Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SMC Corporation LECSB

- Page 1 Doc. no. LEF-OM00403 PRODUCT NAME Electric Actuator /Slider Type 《 AC Servo Motor 》 MODEL / Series LEF Series Applicable models: LEFS/LEFB AC Servo Motor Driver LECS Series LECSA LECSB LECSC LECSS (Pulse input / (Pulse input) (CC-Link) (SSCNETⅢ) Positioning)...

-

Page 2: Table Of Contents

Contents Safety Instructions ................2 1. Procedure before operation ............4 1.1 Preparation ................4 1.2 Startup ..................6 1.3 Gain tuning ................7 2. Slider type LEFS series ..............8 2.1 Specification................8 2.2 How to Order ................9 2.3 Construction ................ -

Page 3: Safety Instructions

LEF Series / Slider type Safety Instructions These safety instructions are intended to prevent hazardous situations and /or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO /IEC), Japan Industrial Standards (JIS)*1) and other safety regulations*2). - Page 4 LEF Series / Slider type Safety Instructions Caution The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary.

-

Page 5: Procedure Before Operation

1(in case with I/O connector) LECSA(Pulse input / Positioning) Driver Motor cable Encoder cable Lock cable DC24V Host controller, Electric Actuator I/O Connector LECSB(Pulse input) Driver Motor cable Lock cable DC24V Encoder cable Host controller, Electric Actuator I/O Connector - 4 -... - Page 6 LECSC(CC-Link) Driver Motor cable Lock cable DC24V Encoder cable Host controller, Electric Actuator I/O Connector LECSS(SSCNET III) Driver Motor cable Lock cable DC24V Encoder cable Host controller, Electric Actuator I/O Connector - 5 -...

-

Page 7: Startup

1.2 Startup When switching the power on for the first time, follow the startup procedure below. The setting of the filter parameter might become necessary for LEFB25S, and confirm paragraph 7.6, please. Refer to the “Driver operation manual” for wiring method and detailed procedure. Confirm that the cables to the driver and the actuator are - - - Wiring check... -

Page 8: Gain Tuning

3)Please set load moment of inertia ratio to about 50 times after it sets it to auto-tuning Mode 2 when you drive in low speed in LECSB, LECSC, and LECSS (state that the auto-tuning mode doesn't operate). - 7 -... -

Page 9: Slider Type Lefs Series

2. Slider type LEFS series 2.1 Specification LEFS25,32,40 AC servo motor (100W / 200W/400W/) Model LEF25S* LEF32S* LEF40S* 200, 300, (400), 500, 100,200,300,(400), 100,200,300,(400), Note 1) (600),(700), 800, (900), Stroke [mm] 500,(600) 500,(600),(700),(800) (1000) Note 2) Horizontal Work load [kg] Vertical to 400 1000... -

Page 10: How To Order

2.2 How to Order <Ball screw drive> - 9 -... -

Page 11: Construction

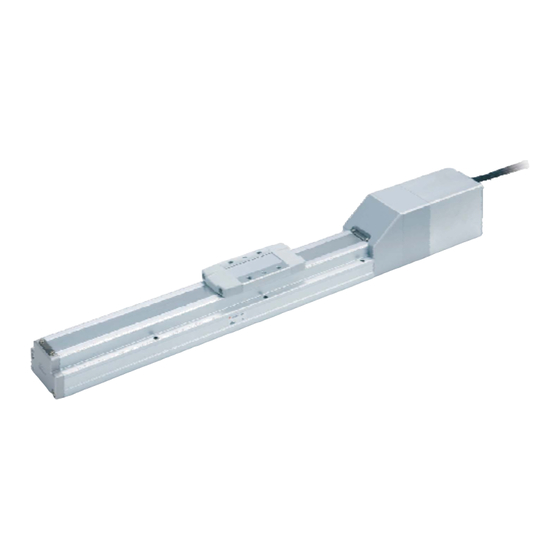

2.3 Construction LEFS□S□S <Ball screw drive> In-line mouting type Parts list - 10 -... - Page 12 LEFS□R/LS□S <Ball screw drive> Right / Left side parallel type Parts list Description Material Note Description Material Note Body Aluminum alloy Anodized Cover plate Aluminum alloy Anodized Rall guide Table spacer Aluminum alloy Only LEFS32 Ball screw (shaft) Alloy steel Motor Ball screw nut Resin/Alloy steel...

-

Page 13: Slider Type Lefb Series

3. Slider type LEFB series 3.1 Specification LEFB25,32,40 AC servo motor (100W / 200W/400W/) Model LEFB25S* LEFB32S* LEFB40S* 300,400,500,600, 300,400,500,600, 300,400,500,600, 700,800,900,1000, 700,800,900,1000, 700,800,900,1000, (1100),1200, (1100),1200,(1300,1400), Note 1) Stroke [mm] (1100),1200,(1300,1400), (1300,1400), 1500,(1600,1700), 1500,(1600,1700), 1500,(1600,1700), (1800,1900),2000 (1800,1900),2000,2500 (1800,1900),2000 2500,3000 Note 2) Work load [kg] Horizontal Note3) -

Page 14: How To Order

3.2 How to Order <Belt drive> - 13 -... -

Page 15: Construction

3.3 Construction LEFB25S□S <Belt drive (25)> Parts list - 14 -... - Page 16 LEFB32/40S□S <Belt drive (32/40)> Parts list - 15 -...

-

Page 17: Product Outline

4. Product Outline 4.1 System construction Incremental Encoder Prepared by user ◎option (Pulse input / Pisitioning) Control circuit power Setup software supply Main circuit Prepared by user power connector Driver LEC-MR-SETUP221 (accessory) Power supply 1-phase 100 to 120VAC (50/60Hz) 200 to 230VAC (50/60Hz) ◎option Control circuit Regenerative option... - Page 18 Absolute Encoder (CC-Link) Driver ◎option Main circuit Prepared by user USB cable power LEC-MR-J3USB Power supply connector (accessory) Setup software 1-phase 100 to 120VAC (50/60Hz) 200 to 230VAC (50/60Hz) 3-phase 200 to 230VAC (50/60Hz) LEC-MR-SETUP221 ◎option Regenerative option RS-422 interface LEC-MR-RB-□...

-

Page 19: Function/Configuration

ON/OFF signal (Pulse input / Pulse train Incremental 3 points 4 programs PA01 Note2) Note2) (max. 7 points) (max. 8 Programs) positioning) LECSB Pulse train Absolute PA01 (Pulse input) CC-Link CC-Link LECSC Absolute 31 points PC30 (When 1 station is occupied) -

Page 20: Wiring Of Cables / Common Precautions

5. Wiring of cables / Common precautions Warning Adjusting, mounting or wiring change should never be done before shutting off the power supply to the product. Electrical shock, malfunction and damaged can result. Never disassemble the cable. Use only specified cables. Never connect or disconnect the cable or connector with power on. -

Page 21: Electric Actuators / Common Precautions

6. Electric actuators / Common precautions 6.1 Design and selection Warning 1. Be sure to read the Operation Manual (this manual and the one for the driver: LEC series). Handling or usage/operation other than that specified in the Operation Manual may lead to breakage and operation failure of the product. -

Page 22: Mounting

6.2 Mounting Warning 1. Install and operate the product only after reading the Operation Manual carefully and under standing its contents. Keep the manual in a safe place future reference. 2. Observe the tightening torque for screws. Tighten the screws to the recommended torque for mounting the product. 3. -

Page 23: Handling

6.3 Handling Warning 1. If abnormal heating, smoking or fire, etc., occurs in the product, immediately shut off the power supply. 2. Immediately stop operation if abnormal operation noise or vibration occurs. If abnormal operation noise or vibration occurs, the product may have been mounted incorrectly. Unless operation of the product is stopped for inspection, the product can be seriously damaged. -

Page 24: Operating Environment

6.4 Operating environment Warning 1. Avoid use in the following environments. a. Locations where a large amount of dusts and cutting chips are airborne. b. Locations where the ambient temperature is outside the range of the temperature specification (refer to specifications). c. -

Page 25: Maintenance

6.5 Maintenance Warning 1. Do not disassemble or repair the product. Fire or electric shock can result. 2. Before modifying or checking the wiring, the voltage should be checked with a tester 5 minutes after the power supply is turned off. Electrical shock can result. -

Page 26: Electric Actuators / Slider Type Common Precautions

7. Electric actuators / Slider type Common precautions 7.1 Design and selection Warning Do not apply a load in excess of the actuator specification. A product should be selected based on the maximum work load and allowable moment. If the product is used outside of the operating specification, eccentric load applied to the guide will become excessive and have adverse effects such as creating play in the guide, reduced accuracy and reduced product life. -

Page 27: Mounting

7.3 Mounting Caution 1. Keep the flatness of mounting surace to within 0.1mm or less. Insufficient flatness of the work piece or the surface onto which the actuator body is to be mounted can cause play in the guide and increased sliding resistance. 2. -

Page 28: Precaution On Maintenance

7.4 Precaution on maintenance Warning 1. Turn off the power supply before maintenance and replacement of the product.. 2. Put on protective goggles when applying grease. [Maintenance frequency] Perform maintenance according to the table below. Contact SMC if any abnormality is found. Appearance Internal Belt... -

Page 29: How To Detach And Attach The Dust Seal Band

7.5 How to detach and attach the dust seal band For the internal-check as the maintenance, the method of detaching and attaching the dust seal band is shown as the following . <Dis-assembly> Loosen the fixing bolts of end side of the “Band holder”. (The picture shows LEFB, but LEFS is same instruction as LEFB.) Pay attention to not cut hand on the edges of the "Dust seal band". -

Page 30: Replacement Of Belt

7.6 Replacement of belt 1. After Bolt is removed, "Pulley plate" is removed. Bolts 2. "Motor cover" and "Grommet" are removed. (Only "With motor cover") Bolts 3. After "Belt" is installed, and the bearing support is obtained, the root of "Motor" is pulled in a string or a long banding band. -

Page 31: Troubleshooting

8.Troubleshooting 8.1 Alarms and Warning When a fault occurs during the operation, the corresponding alarm or warning is displayed. If any alarm or warning has occurred, refer to 「Driver Operation Manual」and take the appropriate action. After removing the cause of the alarm, the alarm can be deactivated in any of the methods marked ○ in the alarm deactivation column. - Page 32 ・LECSB(Pulse input) Alarm deactivation Press "SET" on Alarm Display Name Power current alarm reset OFF→ON screen. (RES) AL.10 Undervoltage ○ ○ ○ AL.12 ○ Memory error 1 (RAM) AL.13 ○ Clock error AL.15 Memory error 2 (EEP-ROM) ○ AL.16 ○...

- Page 33 ・LECSC(CC-Link) Alarm deactivation Alarm MR Configuratior Display Name Power reset parameter OFF→ON unit(Note3) (Note2) ○ ○ ○ Undervoltage ○ Memory error 1 (RAM) ○ Clock error ○ Memory error 2 (EEP-ROM) ○ Encoder error 1(At power on) ○ Board error ○...

- Page 34 ・LECSS(SSCNET III) Alarm deactivation Display Name Power Error reset CPU reset OFF→ON Undervoltage ○ ○ ○ ○ Memory error 1 (RAM) ○ Clock error Memory error 2 (EEP-ROM) ○ ○ Encoder error 1(At power on) ○ Board error Memory error 3(Flash-ROM) ○...

- Page 35 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 http: / /www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. © 2013 SMC Corporation All Rights Reservedd...

Need help?

Do you have a question about the LECSB and is the answer not in the manual?

Questions and answers