Summary of Contents for Amica PG4VI512FTB*S

- Page 1 PG4VI512FTB*S USER MANUAL INDUCTION HOB WITH TOUCH SENSOR CONTROL Please carefully read this manual before using the appliance. IOAA-603 (06.2014/1)

-

Page 2: Basic Information

DEAR CUSTOMER, Your Amica hob combines exceptional ease of use with excellent effectiveness. Once you have read the instructions, operating your hob will not be a problem. Before being packed and leaving the factory, the safety and functions of this hob were ca- refully tested. -

Page 3: Table Of Contents

CONTENTS Basic Information....................2 Safety instructions....................4 Description of the appliance..................9 Installation......................10 Operation......................16 Cleaning and maintenance..................32 Troubleshooting......................34 Specification......................36... -

Page 4: Safety Instructions

SAFETY INSTRUCTIONS Warning: The appliance and its accessible parts become hot during use. Care should be taken to avoid touching heating elements. Children less than 8 years of age shall be kept away unless continuously supervised. This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or... - Page 5 SAFETY INSTRUCTIONS Warning: If the surface is cracked, switch off the ap- pliance to avoid the possibillity of electric shock. Metallic objects, such as knives, forks, spoons and lids should not be placed on the hob surface since they can get hot. After use, switch off the hob element by its control and do not rely on the pan detector.

- Page 6 SAFETY INSTRUCTIONS FOR USE ● Before using the induction hob for the first time, carefully read its user manual. This will ensure user safety and prevent damage to the appliance. ● If the induction hob is operated in immediate vicinity to the radio, television set or other radio-frequency-emitting device, make sure that the hob’s touch sensor controls operate correctly.

- Page 7 SAFETY INSTRUCTIONS FOR USE ● When cooking on induction hob only use pots and pans with a flat base having no sharp edges or burrs as these can permanently scratch the cooking surface. ● Induction hob cooking surface is resistant to thermal shock. It is not sensitive to cold nor hot.

- Page 8 HOW TO SAVE ELECTRICITY UNPACKING Using the electricity in a re- The appliance was protected sponsible manner not only from damage at the time of saves money, but also helps transport. After unpacking, protect the environment. So please dispose of all ele- let’s save electricity! This is ments of packaging in a way how it’s done:...

-

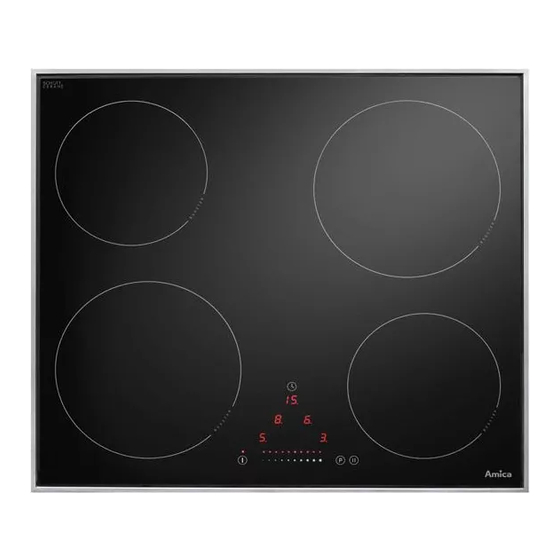

Page 9: Description Of The Appliance

DESCRIPTION OF THE APPLIANCE Description of PG4VI512FTB4S hob Rear right booster cooking zone Rear left booster cooking zone Front left booster cooking zone Front right booster cooking zone Control Panel 1. On/off sensor with LED pilot light 2. Heat setting selection sensor field 3. -

Page 10: Installation

INSTALLATION Making the worktop recess l Worktop thickness should be 28 - 40 mm, while its width at least 600 mm. The worktop must be flat and level. Edge of the worktop near the wall must be sealed to prevent ingress of water or other liquids. - Page 11 INSTALLATION Fig.2 5 10mm ÷ 25mm 30mm Installing hob in kitchen cabinet worktop. 500x10mm 5 10mm ÷ Installing hob in kitchen worktop above oven with ventilation. 500x20mm Do not install the hob above the oven without ventilation.

- Page 12 INSTALLATION Installation of self-adhesive foam gasket Do not install the appliance without the foam gasket. The gasket must be applied on the appliance as follows: Before fitting the appliance in the kitchen worktop, apply self-adhesive foam gasket provided underneath the rim. - before applying, remove the protective film from the self-adhesive foam gasket - apply the self-adhesive foam gasket underneath the appliance rim (Figure)

- Page 13 INSTALLATION Installing PB*4VI512FTB* hob - bracket • Use four “A” brackets for 38 mm thick worktops. Fit the hob into worktop opening as shown on figure 3 and 4. To properly secure hob in 28 mm thick worktop, use four 15x15x50 mm wooden blocks in addition to “A”...

- Page 14 INSTALLATION Connecting to electrical mains Important! Electrical connection must be made by a properly certified qualified installer. Do not make any alterations or changes in the appliance electrical system. Tips for the installer The hob is equipped with a terminal block allowing different connections appropriate for a specific type of power supply.

-

Page 15: Wiring Diagram

INSTALLATION WIRING DIAGRAM Important! Heating elements operate at 230V. Important! For each connection the protective conductor must Recom- be connected to the terminal mended marked connec- tion lead 1 For a 230 V single phase connection with a neutral lead, terminals 1-2 are 3X 4 mm bridged, neutral lead is connected to terminal 4, and the protective... -

Page 16: Operation

OPERATION Before using the appliance for the first time ● thoroughly clean your induction hob first. The induction hob should be treated with the same care as a glass surface. ● switch on the ventilation in the room or open a window, as the appliance could emit an unpleasant smell during first use. -

Page 17: Pan Detector

OPERATION Pan detector Pan detector is installed in induction hobs. Pan detector starts heating automatically when a pan is detected on a cooking zone and stops heating when it is removed. This helps save electricity. ● When an suitable pan is placed on a cooking zone, the display shows the heat setting. ●... -

Page 18: Selecting Cookware For Induction Cooking

OPERATION The high-quality cookware is an essential condition for efficient induction cooking. Selecting cookware for induction cooking ● Always use high-quality cookware with a perfectly flat base: this will prevent local overhe- ating, where food could stick while cooking. Pots and pans with thick steel walls provide superior heat distribution. - Page 19 OPERATION Selecting cookware for the induction cooking zone Marking of kitchen Check for marking indicating that the cookware cookware is suitable for induction cooking. Use magnetic cookware (enamelled steel, ferrite sta- inless steel, cast iron). The easiest way to determine if your cookware is suitable is to perform the „magnet test”.

-

Page 20: Control Panel

OPERATION Control Panel The touch control sensor panel is equipped with new generation (3.4) „DIGI Select-Sensor” sensor fields, where the cooking zone display is also the cooking zone selection sensor and the timer. Heat setting selection sensor (2) is a slider type touch control sensor allowing se- lection of heat setting (1-9) and timer setting (1-99) by touching and sliding your finger across the marked area (2): •... - Page 21 OPERATION If none of the sensor fields is touched within 20 seconds of switching on the appliance, the cooking zone switches off. A cooking zone is active when its display shows a digit or a letter and a decimal point. This indicates the cooking zone is ready for the heat setting to be set or changed.

-

Page 22: Booster Function Control

OPERATION Booster function control Booster function can be activated on all co- oking zones. Two left cooking zones and two right cooking zones are paired (see figure) Booster function can be activated at any time for one cooking zone in a pair. If activating Booster function causes the overall power limit of a pair to be exceeded, the heat... - Page 23 OPERATION The Child Lock function remains set until it is released even after the appliance has been switched off and then switched on again. Disconnecting the appliance from electrical mains does not release the child lock. Releasing the child lock function to cook only Switch the appliance on using the on/off sen- sor field (1);...

- Page 24 OPERATION The residual heat indicator Once a cooking zone is switched off, „H” is displayed on the relevant cooking zone’s display to warn that the „cooking zone is still hot!”. Do not touch the cooking zone at this time owing to the risk of burns from residual heat, and do not place any object on it which is sensitive to heat!

- Page 25 OPERATION Automatic warm-up function ● Select the required cooking zone (3) so that the display shows „0.” (the dot is on). • Select the heat setting „9” by sliding your finger across the heat setting selection sensor field (2). • Touch the heat setting selection sensor field (2) again to confirm the selected heat setting „9”.

-

Page 26: Setting The Timer

OPERATION Timer Timer function makes cooking easier by making it possible to set cook time. It can also be used as a Kitchen Timer. Setting the Timer Timer function allows the cooking zone to be switched off after the set time has elapsed. The timer function can only be set when a cooking zone is operating (heat setting is greater than „0”). -

Page 27: Checking Timer Countdown

OPERATION Changing Timer (cook time) setting Programmed Timer setting can be changed at any time. To change the programmed Timer setting, select a cooking zone by touching the cooking zone selection sensor field (3), and then touch the Timer selection sensor field (4). Checking Timer countdown To check progress of Timer countdown at any time, touch the cooking zone selection sensor field (3). -

Page 28: Kitchen Timer

OPERATION Kitchen Timer When no cooking zones are in use, the Timer function can be used as a regular Kitchen Timer. Setting Kitchen Timer When the appliance is off: ● Switch on the appliance by touching the on/off sensor (1). „0” will be shown on cooking zone displays (3) and the LED pilot light will light up above the on/off sensor (1). -

Page 29: Keeping Food Warm

OPERATION Keeping food warm Keep warm function allows for keeping food warm on a cooking zone. The selected cooking zone operates at a low heat setting. Cooking zone’s heat setting is automatically adjusted so that food temperature is kept at a constant temperature of 65°C. Thanks to this, ready to serve, warm food retains its taste and does not stick to the pot’s bottom. - Page 30 OPERATION The Stop’n go function can be activated for a maximum of 10 minutes. If the Stop’n go function is not deactivated within this time, the appliance or will switch itself off. If the appliance was accidentally switched off using the on/off sensor (1), the Stop’n go function makes it possible to quickly restore the settings.

- Page 31 OPERATION Switching off cooking zones ● A given cooking zone must be active. The decimal point is on. ● Slide your finger across the heat selection sensor field (2) to reduce the heat setting to „0”. The cooking zone will be deactiva- ted after approximately 10 seconds.

-

Page 32: Cleaning And Maintenance

CLEANING AND MAINTENANCE Proper routine maintenance and cleaning of the appliance can significantly extend its trouble-free operation. When cleaning induction hobs, the same principles apply as for glass surfaces. Do not use under any cir- cumstances any abrasive or caustic cleaners or scouring powders or pads! Do not use steam or pressure cleaners. - Page 33 CLEANING AND MAINTENANCE Never apply a detergent on the hot cooking Important! zone. It is best to let the cleaner dry and then If the hob’s controls do not respond wipe it wet. Any traces of the detergent should for whatever reason, then turn off the be wiped off clean with a damp cloth before main circuit breaker or remove the re-heating.

-

Page 34: Troubleshooting

TROUBLESHOOTING In the event of any fault: ● turn off the appliance ● disconnect the power supply ● have the appliance repaired ● Based on the instructions given in the table below, some minor issues can be corrected by the user. Please check the consecutive points in the table before you refer the repair to customer service. - Page 35 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE REMEDY 7.Residual heat indicator - a power outage or the - residual heat indicator will extinguished even though appliance has been discon- be shown again the next the cooking zones are hot nected time the appliance is turned on and off again 8.Hob cooking surface is Danger! Immediately unplug the appliance or...

-

Page 36: Specification

SPECIFICATION Rated voltage 400V 2N~50 Hz Rated power: PG4VI512FT*S - induction cooking zone : - induction cooking zone : Ø 180 mm 1400 W - induction cooking zone : Ø 220 mm 2300 W - Booster induction cooking zone: Ø 220 mm 2300/3000 W - Booster induction cooking zone: Ø... - Page 38 Service Help Line 0844 815 8880 For the UK: please call 0818 46 46 46 For Ireland: please call...

Need help?

Do you have a question about the PG4VI512FTB*S and is the answer not in the manual?

Questions and answers