Table of Contents

Advertisement

NATURAL GAS MODELS:

PROPANE GAS MODELS:

SAFETY INFORMATION

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

- Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not

use any phone in your building.

•

Immediately call your gas supplier from a

neighbour's phone. Follow the gas

supplier's instructions.

•

If you cannot reach your gas supplier, call

the fi re department.

- Installation and service must be

performed by a qualifi ed installer, service

agency, or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

a certifi ed kit is used.

INSTALLER:

Leave this manual with the appliance

CONSUMER:

Retain this manual for future reference

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada / 103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone 1 (866) 820-8686 • www.napoleonfi replaces.com • hearth@napoleonproducts.com

$10.00

LVX38N / LVX50N / LVX62N / LVX74N / LVX38N2 / LVX50N2 / LVX62N2 / LVX74N2

ADD PRODUCT CODE HERE (TRADE GOTHIC LT STD FONT)

LVX38P / LVX50P / LVX62P / LVX38P2 / LVX50P2 / LVX62P2

INSTALLATION MANUAL

ADD MANUAL TITLE

CERTIFIED TO THE CANADIAN AND AMERICAN NATIONAL STANDARDS:

CSA 2.22 AND ANSI Z21.50 FOR VENTED DECORATIVE GAS APPLIANCES

CERTIFIED TO THE CANADIAN AND AMERICAN NATIONAL STANDARDS:

CSA 2.22 AND ANSI Z21.50 FOR VENTED DECORATIVE GAS APPLIANCES

CSA /

INTERTEK

LOGO

Luxuria™ Series

PRODUCT NAME™

ADD ____ ILLUSTRATED

ADD PRODUCT IMAGE

THIS APPLIANCE IS INSTALLED WITH

FOR INDOOR USE ONLY

FOR INDOOR USE ONLY

PLACE BARCODE LABEL ON THE

OWNER'S MANUAL

ENGLISH

FRENCH PG. 81

(LVX38 illustrated)

W415-1710 / A / 07.27.17

Advertisement

Table of Contents

Summary of Contents for Napoleon LVX38N

- Page 1 CSA / INTERTEK OWNER’S MANUAL LOGO Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada / 103 Miller Drive, Crittenden, Kentucky, USA, 41030 Phone 1 (866) 820-8686 • www.napoleonfi replaces.com • hearth@napoleonproducts.com W415-1710 / A / 07.27.17 $10.00...

-

Page 2: Safety Information

safety information WARNING DANGER • This appliance is hot when operated and can cause severe burns if contacted. • Any changes to this appliance or its control can be dangerous and are prohibited. HOT GLASS WILL CAUSE BURNS. • Do not operate appliance before reading and understanding operating instructions. - Page 3 • Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water. safety information WARNING •...

-

Page 4: Table Of Contents

table of contents general information 11.0 finish framing - after appliance rates and efficiencies installation installation overview 11.1 framing with Dynamic Heat Dynamic Heat Control™ Control™ rating plate/lighting instruction 12.0 finishing location mobile home installation 12.1 fastener placement restriction hardware list 12.2 finishing with combustibles lifting handles installation/removal... -

Page 5: General Information

general information Installer: please fill out appliance checklist in the owner’s manual. 1.0 general information When the appliance is installed at elevations above 4,500ft (1372m), and in the absence of specific recommendations from the local authority having jurisdiction, the certified high altitude input rating shall be reduced at the rate of 4% for each additional 1,000ft (305m). -

Page 6: Rates And Efficiencies

LVX38 Single-Sided See-thru LVX38N LVX38P LVX38N2 LVX38P2 Appliance Type Natural Gas Propane Natural Gas Propane Fuel Type Altitude (FT) 0-4,500 0-4,500 0-4,500 0-4,500 Max. Input (BTU/HR) 32,000 32,000 32,000 32,000 Min. Input (BTU/HR) 22,000 25,000... -

Page 7: Installation Overview

general information installation overview Recommended installation steps: 1. Determine venting requirements before deciding the final location of the appliance 2. Plan out appliance enclosure, framing, fronts, accessories, etc. 3. Install rough framing (refer to “rough framing” section) 4. Place the appliance in its final position 5. -

Page 8: Dynamic Heat Control

general information Dynamic Heat Control™ Dynamic Heat Control™ is a system for managing the heat produced by the appliance at and around the fire- place. The purpose of the Dynamic Heat Control™ is to move the heat away from the fireplace to allow it to cir- culate more effectively within the living space. - Page 9 general information WARNING • Always light the pilot whether for the first time or if the gas supply has run out, with the glass door opened or removed. • Provide adequate clearance for servicing and operating the appliance. • Provide adequate ventilation. •...

-

Page 10: Rating Plate/Lighting Instruction

0" RECESSED DEPTH ONE SIDED/ PROFONDEUR D'ENCASTRE UNE FACE 17 15/16" avec les types de gaz indiqués sur la plaque THE APPLIANCE MUST BE VENTED USING THE APPROPRIATE NAPOLEON VENT KITS. SEE OWNER'S INSTALLATION MANUAL AVERTISSEMENT: D’INSTALLATION. PAR NE PAS FLOOR / PLANCHER 0"... -

Page 11: Mobile Home Installation

general information mobile home installation This appliance must be installed in accordance with the manufacturer’s instructions and the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, in the United States or the Mobile Home Standard, CAN/CSA Z240 MH Series, in Canada. This appliance is only for use with the type(s) of gas indicated on the rating plate. -

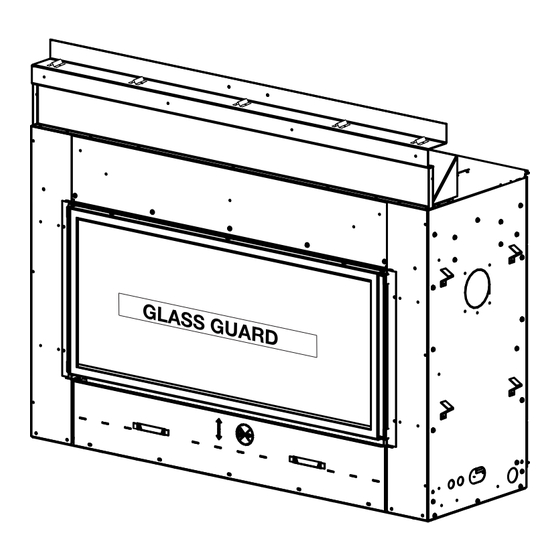

Page 12: Single-Sided

dimensions 2.0 dimensions single-sided Base of air collar 41 3/16" 1046mm 32 3/4" 39 11/16" 18 5/8" GLASS GUARD 832mm 1008mm 473mm 8 1/16" 7 1/16" 205mm 179mm 3 1/8" 80mm 17 3/16" 1/2" 437mm [12.7mm] Ø 8" 203mm Ø 5" 127mm 8 1/16"... -

Page 13: See-Thru

dimensions see-thru Base of air collar 41 3/16" 1046mm 39 11/16" 1008mm 32 3/4" 18 5/8" GLASS GUARD 832mm 473mm 8 1/16" 7 1/16" 205mm 179mm 3 1/8" 80mm 16 3/16" 1/2" 411mm Ø 8" 1/2" [12.7mm] [12.7mm] 203mm Ø 5" 127mm 8 1/16"... - Page 14 3.0 minimum venting requirements minimum venting requirements WARNING • Risk of fi re. Maintain specifi ed air space clearances to vent pipe and appliance. • If venting is included with spacers, the vent system must be supported every 3’(0.9m) for both vertical and horizontal runs.

-

Page 15: Minimum Venting Requirements

minimum venting requirements Use only Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent or Metal-Fab venting components. Minimum and maximum vent lengths, for both horizontal and vertical installations, clearances from vent pipes to combustibles and air terminal locations as set out in this manual apply to all vent systems and must be adhered to. -

Page 16: Typical Venting Installation

minimum venting requirements typical venting installation 18" (45.7cm) maximum LVX38 & LVX50: 62 3/4” (76.2cm) 30” LVX38 & LVX50: 30” (76.2cm) min min plus rise (76.2cm) LVX62 & LVX74: 48” (121.9cm) min LVX62 & LVX74: 80 3/4” (205.1cm) minimum min plus rise base of base of 62 3/4"... - Page 17 minimum venting requirements SINGLE-SIDED OR SEE-THRU 16" (40.6cm) minimum 40 ft (12m) maximum 6 ft (1m) minimum base of air collar W415-1710 / A / 07.27.17...

-

Page 18: Minimum Air Terminal Location Clearances

minimum venting requirements minimum air terminal location clearances Covered balcony applications ††* = 3 feet ≤ 15 feet = 2 x ACTUAL (0.9m) (4.6m) INSTALLATIONS CANADA U.S.A. 12” (30.5cm) 12” (30.5cm) Clearance above grade, veranda porch, deck or balcony. 12” (30.5cm) 9”... -

Page 19: Horizontal Termination

minimum venting requirements horizontal termination LVX38 / LVX50 / LVX62 / LVX74 SINGLE-SIDED & LVX38 / LVX50 SEE-THRU 40’ V+H ≤ 40 ft. (For longer vent runs, a power 38 1/2’ vent is required). (462”) H ≤ 20 ft. V + H are measured from the centre of vent elbows. - Page 20 minimum venting requirements LVX62/ LVX74 SEE-THRU 40’ V+H ≤ 40 ft. (For longer vent runs, a power vent is required). 38 1/2’ (462”) H ≤ 20 ft. V + H are measured from the centre of vent elbows. Elbows are considered as 90º. Two 45º...

- Page 21 minimum venting requirements 40’ V = V = 8 ft H = H = 10 ft 30’ 90° 20’ 90° 1-3 elbow zone 15’ Base of air collar 10’ 5’ 0’ 20’ 5’ 10’ 15’ Base of air collar 0’ V and H are measured from the center of the vent elbows This example represents a vent that has a maximum of three 90º...

-

Page 22: Vertical Termination

minimum venting requirements vertical termination ALL APPLIANCES V+H ≤ 40 ft. (For longer vent runs, 40’ a power vent is required). H ≤ 20 ft. V + H are measured from the 0 elbow zone centre of vent elbows. Elbows are considered as 90º. - Page 23 installation planning 4.0 installation planning WARNING • Do NOT cover or place any items in the Dynamic Heat Control™ air outlet. Failure to comply with these instructions will create a fire hazard. ir flow within the air passage is not restricted in any way with the exception of approved venting. •...

-

Page 24: Installation Planning

installation planning installation option 1 - open enclosure (enclosure stops short of the ceiling) NOT Suitable for Dynamic Heat Control™ Plus It is one option not to finish or close in the top of the enclosure to provide the necessary air circulation path for the Dynamic Heat Control™... -

Page 25: Installation Option 2 - Front Opening

installation planning installation option 2 - front opening Suitable for Dynamic Heat Control™ Plus Minimum air outlet opening dimensions must be followed. The opening is required to be framed no more than 1.5” below the enclosure top (see option 2 diagram) to avoid trapping heat in the upper areas and the air outlet opening centered on the appliance center. -

Page 26: Installation Option 3 - Rear Opening

installation planning installation option 3 - Rear Opening Suitable for Dynamic Heat Control™ Plus Minimum air outlet opening dimension must be followed. The opening is required to be framed no more than 1.5” below the enclosure top (see option 3 diagram) to avoid trapping heat in the upper areas and centered on the appliance center. Framing the rear opening lower will overheat the appliance, the enclosure, and finishing material. -

Page 27: Installation Option 4 - Open Enclosure With Hard Combustible Valance

installation planning installation option 4 - open enclosure with hard combustible valance NOT Suitable for Dynamic Heat Control™ Plus is similar to option 1 with the addition of a hard combustible valance. Minimum opening dimensions and valance dimensions must be followed (See option 4 diagram). Restricting air movement within the valance area will overheat the appliance, the enclosure, and finishing material. -

Page 28: Rough Framing - Before Appliance Installation

rough framing - before appliance installation 5.0 rough framing - before appliance installation note: When using optional finishing accessories, the framing dimensions and finishing materials may differ from what is outlined in the section below; refer to the leaflet instructions supplied in the accessory kit for specific framing and finishing specifications. WARNING •... -

Page 29: Minimum Clearance To Combustible Enclosures

rough framing - before appliance installation 5.1.1 minimum clearance to combustible enclosures single-sided 1” [25mm] minimum to sides for vertical venting. 6” [152mm] minimum When passing through a ceiling, use firestop spacer W500-0028 3” [76mm] to top (not supplied) 2” [51mm] to sides / bottom When passing through a wall, use firestop... - Page 30 rough framing - before appliance installation see-thru 1” [25mm] minimum to sides for vertical venting. 6” [152mm] minimum When passing 3” [76mm] to top through a ceiling, use 2” [51mm] to sides / firestop spacer bottom W500-0028 (not When passing through supplied) a wall, use firestop spacer assembly...

- Page 31 rough framing - before appliance installation Before framing your appliance, determine vent requirements before deciding the final location of the appliance. After rough framing, place the appliance in its final position. single-sided Before framing the appliance, ensure to install the firestop first as it will not fit between the studs if installed after framing.

-

Page 32: Venting Installation

6.0 venting installation venting installation WARNING • Ensure to unpack all loose materials from inside the fi rebox prior to connecting the gas and electrical supply • If your appliance is supplied with a remote, ensure the remote receiver is in the “OFF” position prior to connecting the gas and electrical supply to the appliance. - Page 33 venting installation 4. Bend vent sleeve as shown and ensure to clip the ends together (Figure 4). 5. Ensure both ends line up and secure ends with clip and fasteners (Figure 5). Fig. 4 Fig. 5 6. Insert the vent sleeve tabs into the firestop spacer sockets, bend vent sleeve tabs, and secure to the fire- stop spacer with 4 supplied fasteners (Figure 6).

-

Page 34: Venting Installation

venting installation horizontal installation WARNING • The fi restop assembly must be installed with the vent shield to the top. • Terminals must not be recessed into a wall or siding more than the depth of the return fl ange of the mounting plate. -

Page 35: Using Flexible Vent Components

venting installation using flexible vent components WARNING • Do not allow the inner fl ex pipe to bunch up on horizontal or vertical runs and elbows. Keep it pulled tight. • Spacers are attached to the inner fl ex pipe at predetermined intervals to maintain an even air gap to the outer fl ex pipe. -

Page 36: Vertical Air Terminal Installation

venting installation vertical air terminal installation WARNING • Maintain a minimum 2” (51mm) space between the air inlet base and the storm collar. NOTE: Fastening hardware provided with appropriate roof terminal and liner kits. Fasten the roof support to the roof using 6 screws. The roof support is optional. -

Page 37: Vent Shield Installation

venting installation vent shield installation note: The vent shield is telescopic and must be adjusted to shield the first 30” of vertical vent always used. 1. Loosen the fasteners on the vent shield assembly. DO NOT DISCARD FASTENERS (Figure 1). 2. -

Page 38: Electrical Information

venting installation 7.0 electrical information hard wiring connection It is necessary to hard wire this appliance. Permanently framing the appliance with an enclosure, requires the appliance junction box to be hard wired. This appliance must be electrically connected and grounded in accordance with local codes. In the absence of local codes, use the current CSA C22.1 Canadian Electrical Code in Canada or the ANSI/NFPA 70-1996 National Electrical Code in the United States. -

Page 39: Battery Holder/Switch Installation

electrical information battery holder/switch installation Install the battery holder/switch into a standard electrical switch box. Determine an appropriate location and install the electrical box. note: Ensure the 3 position slider switch is in the “REMOTE” position (middle). initializing the battery holder/switch for the first time note: The initializing process must be completed within 10 seconds of pressing the reset / program (PRG). -

Page 40: Wiring Diagram

Napoleon’s eFIRE app controls every function of your fireplace including; on/off, flame height and blower speed. Using the instructions on the eFIRE controller application website http://napoleonfireplaces.com/efire , install the app and enjoy the features the eFIRE Controller app offers. -

Page 41: Lvx38/50 Wiring Diagram

electrical information 7.7.1 LVX38/50 wiring diagram LAMP COMFORT W415-1710 / A / 07.27.17... -

Page 42: Lvx62/74 Wiring Diagram

electrical information 7.7.2 LVX62/74 wiring diagram W415-1710 / A / 07.27.17... -

Page 43: Access Panel

electrical information access panel WARNING • Do not use this appliance if any part has been under water. Call a qualifi ed service technician immediately to have the appliance inspected for damage to the electrical circuit. • Risk of electrical shock or explosion. Do not wire 110V to the valve or to the appliance wall switch. Incorrect wiring will damage controls. -

Page 44: Gas Installation

electrical information 8.0 gas installation WARNING • Risk of fi re, explosion, or asphyxiation. Ensure there are no ignition sources such as sparks or open fl ames. • Support gas control when attaching gas supply pipe to prevent damaging gas line. •... -

Page 45: Operation

electrical information 9.0 operation WARNING • If you do not follow these instructions exactly, a fi re or explosion may result causing property damage, personal injury, or loss of life. • If applicable always light the pilot whether for the fi rst time or if the gas supply has run out with the glass door opened or removed. -

Page 46: Nailing Tab Installation

nailing tab installation 10.0 nailing tab installation ALIGN THE NAILING TAB WITH THE HOLES ON THE REMOVE THE SCREWS FROM THE APPLIANCE. APPLIANCE, SECURE WITH THE SCREWS FROM STEP 1. DO NOT DISCARD. Type 1 (x2) SECURE WITH SCREW SUPPLIED IN THE MANUAL BAGGIE TO THE UPPER FRONT FRAME TO INSTALL NAILING TABS FOR SEE-THRU APPLIANCES, REPEAT STEPS WITH THE OPPOSITE SIDE. - Page 47 11.0 finish framing - after appliance installation finish framing - after appliance installation 11.1 framing with Dynamic Heat Control™ note: Appliances equipped with Dynamic Heat Control™ can be built in with combustible framing and finishing un- less stated. There are various methods to ventilate the enclosure. Refer to “Dynamic Heat Control™ planning” section. The appliance must be installed at this point of framing.

- Page 48 finish framing - after appliance installation single-sided recessed WARNING • Shaded components (finish framing) must be non-combustible materials. Ceiling note: Finish framing must be built after appliance has been placed in its final position and venting con- nected. This configuration also re- quires recess area to use non-combustible facing due to close proximity to vent.

-

Page 49: Finish Framing - After Appliance Installation

finish framing - after appliance installation see-thru flush Ceiling note: Finish framing must be built after appliance has been placed in its final position and venting connected. Although the minimum enclosure height for the LVX series is 73”, some venting configurations Drywall that require more vertical rise will require a larger enclosure to... - Page 50 finish framing - after appliance installation see-thru built out Drywall note: Finish framing must be built Insulation after appliance has been placed in its final position and venting connected. Option 2 illustrated (appliance not shown) minimum framing LVX38 LVX50 LVX62 LVX74 16 3/16”...

-

Page 51: Finishing

12.0 finishing finishing WARNING • Risk of fire! • Never obstruct the front opening of the appliance. • The front of the appliance must be finished with any non-combustible materials such as brick, marble, granite, etc., provided that these materials do not go below the specified dimension, as illustrated. •... -

Page 52: Finishing With Combustibles

finishing 12.2 finishing with combustibles With Dynamic Heat Control™, you can finish the appliance with any combustible materials except ap- pliances with recessed installation. Air outlet opening must be located out of reach of the user. Air outlet opening must not be restricted by furnishings or decor. -

Page 53: Side View

finishing WARNING • Finishing material tight to the frame around the glass barrier frame must not project more than 4” (10cm) from the face of the glass barrier (above the door and sides only). 4" (10cm) Maximum projection (must not encroach on opening) SIDE VIEW 4"... -

Page 54: Minimum Combustible Mantel Clearances

finishing 12.3 minimum combustible mantel clearances WARNING • Risk of fire. Maintain all specified air space clearances to combustibles. Failure to comply with these instructions may cause a fire or cause the appliance to overheat. Ensure all clearances (i.e. back, side, top, vent, mantel, front, etc.) are clearly maintained. -

Page 55: Glass Guard Installation / Removal

finishing 12.4 glass guard installation / removal note: The glass guard assembly (GGA) installation and/or removal will require 2 people. important: The Glass Guard Assembly (GGA) must be fitted before finish framing and finishing the appliance. Unpack the Glass Guard Assembly (GGA) and keep packaging materials to store the GGA after test fitting. Note: The polystyrene may scratch the glass if it is not covered by a plastic bag. - Page 56 finishing Loosen the securing screws of the safety latches, slide it all the way down, and retighten securing screws. NOTE: DO NOT OVERTIGHTEN Fully extend door mounting brackets of appliance. Carefully place GGA onto supports. Heat Rail (with Gasket) Bottom Hook W415-1710 / A / 07.27.17...

- Page 57 finishing Hold the GGA firmly against the mounting surface. The GGA bracket holes should be lined up with the screw holes of the door mounting brackets to ensure a clear line of sight. Raise the vertical adjustment screw approximately 1/8” for best alignment. DO’S clear line of sight...

- Page 58 finishing Secure with two fasteners on each door mounting bracket. Loosen the securing screws of the latch clips, slide them all the way back, and retighten securing screws. W415-1710 / A / 07.27.17...

- Page 59 finishing Slide GGA into the appliance until outer glass panel makes contact with heat rail gasket. The GGA will ‘click’ into safety latches when secure. If GGA does not engage with safety clips, an adjustment may be required. important: Ensure that the heat rail gasket is touching the both ends of the back of the outer glass as shown Heat Rail Gasket Heat Rail...

- Page 60 finishing Check if the outer glass of the GGA is touching the heat rail gasket on both ends. Check for any excessive play by lightly pulling the GGA outwards. The play (rattle / movement) should be negligible in the system when the GGA is held in position by the safety clips. If there is excessive play, the latch clips on the bottom of the GGA should be adjusted to reduce the play to a minimal level.

-

Page 61: Anti Condensation Switch

finishing Remove the screws and washers securing the GGA to the door support brackets (1 per corner). Carefully lift the GGA up and off the door support brackets (2 per side). Set assembly on a clean, soft surface. Care must be taken to protect the edges of glass. - Page 62 finishing Side view Door trim Door frame LVX38 Illustrated For door removal, locate the top and bottom door latches. Pull latches forwards and away to disengage door latches. note: Ensure to leave one hand on the glass door during entire door removal. Tilt the top of the door forwards 90 degrees, then lift it up and out of the door latches.

-

Page 63: Glass Media Installation / Removal

finishing 12.7 glass media installation / removal WARNING • Clean the glass media prior to installation. Before applying the cleaned glass, ensure that it is dry. • If replacing, use only the replacement glass media available from your local authorized dealer / distributor. •... -

Page 64: Adjustments

finishing 13.0 adjustments 13.1 restricting vertical vents Vertical installations may display a very active flame. If this appearance is not desirable, the vent exit in the appliance must be restricted using a restrictor vent kit. Refer to the “replacements” section of the owner’s manual for the appropriate kit. -

Page 65: Pilot Burner Adjustment

finishing 13.3 pilot burner adjustment Adjust the pilot screw to provide properly sized fl ame. Turn in a clockwise direction to reduce the gas fl ow. Check Pressure Readings: Inlet pressure can be checked by turning screw (A) counter- ODS - MILLIVOLT clockwise 2 or 3 turns and then placing pressure gauge tubing over the test point. -

Page 66: Maintenance

maintenance 14.0 maintenance WARNING • Turn off the gas and electrical power before servicing the appliance. • Appliance may be hot. Do not service until appliance has cooled. • Do not use abrasive cleaners on glass. • Do not paint the pilot assembly. This appliance and its venting system should be inspected before use and at least annually by a qualifi ed service person. -

Page 67: Annual Maintenance

maintenance 14.1 annual maintenance WARNING • Annual maintenance should be performed by a qualifi ed service technician • The fi rebox becomes very hot during operation. Let the appliance cool completely or wear heat resistant gloves before conducting service. • Never vacuum hot embers. -

Page 68: Burner Removal

maintenance 14.3 burner removal Remove the safety screen and glass door, refer to the “Glass Guard installation/removal” & Door installation/removal” sections for details. Remove the control cover from the appliance by sliding it up and out of the clips of the front cover. Remove the media from the appliance. -

Page 69: Control Module Removal

maintenance Disconnect the flex connector from the valve. Remove the valve wire connections, labeling each one to aid with re-connection. Remove the screws from the valve bracket and remove the valve. Replace all components before returning the appliance to service. Check for gas leaks by brushing on a soap and water solution. -

Page 70: Led Replacement

maintenance 14.6 LED replacement This appliance comes equipped with an LED strip. If in the event the LED strip needs to be replaced, follow these instructions. Turn off all electrical supply. Remove the safety screen and glass door, refer to the “Glass Guard installation/removal” & Door installation/removal”... -

Page 71: Glass / Door Replacement

maintenance 14.7 glass / door replacement WARNING • Do not use substitute materials. • Glass may be hot. Do not touch glass until cooled. • Care must be taken when removing and disposing of any broken door glass or damaged components. Be sure to vacuum up any broken glass from inside appliance before operation. -

Page 72: Replacements

replacements 15.0 replacements WARNING • Failure to position the parts in accordance with this manual or failure to use only parts specifi cally approved with this appliance may result in property damage or personal injury. Contact your dealer for questions concerning prices and policies on replacement parts. Normally, all parts can be ordered through your Authorized dealer / distributor. -

Page 73: Overview

W010-1426 W010-1426 W010-1426 W010-1426 Door Latch Assembly W010-3554 W010-3554 W010-3554 W010-3554 High Limit Switch W660-0204 W660-0204 W660-0204 W660-0204 Napoleon Logo W385-2010 W385-2010 W385-2010 W385-2010 Heat Rail (w/ gasket) W010-4257-SER W010-4258-SER W010-4259-SER W010-4260-SER *Part not illustrated W415-1710 / A / 07.27.17... -

Page 74: Burner Components

replacements 15.2 burner components Items may not appear exactly as illustrated W415-1710 / A / 07.27.17... - Page 75 replacements Ref. Description Part Number Stocked LVX38 LVX50 LVX62 LVX74 Flex Connector (c/w Shut-Off) W175-0217 W175-0217 W175-0217 W175-0217 Valve (NG) W725-0056 W725-0056 W725-0056 W725-0056 Valve (P) W725-0057 W725-0057 W725-0057 Control Board W190-0124 W190-0124 W190-0124 W190-0124 Control Board Wiring Harness W750-0276 W750-0276 W750-0276 W750-0276...

-

Page 76: Troubleshooting

16.0 troubleshooting troubleshooting WARNING • Always light the pilot whether for the fi rst time or if the gas supply has run out, with the glass door open or removed. • Turn off gas and electrical power before servicing the appliance. •... - Page 77 troubleshooting symptom problem test solution Pilot will not light. Makes Wiring: short, loose, or damaged Verify the thermocouple/sensor is clean and the wiring is undamaged. Verify the interrupter block is not damaged or too tight. Verify noise with no spark at connections connections from pilot assembly are tight;...

- Page 78 Remote too far away from receiver. Refer to “WIRING DIAGRAM“ section. Wire connector pins are bent. Straighten pins. troubleshooting Valve wiring is damaged. Replace valve. symptom problem test solution Motor is turning, Receiver batteries low. Replace batteries. frequent beeping occurs. Lights or blower Control module switch in Verify ON/OFF switch is in the “I”...

-

Page 79: Notes

troubleshooting 17.0 notes 29.1 W415-1710 / A / 07.27.17... - Page 80 NAPOLEON CELEBRATING OVER 40 YEARS OF HOME COMFORT PRODUCTS 7200, Route Transcanadienne, Montréal, Québec H4T 1A3 24 Napoleon Road, Barrie, Ontario, Canada L4M 0G8 214 Bayview Drive, Barrie, Ontario, Canada L4N 4Y8 103 Miller Drive, Crittenden, Kentucky, USA 41030 Phone: 1-866-820-8686...

Need help?

Do you have a question about the LVX38N and is the answer not in the manual?

Questions and answers