Triton ELINA Installation And Operating Instructions Manual

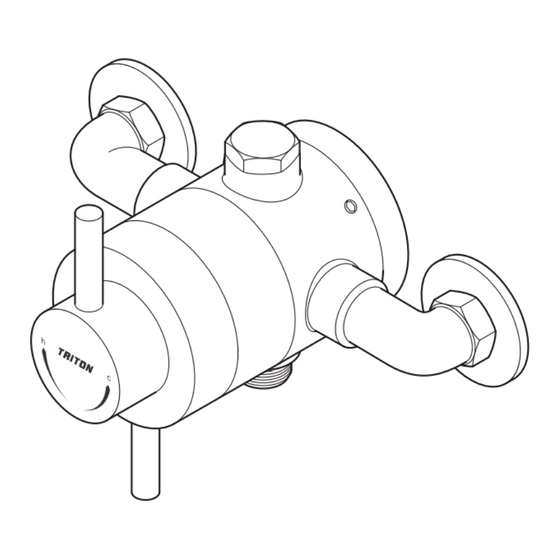

Sequential lever exposed thermostatic mixer valve

Hide thumbs

Also See for ELINA:

- Installation and operating instructions manual (28 pages) ,

- Installation and operating instructions manual (20 pages) ,

- Installation and operating instructions manual (20 pages)

Table of Contents

Advertisement

ELINA

sequential lever exposed

thermostatic mixer valve

86002230

Installation and

operating instructions

The showerhead and hose supplied with this product are an integral

part of the safety of your shower. Failure to use genuine Triton

parts may cause injury and will invalidate your warranty.

2180688K - March 2016

Advertisement

Table of Contents

Summary of Contents for Triton ELINA

- Page 1 Installation and operating instructions The showerhead and hose supplied with this product are an integral part of the safety of your shower. Failure to use genuine Triton parts may cause injury and will invalidate your warranty. 2180688K - March 2016...

-

Page 2: Table Of Contents

TEST RECORD ................19 Guarantee, service policy, etc...........rear cover nstallers please note these InstructIons are to be left wIth the user To check the product suitability for commercial and multiple installations, please contact Triton’s specification advisory service before installation. Telephone:... -

Page 3: Main Components

thermostatic mixer valve MAIN COMPONENTS Main components Fig.1 Ref. Description Mixer shower body Mounting plate Blanking plug Wall trim Outlet adapter Inlet nut and Olive X2 Flow regulator X2 All dimensions listed in this fitting book regarding the product and installation are approximate. All kits are for illustration purposes only and are not supplied unless otherwise stated. -

Page 4: Introduction

‘site requirements’. d. DO NOT connect the mixer shower to a gravity hot supply and a mains cold supply Replacement parts can be ordered from Triton Customer (or vice versa). Service. See ‘spare parts’ for details and part numbers. -

Page 5: Plumbing Requirements

DO NOT solder fittings near the mixer unit have to be fitted. For advice on the Triton as heat can transfer along the pipework and scale inhibitor, please contact Customer damage the mixer valve. -

Page 6: Typical Commercial Installations

thermostatic mixer valve TYPICAL COMMERCIAL INSTALLATIONS *Fig.2 (diagrammatic view – not to scale) Commercial gravity fed systems (fig.2) Vent Cold feed to Calorifier The shower control MUST be fed from a cold Cold water to taps water cistern and hot water cylinder providing Cold water cistern nominally equal pressures. -

Page 7: Installation

thermostatic mixer valve INSTALLATION *Fig.4 (diagrammatic view – not to scale) Preparing the mixer valve Check the contents to make sure all parts are present. Before starting the mixer installation, make sure all the openings on the valve are carefully covered to stop ingress of any debris, etc. -

Page 8: Fitting The Mixer

thermostatic mixer valve FITTING THE MIXER Fig.6 Mark the position of the four locating screws for the mounting plate, although if installing to a solid brick wall using two diagonal holes will usually be enough. Drill and plug the holes using the wall plugs provided. -

Page 9: Anti-Scald Protection

thermostatic mixer valve To fit the flow regulators Fig.9 To fit the flow regulators unscrew the elbows. Place the flow regulator, correctly, into the inlet elbows and secure with the retaining nut. Reassemble the elbows (fig.10). ANTI-SCALD PROTECTION It is important that the mixer valve is tested regularly to prevent the risk of scalding and guarantee user safety. -

Page 10: Commissioning

thermostatic mixer valve COMMISSIONING (TMV3) The following conforms to NHS Estates Model Engineering Specification D08 for when the mixer has been installed in healthcare premises. Important: Make sure that all supply pipework has been flushed through before commissioning. The maximum temperature should not exceed 41°C. Start the water flow by rotating the flow control. -

Page 11: Adjusting The Maximum Temperature Setting

thermostatic mixer valve ADJUSTING THE MAXIMUM Fig.11 TEMPERATURE SETTING (and fitting the lever) The mixer valve is supplied with the flow and temperature knob fitted and the maximum temperature stop factory set to 38°C (this can be adjusted during installation). The lever is supplied loose in the box. -

Page 12: Operating The Shower

thermostatic mixer valve OPERATING THE SHOWER (fig.13) Fig.13 To start the shower, turn the On/Off Temperature anti-clockwise. To adjust the showering temperature rotate the temperature control – clockwise for cooler and anti-clockwise for hotter. CAUTION: Exposed metal surfaces may Temperature control become hot during use. -

Page 13: Approvals

thermostatic mixer valve APPROVALS This mixer valve has been designed to comply with the requirements of: WRAS DESIGNATION This valve has been approved for the following designations: HP-S High Pressure Shower LP-S Low Pressure Shower MARKING The unique reference for this product is: 86002230 This can be found, laser marked onto the body of the mixer valve. -

Page 14: Dimensions

thermostatic mixer valve DIMENSIONS 131.5mm 37mm G1/2 150mm All dimensions listed in this fitting book regarding the product and installation are approximate. -

Page 15: Spare Parts

thermostatic mixer valve SPARE PARTS Ref. Description Part No. Lever 86002560 Knob 83313000 Collar 83312990 Thermostatic valve assembly 83312940 Outlet connector 83312950 Blanking plug 83312980 Wall bracket 83312970 Elbow assembly complete 83312960 Flow regulator 83307760... -

Page 16: In Service Testing/Frequency Of Testing

thermostatic mixer valve IN SERVICE TESTING With an acceptable mixed water temperature, Maintenance of the unit is required to give complete the following procedure: continued performance after installation and that it continues to provide scald prevention. a) record the temperature of the hot and cold water supplies Note: A thermostatic mixing valve in need of maintenance can be undetectable in normal... - Page 17 thermostatic mixer valve described in Annex F of D 08 may be used Annex F of D 08 (informative) FREQUENCY OF IN-SERVICE TESTS General In the absence of any other instruction or guidance on the means of determining the appropriate frequency of in-service testing, the following procedure may be used: a) 6 to 8 weeks after commissioning carry out the tests detailed in...

-

Page 18: Cleaning

CLEANING Triton recommends that all products are cleaned using warm, soapy water. Do not use abrasive or aggressive chemical cleaning products as this may affect the product surface finish and invalidate your guarantee. Cleaning the filters (fig.14) It is advised that this should be carried out by a qualified person. -

Page 19: Fault Finding

thermostatic mixer valve FAULT FINDING The following can be carried out by a competent person Problem/Symptom Cause Action/Cure 1 Water too hot. 1.1 Temperature control 1.1.1 Refer to commissioning section. incorrectly commis- sioned. 1.2 Not enough cold 1.2.1 Reposition the temperature control. water flowing through shower. - Page 20 thermostatic mixer valve FAULT FINDING Problem/Symptom Cause Action/Cure 4 Water does not 4.1 Water supplies cut off. 4.1.1 Check water elsewhere in house and if flow or shower necessary contact local water company. pattern collapses 4.2 Shower unit blocked. 4.2.1 Inspect the filters. Clean if necessary. when another 4.3 Blockage in pipework.

-

Page 21: Test Record

thermostatic mixer valve COMMISSIONING, MAINTENANCE and IN-SERVICE TESTING RECORD Where installed: Mixer valve location: Date installed: Installed by: Commissioning details: Hot water - Temp: °C Pressure: Cold water - Temp: °C Pressure: Maximum temperature setting - Temp: °C Pressure: Equipment used: Inspection and maintenance record:... - Page 22 thermostatic mixer valve...

- Page 23 thermostatic mixer valve...

- Page 24 Fax: 02476 324504 Nuneaton Warwickshire www.tritonshowers.co.uk CV11 4NR Triton is a division of Norcros Group (Holdings) Limited E-mail: serviceenquiries@tritonshowers.co.uk TRITON reserve the right to change product specification without prior notice. E&OE. © TRITON SHOWERS 2015 12-01-15 - 3 yr c mix...

Need help?

Do you have a question about the ELINA and is the answer not in the manual?

Questions and answers