Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for SENKO SP12C7

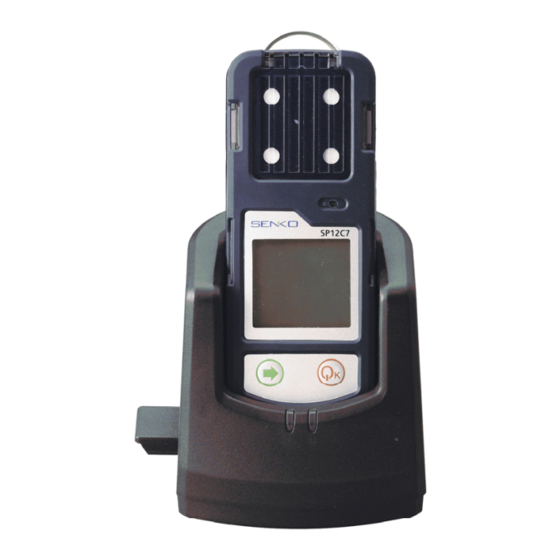

- Page 1 MODEL: SP12C7 (Portable 4 gas detector) Operating Manual...

- Page 2 Senko’s authorized aftercare center. Introduction SP12C7 is 4 Gases Alarm Detector that is required to protect users’ safety at dangerous work environments where an explosion accident can occur. The apparatus can indicate simultaneously the concentration of 4 gases (Oxygen, Inflammable Gas, Carbon Monoxide and Hydrogen Sulfide) on a digital LCD monitor, and the methods of operation and calibration are easy and convenient.

-

Page 3: Table Of Contents

Contents of Operating Manual Product Specification ---------------------------------- 3 Names and Functions of Exterior --------------------- 4 Start of Operation -------------------------------------- 5 Operation Method ------------------------------------- 6 Calibration ---------------------------------------------- 7 Method of Alarm Set and Display ------------------- 10 Applicable Battery and External Pump ------------- 15 Battery &... -

Page 4: Product Specification

Product Specification Product Specification MODEL SP12C7 Detecting Gas 0~500ppm 0~100ppm Detecting Range 0~30% 0~100%LEL 0~1,000ppm 0~200ppm Sensor Type Galvanic Electrochemical Electrochemical Catalytic Sampling Method Diffusion Display Digital LCD Audible Alarm 90dB Visual Alarm Visual Alarm Red LED & White back light Red LED &... -

Page 5: Names And Functions Of Exterior

Names and Functions of Exterior 1. Gas sensor 6. Alarm LED 2. Buzzer 7. Fastening clip 3. LCD display 8. Type label 4. On/Off Key 9. Charging contacts 10. Battery pack LCD display symbols... -

Page 6: Start Of Operation

Start of Operation Instrument Power-On Instrument Power-On Press Power key for 3 seconds, and power is turned on displaying 3, 2, and 1 in order on the monitor. (Power won’t turned on, if pressing the Power key is stopped before 3 seconds) Afterwards during the instrument is being stabilized, it displays consecutively A1 &... -

Page 7: Operation Method

Operation Method Detection Mode The instrument is converted to Gas Measure Mode as below, when power is turned on. Gas Measure Mode indicates the concentration of gas and the remained capacity of battery on LCD, and it displays the gas concentration of Oxygen by %, Inflammable Gas by %LEL, H2S and CO t ti b % I fl... -

Page 8: Calibration

Calibration Calibration Caution: Senko Co., Ltd. performs the initial calibration before the shipment. Incorrectly calibrated value can reduce the accuracy of the product, as the calibrated value is stored in the instrument. Calibration is in general to be performed monthly or quarterly, and can be adjusted according to frequency of the use. - Page 9 Caution: Fresh Gas Calibration should be performed at the environment of fresh air without any influence of other gases since the calibration is performed on the assumption that the influence of other gases, since the calibration is performed on the assumption that the concentration of Oxygen is 20.9%, that of Inflammable Gas is 0%LEL, and the concentration of Toxic Gas is 0ppm in the fresh air.

- Page 10 Method of Calibration The method of Standard Gas is as below. The program enters to %LEL Calibration Mode blinking the numbers, when Power key is pressed at %LEL Standard Gas Calibration Mode. In case that the inflammable gas that conforms to %LEL concentration input initially at the instrument is used, calibration is executed indicating the concentration value connected at the moment by pressing Power key twice.

-

Page 11: Method Of Alarm Set And Display

When STEL / TWA alarm occurs, the icon can be deleted only by Power Off. Note: It is available to set the different alarm sound of each gas respectively by requirement of the user. Please consult Senko Co., Ltd. for further detailed information. - Page 12 Primary battery alarm sounds repeatedly at 5 minute intervals when only a bar of battery icon is remained. Secondary battery alarm starts right before the end of power, and the power source finishes after 10 seconds from the outbreak of alarm. In the event of failure of test or calibration, the icon of Test Failure is displayed with the sound of alarm.

- Page 13 Alarm Set of Each Gas Alarm Set of Each Gas A1 icon blinks by pressing Power key at Lock Blink Mode. And it is converted to %LEL Alarm Value Set Mode by pressing Power key again. After moving to %LEL Alarm Value Set Mode, Alarm Value of %LEL, that has been input initially, blinks.

- Page 14 Password Input Password Input Password input screen appears by pressing Power key for 5 seconds. Number changes from far left to the right side. It moves upward by each 1 step and blinks by pressing Arrow key, and the blinking 2nd number moves the position by pressing Power key. If you press Arrow key, the number moves upward, and the 3rd number blinks and moves the position by pressing Power key After blinks and moves the position by pressing Power key.

- Page 15 Applicable Battery Caution: It is absolutely prohibited to replace battery at potential explosion areas or dangerous regions. And the charger should be always used at the safe place, since it is not an explosion- proof product. - The applicable batteries that are tested and are allowed in Ex zones are as below. - It is a condition of safe use that the instrument should be used only with one of the below applicable batteries.

-

Page 16: Battery & Sensor Replacement

Battery & Sensor replacement When you replace the Battery and sensors of SP12C7, you need some instrument and components as below. - Tool : - Phillips screw driver, Tip size : M2 x 20mm, M2 x 6mm - wrench(hexagon) M3 x 12mm - Battery : Energizer No.E91, EN91 or GP rechargeable Battery GP210AAHCB... -

Page 17: Operation Flow Chart

Operation Flow Chart Calibration & Configuration Flow... -

Page 18: Notice For User

Notice for User Notice for User Please use the instrument in the range of the applicable temperature, humidity and pressure that are appropriate for the specification of the product. Using the instrument beyond this range may cause malfunction or glitch of the instrument. . Gas concentration measurement value by the sensor or the instrument can vary Gas concentration measurement value by the sensor or the instrument can vary according to the environment at site (temperature, pressure and humidity). - Page 19 Notes on Approval(Label) CE marking: Electromagnetic Compatibility (Directive 2004/108/EEC) Explosion Protection (Directive 94/9/EEC) KS marking: Korean Gas Safety for Explosion Protection Protection This Ex marking means that this device is an intrinsically safe apparatus of ATEX category 1 according to directive 94/9/EC, the certificate number is DNV 10 ATEX ------X. It can be operated in non-mining locations (II) with potential explosive gas atmospheres (G) in zone 0, 1 and 2 with gas group C, B or A.

- Page 20 Certificates...

Need help?

Do you have a question about the SP12C7 and is the answer not in the manual?

Questions and answers