Table of Contents

Advertisement

E2006 Lennox Industries Inc.

Dallas, Texas, USA

WARNING

Improper installation, adjustment, alteration, ser-

vice or maintenance can cause personal injury, loss

of life, or damage to property.

Installation and service must be performed by a

qualified installer or service agency.

IMPORTANT

The Clean Air Act of 1990 bans the intentional vent-

ing of refrigerant (CFC's and HCFC's) as of July 1,

1992. Approved methods of recovery, recycling or

reclaiming must be followed. Fines and/or incar-

ceration may be levied for noncompliance.

WARNING

This product and/or the indoor unit it is matched

with may contain fiberglass wool.

Disturbing the insulation during installation, main-

tenance, or repair will expose you to fiberglass wool

dust. Breathing this may cause lung cancer. (Fiber-

glass wool is known to the State of California to

cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

03/06

*2P0306*

INSTALLATION

INSTRUCTIONS

10ACE Series Units

CONDENSER UNITS

505,128M

03/06

Supersedes 01/06

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Physical contact with metal edges and corners

while applying excessive force or rapid motion can

result in personal injury. Be aware of, and use

caution when working near these areas during

installation or while servicing this equipment.

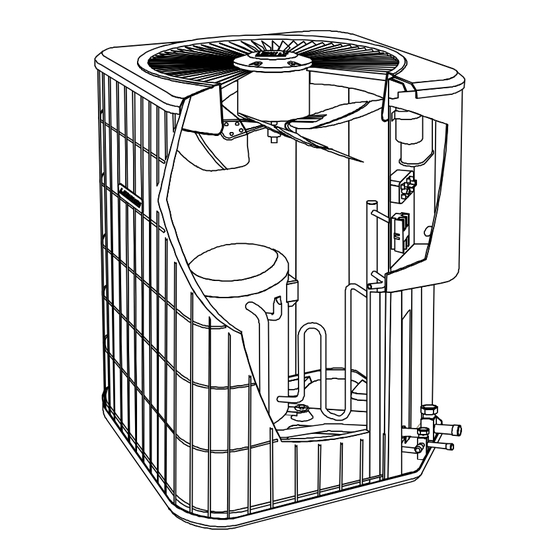

10ACE Outdoor Units

®

Lennox Merit

10ACE outdoor units are designed for use

in either fixed orifice or expansion valve (TXV) systems.

The TXV may require a field−installed hard start kit. Refer

to the Lennox Engineering Handbook for expansion valve

kits which must be ordered separately.

Shipping & Packing List

1 − Assembled outdoor unit

1 − Fixed orifice refrigerant metering device

Check the unit for shipping damage. Consult last carrier

immediately if damage is found.

Page 1

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

CAUTION

505,128M

*P505128M*

Litho U.S.A.

1

1

2

2

2

3

4

4

5

5

6

6

7

8

10

10

11

11

Advertisement

Table of Contents

Summary of Contents for Lennox 10ACE Series

-

Page 1: Table Of Contents

State of California to The TXV may require a field−installed hard start kit. Refer cause cancer.) to the Lennox Engineering Handbook for expansion valve Fiberglass wool may also cause respiratory, skin, kits which must be ordered separately. -

Page 2: General Information

Unit Dimensions − inches (mm) 4−3/8 4−3/8 (111) (111) 4−3/8 4−3/8 (111) (111) OPTIONAL UNIT COMPRESSOR STAND−OFF KIT (4) (Field Installed) COIL DRAIN OUTLETS (Around perimeter of base) 6−3/8 4−3/8 VAPOR LINE (162) (111) CONNECTION 4−3/8 6−3/8 LIQUID LINE (111) (162) CONNECTION TOP VIEW BASE SECTION... -

Page 3: Electrical

5 feet (1.5 m) from the floor. It should not be nameplate for minimum circuit ampacity and maximum installed on an outside wall or where it can be effected overcurrent protection size. by sunlight, drafts or vibrations. Page 3 10ACE SERIES... -

Page 4: Refrigerant Piping

NOTE − Units are designed for line sets of up to 50 feet (15 m). For Expansion valves equipped with Chatleff fittings are avail- applications longer than 50 feet, consult the Lennox Refrigerant Piping able from Lennox. Refer to the Engineering Handbook for Guide (Corp. -

Page 5: Manifold Gauge Set

The ball valve is COIL SERVICE equipped with a service port with a factory−installed PORT CAP Schrader valve. A service port cap protects the Schrader Figure 8 valve from contamination and assures a leak−free seal. Page 5 10ACE SERIES... -

Page 6: Leak Testing

4. Connect a cylinder of nitrogen with a pressure regulat- Leak Testing ing valve to the center port of the manifold gauge set. After the line set has been connected to the indoor and out- 5. Connect the manifold gauge set high pressure hose to door units, check the line set connections and indoor unit the vapor valve service port. -

Page 7: Start Up

Close manifold gauge valves and shut off the HCFC-22 cylinder and remove 7. Recheck voltage while the unit is running. Power must the manifold gauge set. be within range shown on the nameplate. Page 7 10ACE SERIES... -

Page 8: Refrigerant Charging

2. Conduct a leak check, then evacuate as previously Refrigerant Charging outlined. Units are factory charged with the amount of HCFC-22 re- 3. Weigh in the charge according to the total amount frigerant indicated on the unit nameplate. This charge is shown on the unit nameplate. - Page 9 ** Temperature of the air entering the outside coil. proach temperature. Page 9 10ACE SERIES...

-

Page 10: System Operation

If debris has collected between the mesh screen and System Operation the coil and cannot be dislodged by spraying unpres- The outdoor unit and indoor blower cycle on demand from surized water from the inside coil surface to the out- the room thermostat. -

Page 11: Optional Accessories

Discharge Pressure Vapor Pressure Refrigerant Charge Checked? Leak Checked? - Properly Insulated? - Refrigerant Lines: Outdoor Fan Checked? Fully Opened? - Caps Tight? Service Valves: Thermostat Calibrated? - Properly Set? - Level? - Voltage With Compressor Operating Page 11 10ACE SERIES...

Need help?

Do you have a question about the 10ACE Series and is the answer not in the manual?

Questions and answers