Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Gree HNTF24/A-D

- Page 1 Condensing Unit Service Manual T1/R410A/60Hz (GC201408- І )

-

Page 2: Table Of Contents

CONTENTS PRODUCT ..................... 2 1 MODELS LIST ......................2 1.1 Indoor Unit ............................2 2 NOMENCLATURE ..................... 2 2.1 Indoor unit .............................2 3 FUNCTION ........................ 3 4 PRODUCT DATA ....................... 4 4.1 Product Data at Rated Condition ....................4 4.2 Operation Range ...........................4 4.3 Electrical Data ..........................5 CONTROL ...................... - Page 3 Condensing Unit Service Manual PRODUCT PRODUCT...

-

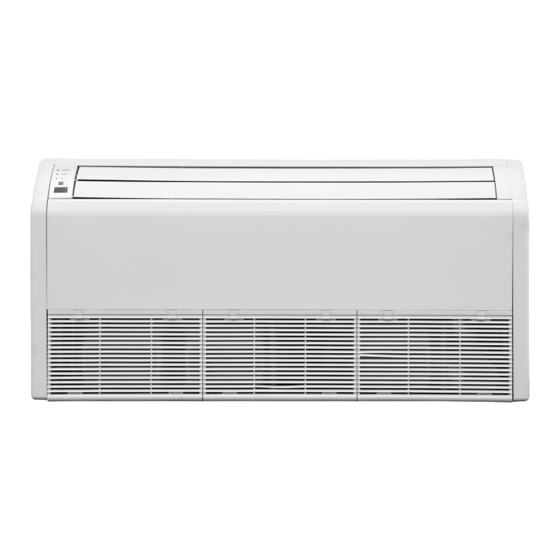

Page 4: Product

Model Nominal Capacity Power Supply Refrigerant Appearance Model Name Product Code Cooling(T on) Heating(T on) V, Ph, Hz HNTF24/A-D EM116N0760 HNTF36/A-D EM116N0780 220V-230v R410a 1PH 60HZ HNTF48/A-D EM116N0800 HNTF60/A-D EM116N0820 Note:1 Ton =12000Btu/h = 3.517kW 2 NOMENCLATURE 2.1 Indoor unit... -

Page 5: Function

Condensing Unit Service Manual 3 FUNCTION Function Description when unit restart after power off, it will run on former status, Memory function the mode and parameter are kept the same wireless controller and remote controller can be opted, and the Remote control function maximum control distance of remote controller is 10m. -

Page 6: Product Data

Condensing Unit Service Manual 4 PRODUCT DATA 4.1 Product Data at Rated Condition HNTF24/A-D HNTF36/A-D HNTF48/A-D HNTF60/A-D Product Code EM116N0760 EM116N0780 EM116N0800 EM116N0820 Blower Diameter(inch) Width(inch) Coil Drain Connection FPT(inch) Liquid(inch) Suction(inch) Electrical Data Voltage(V) 220-230 220-230 220-230 220-230 Min Circuit Ampacity (A) Max .Overcurrent... -

Page 7: Electrical Data

Condensing Unit Service Manual 4.3 Electrical Data Indoor unit Fuse/Breaker Min. Power Power Supply Fan Motor FLA Capacity Supply Cord V/Ph/Hz HNTF24/A-D 220-230,1,60 0.65 HNTF36/A-D 220-230,1,60 0.65 HNTF48/A-D 220-230,1,60 HNTF60/A-D 220-230,1,60 Notes: RLA:Rated load amperes LRA:Locked rotor amperes FLA:Full load current a. - Page 8 Condensing Unit Service Manual CONTROL CONTROL...

-

Page 9: Control

Condensing Unit Service Manual CONTROL 1 OPERATION FLOWCHART 1.1 Cooling/Dry Operation Power on Uint start and running at cool or dry mode Indoor fan run Satisfying start Comp.conditon Comp.and outdoor fan run Comp.and outdoor fan stop Comp.stop for 3 min CONTROL... -

Page 10: Main Logic

Condensing Unit Service Manual 2 MAIN LOGIC 2.1 Cooling Mode (for Cooling Only and Heat Pump) The temperature of condensing unit is set at the wired controller equipped by users When the control-board of the outdoor unit detects the ON signal from wired controller, it will enter cooling ON sub mode, and compressor, outdoor fan will start running synchronously. -

Page 11: Dry Mode

Condensing Unit Service Manual Cooling OFF Sub Mode Flowchart: OFF signal is sent out from wired controller Object Compressor Outdoor fan Time 2.2 Dry Mode Dry mode operation is as follows: Control Object ON(24V) ON(24V)O N(24V) Compressor Control Wire OFF(OV) OFF(OV) ON(24V) 4-way valve Wire (O) -

Page 12: Wireless Remote Controller

Condensing Unit Service Manual 3.1 wireless remote controller 3.1.1 User notice CAUTION ! ① .Be sure that there are no obstructions between receiver and wireless remote controller. ② .Don't drop or throw the wireless remote controller. ③ .Don't let any liquid in the wireless remote controller and put the wireless remote controller directly under the sunlight or any place where is very hot. - Page 13 Condensing Unit Service Manual Name Function Description Signal transmitter ● Signal transmitter ● Press this button, the unit will be started or stopped, which can clear the timer or sleeping ON/OFF button function of last time. ● Press this button, the running mode will change as below: MODE button AUTO ;...

- Page 14 Condensing Unit Service Manual ● Pressing X -FAN button in COOL or DRY mode, the icon "X-FAN" is displayed and the indoor fan will continue operation for 10 minutes in order to dry the indoor unit even X-FAN button though you have turned off the unit. After energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO,FAN and HEAT mode.

- Page 15 Condensing Unit Service Manual be off directly. About AUTO RUN When AUTO RUN mode is selected, the setting temperature will not be displayed on the LCD, the unit will be in accordance with the room temp. automatically to select the suitable running method and to make ambient comfortable.

-

Page 16: Wired Controller (Chosen Accessory Part)

Condensing Unit Service Manual When the wireless remote controller sends out signal, a mark will flicker for about 1s. The bell will ring if the main unit receives effective signal. 3.2 Wired Controller (Chosen Accessory Part) 3.2.1 Display View Fig.3.2.1 Outline of wired controller 3.2.2 Operation View Fig.3.2.2 Instruction to Function of Buttons Description... - Page 17 Condensing Unit Service Manual Timer Timer setting On/off Turn on/off indoor unit Press Mode and ▲for 5s under off state of the unit to enter/cancel key memory 4 Mode function (If memory is set, indoor unit will resume original setting state after Memory function power failure and then power recovery.

- Page 18 Condensing Unit Service Manual Dry mode Fan mode Heating Heating mode Defrost Defrosting state Gate-control Gate control card Lock Lock state Shielding state (buttons, temperature, on/off, mode or save is shielded by long-distance Shield monitoring Turbo Turbo function state Memory state (Indoor unit resumes original setting state after power failure and then Memory power recovery) Twinkle...

- Page 19 Condensing Unit Service Manual 3.2.5 Installation Fig.3.2.5 Sketch for Installation of Wired Controller Socket’s base Soleplate of Front panel of Description box installed in Screw M4×25 Screw ST 2.9×6 controller controller the wall (1). Cut off power supply of heavy-current wire embedded in mounting hole in the wall before installation. It is prohibited to perform the whole procedure with electricity.

- Page 20 Condensing Unit Service Manual INSTALLATION...

-

Page 21: Installation

Condensing Unit Service Manual INSTALLATION 1 INDOOR UNIT INSTALLATION 1.1 Installation of Ceiling Type 1.1.1 Before Installation When the unit arrives, please check if any damage due to transport is existent. If any hurt is found on the surface or inside, please declare to the transport company or the manufacturer in writing. When the unit arrives, please check if any damage due to transport is existent. - Page 22 Condensing Unit Service Manual Figure 1-2-3 Hanger bracket Figure 1-2-4 In case of hanging: It is possible to install using inward facing hanger bracket by not removing the brackets from the indoor unit. (Refer to Figure 1-2-6) Be sure to use only the specified accessories and parts for installation work. Figure 1-2-5 Figure 1-2-6 1.1.4 Dimension Data...

- Page 23 Condensing Unit Service Manual Table 6 Unit: mm Model HNTF24/A-D 1220 1158 HNTF36/A-D HNTF48/A-D 1420 1354 HNTF60/A-D 1.1.5 Installation Clearance Data 150cm or m ore 60cm or m ore 60cm or m ore 100cm or m ore 30cm or m ore Figure 1-2-8 1.1.6 Drain Piping Work...

-

Page 24: Refrigeration Piping Work

Condensing Unit Service Manual (2). Testing of Drainage System After the electrical installation is completed, carry out the testing of the drainage system. During the test, check if the water correctly flows through the pipelines. Carefully observe the joints to ensure that there is no leakage. - Page 25 Condensing Unit Service Manual Clean Air tight Make syre there is no Make sure there is no Make sure the refrigerant moisture inside the pipes dirt inside the pipe does not leak out Moisture Leak Dirt (V0965) (V1148) (V1149) Figure 3-1-1 Align copper pipe flare with the center of screwed connector and tighten fully the nut of the flare by hand.

- Page 26 Condensing Unit Service Manual Recommended methed Solder Bume Side facing Downward facing Upward facing Figure 3-1-3 Uninsulated connecting pipes and connectors should be packed with sponge and tied with plastic adhesive tapes. (2). Vacuum-pumping and leak detection Dismantle the bonnet of refrigerant valve and air valve. Align with the center of piping and adequately tighten nuts of connecting pipes by hand Tighten the nuts with a spanner.

- Page 27 Condensing Unit Service Manual Pressure Gage Pressure Gage “HI” Knob “LO” Knob Liquid Valve Vacuum Pump Gas Valve Connecting Hose Figure 3-1-5 Starting the vacuum pump, when the indicator turns to-1 bar, closing the low pressure handle and stopping vacuumize.

-

Page 28: Caution In Connecting Pipes

Height between of Connection Pipe of Refrigerant Mode Outdoor and Indoor Unit Gas Pipe Liquid Pipe HNTF24/A-D HNTF36/A-D HNTF48/A-D HNTF60/A-D 4 ELECTRIC WIRING WORK 4.1 Wiring Principle 4.1.1General Perform wiring of the power supply in conformance with the regulations of the local electric company. - Page 29 Condensing Unit Service Manual damaged, it should be replaced by the exclusive cable. All electric installation must be done by professional personnel according to local law, regulation and this manual. It should be reliably earthed, and it should be connected to the special earth device, the installation work should be operated by the professional.

-

Page 30: Wiring Diadram

Do not let any cable contact the refrigerant pipe, the compressor and moving parts such as fan. Do not change the internal line connections inside the air-conditioning unit. The manufacturer shall not be liable for any loss or abnormal operation arising from wrong line connections. 4.2 WIRING DIADRAM (1). Model: HNTF24/A-D, HNTF36/A-D, HNTF48/A-D, HNTF60/A-D... -

Page 31: Electric Wiring Design

Condensing Unit Service Manual 4.3 Electric Wiring Design Model: HW24Na/A-D + HNTF24/A-D, HW36Na/A-D + HNTF36/A-D; POWER 220/230V 60HZ POWER 220/230V 60HZ Outdoor Unit Indoor Unit Model:HW48Na/A-D+HNTF48/A-D; HW60Na/A-D+ HNTF60/A-D; POWER 220/230V 60HZ POWER 220/230V 60HZ Outdoor Unit Indoor Unit... - Page 32 Condensing Unit Service Manual MAINTENANCE...

-

Page 33: Maintenance

Condensing Unit Service Manual MAINTENANCE 1TROUBLE TABLE(Only for floor ceiling) Fault code Fault Fault code Fault Indoor Frost- Failure of Indoor Room Proof Protection Sensor at Air Intake Communications Failure Failure of Evaporator Temp. Sensor Failure of Auxiliary Failure of Indoor Room Heater Sensor at Wire Controller 2 FLOW CHART OF TROUBLESHOOTING... -

Page 34: The Unit Can Not Start Up For Cooling

Condensing Unit Service Manual 2.2 The unit can not start up for cooling The unit can not start up for coolin g Power supply is normal, Resume power suppl y,replace fuse is not burned out and fuse or re-conn ect circuit circuit does not break Power switch is switched Repair or replace power switch... -

Page 35: Poor Cooling Effect

Condensing Unit Service Manual 2.3 Poor cooling effect Poor cooling effect Installation location Eliminate affected factors or of unit conforms to requirements or there isn’t any factor around the unit which re-select installation location of unit affects heat dispersion of unit Condenser isn’t Clear sundries blocked by sundries... -

Page 36: Noise Or Abnormal Vibration Of Unit

Condensing Unit Service Manual 2.4 Noise or abnormal vibration of unit The unit can not start up for cooling Re-install unit or eliminate Installation of unit or pedestal meet requirements affected factors Fixation of compressor’s Adjust tightness of compressor holding bolt is all right, and there is no strenuous vibration of compressor Fixation of fan bracket is all right, motor is tight ened, and there is no strenuou s... -

Page 37: Disassembly And Assembly Procedure Of Main Parts

4 DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS Model: HNTF24/A-D, HNTF36/A-D, HNTF48/A-D, HNTF60/A-D Disassembly of panel grating module Remark: Make sure that the power supply is cut off before disassembling and protect all the parts during disassembly. Do not put filter screen near the high temperature heat source. - Page 38 Condensing Unit Service Manual Disassemble of water-containing plate modules Remark: Make sure the power supply is cut off before disassembling and protect all the parts during disassembly. Step Illustration Handling Instruction Disassemble of water- ●Remove the water-containing plate modules. containing plate modules Disassembly of evaporator components Remark: Make sure that the power supply is cut off and protect the copper tube and aluminum fin.

- Page 39 Condensing Unit Service Manual ●Loosen the 2 screws of the motor attaching clamp, remove the motor attaching clamp and 4. Disassembly of motor motor attaching clamp subassembly to remove the motor. Disassembly of right and left fixing plates Remark: Make sure that the power supply is cut off before disassembling and protect all the parts during disassembly. Step Illustration Handling Instruction...

-

Page 40: Exploded Views And Part List

Condensing Unit Service Manual 5 EXPLODED VIEWS AND PART LIST (1). Model: HNTF24/A-D, HNTF36/A-D Exploded Views... - Page 41 Condensing Unit Service Manual HNTF24/A-D, HNTF36/A-D Spare Parts List Description Product Code Top Cover Board Sub-Assy '01269409 Water Tray Assy '01289404 Filter Sub-Assy '07210028 Connected Board (Evaporator) '01349421 Evaporator Assy '01022200017 Temperature Sensor '3900020723 Room Sensor '39000191 Remote Controller '305100611...

- Page 42 Condensing Unit Service Manual O-Gasket of Bearing '76512404 Centrifugal Fan '10425200 Front Volute Casing '26905205 Rear Connection board '01349422 Bar Clasp Sub-Assy '70818000001 Fan Motor '15709409 Joint Slack '73018731 Drainage Pipe Sub-Assy '05235434 Rear Volute Casing '26905206 Filter Sub-Assy '11729402 Front Grill Sub-Assy '01579403 Note: Above data is subject to change without notice, pls reference the SP in global service website.

- Page 43 Condensing Unit Service Manual (2). Model: HNTF48/A-D, HNTF60/A-D Exploded Views HNTF48/A-D, HNTF60/A-D Spare Parts List Description Product Code Top Cover '01269404P Water Tray Assy '01289405 Air Louver '26909418 Connected Board (Evaporator) '01349413 Filter Sub-Assy '07210029 Throttle Valve Sub-assy '07332200032 Evaporator Assy '01022200026 Room Sensor '39000191...

- Page 44 Condensing Unit Service Manual Connection Board '02229406 Right Foam Assy '12509425 Axile Bush '10542704 Plate Board of Water '26909442 Releasing Flume Water Releasing Flume '26909441 Rotating Shaft '26909413 Guide Louver '26909432 Front Connection Board '01349408P Front Connection '12509424 Board Foam Assy Membrane '63079403 Fixed Mount...

- Page 45 JF00302341...

Need help?

Do you have a question about the HNTF24/A-D and is the answer not in the manual?

Questions and answers