Brother PT-1090 Service Manual

Hide thumbs

Also See for PT-1090:

- User manual (3 pages) ,

- Manual del usuario (3 pages) ,

- Brochure & specs (2 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Brother PT-1090

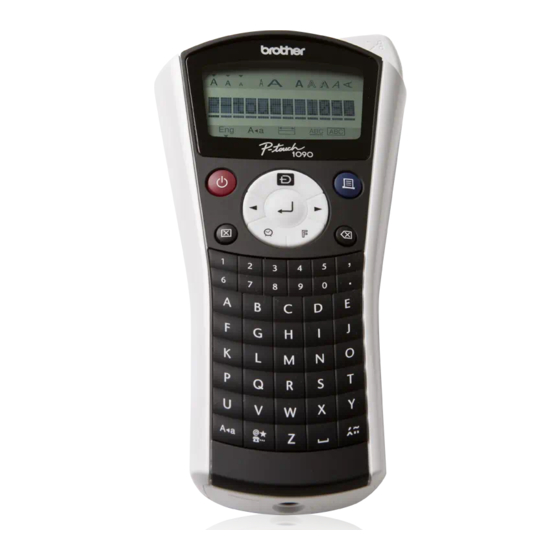

- Page 1 SERVICE MANUAL MODEL: PT-1090...

- Page 2 This publication is a service manual covering the specifications, theory of operation, disassembly/reassembly procedure, and troubleshooting of the Brother PT-1090. It is intended for service personnel and other concerned persons to accurately and quickly provide after-sale service for our PT-1090.

-

Page 3: Table Of Contents

CONTENTS CHAPTER I SPECIFICATIONS 1.1 Mechanical Specifications ......................I-1 1.1.1 External Appearance ......................I-1 1.1.2 Keyboard ..........................I-1 1.1.3 Display..........................I-1 1.1.4 Printing Mechanism......................I-2 1.1.5 Tape Cassette........................I-2 1.1.6 Tape Cutter ..........................I-2 1.2 Electronics Specifications......................I-4 1.2.1 Character Generator......................I-4 1.2.2 Power Supply........................I-4 1.3 Key Commands for Special Functions ..................I-5 1.3.1 Initializing..........................I-5 CHAPTER II THEORY OF OPERATION 2.1 Outline of Mechanisms...................... - Page 4 [ 10 ] Removing the Battery Terminals A................III-14 [ 11 ] Removing the Cutter Sensor ASSY, the Main PCB ASSY and the Cassette Sensor PCB ASSY ................III-15 [ 12 ] Removing the Contact Sheet and the Rubber 52 Key ..........III-17 3.1.2 Reassembly Procedure....................

-

Page 5: Chapter I Specifications

CHAPTER I SPECIFICATIONS 1.1 Mechanical Specifications 1.1.1 External Appearance 57.6 mm (2.3") 107.9 mm (4.2") Figure 1.1-1 External Appearance (1) Dimensions (W x D x H) 107.9 x 209.4 x 57.6 mm (4.2 x 8.2 x 2.3 inches) (incl. keys, cutter lever and bottom feet) (2) Weight - Machine proper Approx. -

Page 6: Printing Mechanism

1.1.4 Printing Mechanism (1) Print system Thermal transfer onto plastic and fabric tapes (Fixed thermal print head and tape feed mechanism) (2) Print speed 10 mm/second (3) Print head - Type Thermal print head - Heat generator Consists of 64 heating elements vertically aligned in 180 dpi - Size of a heating element 0.18 mm wide by 0.127 mm high... - Page 7 USA version EUROPE version Figure 1.1-2 Display and Key Arrangement I - 3...

-

Page 8: Electronics Specifications

1.2 Electronics Specifications 1.2.1 Character Generator (1) Internal characters (2) Internal fonts HELSINKI, BELT, DOT (3) Text buffer Max. 80 characters (Decoration label: Max. 50 characters) (4) File memory 9 files (5) Memory backup No dedicated backup battery is provided. However, the memory is backed up for 5 minutes even after: 1) you remove the dry cells (e.g., at the replacement time of dry cells) without connection of the optional AC adapter. -

Page 9: Key Commands For Special Functions

1.3 Key Commands for Special Functions 1.3.1 Initializing When the machine power is off, pressing the key with both the Function and R keys held down initializes the machine. When releasing those keys, be sure to first release the key and then release the Function and R keys. I - 5... -

Page 10: Chapter Ii Theory Of Operation

CHAPTER II THEORY OF OPERATION 2.1 Outline of Mechanisms 2.1.1 Print Mechanism ■ Structure of Thermal Head This machine uses direct thermal printing. The thermal print head has a heat generator consisting of 64 heating elements which are vertically aligned in 180 dpi as shown in Figure 2.1-1. -

Page 11: Roller Holder Assy Setting & Retracting Mechanism

2.1.2 Roller Holder ASSY Setting & Retracting Mechanism This mechanism consists of the roller holder ASSY and the holder cam. The cassette cover has a holder cam on the inside. Closing the cassette cover causes its holder cam to press section A of the roller holder ASSY as shown below. This pivots the roller holder ASSY around the shaft provided on the frame ASSY so as to press the roller holder ASSY against the thermal head side. - Page 12 The roller holder ASSY supports the platen roller and tape feed sub roller so that they can move perpendicularly to the thermal head and tape feed roller built in a tape cassette, respectively, as well as rotating freely. Closing the cassette cover presses the platen roller perpendicularly against the thermal head with the tape and ink ribbon sandwiched inbetween under a uniform load by the upper and lower roller holder springs.

-

Page 13: Tape & Ribbon Feed Mechanism

2.1.3 Tape & Ribbon Feed Mechanism This mechanism consists of a drive motor (DC motor), gear train, and roller holder ASSY. ■ Tape Feeding As the drive motor rotates, the rotation is transmitted via the gear train to the platen idle gear (which rotates the platen gear) and tape idle gear (which rotate the sub roller gear). - Page 14 ■ Adhesive Base Tape Feeding (only for laminate tape cassettes) A laminate tape cassette contains both a transparent laminate tape roll and a separate adhesive base tape roll. When a transparent laminate tape and adhesive base tape pass through the contact point (between the tape feed roller and tape feed sub roller), they are then bonded together into a single, printed tape.

-

Page 15: Tape Cutter Mechanism

2.1.4 Tape Cutter Mechanism The tape cutter ASSY consists of a cutter case ASSY and cutter board. Pressing the cutter lever pushes out the cutter blade against the cutter board, cutting the printed tape coming through the cutter case ASSY and cutter board. Cutter case ASSY Tape cassette Cutter board... -

Page 16: Cutter Safety Lock Mechanism

2.1.5 Cutter Safety Lock Mechanism When the cassette cover is opened and no tape cassette is loaded, the roller holder ASSY is retracted from the thermal head with the roller holder release spring (as described in Section 2.1.2). In this retracted position, the cutter lever stopper of the roller holder ASSY blocks the end of the cutter lever, preventing the cutter blade from getting driven for safety, as shown below. -

Page 17: Cutter Jam Prevention Mechanism

2.1.6 Cutter Jam Prevention Mechanism When the machine is printing or feeding tape, pressing the cutter lever turns on the cutter sensor switch and immediately stops the DC motor. This prevents the cutter blade from interrupting the tape being fed and causing a tape jam. Cutter blade Tape Cutter lever... -

Page 18: Outline Of Control Electronics

2.2 Outline of Control Electronics 2.2.1 Configuration Figure 2.2-1 shows a block diagram of the control electronics of this machine. The control electronics consists of three PCBs (main PCB, key PCB and cassette sensor PCB), an LCD, motor, thermal print head and cutter sensor. ■... - Page 19 Thermal head Main PCB Cassette sensor Jumper lead wire Key PCB Drive motor Cutter (Key contacts) (DC motor) sensor Negative (-) battery terminal (black) Positive (+) battery terminal (red) AC adapter (option) Figure 2.2-1 Configuration of the Electronic Parts II - 10...

-

Page 20: Main Pcb

2.2.2 Main PCB [ 1 ] Block Diagram Figure 2.2-2 shows a block diagram of the main PCB. The main PCB consists of the following: (1) CPU (2) DC motor driver (3) Thermal head driver (4) Oscillation circuit (5) Solder points (6) Power supply circuit (7) Key detector circuit (8) Voltage detector circuit... -

Page 21: 2 ] Solder Points

[ 2 ] Solder Points This machine has seven solder points--1 through 3, A through D. ■ Destination Solder points 1 through 3 customize the machine for destination. as listed in Table 2.2-1. Table 2.2-1 Destination Solder points Destination High High (Closed) (Open) -

Page 22: 3 ] Identification Of Tape Cassette Type

[ 3 ] Identification of Tape Cassette Type The cassette sensor PCB has four sensor switches (SW2, SW3, SW6 and SW7). Loading a tape cassette turns on some of those switches while keeping others off depending upon the ID encoding holes provided in the tape cassette currently loaded. If an encoding ID hole is closed, the corresponding sensor switch goes on. -

Page 23: Chapter Iiidisassembly & Reassembly

CHAPTER III DISASSEMBLY & REASSEMBLY ■ Safety Precautions (1) You should carry out disassembly & reassembly jobs on an anti-static sheet grounded correctly. Otherwise, the LSI and other electronic devices will be damaged due to the electricity charged in your body. (2) When transporting PCBs, be sure to wrap them in conductive sheets such as aluminum foil. -

Page 24: Disassembly/Reassembly

3.1 Disassembly/Reassembly 3.1.1 Disassembly Procedure [ 1 ] Removing the Cassette Cover, Tape Cassette, and Dry Cells (1) Turn the machine upside down. (2) Press the section "A" of the cassette cover to release the latch, and remove the cassette cover. Cassette cover "A"... - Page 25 (3) Remove the tape cassette and the six dry cells. Tape cassette Dry cells Bottom cover Figure 3.1-2 Removing the Tape Cassette and Dry Cells (4) Release the two hooks, and remove the cassette panel from the inside of the cassette cover.

-

Page 26: 2 ] Removing The Cutter Case Assy And Board

[ 2 ] Removing the Cutter Case ASSY and Board, and Separating the Bottom Cover and the Upper Cover (1) Pull out the cutter case ASSY and board. (2) Remove the seven screws from the bottom cover. (3) Discharge the capacitor mounted on the main PCB by touching both the + and - terminals (of the main PCB ASSY) with a tweezers. - Page 27 (4) Release the three hooks, and open the bottom cover from the upper cover. NOTE: Do not pull the bottom cover away from the upper cover. Those covers are connected with the lead wires and the head flat cable. (5) Disconnect the head flat cable from the main PCB ASSY. (6) Remove the two screws, and remove the cassette sensor PCB ASSY from the bottom cover.

-

Page 28: 3 ] Removing The Terminal Press Cover And The - Terminal Assy

[ 3 ] Removing the Terminal Press Cover and the - Terminal ASSY (1) Turn the bottom cover upside down. (2) Press the two latches on the terminal press cover inward with the tip of the flat screwdriver and push down the terminal press cover. Latches on the terminal press cover Unlatching the terminal... - Page 29 (3) Remove the two battery terminals B and the - terminal ASSY from the terminal press cover. Releasing the - terminal ASSY Terminal press cover - terminal ASSY - terminal ASSY (black lead) Battery terminals B Figure 3.1-7 Removing the - Terminal ASSY III - 7...

-

Page 30: 4 ] Removing The + Terminal Assy

[ 4 ] Removing the + Terminal ASSY (1) Remove the + terminal ASSY from the bottom cover. + terminal ASSY (red read) Bottom cover Figure 3.1-8 Removing the + Terminal ASSY III - 8... -

Page 31: 5 ] Removing The Cutter Lever, The Cutter Lever Spring, The Roller Holder Assy And The Roller Holder Release Spring

[ 5 ] Removing the Cutter Lever, the Cutter Lever Spring, the Roller Holder ASSY and the Roller Holder Release Spring (1) Remove the cutter lever from the bottom cover. (2) Remove the cutter lever spring from the cutter lever. (3) Remove the roller holder ASSY from the bottom cover. -

Page 32: 6 ] Removing The Head Assy

[ 6 ] Removing the Head ASSY (1) Remove the adhesive tape from the bottom cover. (2) Remove the nut 3 M3, the washer and the one screw, and remove the head ASSY from the bottom cover. CAUTION: Before handling the head ASSY, take care not to touch it directly by hand. -

Page 33: 7 ] Removing The Gears

[ 7 ] Removing the Gears (1) Remove the two washers from the bottom cover. (2) Remove the double gear 2, the double gear 1, the double gear 4, the double gear 3, the tape idle gear and the P idle gear from the bottom cover. Washer Double gear 2 Double gear 1... -

Page 34: 8 ] Removing The Motor Holder And Dc Motor Assy

[ 8 ] Removing the Motor Holder and DC Motor ASSY (1) Remove the two screws, and remove the motor holder from the bottom cover. (2) Remove the two screws, and remove the DC motor ASSY from the motor holder. Screws Screws Motor holder... -

Page 35: 9 ] Removing The Ribbon Drive Cam, The Ribbon Drive Gear And The Ribbon Clutch Spring

[ 9 ] Removing the Ribbon Drive Cam, the Ribbon Drive Gear and the Ribbon Clutch Spring (1) Turn the bottom cover upside down. (2) Remove the one screw, and remove the ribbon drive cam and the ribbon drive gear from the bottom cover. (3) Remove the ribbon clutch spring from the ribbon drive cam. -

Page 36: 10 ]Removing The Battery Terminals A

[ 10 ]Removing the Battery Terminals A (1) Press the locking pawls on each of three battery terminals A and push down each battery terminals A with the tip of the flat screwdriver. Bottom cover (placed upside down) Flat screwdriver Battery terminals A Locking pawls Bottom cover... -

Page 37: 11 ] Removing The Cutter Sensor Assy, The Main Pcb Assy

[ 11 ] Removing the Cutter Sensor ASSY, the Main PCB ASSY and the Cassette Sensor PCB ASSY CAUTION: When handling the PCBs, put on the grounding wrist band. Failure to do so might break LSIs and other electronic devices. (1) Remove the one screw, and remove the SW hold plate and the cutter sensor ASSY from the upper cover. - Page 38 (6) Turn the main PCB ASSY upside down. (7) Unsolder the five cassette sensor PCB ASSY leads from the main PCB ASSY. Main PCB ASSY Cassette sensor PCB ASSY leads Main PCB Black Yellow Brown Green Cassette sensor PCB ASSY leads Soldering the cassette sensor PCB ASSY leads Figure 3.1-16 Unsoldering the five Cassette Sensor PCB ASSY Leads...

-

Page 39: 12 ]Removing The Contact Sheet And The Rubber 52 Key

[ 12 ]Removing the Contact Sheet and the Rubber 52 Key (1) Remove the contact sheet and the rubber 52 key from the upper cover. Contact sheet Rubber 52 key Upper cover Figure 3.1-17 Removing the Contact Sheet and the Rubber 52 Key III - 17... -

Page 40: Reassembly Procedure

3.1.2 Reassembly Procedure [ 1 ] Installing the Rubber 52 Key and the Contact Sheet (1) Set the rubber 52 key and the contact sheet to the upper cover. NOTE: Make sure that the rubber 52 key is fitted over the two positioning bosses and the seven ribs. -

Page 41: 2 ] Installing The Cassette Sensor Pcb, The Main Pcb Assy And The Cutter Sensor Assy

[ 2 ] Installing the Cassette Sensor PCB, the Main PCB ASSY and the Cutter Sensor ASSY CAUTION: When handling the PCBs, put on the grounding wrist band. Failure to do so might break LSIs and other electronic devices. (1) Solder the five cassette sensor PCB ASSY leads to the main PCB ASSY. NOTE: Check the wire ID colors as shown below and keep solder within the specified soldering points. - Page 42 (2) Turn the main PCB ASSY upside down. NOTE: The main PCB ASSY consists of the main PCB, the key PCB and the LCD. (3) Set the LCD to the positioning part of the upper cover, and secure the LCD with the locking pawl.

- Page 43 (6) Solder the two cutter sensor ASSY leads to the main PCB ASSY. NOTE: Check the wire ID colors as shown below and keep solder within the specified soldering points. (7) Insert the positioning hole "a" of the cutter sensor ASSY into the pin of the upper cover, and align the boss of the cutter sensor ASSY with the positioning hole "b"...

-

Page 44: 3 ] Installing The Battery Terminals A

[ 3 ] Installing the Battery Terminals A (1) Set the three battery terminals A to the bottom cover, and latch their locking pawls. Bottom cover (placed upside down) Battery terminals A Locking pawls Bottom cover Figure 3.1-22 Installing the Battery Terminals A III - 22... -

Page 45: 4 ] Installing The Ribbon Clutch Spring, The Ribbon Drive Gear And The Ribbon Drive Cam

[ 4 ] Installing the Ribbon Clutch Spring, the Ribbon Drive Gear and the Ribbon Drive Cam (1) Turn the bottom cover upside down. (2) Set the ribbon clutch spring to the ribbon drive cam in the state of that the end "a" of the ribbon clutch spring is the lower side. -

Page 46: 5 ] Installing The Dc Motor Assy And The Motor Holder

[ 5 ] Installing the DC Motor ASSY and the Motor Holder (1) Turn the bottom cover upside down. (2) Set the DC motor ASSY to the motor holder with the two screws. (3) Set the motor holder to the bottom cover with the two screws. NOTE: When installing the motor holder, check that it is 20.22mm ±0.05 between the shaft of the motor holder and the shaft "A"... -

Page 47: 6 ] Installing The Gears

[ 6 ] Installing the Gears (1) Insert the double gear 1 into the shaft of the motor holder. (2) Insert the double gear 2 into the shaft "A" of the bottom cover, and secure their gears with the washer. NOTE: Check that the double gear 1 and the double gear 2 are routed smoothly. -

Page 48: 7 ] Installing The Head Assy

[ 7 ] Installing the Head ASSY (1) Insert the head flat cable into the hole of the bottom cover, and set the head ASSY to the positioning part of the bottom cover with the nut 3 M3, the washer and the one screw. -

Page 49: 8 ] Installing The Roller Holder Release Spring, The Roller Holder Assy

[ 8 ] Installing the Roller Holder Release Spring, the Roller Holder ASSY, the Cutter Lever Spring and the Cutter Lever (1) Insert the end "a" of the roller holder release spring into the guide groove of the roller holder ASSY and set it. (2) Insert the roller holder ASSY into the shaft of the bottom cover, and hang the end "b"... -

Page 50: 9 ] Installing The + Terminal Assy

[ 9 ] Installing the + Terminal ASSY (1) Turn the bottom cover upside down. (2) Set the + terminal ASSY to the bottom cover. (3) Pass the + terminal ASSY lead through the two guide grooves of the bottom cover. -

Page 51: 10 ]Installing The - Terminal Assy And The Terminal Press Cover

[ 10 ]Installing the - Terminal ASSY and the Terminal Press Cover (1) Set the - terminal ASSY and the two battery terminals B to the terminal press cover. Releasing the - terminal ASSY Terminal press cover - terminal ASSY (black lead) - terminal ASSY (black lead) - Page 52 (2) Set the terminal press cover to the bottom cover, and hang the two latches of the terminal press cover on the bottom cover. (3) Pass the - terminal ASSY lead through the four guide grooves of the bottom cover. Guide groove Guide groove Terminal press cover...

-

Page 53: 11 ] Assembling The Bottom Cover And The Upper Cover, And Installing The Board And The Cutter Case Assy

[ 11 ] Assembling the Bottom Cover and the Upper Cover, and installing the Board and the Cutter Case ASSY (1) Solder the two motor leads to the main PCB ASSY. CAUTION: When handling the PCBs, put on the grounding wrist band. Failure to do so might break LSIs and other electronic devices. - Page 54 (5) Set the bottom cover to the upper cover, and hang the three hooks of the upper cover on the bottom cover. (6) Secure the bottom cover to the upper cover with the seven screws. (7) Set the cutter case ASSY to the shaft of the bottom cover, and hang the hook of the cutter case ASSY on the shaft, and then set the board to the rib of the bottom cover, and hang the hook of the board on the rib.

-

Page 55: 12 ]Installing The Dry Cells, The Tape Cassette And The Cassette Cover

[ 12 ]Installing the Dry Cells, the Tape Cassette and the Cassette Cover (1) Set the cassette panel to the cassette cover, and secure the cassette panel with the two hooks. Cassette panel Cassette cover Hooks Figure 3.1-33 Installing the Cassette Panel (2) Set the six dry cells and the tape cassette. - Page 56 (3) Set the two latches of the cassette cover to the two positioning parts of the bottom cover, and close the cassette cover. Cassette cover Latches Positioning parts Bottom cover Figure 3.1-35 Installing the Cassette Cover III - 34...

-

Page 57: Final Check And Inspection Mode

3.2 Final Check and Inspection Mode ■ After completion of reassembling (1) Check that each rubber key works correctly with light touch. (2) Check that the cutter lever works smoothly. (3) To initialize the internal memory, press the key with both the Function and R keys held down. - Page 58 INFO submode (1 key*) (*You may switch back to this INFO submode from any other submode by pressing the 1 key, except during the key depressing test in the KEY submode.) The moment the machine enters the inspection mode, it displays the "INFO" and initiates the INFO submode.

- Page 59 2) Press the key. LCD check will appear as shown below. (All guidance indicators: OFF Cursor at the 1st position: ON) Press the key. LCD check will appear as shown below. (All guidance indicators: ON Cursor at the 5th position from the right: ON) Press the key.

- Page 60 CASSETTE submode (3 key*) With the "CLOCK 1" displayed, LCD check "CST" appear as shown below by pressing the key or the 3 key. Outline of CASSETTE submode - Check the pressing of the five sensor switches (cassette sensor 2, 3, 7 and 6) and the cutter sensor.

- Page 61 As shown below, press/release the cassette sensor 7, 6 and the cutter sensor in this order in same way. Cassette sensor 7 Cassette sensor 6 Cutter sensor After completion of the pressing/releasing the cassette sensor, change the "KEY submode (4 key*)". When the NG is judged in either sensor, the machine displays "CST 1 X".

- Page 62 KEY submode (4 key*) (*You can switch back to this KEY submode from any other submode by pressing the 4 key.) With the cassette sensor status screen displayed, press the Enter key. The machine displays "KEY" and enters the KEY submode. Press the Enter key to start checking keys.

- Page 63 After completion of checking of all keys, the machine displays "Printing..." and prints "OK" together with the head rank and destination (keypad version) as shown below. NOTE: If "Line Limit!" appears instead of "Printing..." it means that the width of the tape cassette loaded is narrow.

- Page 64 PRINT1 submode (5 key*) (*You may switch back to this PRINT1 submode from any other submode by pressing the 5 key, except during the key depressing test in the KEY submode.) With the "PRN1" displayed, the machine is in the PRINT1 submode. Press the key.

- Page 65 CUT submode (6 key*) (*You may switch back to this CUT submode from any other submode by pressing the 6 key, except during the key depressing test in the KEY submode.) NOTE: You may skip this submode since you may check the tape cutter in any other submode.

-

Page 66: Chapter Iv Troubleshooting

CHAPTER IV TROUBLESHOOTING This section gives the service personnel some of the troubleshooting procedures to be followed if an error or malfunction occurs with this machine. It is impossible to anticipate all of the possible troubles which may occur in future and determine the troubleshooting procedures, so this chapter covers some sample troubles. -

Page 67: Troubleshooting Flows

4.3 Troubleshooting Flows [ 1 ] Tape feeding failure The tape is not fed through. Replace the tape cassette with a new one, then try printing again. End of repair. Normal tape feeding? The old tape cassette may be defective. Is there any foreign Clean them up. - Page 68 Replace the cutter Does the cutter sensor work sensor ASSY with normally? lead-free solder. Are the cutter Replace the cutter sensor leads soldered sensor ASSY with correctly? lead-free solder. Replace the main PCB ASSY and regulate the motor speed. (Refer to Chapter III, Section 3.2, PRINT1 submode.) IV - 3...

-

Page 69: 2 ] Printing Failure

[ 2 ] Printing failure The tape is fed normally but no printing occurs. Replace the dry cells with new ones. End of repair. Is the printing normal? Is the head flat cable connected Correct it. correctly? Are the thermal If the platen or thermal print head is stained, head and platen dirtied? clean it with a head cleaning tape or cotton swab. - Page 70 If there is any foreign material on the thermal Any faintly print head, clean it up. printed character? Check that the platen is set into place and works normally. If the printed characters become faint in cycles, the tape feed sub roller gear in the roller holder ASSY may be deformed.

-

Page 71: 3 ] Powering Failure (Nothing Appears On The Lcd

[ 3 ] Powering failure (Nothing appears on the LCD.) Pressing the key does not turn the machine on; nothing appears on the LCD. When driven by dry cells: When driven via the optional AC adapter: Are the specified * AD-24ES US dry cells loaded? Replace them with the AD-24ES EU... -

Page 72: 4 ] No Key Entry Possible

[ 4 ] No key entry possible No key entry is possible. (Or, no correct key entry is possible.) Any dust or foreign Clean the key contacts material on the key or replace the rubber keypad. contacts? Replace the main PCB ASSY and press keys to check. -

Page 73: 5 ] Tape Cassette Type Not Identified

[ 5 ] Tape cassette type not identified The tape cassette type cannot be identified correctly. Does each sensor actuator cassette sensor PCB ASSY on the cassette sensor PCB ASSY is defective. Replace it. work normally? Correct them with Are the cassette sensor PCB ASSY lead-free solder. -

Page 74: Appendix 1 Main Pcb Circuit Diagram

Appendix 1 Main PCB Circuit Diagram MAIN PCB CIRCUIT NAME DIAGRAM PT1090 CODE LW4024001 A - 1... -

Page 75: Appendix 2 Key Pcb Circuit Diagram

Appendix 2 Key PCB Circuit Diagram KEY PCB CIRCUIT NAME DIAGRAM PT1090 CODE LW4025-001 A - 2... - Page 76 Aug. 2009 SM-PT027 Printed in Japan...

Need help?

Do you have a question about the PT-1090 and is the answer not in the manual?

Questions and answers