Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for BeiJer X2 base 7

- Page 1 X2 base 7 Installation Manual English MAEN181B, 2016-10...

- Page 2 The information in this document is subject to change without notice and is provided as available at the time of printing. Beijer Electronics AB, including all its group companies, reserves the right to change any information without updating this publication. Beijer Electronics AB, including all its group companies, assumes no responsibility for any errors that may appear in this document.

-

Page 3: Table Of Contents

Touch Screen Surface ..........15 5 Operator Panel Drawings ..........16 Connectors ............16 Communication Ports ........... 16 X2 base 7 Outline ..........17 6 Additional Installation Tips ..........18 Grounding the operator panel ........18 Ethernet Connection in the Operator Panel ....19 To Achieve Better EMC Protection ...... -

Page 4: Safety Precautions

Install the operator panel according to the accompanying installation • instructions. Ground the operator panel according to the accompanying installation • instructions. Only qualified personnel may install the operator panel. • Separate the high voltage, signal and supply cables. • Beijer Electronics, MAEN181B... -

Page 5: During Use

Replacing the battery incorrectly may result in explosion. Only use batteries • recommended by the supplier. During the warranty period, the battery needs to be replaced by an authorized Beijer Electronics service center. Dismantling and Scrapping The operator panel or parts thereof shall be recycled according to local •... -

Page 6: Installation

Maximum installation plate thickness: 6.5 mm • Space requirements in millimeters when installing the operator panel: • Note: The dimensions on the drawing are not proportional. Caution: The openings on the enclosure are for air convection. Do not cover these openings. Beijer Electronics, MAEN181B... -

Page 7: Installation Process

3. To cut a correct opening for the operator panel, use the cut out dimensions in the outline drawing. A separate cut out drawing is available for download from the Beijer Electronics web site. For more information, see sections Operator Panel Drawings Technical Data. - Page 8 When connecting the operator panel to the power outlet for the first time, make sure not to interrupt power for a minimum of 48 hours in order to charge the battery completely. After that, the battery may be charged partly during a shorter period of time. Beijer Electronics, MAEN181B...

-

Page 9: Connections To The Controller

file for the driver in question. 2.2.2 Other Connections and Peripherals Cables, peripheral equipment and accessories must be suitable for the application and its environment. For further details or recommendations, please refer to the supplier. Beijer Electronics, MAEN181B... -

Page 10: Technical Data

Technical Data Technical Data Parameter X2 base 7 Front panel, W × H × D 196 × 146 × 7.5 mm Cut out dimensions, 185.8 × 135.8 mm W × H Mounting depth 44.7 mm (145 mm including clearance) Front panel seal... - Page 11 5% – 85% non-condensed operation Approvals and CE / FCC / KCC certifications Information is available on the web site www.beijerelectronics.com UL approval According to UL lable on X2 base 7 panel. See section Chemical Resistance for more information. Beijer Electronics, MAEN181B...

-

Page 12: Chemical Resistance

Hydrogen superoxide 30% Urea Lactic acid 10% The material shows limited resistance to the following chemicals at room temperature: Cleaner’s naphtha, free from aromatic Heating oil hydrocarbons Ethyl alcohol 96% Isopropanol Glycerin N-hexane Glycol Persil powder in solution Beijer Electronics, MAEN181B... - Page 13 The material shows little or no resistance to the following chemicals at room temperature: Acetone Methylisobutyl ketone Ammonia solution, diluted Naphthalene Aniline Nitrobenzene Aromatic hydrocarbons Oleic acid Benzene Olive oil Bromin Phenol Butter Potassium carbonate, sat. Chlorine Sodium hydroxide solution 10% Diethyl ether Soya oil Iodine Toluene Lard Trichloroethylene Beijer Electronics, MAEN181B...

-

Page 14: Touch Screen And Overlay Material

Autoflex EB withstands DIN 42 115 Part 2 exposure of up to 1 hour duration to glacial acetic acid without visible change. Autoflex EB is not resistant to high pressure steam at over 100 °C or the following chemicals: Concentrated mineral acids Benzyl alcohol Concentrated caustic solution Methylene chloride Beijer Electronics, MAEN181B... -

Page 15: Touch Screen Surface

Chemical Resistance 4.2.2 Touch Screen Surface The touch screen surface on the operator panel withstands exposure to the following solvents without visible change: Solvents Time Acetone 10 minutes Isopropanol 10 minutes Toluene 5 hours Beijer Electronics, MAEN181B... -

Page 16: Operator Panel Drawings

Serial port, 9-pin female Serial port, 9-pin female COM1 COM2 COM3 RS422 Tx+ RS485 Tx+/Rx+ RS485 Tx+/Rx+ RS232 RxD RS232 RxD RS232 TxD RS232 TxD RS422 Rx+ RS422 Tx- RS485 Tx-/Rx- RS485 Tx-/Rx- RS232 RTS RS232 CTS RS422 Rx- Beijer Electronics, MAEN181B... -

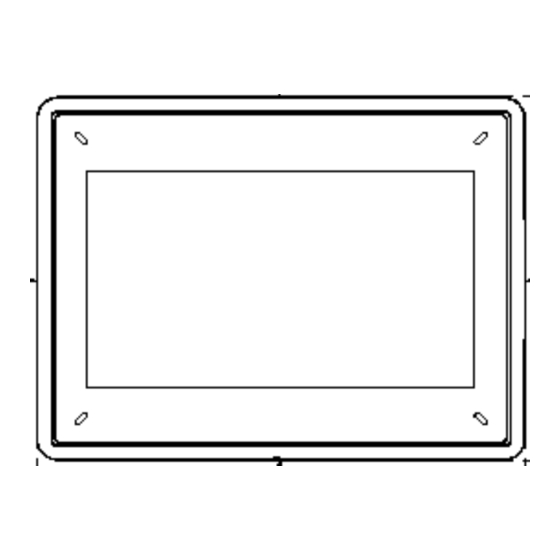

Page 17: X2 Base 7 Outline

Operator Panel Drawings X2 base 7 Outline [mm] 22.2 Max. 6.0 44.7 92.8 35.6 41.1 114.8 185 A.USB Host B. COM3 / COM4 C. Ethernet D. COM1 / COM2 E. 24V DC Beijer Electronics, MAEN181B... -

Page 18: Additional Installation Tips

2 turns around the ferrite core provide 4 times the suppression of 1 turn. 3 turns around the ferrite core provide 9 times the suppression of 1 turn. A ferrite core suppresses disturbances to the 24 V feed, see 6 in drawing above. Beijer Electronics, MAEN181B... -

Page 19: Ethernet Connection In The Operator Panel

1. Check whether the other Ethernet unit has its shield directly grounded or grounded via a capacitor. Note: In many cases, connecting the shielded Ethernet cabling to the chassis at both ends is inappropriate. Hum or grounding loops can occur. Unshielded cabling may even result in fewer communication errors. Beijer Electronics, MAEN181B... - Page 20 A more elegant method is to expand the shielded Ethernet cabling with a piece of unshielded Ethernet cable, see 4 in drawing above. The shield can be grounded via an external 0.1 μF/250 V plastic capacitor, see 5 in drawing above. This connects the HF transients to ground. Beijer Electronics, MAEN181B...

-

Page 21: To Achieve Better Emc Protection

Ferrite cores that are snapped onto the shielded cabling may remove minor disturbances. Large ferrite pieces that are snapped onto unshielded cabling and where the wires go 2-4 times around the cores are approximately 5-25 times more efficient. Beijer Electronics, MAEN181B... -

Page 22: Ambient Temperature

An approximate value of the net power consumption for the operator panel can be calculated by multiplying the supply voltage with the current drawn by the operator panel. This is assuming that all supplied power is transformed to heat. Beijer Electronics, MAEN181B... -

Page 23: Safety

Transients on the 24 V feed are connected to the ground. • No risk that the 24 V feed is at a high level in relationship to the ground. This • is not unusual since there is high static electricity. Beijer Electronics, MAEN181B... -

Page 24: Galvanic Isolation

24 V feed, disturbances and grounding currents from the 0 V on the 24 V side disrupts the communication. Using this type of unit solves one problem but creates a larger problem! A substandard installation may work now, but problems may arise when other devices are connected. Beijer Electronics, MAEN181B... -

Page 25: Cable And Bus Termination Rs485

Depending on the recipients’ design, the bus wires may be on the same level or require pull-up or pull-down to ensure that no faulty signals are detected when the bus is in resting mode (all transmitters are disconnected). Beijer Electronics, MAEN181B... - Page 26 Head office Beijer Electronics AB Box 426 201 24 Malmö, Sweden www.beijerelectronics.com / +46 40 358600...

Need help?

Do you have a question about the X2 base 7 and is the answer not in the manual?

Questions and answers