Table of Contents

Advertisement

Quick Links

Installation INSTRUCTIONS FOR REPLACEMENT DEFROST CONTROL KIT (84W88)

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause personal injury, loss of life, or

damage to property.

Installation and service must be performed by a licensed

professional installer (or equivalent) or a service agency.

WARNING

Electric Shock Hazard. Can cause injury

or death. Unit must be grounded in

accordance with national and local

codes.

Line voltage is present at all components

when unit is not in operation on units with

single‐pole contactors. Disconnect all

remote electric power supplies before

opening access panel. Unit may have

multiple power supplies.

Shipping and Packing List

Package 1 of 1 contains:

4 - 1/4" quick connect terminals

2 - Black wire

1 - Wire (1 foot in length)

1 - Defrost control replacement - information sticker

(401843S)

Application

Replacement defrost control kit (84W88) includes defrost

control 100269. This defrost control may be used in

various heat pump units to replace any defrost control

listed in table 1. The 100269 includes features which may

not be found in all of the existing controls. If the unit was

originally equipped with any defrost control other than a

100269 series, operation should be reviewed at the time of

replacement. Features of 100269 defrost control include:

•

Five-minute compressor anti-short cycle delay;

•

Pressure switch lockout circuit;

•

Loss of charge / low pressure switch circuit;

•

Field-selectable compressor delay

•

Field connection terminals for service light.

HEAT PUMP UNITS

KITS AND ACCESSORIES

504,587M

3/2014

Supersedes1/2013

USED WITH VARIOUS HEAT PUMPS

Page 1

REPLACEMENT DEFROST

Table 1. Applicable Defrost Controls

Original Defrost Control

100269-01, -02 and -04

29M0101

29M0201

56M3701

68J2901

68J8401

Defrost System

The defrost system includes a defrost thermostat and a

defrost control.

DEFROST THERMOSTAT

The defrost thermostat is located on the liquid line between

the check/expansion valve and the distributor. When the

defrost thermostat senses 42°F (5.5°C) or cooler, its

contacts close and send a signal to the defrost control to

start the defrost timing. It also terminates defrost when the

liquid line warms up to 70°F (21°C).

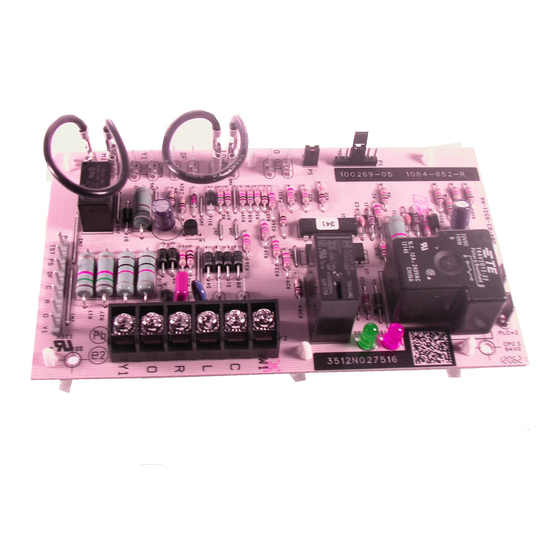

DEFROST CONTROL (CMC1)

The defrost control includes the combined functions of a

time/temperature defrost control, defrost relay, time delay,

Diagnostic Leds, and a terminal strip for field wiring

connections.

The control provides automatic switching from normal

heating operation to defrost mode and back. During

compressor cycle (defrost thermostat is closed, calling for

defrost), the control accumulates compressor run times at

30, 60, or 90 minute field adjustable intervals. If the defrost

thermostat is closed when the selected compressor run

time interval ends, the defrost relay is energized and

defrost begins.

Defrost Control Timing Pins (P1)

Each timing pin selection provides a different

accumulated compressor run time period for one defrost

cycle. This time period must occur before a defrost cycle

is initiated. The defrost interval can be adjusted to 30

(T1), 60 (T2), or 90 (T3) minutes (see figure 1). The

maximum defrost period is 14 minutes and cannot be

adjusted. Factory default is 90 minutes

If the timing selector jumper is missing, the defrost

control defaults to a 90-minute defrost interval.

Litho U.S.A.

CONTROL

Replacement Defrost Control

100269-05

Advertisement

Table of Contents

Summary of Contents for Lennox 84W88

- Page 1 KITS AND ACCESSORIES Litho U.S.A. REPLACEMENT DEFROST 504,587M 3/2014 CONTROL Supersedes1/2013 INSTALLATION INSTRUCTIONS FOR REPLACEMENT DEFROST CONTROL KIT (84W88) USED WITH VARIOUS HEAT PUMPS Table 1. Applicable Defrost Controls WARNING Original Defrost Control Replacement Defrost Control Improper installation, adjustment, alteration, service or...

- Page 2 FIELD SELECT TIMING PINS TEST PINS DIAGNOSTIC LEDS COMPRESSOR DELAY PINS REVERSING VALVE SERVICE LIGHT CONNECTIONS LOW PRESSURE SWITCH 24V TERMINAL STRIP CONNECTIONS DEFROST THERMOSTAT HIGH PRESSURE SWITCH Figure 1. Defrost Control (100269-05) Bypass-Anti-Short Cycle Delay Test Mode The TEST mode is activated by removing the jumper on The Y1 input must be active ON, the high pressure switch the defrost termination pins (30, 60 or 90) and placing the must be closed or a jumper must be installed on the high...

- Page 3 Test Mode Sequence switches heat/cool modes. If the TEST pins are jumpered and the 5-minute delay is being bypassed, Using the defrost termination pin, short the TEST pins for the LO PS terminal signal is not ignored during the a period of two seconds: 90-second start-up period.

- Page 4 Figure 2. Typical Unit Wiring Diagrams - Defrost Control with C, L and Y1 Terminals) Page 4...

- Page 5 Figure 3. Typical Unit Wiring Diagrams - Defrost Controls with W1, C, L and T, T terminals) Figure 4. Earlier Model Defrost Control Terminal Designations for Service Light and Ambient Thermistor Connections Page 5...

- Page 6 Figure 5. Wiring Ambient Compensator (RT3) and Service Light and Service Light Thermostat (S54) to New Defrost Control Page 6...

- Page 7 Figure 6. Wiring Ambient Compensator (RT3) and Service Light and Service Light Thermostat (S54) to New Defrost Control Page 7...

- Page 8 Figure 7. Connector Descriptions 4. Position replacement defrost control properly over Installation mounting holes in unit and snap stand-offs into place. 5. Reconnect labeled wires to the proper terminals on the CAUTION replacement defrost control. Refer to figure 1 for pressure switch wiring and terminal identification.

Need help?

Do you have a question about the 84W88 and is the answer not in the manual?

Questions and answers