must be performed after a safety/emergency stop* occurred: - Identify the reason for emergency stop based on the points listed below. - Work through list of corresponding sub-points. - Contact your Caterpillar/ MaK Service. Type of emergency stop: Overspeed condition...

- Page 9 • Checking governor drive. • Verification of possible out of calibration of actuator (if fitted). Contact your Caterpillar/ MaK Service. Lube oil (lube oil pressure, lube oil temperature) Emergency stop due to lack of lube oil Checks: •...

- Page 10 Pressurize each cylinder through opened indexing valves with shop air. If there is a rapid pressure drop or if no pressure builds up the cause must be investigated. Contact the Caterpillar/ MaK Service. Engine room monitoring Emergency Stop due to excessive oil mist concentration (refer to A3.11.18.01.nn).

-

Page 11: Exhaust Gas

M20/M25/M32/M43 • Check fresh water cooler • Operational test of LT - Cooling water circuit with cooling water pump. Contact your Caterpillar/ MaK Service. Exhaust gas Emergency stop due to excessively high exhaust temperature Checks: • Check exhaust gas temperature sensors. -

Page 12: Emergency Stop

Terminal set X1 voltage failure 9717 * Terminal set X3 voltage failure * see also List of Measuring Points C5.05.02.01.nn.nn. Plant-specific fault messages: - Safety system failure - RPM switch unit failure (overspeed) Please contact the Caterpillar/ MaK Customer Service. en / 20.02.2008 AA033984... - Page 13 Technical Engine Data M20-M601C Technical Engine Data en / 26.05.2009 AA000103...

- Page 14 Governor Data A1.04 Governor Data en / 20.02.2008 AA000097...

- Page 15 Governor-data A1.04.30 en / 26.05.2009 AA045578...

- Page 16 Reglerdatenblatt / Governor Data (Woodward-Regler / Woodward Governor) Motor-Type: Kostenträger-Nr.: Motor-Nr.: Engine type: Record No.: Engine No.: 9 M43 C 281717/1 68280 Motordaten / Engine Data Aussteller: Leistung: Regelbereich: Abteilung: 8100 300-500 Power: Control range: 1/min Vollastdrehzahl: Gesamt-Massenträgheitsmoment: Name: 7845,4 Full load speed: 1/min Total moment of inertia:...

-

Page 17: Governor Data

Reglerdatenblatt / Governor Data (Woodward-Regler / Woodward Governor) Motor-Type: Kostenträger-Nr.: Motor-Nr.: Engine type: Record No.: Engine No.: 9 M43 C 281717/2 68281 Motordaten / Engine Data Aussteller: Leistung: Regelbereich: Abteilung: 8100 300-500 Power: Control range: 1/min Vollastdrehzahl: Gesamt-Massenträgheitsmoment: Name: 7845,4 Full load speed: 1/min Total moment of inertia:... -

Page 18: Working Pressures Of Auxiliary Equipment

Working pressures of auxiliary equipment A1.05 Lubricating oil at the last Camshaft bearing at rated engine speed 4,0 - 5,0 bar Cooling water min. feed head at pump inlet 4 m. water gauge 2,5 - 5,0 bar Fuel at injection pump inlet Distillate fuel 3,0 - 5,0 bar Heavy fuel... -

Page 19: Temperatures Of Operating Media

9 - 11 mPa s (distillate fuel below 10 mm /s or 9 mPa s). The heavy fuel specifications defined by MaK (e.g. RHM 35 (~ IF 380) give the heavy fuel tempe- rature before engine starting. - Page 20 Torsional Vibration Calculation A1.09 Torsional Vibration Calculation en / 20.02.2008 AA020354...

- Page 21 Torsional vibration calculation A1.09.12 en / 10.11.2008 AA043720 1/26...

-

Page 22: Torsional Vibration Calculation

Bericht-Nr./ Drehschwingungsberechnung Drehschwingungsberech nung Drehschwingungsberech Drehschwingungsberech nung nung Report No. Torsional Vibration Calculation Torsional Vibration Calculation Torsional Vibration Calculation Torsional Vibration Calculation 08043087 Motor Motor- - - - Nr. / Engine No. Nr. / Engine No. Ktr. Ktr.- - - - Nr. / Record No. Nr. - Page 23 Bericht-Nr./ Ergebnis der Berechnung Ergebnis der Berechnung Ergebnis der Berechnung Ergebnis der Berechnung Report No. Result of Calculation Result of Calculation Result of Calculation Result of Calculation 08043087 1. 1. 1. 1. B B B B etriebseinschränkungen: etriebseinschränkungen: 1. 1. 1. 1. Operational restrictions: Operational restrictions: etriebseinschränkungen:...

- Page 24 Bericht-Nr./ Ergebnis der Berechnung Ergebnis der Berechnung Ergebnis der Berechnung Ergebnis der Berechnung Report No. Result of Calculation Result of Calculation Result of Calculation Result of Calculation 08043087 1.2.2 Vollaussetzer: 1.2.2 Full failure: Keine Kompression, ausgebautes Triebwerk No compression, running gear dismantled Allgemeine Hinweise: General notes: Siehe Betriebsanleitung Notbetrieb...

- Page 25 58.80 0.00.6-63.13.00-33 Innenteil / inner part 19.80 Kurbelwelle / crankshaft nach MaK-Zeichnung / acc. to MaK drawing: 4309.7-25.10.01-03 Abschnitt Dämpfer-letzter Zyl. / section damper-last cylinder 4.75 MT-Moment eines Zylinders / moment of inertia of a cylinder 132.60 Abschnitt zwischen zwei Zylindern / section between two cylinders 5.00...

- Page 26 Bericht-Nr./ Berechnungsdaten Berechnungsdaten Berechnungsdaten Berechnungsdaten Report No. Calculation Data Calculation Data Calculation Data Calculation Data 08043087 Propellerwelle / propeller shaft: MAN B&W Diesel AS, Project P-20905-10 , Zeichnungs-Nr. / drawing no. 2130882-6, state 1 ½ Zwischenwelle / ½ intermediate shaft 4.37 Elastizität Zwischenwelle / flexibility intermediate shaft 590.00...

- Page 27 Bericht-Nr./ Elastisches System Elastisches System Elastisches System Elastisches System Report No. Mass Elastic System Mass Elastic System Mass Elastic System Mass Elastic System 08043087 2.1 Propeller max. pitch, P=8100 kW 19,8 282,2 282,2 282,2 282,2 282,2 282,2 282,2 282,2 282,2 1571,2 207,3 14,5...

- Page 28 Bericht-Nr./ Elastisches System Elastisches System Elastisches System Elastisches System Report No. Mass Elastic System Mass Elastic System Mass Elastic System Mass Elastic System 08043087 2.2 Propeller 0 pitch, P=3785 kW 19,8 282,2 282,2 282,2 282,2 282,2 282,2 282,2 282,2 282,2 1571,2 207,3 14,5...

- Page 29 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.1 Propeller , max. pitch, 8100 kW Belastung nach Propellerkurve / Load acc. To Propeller Law Gsl.-Dämpfer Systemstelle 1-2 Gsl.-Dämpfer Systemstelle 1-2 Gsl.-damper location 1-2 Gsl.-Damper Location 1-2 Moment / torque [kNm] Verlustleistung / power loss [kW]...

- Page 30 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.1 Propeller max. pitch, P=8100 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 12- 13 Elast. Kupplung Systemstelle 12- 13 Flex.

- Page 31 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.1 Propeller max. pitch, P=8100 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 16- 17 Elast. Kupplung Systemstelle 16- 17 Flex.

- Page 32 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.1 Propeller max. pitch, P=8100 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 12- 13 (Aussetzer Zyl. 9) Elast. Kupplung Systemstelle 12- 13 (Aussetzer Zyl. 9) Flex.

- Page 33 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.1 Propeller max. pitch, P=8100 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 16- 17 (Aussetzer Zyl. 9) Elast. Kupplung Systemstelle 16- 17 (Aussetzer Zyl. 9) Flex.

- Page 34 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.2 Propeller 0 pitch, P=3785 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 12- 13 Elast. Kupplung Systemstelle 12- 13 Flex.

- Page 35 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.2 Propeller 0 pitch, P=3785 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 16- 17 Elast. Kupplung Systemstelle 16- 17 Flex.

- Page 36 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.2 Propeller 0 pitch, P=3785 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 12- 13 (Aussetzer Zyl. 9) Elast. Kupplung Systemstelle 12- 13 (Aussetzer Zyl. 9) Flex.

- Page 37 Bericht-Nr./ Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Drehzahldiagramme Report No. Speed Diagrams Speed Diagrams Speed Diagrams Speed Diagrams 08043087 2.2 Propeller 0 pitch, P=3785 kW Belastung nach Propellerkurve / Load acc. to Propeller Law Elast. Kupplung Systemstelle 15- 16 (Aussetzer Zyl. 9) Elast. Kupplung Systemstelle 15- 16 (Aussetzer Zyl. 9) Flex.

- Page 38 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.1 Propeller max. pitch, P=8100 kW 1.Grad / Node 163 1/min 10 11 21 22 2.Grad / Node 222 1/min 10 11 21 22 3.Grad / Node 563 1/min 10 11 21 22...

- Page 39 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.1 Propeller max. pitch, P=8100 kW 4.Grad / Node 1071 1/min 10 11 21 22 5.Grad / Node 1513 1/min 10 11 21 22 6.Grad / Node 2287 1/min 10 11 21 22...

- Page 40 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.1 Propeller max. pitch, P=8100 kW 7.Grad / Node 2315 1/min 10 11 21 22 8.Grad / Node 2377 1/min 10 11 21 22 9.Grad / Node 2549 1/min 10 11 21 22...

- Page 41 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.1 Propeller max. pitch, P=8100 kW 10.Grad / Node 4159 1/min 10 11 21 22 11.Grad / Node 4321 1/min 10 11 21 22 12.Grad / Node 6624 1/min 10 11 21 22...

- Page 42 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.2 Propeller 0 pitch, P=3785 kW 1.Grad / Node 174 1/min 10 11 21 22 2.Grad / Node 232 1/min 10 11 21 22 3.Grad / Node 566 1/min 10 11 21 22...

- Page 43 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.2 Propeller 0 pitch, P=3785 kW 4.Grad / Node 1071 1/min 10 11 21 22 5.Grad / Node 1513 1/min 10 11 21 22 6.Grad / Node 2287 1/min 10 11 21 22...

- Page 44 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.2 Propeller 0 pitch, P=3785 kW 7.Grad / Node 2315 1/min 10 11 21 22 8.Grad / Node 2377 1/min 10 11 21 22 9.Grad / Node 2550 1/min 10 11 21 22...

- Page 45 Bericht-Nr./ Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Eigenfrequenzen Report No. Natural Frequencies Natural Frequencies Natural Frequencies Natural Frequencies 08043087 2.2 Propeller 0 pitch, P=3785 kW 10.Grad / Node 4159 1/min 10 11 21 22 11.Grad / Node 4321 1/min 10 11 21 22 12.Grad / Node 6624 1/min 10 11 21 22...

- Page 46 Bericht-Nr./ Erläuterungen Erläuterungen Erläuterungen Erläuterungen Report No. Explanations Explanations Explanations Explanations 08043087 Verwendete Maßeinheiten: Units of measurement used: Alle in diesem Bericht genannten Zahlenwerte All figures mentioned in this report correspond entsprechen dem internationalen Maßsystem (SI- with the International System of Units (SI Units). System).

-

Page 47: Acceptance Test Records

Acceptance Test Records A1.10 Acceptance Test Records en / 20.02.2008 AA000095... - Page 48 Technical Data A1.10.20.32.33 Acceptance test records en / 22.05.2009 AA045559...

- Page 53 Operating Instructions M20-M601C Operating Instructions en / 26.05.2009 AA000108...

- Page 54 Table of Contents A3.01 Operating Instructions Table of Contents A3.01 Introduction A3.02 Safety Instructions A3.03 Instructions for Heavy Fuel Operation A3.04 Instructions for Heavy Fuel Operation Fuel system A3.04.07.00 Instruction for heavy fuel operation Care and supervision / Engine fuel A3.04.07.01 Instructions for heavy fuel operation Lubricating oil system...

- Page 55 Table of Contents A3.01 Operational supervision Adjustment Instructions A3.06.09.01 Operational supervision Starting system A3.06.10.00 Operational supervision Partial load operation A3.06.18.00 Removal from operation Engine A3.07.00 Decommissioning Decommissioning/Stopping A3.07.18.02 Danger of Frost Engine A3.08.00 Danger of frost Antifreeze protection A3.08.01.00 Preservation Engine A3.09.00.00 Preservation...

- Page 56 Table of Contents A3.01 Emergency operation Operational misfire A3.12.02.01 en / 26.05.2009 AA020023...

- Page 57 The alteration of the fuel rack position may only be carried out by personnel who have received permission to do this from Caterpillar / MaK ! en / 17.01.2006...

- Page 58 MaK. The preparations for the first startup are made by the MaK service engineer, who will explain the plant to the engine room staff in detail. Detail questions are to be settled on site from the operating instructions and explanations should be noted down in the instructions.

- Page 59 Introduction A3.02 M20-M601C Basic notes on engine operation relating to the service life of combustion chamber components Of vital importance to the service life of highly loaded combustion chamber components such as inlet and exhaust valves, piston, and liner are the operating conditions of the engine. These, however, can be influ- enced to a very large extent by the operator of the plant.

- Page 60 Introduction A3.02 M20-M601C Lubricating oil As regards the lubricating oil treatment it is of particular importance to ensure correct separation and filtration and keep an eye on the operating values of the oil. To this end, we recommend to have the lubricating oil analyzed at regular intervals by a laboratory.

- Page 61 Introduction A3.02 M20-M601C Problems in case of wrongly adjusted injection viscosity: Low viscosity: • Seizure of the injection pumps due to decreased lubrication of the pump plunger (especial- ly in case of gas oil operation), • Formation of steam bubbles due to excessive temperature and resulting excess consump- tion.

- Page 62 An introduction to the system specifications, requirements/characteristics can be carried out in the training center of Caterpillar / MaK. For the operators of the system this is a necessary requirement to the order. General safety instructions...

-

Page 63: Proposition 65 Warning

Safety Instructions A3.03 M20-M601C Remote control The engine remote control of seegoing ships and inland ships will be constructed according to the safety regulations of the classification society. Inland ships must also observe the relevant customary safety recommendations! Safety measures for local control of the engine Before the start: •... -

Page 64: Instructions For Heavy Fuel Operation

Instructions for Heavy Fuel Operation A3.04 M20-M601C The instructions stated below are to be stringently observed, as the readiness for service and operational reliability of the engine system during high extremes of use, requires perfect fuel and depends upon optimal concentrations and monitoring supervision. - Page 65 Instructions for Heavy Fuel Operation A3.04.07.00 Fuel system M20-M601C Fuel system The evermore intensive utilization of crude oils by modern processing is the reason the portion of the residual oils (heavy fuel) has become smaller and the portion of the in the residual oils remaining contaminating matter has, however, increased.

- Page 66 Instruction for heavy fuel operation A3.04.07.01 Care and supervision / Engine fuel Care and supervision If you are uncertain of the bunker quality, a careful ascertation of the quality must take place. Basic schema of the heavy fuel system Diesel oil day tank Fuel pressure regulating valve Viscometer Fuel fine filter (duplex filter)

- Page 67 Instruction for heavy fuel operation A3.04.07.01 Care and supervision / Engine fuel Note: The shown fuel circutory diagram is as well valid for operation with destillate fuel after periods of longer operation on low partial load and prior to planned service measures. For permanent opera- tion of the engine with destillate fuel, please refer to diagram A3.06.07.nn.

- Page 68 Instruction for heavy fuel operation A3.04.07.01 Care and supervision / Engine fuel Day tank HT1 The day tank is designed to collect the treated fuel, for a minimum of 4 hours of full load operati- on. If the treatment plant is in order, it will always be filled to the overflow level. This prevents the formation of water condensation.

- Page 69 Instruction for heavy fuel operation A3.04.07.01 Care and supervision / Engine fuel Circulating pump HP3, HP4 This pump is designed like a force pump. The pump relief valve has to be closed in operation. Final preheater HH1 The preheater is to lower the fuel viscosity to a level that is optimal for injection, 10 - 12 mm /s cSt;...

- Page 70 Instructions for heavy fuel operation A3.04.08.00 Lubricating oil system M20-M601C Lubricating oil system The progressively declining quality of heavy fuel oils and the contamination contained therein can lead to engine troubles with increasing frequency if the lube oil is not cared for in an adequate manner. For this reason, the following instructions point out the importance of a careful lube oil treatment and supervision of the lube oil circuit so as to ensure a trouble-free and economical engine operation.

- Page 71 Instructions for heavy fuel operation A3.04.08.01 Care and supervision / Lubricating Oil Care and supervision In heavy fuel operation, lube oil purification by separators is indispensible for a proper treatment. There are no other means to eliminate from the oil, the products resulting from cleaning and neutralisation (carbon and asphalt compounds) including water.

- Page 72 Instructions for heavy fuel operation A3.04.08.01 Care and supervision / Lubricating Oil Basic schema of the lubricating oil system Precise schema see yard drawing Duplex lubeoil filter Lubeoil thermostat valve Lubeoil automatic filter Oil pressure regulaging valve Suction strainer Lubeoil separator Lubeoil cooler Lubeoil preheater Lubeoil sump tank...

- Page 73 Instructions for heavy fuel operation A3.04.08.01 Care and supervision / Lubricating Oil 3.1. Prelubrication LP2 (standby or prelubrication pump) Only a sufficient prelubrication will produce the necessary oil filn on all bearings for engine star- ting. • Check the pressure build-up at the last main bearing (if there is no automatic engine locking). •...

- Page 74 Instructions for heavy fuel operation A3.04.08.01 Care and supervision / Lubricating Oil • Check and clean the filter elements. See servicing instructions in the documents form the manufacturer, book C. • If the back-flushing filter flushes with oil, set the flushing flow (valve in the flushing line) so that there will be no drop in the working pressure, see A1.05.

- Page 75 Initial Operation A3.05.00 Engine Initial Operation en / 20.02.2008 BA000022...

- Page 76 Initial operation A3.05.07.01 Fuel system Fuel system After a long break from service and/or before the initial operation with heavy and destillated fuels we recommend: • Remove the fuel injectors according to A5.05.07.07.01.nn. • Check the nozzles and opening pressure according to A5.05.07.08.01.nn. •...

- Page 77 Initial operation A3.05.08.00 Lubricating oil system M20-M601C Lubricating oil system The lubricating oil should be analyzed regularily during operation and after a longer period of engine down- time, see A4.05.08.nn. • Clean the lubricating oil duplex filter and the suction strainer, these both being situated in front of the lube oil force pump and the standby pump (see A5.05.08.02.01.nn, A5.05.08.04.01.nn) •...

- Page 78 Initial operation A3.05.09.00 Cooling water system M20-M601C Cooling water system • Fill the cooling water system via the expansion tank. It is required that the cooling water has a level of corrosion protection (see A4.05.09.nn). • Set the correct position of the isolating and changeover cocks and/or valves on the cooling water system, see book C.

- Page 79 Initial operation A3.05.11.00 Starting air system M20/M25/M32/M43/M282/M332C/M452/M453C/M551/M552C/M601/ M601C Do not close starting air shut-off valve during operation! • Apart from the starting system, the engine air system also supplies the emergency stop devices and the crankcase oil mist detector. • When the shut-off valve is closed, the air supply of the emergency stop cylinders at the injection pumps and at the crankcase oil mist detector are shut off, in addition to the starting air.

- Page 80 Where these devices are included in the scope of supply of the Caterpillar / MaK, a matching function diagram and a description has been created for this system, see Book C.

- Page 81 Commissioning A3.05.18.00 Putting into operation/starting M20/M32/M43 Wrong start Start locking Run from remote control Speed adjustment S11 / H9 Start S12 / H10 Stop Change-over switch 1 = Engine 2 = Remote control Lamps test Change-over switch ahead / back en / 30.01.2001 BA000636...

- Page 82 Commissioning A3.05.18.00 Putting into operation/starting M20/M32/M43 Emergency start • Switch change-over switch S13 to "1 = Engine". • Put emergency-off leaver (10) in operating position at the control station/regulation linkage. • Prelubricate engine. Switch on lubrication oil - lubrication - or backing pump approximately 5 minutes before starting the engine.

- Page 83 3 - 4 min. Cold starting, below the above preheating temperature MaK generally advises against cold starting because of the higher wear and the high thermal loads on the parts forming the combustion chamber. Only the following brief instructions are therefore given: It is possible to start the cold engine on distillate fuel, however, this should only be done in exceptional cases and the engine should be warmed up very carefully.

- Page 84 Operational Supervision A3.06.00 Engine Operational Supervision en / 20.02.2008 BA000058...

- Page 85 Monitoring A3.06.05.00 Intake air temperature M20-M601C Operation in the case of low intake air temperatures The engine is only allowed to be operated at max. 90 % power if the air intake temperatures are below +10 °C as otherwise the permissible nominal ignition pressure is exceeded. It can be run at full power if the intake air is pre-warmed or mixed with machine air so that the temperature at the compressor inlet is higher than +10 °C.

- Page 86 Monitoring of operation A3.06.06.01 Exhaust system/Firing pressure M20/M25/M32/M43 The engine is designed so that an adjustment of delivery take-up as well as filling of the individual cylinders is no longer necessary. The individual erection heights of the injection pumps of the individual cylinders are secured by ground, cylinder-tied, firmly mounted plates.

- Page 87 Operational supervision A3.06.06.04 Exhaust system/supercharging Waste gas temperatures 1.1 General A comparison of the waste gas temperatures with the values from the acceptance brake certificate and/or the records from the test/preliminary trial run is the best method of evaluating the thermodynamic behaviour of the engine and to additionally pinpoint any changes (supercharging, injection, combustion) from the new condition of the engine.

- Page 88 Operational supervision A3.06.06.04 Exhaust system/supercharging 1.3 Permissible temperatures: The waste gas temperatures at 100% load should not exceed the following values according to the values specified in the acceptance brake certificates A1.10: Downstream of cylinder: + 70 ° ° ° ° C * Upstream of turbine: + 50 °...

- Page 89 • Maximum permissible ignition pressure (pz) see acceptance brake certificate A1.10. • Permissible variation from cylinder to cylinder acc. to MaK ± 5 bar. • Variation/correction for cylinder pressure measurement: The pressure measured at the indicator valve is higher than in the combustion chamber...

- Page 90 Operational supervision A3.06.06.04 Exhaust system/supercharging Indication Attention: Completely close the indicator valve after indication. If there is no longer any pressure at the indicator, release the connection. • Note down the following on the diagram: date, engine number, cylinder number, waste gas tempera- ture per cylinder, charge, speed, charge air pressure.

- Page 91 Operational supervision A3.06.06.31 Exhaust system/supercharging M43/VM43 Turbocharger: Compressor side Preface How fast the compressor stage (compressor impeller and diffusor) will be contaminated depends on the cleanliness of the aspired air and the operating point. Dirt will be deposited in the air ducts in particular when oil or salt mists or various types of dust are aspired from the engine compartment or from outside.

- Page 92 Operational supervision A3.06.06.31 Exhaust system/supercharging M43/VM43 Please see work card A5.05.06.05.00.nn for the operating procedure of the cleaning device. Note A thick layer of encrusted deposits can only be removed from the compressor after the latter has been removed from its location. That is why regular cleaning of the compressor during operation is recommended for machines with increased dust, oil, or salt mist exposure.

- Page 93 Operational supervision A3.06.06.31 Exhaust system/supercharging M43/VM43 Turbocharger: Turbine side Preface The combustion of heavy oil in Diesel engines causes contamination of the turbine blades and nozzle rings of the turbochargers. The deposits on turbine components are caused by combustion products and include mostly soot, molten ash, slag, non-burned oil, fuel that was not burned completely and Sodium-Vanadyl Vanadate.

- Page 94 Operational supervision A3.06.06.31 Exhaust system/supercharging M43/VM43 Turbine and Nozzle Ring Wet Cleaning Procedure There are two types of wet cleaning: - low load washing, (washing of turbine and nozzle ring at low exhaust gas temperature or low engine load **), - “thermo shock cleaning“...

- Page 95 Operational supervision A3.06.06.31 Exhaust system/supercharging M43/VM43 Sequential or parallel cleaning? On “inline engines“, there is no difference. Compressor Cleaning (air-side) for “V-type engines“ : 3.2.1 During compressor cleaning, a certain amount of water is sprayed - sequentially - into each turbocharger; this procedure is called “sequential cleaning“. 3.2.2 The volume of the washing water container is designed for cleaning one turbocharger;...

- Page 96 Operational supervision A3.06.06.31 Exhaust system/supercharging M43/VM43 Turbine-side Cleaning Parameters for : ABB turbochargers TPL 76 C < temperature before turbine intake: 430 ° C injection time: min. of 10 minutes water pressure before control valve : 2.0 bar ± 0.2 bar volume flow: (A5.05.06.13.01.nn) needle valve opening diameter:...

- Page 97 Operational supervision A3.06.07.01 Changing the type of fuel M20-M601C Changing the type of fuel Changing over from distillate fuel to heavy fuel Prepare the system according to A3.05.07.nn. Changing over from heavy fuel to distillate fuel while the engine is running see diagram in A3.04.07.nn.

- Page 98 Operational supervision A3.06.08.00 Lubricating oil system M20-M601C Lubricating oil system • Check daily the levels in the: Lube oil sump tank Base frame Oil sump • Monitor the lubricating oil pressure, - temperature For Pressure-, Temperature indications see A1.05 and A1.06 and also Acceptance Test Records page A1.10. en / 16.12.1997 BA000078...

- Page 99 Operational supervision A3.06.09.00 Cooling water system M20-M601C Cooling water system • Check the level in the fresh-water expansion tank. • Check the water pressure, temperatures and temperature rise. For pressure-temperature indications, see A1.05 of the operation media, for Temperatures of the Operating Media A1.06 as well as Acceptance Test Records A1.10.

- Page 100 Operational supervision A3.06.09.01 Adjustment Instructions M20/M25/M32/M43 Adjustment Instructions for Cooling Water Pressure (Start of Standby Pump, Alarm, and Emergency Stop) There must be a minimum cooling water pressure of 2.5 bar at the engine in order to safely dissi- pate from the engine the amount of heat generated under full load operation. Terminal temperature difference Under full load operation the cooling water will be heated up by 7 to 10 K to a max.

- Page 101 Operational supervision A3.06.09.01 Adjustment Instructions M20/M25/M32/M43 Minimum operating pressure (add static pressure) 3.5 bar Start of standby HT freshwater pump 3.3 bar Low HT freshwater pressure at engine inlet – Alarm 2102 3.1 bar Low HT freshwater pressure at engine inlet – Emergency stop 2103 2.9 bar For sensor equipment adjustment and test instructions please refer to the manual.

- Page 102 Operational supervision A3.06.09.01 Adjustment Instructions M20/M25/M32/M43 Adjustment at 70 % nominal speed The engine is running at 70 % nominal speed and the electric standby pump is switched off. The pressure indicator for HT freshwater on the engine control stand displays an operating pressure of min.

- Page 103 Operational supervision A3.06.09.01 Adjustment Instructions M20/M25/M32/M43 Adjustment at nominal speed: The engine is running at nominal speed and the electric standby pump is switched off. The pres- sure indicator for HT freshwater on the engine control stand displays an operating pressure of min.

-

Page 104: Air Starting System

Operational supervision A3.06.10.00 Starting system M25-M601C Air starting system • Check the pressure in the air bottles. • Drain the water daily from the air bottles, compressed air filter, water traps and fittings. • Secure the compressed air supply for the emergency stop facility! •... - Page 105 Operational supervision A3.06.18.00 Partial load operation M20-M601C Partial load operation with heavy fuel In order to prevent increased wear and tear, pollution of air and exhaust systems and an increased contamination of the lube oil, the partial load operation has to be carried out with distillate fuel only. The distillate fuel provides for an unlimited partial load operation.

- Page 106 Operational supervision A3.06.18.00 Partial load operation M20-M601C Note: If neither a changing-over to destillate fuel nor to high-load operation is possible, an increased contamination of the lubricating oil is to be expected! Notes: • The permissible exhaust gas temperature after the turbine (see A3.06.06.nn) must not be exceeded over the entire operating range, including partial load.

- Page 107 Removal from operation A3.07.00 Engine Removal from Operation en / 21.02.2008 BA000094...

- Page 108 Within the framework of this decommissioning, only the stoppage of the engine at the main engine is discussed. The functions of the remote control are documented with a function diagram and its description if it is included in the scope of supply of the Caterpillar / MaK, see Book C. Attention:...

- Page 109 Decommissioning A3.07.18.02 Decommissioning/Stopping M20/M25/M32/M43 Wrong start Start locking Run from remote control Speed adjustment S11 / H9 Start S12 / H10 Stop Change-over switch 1 = Engine 2 = Remote control Lamps test Change-over switch ahead / back en / 11.05.2000 BA000630...

- Page 110 Decommissioning A3.07.18.02 Decommissioning/Stopping M20/M25/M32/M43 Note: The push-button switch "Reset" located at the safety system must be activated after an activation of the external emergency stop device! Aftercooling If the engine is stopped under load, it must be aftercooled for approximately 5 min. to prevent steam bubble formation.

- Page 111 Decommissioning A3.07.18.02 Decommissioning/Stopping M20/M25/M32/M43 • Keep lubrication oil system warm by means of permanent separation to prevent an accumulation of condensation products and sludge. • Switch off ventilation for engine room only if required to make cooling-off of the engine more difficult. Before a long term operation stop (e.g.

- Page 112 Danger of Frost A3.08.00 Engine Danger of Frost en / 20.02.2008 BA000106...

- Page 113 Danger of frost A3.08.01.00 Antifreeze protection M20-M601C Antifreeze protection If the engine is repeatetely taken out of service for only short periods (without a device in the system to keep it warm), during times when the temperature can fall under freezing point, it will be necessary to protect the system by the use of an antifreeze solution with protection against corrosion (see A4.05.09.nn).

- Page 114 (under deck) of seagoing ships into similar international areas! Attention: The measures for preservation for subtropical or tropical areas are to be coordinated with Caterpillar / MaK according to the destination and storage location and the intended period of storage! en / 16.12.1997 BA000114...

- Page 115 Preservation A3.09.00.00 Engine M20-M601C Package/Storage: The measures for storage and package depend on period of storage and storage location. The short term preservation provides sufficient protection when stored and placed in well ventilated machine rooms/halls and when transported on road under European climate conditions. In case of storage in the open the engine is to be carefully protected against atmospheric influences with a water restistent tarpaulin or a plastic foil.

- Page 116 Preservation A3.09.01.00 Short term preservation M20-M601C Light preservation (short term preservation) Required tools, preservation, cleaning and auxiliary means spray gun, injection pipe, brush preserving oil that can be sprayed and does not dry (e.g. Aral Konit SAE 30) a viscous, sticking and drying preservative (e.g. Valvoline Tectyl 506) corrosion-inhibiting oil (e.g.

- Page 117 Preservation A3.09.01.00 Short term preservation M20-M601C Lubricating oil system • Cleaning the lubricating oil duplex filters, see A5.05.08.04.01.nn. Note: The lubricating oil remains in the circuit if the values required for engine operation are in order (see A4.05.08.nn). Recommendation: Pump fresh lubricating oil through the engine circuit, until clean oil drips out of the last small end bearing.

- Page 118 Preservation A3.09.01.00 Short term preservation M20-M601C External preservation • Clean or wash all unpainted bright parts of the engine. Attention: The engine finish may not be etched by cleaning and/or washing agent! Use only suitable washing agents! Keep to the operation, safety and sanitation instructions of the manufacturer! •...

- Page 119 Preservation A3.09.02.00 Long term preservation M20-M601C Heavy preservation (long term preservation) Required tools, preservation, cleaning and auxiliary means spray gun, injection pipe, brush, cloth preserving oil that can be sprayed and does not dry (e.g. Aral Konit SAE 30) a viscous, sticking and drying preservative (e.g. Valvoline Tectyl 506) non-drying corrosion-inhibiting grease (e.g.

- Page 120 Preservation A3.09.02.00 Long term preservation M20-M601C Starting system and starting air distributor • Remove the sealing flange from the starting air distributor. • Slacken the drain plug at the staring valve as well as the banjo plugs of the air feed lines at the starting valves of all cylinders.

- Page 121 Preservation A3.09.02.00 Long term preservation M20-M601C External preservation • Close the crancase ventilation with protective plug so that it is air tight (see 1.8). • Clean or wash all unpainted bright parts of the engine. Attention: The engine finish may not be etched by cleaning and/or washing agent! Use only suitable washing agents! Keep to the operation, safety and sanitation instructions of the manufacturer! •...

- Page 122 Preservation A3.09.03.00 Depreservation M20-M601C Depreservation Required cleaning and auxiliary means Clean turbine or hydraulic oil (A4.05.08.nn) Solvent-free washing and/or cleaning agent Attention: The engine finish may not be etched by the cleaning and/or washing agent! Use only correspondingly suitable washing agents! Keep to operation, safety and sanitation instructions of the manufacturer! Depreservation measures The following measures are to be implemented after a light or heavy preservation.

- Page 123 Preservation A3.09.03.00 Depreservation M20-M601C Governor (mechanical-hydraulic regulator) • Re-establish the correct oil level in the governor. • Dial governors: remove any excess preserving grease from the gear wheels behind the governor dial. Turbocharger (with independent lubrication) • If necessary, clean the preserved parts according to instructions of the manufacturer. •...

- Page 124 Running-in A3.10.00 Engine Running-in en / 16.02.2001 BA000242...

- Page 125 Running-in A3.10.01.00 Engine M20-M601C Running-in All engines leaving our works have been fully run in, thus no further running in instructions are required. In the case of certain repairs however, such as reconditioning work on pistons (A5.05.02.10.01.nn), piston rings (A5.05.02.07.01.nn) and cylinder liners (A5.05.03.04.02.nn), as is pointed out on the job card in question, the following instructions must be observed: •...

- Page 126 Fault Tracing A3.11.00 Engine Fault Tracing en / 20.02.2008 BA000130...

- Page 127 Fault tracing A3.11.18.00 Introduction M20-M601C Fault tracing In the event of any irregularity in the machinery the characteristic of the trouble should be ascertained, the fault traced and the cause found. Remedial actions must be initiated immediately. Attention: In case of discernible faults stop the motor timely to avoid the risk of greater damages. Minor troubles, whose cause is not obvious or whose influence on operation seems to be less important for the present, must never be ignored.

- Page 128 After standstill of an engine that has run hot, wait 10 to 15 minutes before opening the crankcase doors in order to prevent a possible explosion by air supply from outside. If ne- cessary, contact the Caterpillar/ MaK-Customer Service! Checks after an engine stop due to oil mist alarm:...

- Page 129 Fault tracing A3.11.18.01.01 Oil mist detector M25-M601C Extended checks: Check of the main running gear: • Remove all crankcase doors. • Check the main running gear for ease of movement by turning the crankshaft. • Visually inspect the main running gear (bearings, piston skirts, liners, etc.) for discoloration and traces of seizing.

- Page 130 The engine must not be restarted until the disturbance or damage has been eliminated. Contact the Caterpillar / MaK Customer Service! Note: The indicated checks are intended to assist in troubleshooting and will allow to identify the main causes of an oil mist alarm.

- Page 131 Fault tracing A3.11.18.02 Remedial measures M20-M601C Engine starts poorly or does not start at all Possible cause: Remedy: • Air pressure in the starting air bottle is too See A1.05 for required bottle pressure • Solenoid valve to the air starter is defective •...

- Page 132 Fault tracing A3.11.18.02 Remedial measures M20-M601C Filter differential pressure is too high during starting/pre-lubrication Possible cause: Remedy: • Fuel filter is dirty Clean filter; see A5.05.07.12.01.nn • Differential pressure gauge is defective • Oil is too cold • Water in the oil causes greasy emulsion and oil thickening •...

- Page 133 Fault tracing A3.11.18.02 Remedial measures M20-M601C Engine speed is not steady Possible cause: Remedy: • Too much clearance in the linkage between governor and injection pump • Fuel line is sluggish • Friction in the injection pumps caused by excessive fuel feed pressure •...

- Page 134 Fault tracing A3.11.18.02 Remedial measures M20-M601C Exhaust gases are blue Possible cause: Remedy: Oil in the combustion chamber • Piston rings are sticking For servicing the pistons and rings see, A5.05.02.07.01.nn • Severe wear and tear of cylinder liner: For checking the cylinder liners see scoring, ovality A5.05.03.03.01.nn •...

- Page 135 Emergency Operation A3.12.00 Engine Emergency Operation en / 20.02.2008 BA000142...

- Page 136 Emergency operation A3.12.01.00 With a defective turbocharger M20-M601C Defective turbocharger For supercharged marine diesel engines, it may occur that they have to continue their operation as a naturally aspirated engine with a reduced output, when the turbocharger has failed. As the valve timing of the engine has been adjusted to full load, the engine will exhaust part of the combustion gases into the induction manifold and take them in again when the turbocharger is inoperative (and also normally in the lower partial load range).

- Page 137 Emergency operation A3.12.01.02 With a defective turbocharger M20-M601C Emergency operation of the main engine • Stop the engine • Remove the air filter silencer • Shut down the turbocharger (block the rotor), see manufacturer´s instructions book C. Note: If blocking is not possible: disassemble the rotor.

- Page 138 Emergency operation A3.12.01.02 With a defective turbocharger M20-M601C Monitoring the engine while the turbocharger is defective Change the fuel rack position gradually until the exhaust gas temperature after the turbine is a maximum 500 ° ° ° ° C Carefully monitor the exhaust gas temperatures during emergency operation, especially if exhaust gas alarms have been cut out.

- Page 139 Emergency operation A3.12.01.03 With a defective turbocharger Defective turbocharger Under ship service conditions the turbocharged diesel engine may have to continue to operate in spite of a turbocharger failure as naturally aspirated engine with reduced output. As the valve timing of the engine has essentially been adjusted to operation with turbocharger, the engine will exhaust part of the combustion gases into the charge air manifold and take them in again in the event of a turbocharger failure (and also in the lower part load range).

- Page 140 Emergency operation A3.12.01.03 With a defective turbocharger • Remove the cover from the free end of the charge air duct (B1.05.06.437240) • Always remove the expansion joint between air inlet casing and turbocharger (B1.05.06.437250) • Put the engine into operation with reduced output. •...

- Page 141 Emergency operation A3.12.01.03 With a defective turbocharger Multi-engine plants with one propeller The propellers are normally of the controllable pitch type. Declutch the engine with the defective turbochar- ger. Set the propeller pitch so that the engine remaining in service can be run at rated speed and conti- nuous power.

- Page 142 Emergency operation A3.12.02.00 Operational misfire M20-M601C Operational misfire - protection of the flexible coupling The following instructions and restrictions refer only to engines with flexible couplings. Attention: If one cylinder fails partially or completely, this will always increase the stresses in the flexible coupling.

- Page 143 Emergency operation A3.12.02.00 Operational misfire M20-M601C The permissible surface temperature in misfiring operation is approx. 60 C. If heating is only moderate, the power output can be increased in steps up to max. 80 % of the rated power, which should not be exceeded for thermal reasons. •...

- Page 144 Emergency operation A3.12.02.01 Operational misfire M20/M25/M32/M43 Operational misfire In general, „operational misfire“ means that the engine is operated with non-uniformly loaded cy- linders. This will cause additional loads which are the higher the more the march of the gas pressure of a defective cylinder deviates from the remaining cylinders.

- Page 145 The engine output possible under these conditions is approx. 35 % of the rated output. In case of doubt please contact Caterpillar / MaK . Twin engine systems / generator systems The damaged engine should not be restarted.

-

Page 146: Operating Media

Operating Media Operating Media en / 26.05.2009 AA020105... -

Page 147: Regulations And Recommendations Engine

Table of Contents A4.01 Operating Media Table of Contents A4.01 Introduction A4.02 Safety instructions A4.03 Regulations and Recommendations Engine A4.05.00 Regulations and care Engine fuel A4.05.07.00 Regulations and care Heavy fuels A4.05.07.02 Regulations and care CCAI-limit curves A4.05.07.03.01 Regulations and care Limit specification A4.05.07.04 Regulations and care... - Page 148 Introduction A4.02 M20-M601C The use of suitable and unobjectionable operating media is an assumption for working readiness and relia- bility of surface of the engine system. For that, the following notes and instructions must be observed. • Warranty When unsuitable operating media are used or are maintained insufficiently, no warranty for trouble free operation can be guaranteed.

- Page 149 Safety instructions A4.03 M20-M601C Safety instructions • No open fire during work at the fuel system! • No smoking! • Lube oil and fuel vapours may ignite on contact with ignition sources! • Caution! Burning and scalding hazard when handling hot process materials! During all work or contact with: •...

- Page 150 Regulations and Recommendations A4.05.00 Engine Regulations and Recommendations en / 20.02.2008 BA000158...

- Page 151 Regulations and care A4.05.07.00 Engine fuel M20-M601C For the Caterpillar / MaK-engines used in shore-based and ship-based operation according to their equip- ment condition two product groups of fuels are allowed, these are: • Destillate fuel • Heavy oil en / 28.06.1996...

- Page 152 Regulations and care A4.05.07.02 Heavy fuels M20-M601C Heavy fuels (Viscosity in mm /s (cSt) at 100 °C for CIMAC, at 50 °C for ISO) All fuels are called heavy fuels that consits in the main of residual oils from oil refining. General Requirements: The fuel must represent a homogenous mixture of hydro-carbon coming from the mineral oil processing.

- Page 153 – Introduction of minimum viscosity with CIMAC. The CIMAC-specification is the basis for the Caterpillar / MaK heavy fuel specification (A4.05.07.05). BSI-Specification The BS MA 100 which came into force in 1982 was with drawn in September 1989. Since then the contents of BS MA 100 conforms with ISO 8217.

- Page 154 50 °C, 80 °C and Redw. I sec. The heavy fuel grades permitted for Caterpillar / MaK engines can be found in the table “Permissible limits for heavy fuels to be burnt in Caterpillar / MaK engines” (A4.05.07.04).

- Page 155 Caribbean area. It will frequently happen in the near future that the limits of the Caterpillar / MaK heavy fuel specifica- tion are reached owing to a general change on the fuel market. If it is intended to take such fuels for a lengthy period of time and the owners have no experience with this, we recommend to contact Caterpillar / MaK first.

- Page 156 High-temperature corrosion can occur on exhaust valves and turbine blades when burning heavy fuel containing vanadium and sodium. Caterpillar / MaK does not require additives against high-temperature corrosion. Should they be used, however, it must at least be ensured that they are not sensitive to water, compatible with the fuel in any case and no cause of troubles, in the fuel filters, for instance.

- Page 157 Regulations and care A4.05.07.03.01 CCAI-limit curves M20-M601C CCAI-limit curves Density (kg/l 15 C) to be avoided * limited approved * permissible Viscosity (cSt 50 C) en / 28.05.1998 BA000178...

- Page 158 Regulations and care A4.05.07.04 Limit specification M20/M25/M32/M43 Admissible limit specification for the operation with heavy fuel in Caterpillar/MaK engines Engine series Limit M 20 specification CIMAC A10 CIMAC B10 CIMAC C10 CIMAC D15 CIMAC E25 CIMAC F25 CIMAC G35 CIMAC H35...

- Page 159 Regulations and care A4.05.07.05 Heavy fuel specification M20-M601C en / 27.11.2006 BA000186...

- Page 160 Regulations and care A4.05.07.06 Viscosity temperature sheet M20-M601C en / 28.06.1996 BA000190...

- Page 161 This is usually given as the Base Number (BN), or as Alka- linity Value (AV) and recorded in mgKOH/g. For Caterpillar/MaK engines operating on heavy fuel this value should be between 30 and 40 mg KOH/g for fresh oils.

- Page 162 Cater- pillar/MaK. Furthermore no guarantee can be given for poor quality engine and lubricating oil care nor for the use of non-approved fuels. Proof that a defect has not been brought about by the lubricating oil must be provided by the user.

- Page 163 DISOLA M 4015 AURELIA XL 4030 AURELIA TI 4030 Proven in use I I Permitted for controlled use.When these lubricating oils are used, Caterpillar/MaK must be informed Caterpillar/MaK because at the moment there is insufficient experience available in engines. Otherwise the warranty cover is invalid.

- Page 164 AURELIA TI 4030 AURELIA TI 4040 Proven in use I I Permitted for controlled use.When these lubricating oils are used, Caterpillar/MaK must be informed because at the moment there is insufficient experience available in Caterpillar/MaK engines. Otherwise the warranty cover is invalid.

- Page 165 20 % of the amount in circulation has been used. Note: Modern MaK engines are characterized by low lubricating oil consumption rates of < 1 g/kWh, which in individual cases may even be significantly below this value.

- Page 166 1.6.4 Contamination When Caterpillar/MaK engines are running on heavy fuel, separators are specified to keep the oil clean. In this way the content of insolubles can usually be kept well below 1 % by weight. If the content increases beyond 1 % weight, the oil must be separated more intensively.

- Page 167 Regulations and care A4.05.08.00 Lubricating Oil M20-M601C Lubricating oil for exhaust turbocharger, hydraulic governor and reversing controls A turbine or hydraulic oil with very good anti-oxidation properties and a viscosity between 68 and 90 mm (cSt) at 40 °C should be selected. For highly loaded ABB-turbochargers fully synthetic special oils (see footnote) are recommended.

- Page 168 Regulations and care A4.05.08.00 Lubricating Oil M20-M601C Multi-purpose grease – lithium saponified – consistency number 2 (also suitable for pneu- matic control instruments) Lubricating oil firm Brand name AGIP GR MU 2 ENERGREASE MP-MG 2 CALTEX MULTIFAK EP 2 CASTROL SPHEEROL SX 2 CHEVRON DURA-LITH GREASE EP 2...

- Page 169 Regulations and care A4.05.09.00 Cooling Water M20-M601C Recirculating Cooling Water The cooling system consists of a closed cooling water circuit with a cooling water volume which must be kept constant by topping up, depending on the evaporation loss. The checking of the recirculating cooling water level has to occur at the expansion tank.

- Page 170 Regulations and care A4.05.09.00 Cooling Water M20-M601C *) Water hardness: Water which does not fulfil the above requirements must be hardened or softened. Water with a hardness of > 12° (10°) dGH must be brought within the specified range by mixing with condensate or fully de-ionized water (by ion exchange), see Diagram I (A4.05.09.03).

- Page 171 Association for Internal Combustion Engines Inc). MaK/CAT will issue a recommendation on the basis of the results of the test. No liability for the anticorrosive agent used will be accepted because MaK/CAT is unable to control the recipe and treatment.

- Page 172 Attention: It is important to avoid too low concentration, because this may result in crevice corrosion! As far as we know, the following materials are being used in MaK/CAT Diesel engines at the moment: Manufacturer Additive...

- Page 173 Regulations and care A4.05.09.01 Treatment of cooling water M20-M601C Note: A chemical anticorrosive agent is added to the delivery scope (fittings) of some stationary engines. In any case, a filling with this chemical is to be implemented prior to commisioning. Checking and care of the treated water Anti-corrosion oil A daily check of the coolant level in the sight glass on the expansion tank is just as important as...

- Page 174 Regulations and care A4.05.09.02 Changing the cooling water M20-M601C Changing the cooling water Anti-corrosion oil emulsion The anti-corrosion emulsion must be changed at the latest every 7500 operating hours, at least annually if the 7500 operating hours are spread over a period of more than one year due to long breaks in operation.

- Page 175 When an anti-freeze agent is used, a reduction in cooling efficiency must be expected. In cases of doubt MaK should be contacted. For summer operation, it is advisable to drain off the cooling water with anti-freeze in it and replace it with cooling water with chemical corrosion protection in order to guarantee adequate radiator performance at higher ambient temperatures.

- Page 176 Regulations and careÿ A4.05.09.03 Diagram I M20-M601C Diagram I Determining the cooling water mixture for 10 dGH Cooling system capacity (litres) Example: Cooling system capacity: 2300 l Hardness of available fresh water: 19 dGH To determine the fresh water mixture, proceed from the abscissa “Cooling system capacity” (2300 l) via the intersection of the 19 dGH line to the ordinate “Amount used”...

- Page 177 Regulations and care A4.05.09.04 Diagram II + III M20-M601C Diagram II Emulsion freshening for weak concentration measured oil concentration in vol. % amount of oil to be added in litres to obtain a 0.7 % oil concentration Diagram III Emulsion freshening for excessive concentration measured oil concentration in vol.

- Page 178 Maintenance Maintenance en / 26.05.2009 AA000026...

- Page 179 Table of Contents A5.01 Maintenance Table of Contents A5.01 Introduction A5.02 Safety instructions A5.03 Periodical schedule Heavy fuel A5.04.02 Engine, cylinder head A5.05.01 Valve clearance A5.05.01.01.01.00 Valve Rocker Brackets A5.05.01.02.01.30 Valve Rockers A5.05.01.02.02.00 Valve Rocker Bush A5.05.01.02.03.00 Valve Rotor A5.05.01.03.01.00 Valve guide/Oil scraper ring A5.05.01.05.01.01 Media guiding system...

- Page 180 Table of Contents A5.01 Engine, gear A5.05.02 Running Gear / Engine Timing A5.05.02.01.01.00 Crank Web Deflection A5.05.02.02.01.00 Bearing Shells and Bearing Bushes A5.05.02.03.03.01 Bearing Shells A5.05.02.03.07.01 Big End Bearings A5.05.02.04.01.30 Big End Bearings A5.05.02.04.02.30 Hydraulic Jack A5.05.02.04.51.00 Main Bearings A5.05.02.05.01.30 Main Bearings A5.05.02.05.02.30 Main Thrust Bearings...

- Page 181 Table of Contents A5.01 Engine, regulation A5.05.05 Control Shaft Bearings A5.05.05.01.02.00 Starting Valve A5.05.05.02.01.02 Control Rod A5.05.05.08.01.00 Compressed-Air Filter A5.05.05.09.06.00 Compressed-Air Filter A5.05.05.09.06.01 Engine, exhaust gas system/supercharging A5.05.06 Exhaust Line A5.05.06.01.01.17 Exhaust Line A5.05.06.01.01.18 Charge Air Cooler A5.05.06.04.02.30 Exhaust gas turbocharger A5.05.06.05.00.30 Exhaust gas turbocharger A5.05.06.13.01.30...

- Page 182 Table of Contents A5.01 Engine, starting system A5.05.10 Stop Piston A5.05.10.03.01.00 Engine control equipment A5.05.11 Pressure Switches A5.05.11.01.02.01 RPM Switch A5.05.11.05.01.02 Lubricating Oil/Cooling Water Thermostat A5.05.11.06.01.01 Pressure Switch A5.05.11.06.05.02 Pressure Switch A5.05.11.06.06.02 Crankcase Monitoring Device A5.05.11.09.01.03 Engine auxiliary units A5.05.12 Vibration Damper A5.05.12.04.01.02 Vibration Damper...

- Page 183 The explanations are used to make the user of this engine plant familiar with the existing mainte- nance system of MaK and to interest and deepen the understanding of the user for the problems and importance of the “Scheduled maintenance”.

- Page 184 Maintenance work to be carried out independent of deadlines List of work which may be required in the scope of scheduled work which cannot be allocated to a deadline. * will be handed over by the MaK service department for commissioning of the engine en / 27.02.2008 AA000021...

- Page 185 Introduction A5.02 M20-M601C 2.2.2 Job cards The job cards are instructions for inspection, maintenance, repair and safety check. ¬ Title of the job card Activity Maintenance work Discharge valve A5.05.01.04.01.03 Inspection / Dismounting and mounting Operating hours/maintenance deadline M 551 / M 552 6,000 / 12,000 Engine type Register...

- Page 186 Introduction A5.02 M20-M601C The job card number consists of the index breakdown (A5.05) and the maintenance number (bold) subdivided into four pairs of digits. • The first pair of digits indicates the engine main maintenance group: Cylinder head Lube oil system Driving mechanism Cooling water system Engine housing...

- Page 187 Typical consumption parts which are replaced routinely or any time mounting is carried out (O- ring seals, O-rings etc.) are not considered defective parts. * The map will be handed over by the MaK service department for commissioning of the engine en / 27.02.2008...

-

Page 188: General Safety Instructions

Safety instructions A5.03 M20-M601C Safety instructions Work safety symbol All texts marked with this symbol in the maintenance sheets are safety instructions which have to be observed in all cases in order to eliminate danger to life and limb of the user or of third parties! General safety instructions The provisions of the relevant accident prevention regulations of the appropriate employer's liability insurance association are to be observed any time operation and... - Page 189 Safety instructions A5.03 M20-M601C • When work is being carried out on engines and systems, the switch-on devices have to be switched off and protected. In order to prevent reconnection, the engines and systems have to be marked with a plate “Do not switch” or an appropriate pictogram plate! •...

- Page 190 Safety instructions A5.03 M20-M601C Working on electrical equipment • Work on the electrical equipment of the engine/plant must be carried out only by a skilled electrician or by instructed persons under the supervision and guidance of a skilled electrician in accordance with the electrical engineering rules and regulations! •...

- Page 191 Safety instructions A5.03 M20-M601C Handling of liquid nitrogen or carbon dioxide snow • When handling liquid nitrogen or carbon dioxide snow, safety shoes, safety gloves and safety glasses are to be worn in order to avoid injuries. Observe protection against cold! •...

- Page 192 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks Daily inspection and monitoring procedures (if it is not automated) -------------------------------------------------------------------------------------------------------------------------------- General Engine operating data A1.10 Compare with acceptance test records: Speed, rating Temperature Lubricating oil A1.06 Engine inlet;...

- Page 193 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks Fuel system Fuel duplex filter A5.05.07.12.01.08 Maintenance/Cleaning at 50 % differential pressure Pressure Air bottles A3.06.10.00 Drain en / 26.05.2009 AA000649 2/10...

- Page 194 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks First inspection and maintenance procedures Work to be carried out after the first commissioning or after major repairs. -------------------------------------------------------------------------------------------------------------------------------- 24 h Duplex fuel filter A5.05.07.12.01.08 Maintenance/Cleaning Strainer...

- Page 195 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks Periodical maintenance procedures -------------------------------------------------------------------------------------------------------------------------------- 24 h Compressed air strainer A5.05.05.09.06.nn Maintenance/Cleaning 24 h Exhaust gas turbocharger A5.05.06.05.00.30 Maintenance/Cleaning see book C 150 h Valve rotor A5.05.01.03.01.00 Inspection/Evaluate 150 h...

- Page 196 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks 3.750 h Starting valve A5.05.01.09.01.00 Inspection/Checking 3,750 h Governor Oil change see book C 3,750 h Monitors Checking of alarm and safety system see book C 3,750 h Running gear/engine timing A5.05.02.01.01.00...

- Page 197 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks 7,500 h Injection valve A5.05.07.09.01.30 Repair/Disassembly and reassembly 7,500 h RPM-switch A5.05.11.05.01.02 Inspection/Adjust 7,500 h Lubricating oil/Cooling water thermostat A5.05.11.06.01.01 Maintenance/Checking 7,500 h Oil mist detector A5.05.11.09.01.03 Inspection/Checking 12,000 h...

- Page 198 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks 15,000 h Timing gear train A5.05.04.08.01.02 Inspection/Checking 15,000 h Governor drive A5.05.04.08.03.02 Inspection/Disassembly and reassembly 15,000 h Exhaust gas turbocharger Maintenance/Cleaning resp. revision of turbocharger see book C 15,000 h Injection pump...

- Page 199 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks 30,000 h Cylinder liner A5.05.03.03.01.01 Inspection/Measuring at all cylinder units 30,000 h Cylinder Liner A5.05.03.04.01.00 Maintenance/Disassembly 30,000 h Camshaft bearings A5.05.04.01.01.00 Inspection/Checking at all bearings 30,000 h Camshaft bearings A5.05.04.01.02.00...

- Page 200 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks Non-interval dependent maintenance procedures -------------------------------------------------------------------------------------------------------------------------------- Valve rocker brackets A5.05.01.02.01.30 Maintenance/Disassembly and reassembly Valve rocker bush A5.05.01.02.03.00 Inspection/Replace Media guiding system A5.05.01.05.50.01 Maintenance/Disassembly and reassembly Cylinder head A5.05.01.06.01.30 Maintenance/Disassembly...

- Page 201 Periodical schedule A5.04.02 Heavy fuel M43/VM43 Intervall Designation / Doc-Nr. Work to be carried out Remarks Piston A5.05.02.10.01.30 Maintenance/Reassembly Cooling water distributor housing A5.05.03.02.00.00 Maintenance/Disassembly and reassembly Cylinder liner A5.05.03.04.02.00 Maintenance/Reassembly Camshaft A5.05.04.04.01.06 Repair/Disassembly and reassembly Timing Gear Train A5.05.04.08.02.02 Maintenance/Disassembly and reassembly Charge air cooler A5.05.06.04.02.30...

-

Page 202: Valve Clearance

Valve clearance A5.05. 01.01.01.00 Inspection / Adjust M43/VM43 1500 See also: 02.01.01.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,50 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel -------------------------------------------------------------------------------------------------------------------------------- Inspection: The valve clearance must be checked every 1,500 operating hours and adjusted if necessary. - Page 203 Valve clearance A5.05. 01.01.01.00 Inspection / Adjust M43/VM43 1500 Release valve bridge of rocker arm (Fig. 1/1). Enlarge clearance „S“ and/or flap back rocker arm (1). Release locknut (Fig. 2/3) and unsrew set- ting bolt (4) until a contact in „X” without clearance is reached.

- Page 204 Valve Rocker Brackets A5.05. 01.02.01.30 Maintenance / Disassembly and reassembly M43/VM43 See also: 01.01.01.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,20 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel -------------------------------------------------------------------------------------------------------------------------------- Tools: Store hydraulic device kit consisting of clamping cylinder W1.1...

- Page 205 Valve Rocker Brackets A5.05. 01.02.01.30 Maintenance / Disassembly and reassembly M43/VM43 Remove the four rocker arm nuts with the hydraulic clamping unit. 1.5.1 Place the hydraulic clamping elements (W1.1) on the round nuts (1), unscrew threaded bush up to the limit stop and pull. Ensure that the slits are easily accessible. 1.5.2 Connect the clamping elements with the high pressure pump by means of the high pressure lines (W1.2, W1.3).

- Page 206 Valve Rocker Brackets A5.05. 01.02.01.30 Maintenance / Disassembly and reassembly M43/VM43 Note: If the round nuts cannot be removed, the pressure on the nuts can be increased by ca. 50 bar more. If the round nuts are subject to higher pressure, the pin threading may stretch, which can cause the round nuts to lock into place.

- Page 207 Valve Rocker Brackets A5.05. 01.02.01.30 Maintenance / Disassembly and reassembly M43/VM43 2.5.6 Check to ensure that the round nut is seated properly. • Reduce pressure by 50 bar. • The round nuts must be tight enough that they cannot be loosened with the pin. 2.5.7 Depressurize the clamping elements, dismantle the clamping unit.

- Page 208 Valve Rockers A5.05. 01.02.02.00 Maintenance / Disassembly and reassembly M43/VM43 30000 See also: 01.02.01.nn, 01.02.03.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,20 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel ---------------------------------------------------------------------------------------------------------------------------------- Maintenance: Disassemble intake and exhaust rocker arms and check bearing clearance every 30,000 h Note:...

- Page 209 Valve Rockers A5.05. 01.02.02.00 Maintenance / Disassembly and reassembly M43/VM43 30000 Check the bearing surfaces of the ball pin (Fig. 2/10) and the adjusting screw (12) for wear and damage. Replace parts as ne- cessary. Cool ball pins to -195 °C with liquid nitrogen and slide into place.

- Page 210 Valve Rocker Bush A5.05. 01.02.03.00 Inspection / Replace M43/VM43 See also: 01.02.01.nn, 01.02.02.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,40 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel -------------------------------------------------------------------------------------------------------------------------------- Tools: Copper punch W1 * * no picture Note: The liners may only be lubricated with oil.

- Page 211 Valve Rotor A5.05. 01.03.01.00 Inspection / Evaluate M43/VM43 See also: 01.07.01.nn, 01.10.00.nn Spare parts list: B1.05.01.432107, B1.05.01.432225 Time requirement: 1 Pers./ 0,10 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel -------------------------------------------------------------------------------------------------------------------------------- Inspection: of the valve rotor and the free-wheels every 150 h Note: The valve rotational speed in relation to the engine speed must be measured and documented...

- Page 212 Valve Rotor A5.05. 01.03.01.00 Inspection / Evaluate M43/VM43 The valve rotor or free-wheel is functioning correctly when the valves rotate evenly in relation to the engine speed. The valve rotor and free-wheel must be lubricated with a few drops of oil-gas oil mixture (mixture ratio 1:1) if the rotational speed is noticeably slower than the speed indicated for new valves.

- Page 213 Valve guide/Oil scraper ring A5.05. 01.05.01.01 Inspection / Replace M43/VM43 15000 See also: 01.01.01.nn, 01.02.01.nn, 01.06.01.nn, 01.07.01.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,20 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel -------------------------------------------------------------------------------------------------------------------------------- Inspection: of the valve guide clearance of the intake and exhaust valves after 15,000 h Auxiliary materials: Molykote Paste “G-Rapid Plus”...

- Page 214 Intake Valve guide replacement Note: The valve guides should be replaced by a certified MaK workshop within the scope of a cylinder cover overhaul if possible. The cylinder cover may be damaged when removing the old valve guides. en / 05.06.2003...

- Page 215 Media guiding system A5.05. 01.05.50.01 Maintenance / Disassembly and reassembly See also: 01.06.01.nn, 01.11.01.nn Spare parts list: B1.05.01.432144 Time requirement: 1 Pers./ 0,25 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel -------------------------------------------------------------------------------------------------------------------------------- Auxiliary material: Vaseline * * or a product of equal standard Sequence of operations: Disassembly...

- Page 216 Media guiding system A5.05. 01.05.50.01 Maintenance / Disassembly and reassembly Pull the sleeves (fig. 2/9) out of the connecting flanges (1, 2). Check the O-rings (14). Replace faulty O-rings (14). Insert the O-rings in the grooves using vaseline and making sure that they are not twisted! Remove hexagon screws (Fig.

- Page 217 Media guiding system A5.05. 01.05.50.01 Maintenance / Disassembly and reassembly Remove the cheese head screws (Fig. 3/22) with connecting flange (8). Pull the sleeves (10) out of the media block (6). Check the O-rings (15). Replace faulty O-rings (15). Remove lubricating oil pipe (4). 1.10 Remove hexagon screws (20, 23) with media block (6).

- Page 218 Media guiding system A5.05. 01.05.50.01 Maintenance / Disassembly and reassembly Reassembly Mount the connecting flanges (fig. 2/1 and 2) with inserted sleeves (9). Replace faulty gaskets (13) beforehand. Mount the media block (fig. 3/6). Insert sleeves (10) with new O-rings (15). Mount lubricating oil pipe (4).

- Page 219 Cylinder Head A5.05. 01.06.01.30 Maintenance / Disassembly See also: 01.02.01.nn, 02.06.01.nn, 03.04.01.nn, 06.01.01.nn, 07.05.01.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,50 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel ---------------------------------------------------------------------------------------------------------------------------------- Tools: Store hydraulic device kit consisting of clamping cylinder W1.1...

- Page 220 Cylinder Head A5.05. 01.06.01.30 Maintenance / Disassembly Disconnect and remove connecting flange of the media conduit for the cylinder head to be re- moved (01.05.50.nn). Remove rocker arm bracket (01.02.01.nn). Note To prevent damage and ensure trouble-free assembly and disassembly, the complete rocker arm bracket must be removed! Remove injection pressure pipe (07.05.01.nn).

- Page 221 Cylinder Head A5.05. 01.06.01.30 Maintenance / Disassembly Loosen the six cylinder head screws using the hydraulic torque device. 10.1 Store hydraulic traction elements (Fig. 3/ W1.1) onto round nuts and tighten. Ensure good acces- sibility of the slots (3). Store hydraulic hydraulic traction elements by a 1 1/3 turn. 10.2 Store hydraulic traction elements via high pressure hoses (W1.2) to each other.

- Page 222 Cylinder Head A5.05. 01.06.01.30 Maintenance / Disassembly Screw ring screws (Fig. 4/W3) into cylinder head. Fit cylinder head lifting device (W2). Lift cylin- der head with hoist. Watch for push rod bushing! Attention: Risk of damage for conduit connection, cylinder head screws, push rods, fuel pressure pipe and charged air inlet connection.

- Page 223 Nozzle sleeve A5.05. 01.06.50.03 Maintenance / Disassembly and reassembly VM43 15000 See also: 01.06.01.nn, 07.07.01.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,50 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel -------------------------------------------------------------------------------------------------------------------------------- Maintenace: Replacement of O-rings every 15.000 h Tools:...

- Page 224 Nozzle sleeve A5.05. 01.06.50.03 Maintenance / Disassembly and reassembly VM43 15000 Attention: The threads of the nozzle sleeve and the cylinder head may no longer mesh. Remove flange (3). Use a brass mandrel (W3) and carefully drive out the nozzle sleeve. Remove the O-rings (4 and 5).

- Page 225 Relief Valve A5.05. 01.06.70.01 Maintenance / Replace M43/VM43 30000 See also: 01.06.01.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,20 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel -------------------------------------------------------------------------------------------------------------------------------- Maintenance: Replacement of relief valve every 30,000 h Tools:...

- Page 226 Relief Valve A5.05. 01.06.70.01 Maintenance / Replace M43/VM43 30000 Slacken relief valve (3) by means of a wrench and remove it. Lubricate the thread of the new relief valve with high-temperature thread paste “Dag 5420 A“ . Mount new relief valve (3) with new joint ring (4). Firmly tighten the relief valve by means of a wrench.

- Page 227 Inlet and Exhaust Valve Cone A5.05. 01.07.01.03 Inspection / Disassembly and reassembly M43/VM43 15000, 7500 See also: 01.02.01.nn, 01.05.01.nn, 01.06.01.nn, 01.08.01.nn Spare parts list: B1.05.01.432107 Time requirement: 1 Pers./ 0,50 h Personnel qualification: skilled engine hand Operating medium: Heavy fuel and distillate fuel ---------------------------------------------------------------------------------------------------------------------------------- Inspection: check the wear pattern of the intake and exhaust valve cone...

- Page 228 Inlet and Exhaust Valve Cone A5.05. 01.07.01.03 Inspection / Disassembly and reassembly M43/VM43 15000, 7500 Sequence of operations: Disassembly Disassemble the cylinder head (01.06.01.nn). Disassemble the rocker arms (01.02.01.nn) and take off valve bridge. Put the valve spring compressor unit (W1) onto valve spring retainer (2).

- Page 229 Inlet and Exhaust Valve Cone A5.05. 01.07.01.03 Inspection / Disassembly and reassembly M43/VM43 15000, 7500 Pull the valve cone out of the cylinder head. Note: Valve cones which display a large degree of wear in the clamping area and clamping piece haves with excessive burring must be replaced with new parts.

- Page 230 Inlet and Exhaust Valve Cones A5.05. 01.08.01.00 Repair / Checking M43/VM43 See also: 01.07.01.nn, 01.08.02.nn Spare parts list: B1.05.01.432107 Time requirement: 0 Pers./ 0,00 h Personnel qualification: Chief engineer / skilled engine hand Operating medium: Heavy fuel and distillate fuel ---------------------------------------------------------------------------------------------------------------------------------- Tools: Valve seat grinding unit...

- Page 231 Inlet and Exhaust Valve Cones A5.05. 01.08.01.00 Repair / Checking M43/VM43 • there is HT corrosion as shown below, i. e. no deep craters over the entire area of the bottom side of the valve heads. • the straightness deviation does not exceed the following values (Fig. 1) Span “s“...

- Page 232 Inlet and Exhaust Valve Cones A5.05. 01.08.01.00 Repair / Checking M43/VM43 Valves may not be re-used for another in- terval when • the valve cone surface is damaged (cracks, blow-by) • there is burnout “s“ caused by high temperature corrosion on the underside of the valve head >...

- Page 233 Inlet and Exhaust Valve Cones A5.05. 01.08.01.00 Repair / Checking M43/VM43 Repair (reworking the sealing surface) Note: The rework must be completed properly on precision spindle grinding machines. If such a machi- ne is not available, the valve cone should be sent to a CAT workshop for regrinding. Regrind the sealing surface in accordance with the indicated angle (Fig.