Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Resol DeltaSol BS/3

-

Page 1: Application Examples

® RESOL D e lt a S o l BS/3 Mounting Connection Application examples Operation Troubleshooting en-US/CA Manual Thank you for buying this RESOL product. Read this manual carefully to get the best perfomance from this unit. Please keep this manual carefully. -

Page 2: Table Of Contents

BS/3 D e lt a S o l ® Contents General ..............2 2.1 Push buttons................14 Overview ..............3 2.2 System monitoring display ..........14 1. Installation ............4 2.3 Flashing codes ..............15 1.1 Mounting ................4 3. Commissioning ..........16 1.2 Electrical connection ............4 4. -

Page 3: Overview

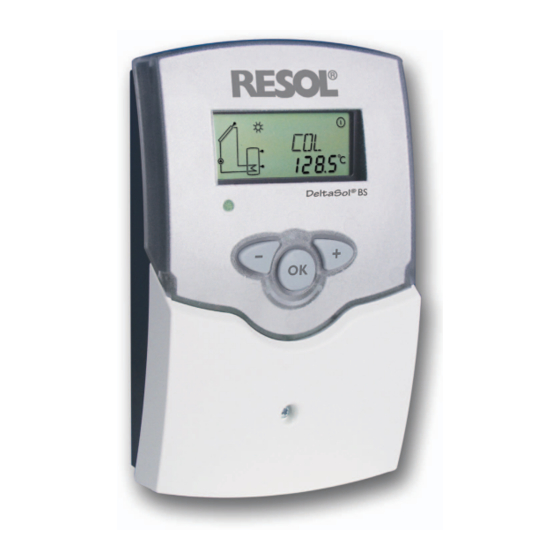

BS/3 D e lt a S o l ® Overview • System-monitoring-display • Up to 4 Pt1000 temperature sensors • 3 basic system layouts to choose from • Energy metering • VBus ® • Function control • Thermostat function (time controlled) •... -

Page 4: Installation

BS/3 D e lt a S o l ® 1. Installation WARNING! Electric shock! 1.1 Mounting Opening the housing will expose display live parts! Î Switch off power supply and discon- nect the device from power supply before opening the housing! The unit must only be installed push button •... -

Page 5: Data Communication/ Bus

FKP type sensors should be used as collector sensors. FRP type sensors are best used as reference sensors in tanks or pipes. 1.3 Data communication/ Bus The controller is equipped with a RESOL VBus for data ® transfer with and energy supply to external modules. The connection is carried out at the terminals marked “VBus”... -

Page 6: Terminal Allocation In The Different System Layouts

BS/3 D e lt a S o l ® 1.4 Terminal allocation in the different system layouts System layout 1 Sensors S3 and S4 can optionally be connected for mea- The controller calculates the temperature difference bet- surement purposes. ween collector sensor S1 and tank sensor S2. If the diffe- rence is larger than or identical to the adjusted switch-on If energy metering (OHQM) is activated, sensor S4 has to be connected as return sensor. - Page 7 BS/3 D e lt a S o l ® Adjustment Channels Channel Description Factory setting Page System DT O Switch-on temperature difference 12.0 °Ra [6.0 K] DT F Switch-off temperature difference 8.0 °Ra [4.0 K] S MX Maximum tank temperature 140 °F [60 °C] Emergency temperature collector 270 °F [130 °C]...

-

Page 8: System Layout 2

BS/3 D e lt a S o l ® System layout 2 The controller calculates the temperature difference bet- when the adjusted thermostat switch-on temperature ween collector sensor S1 and tank sensor S2. If the diffe- (AH O) is reached. This function can optionally be com- rence is larger than or identical to the adjusted switch-on bined with up to three adjustable time frames. - Page 9 BS/3 D e lt a S o l ® Adjustment Channels Channel Description Factory setting Page System DT O Switch-on temperature difference 12.0 °Ra [6.0 K] DT F Switch-off temperature difference 8.0 °Ra [4.0 K] S MX Maximum tank temperature 140 °F [60 °C] Emergency temperature collector 270 °F [130 °C]...

-

Page 10: System-Specific Functions

BS/3 D e lt a S o l ® The following functions are exclusively available in system System-specific functions layout 2. The corresponding channels will not be available in any other system layout. Thermostat function The thermostat function works independently from the Backup heating solar operation and can be used for using surplus energy or for backup heating. - Page 11 BS/3 D e lt a S o l ® Option: Thermal disinfection of the upper DHW zone (OTD) OTD: This function is used for protecting the upper tank zone Thermal disinfection function against Legionella by activating the backup heating. Adjustment range: ON / OFF Reference sensor for the thermal disinfection is S3! Factory setting: OFF Î...

-

Page 12: System Layout 3

BS/3 D e lt a S o l ® System layout 3 The controller calculates the temperature difference bet- will be operated by relay 2 in order to direct the surplus ween collector sensor S1 and tank sensor S2. If the diffe- energy to a heat dump. - Page 13 BS/3 D e lt a S o l ® Adjustment Channels Channel Description Factory setting Page System DT O Switch-on temperature difference 12.0 °Ra [6.0 K] DT F Switch-off temperature difference 8.0 °Ra [4.0 K] S MX Maximum tank temperature 140 °F [60 °C] Emergency temperature collector 270 °F [130 °C]...

-

Page 14: Operation And Function

BS/3 D e lt a S o l ® 2. Operation and function The controller is operated via three push buttons below the display. 2.1 Push buttons Button 1 is used for scrolling forward through the indication menu or to increase the adjustment values. Button 2 is used for scrolling backward and reducing values. -

Page 15: Flashing Codes

BS/3 D e lt a S o l ® System screen The system screen (active system layout) shows the system selected on the controller. It consists of several system component symbols, which are – depending on the current status of the system – either flashing, permanently shown or hidden. -

Page 16: Commissioning

BS/3 D e lt a S o l ® 3. Commissioning Î Establish the power supply During a short initialization phase, the operating control lamp flashes red and green. When the controller is commissioned for the first time or after a reset, it will run a commissioning menu. The commissioning menu leads the user through the most important adjustment channels needed for operating the (OK) - Page 17 BS/3 D e lt a S o l ® Arr: 4. System layout System layout selection Î Adjust the desired system layout of your solar ther- Adjustment range: 1 ... 3 mal system Factory setting: 1 For a detailed description of the different system layouts selectable, see chapter 1.4.

-

Page 18: Channel Overview

BS/3 D e lt a S o l ® 4. Channel overview 4.1 Display channels Note: The displayed values and adjustment channels depend on which system layout, which options and functions have been selected. Only values and adjustment channels available for the indivi- Indication of drainback time periods dual settings selected will appear in the menu. - Page 19 BS/3 D e lt a S o l ® kWh/MWh: Heat quantity Indicates the energy gained in heat quantity – only available if energy metering (OHQM) is activated. in kWh / MWh Display channel The flow rate as well as the reference sensors S1 (flow) and S4 (return) are used for calculating the heat quantity supplied.

-

Page 20: Adjustment Channels

BS/3 D e lt a S o l ® 4.2 Adjustment channels In this channel, a pre-defined system layout can be selected. System layout selection Each system layout has a set of pre-programmed settings Arr: that can be individually changed. System layout selection. - Page 21 BS/3 D e lt a S o l ® Maximum tank temperature Once the adjusted maximum temperature is exceeded, the solar pump is switched off and further loading of the S MX: tank is prevented to reduce scald risk or system damage. A Maximum tank temp.

- Page 22 BS/3 D e lt a S o l ® Cooling functions In the following the three cooling functions – collector cooling, system cooling and tank cooling – are described in detail. The following notes are valid for all three cooling functions: Note: The cooling functions will not become active as...

- Page 23 BS/3 D e lt a S o l ® Tank cooling function When the tank cooling function is activated, the controller aims to cool down the tank during the night in order to OSTC: prepare it for solar loading on the following day. Tank cooling option If the adjusted maximum tank temperature S MX is Adjustment range: OFF / ON...

- Page 24 BS/3 D e lt a S o l ® Evacuated tube collector function O TC: This function helps overcome the disadvantages caused by Evacuated tube collector the non-ideal sensor position with some tube collectors. function This function operates within an adjusted time frame (be- Adjustment range: OFF / ON ginning at TCST and ending at TCEN).

- Page 25 BS/3 D e lt a S o l ® Drainback option Note: A drainback system permits the heat transfer fluid to drain A drainback system layout requires additional back into the holding tank when solar energy is not coll- components such as a holding tank. The ected.

- Page 26 BS/3 D e lt a S o l ® Operating mode For control and service work, the operating mode of the controller can be manually adjusted. For this purpose, select MAN1 / MAN2: the adjustment value MAN1, MAN2 in which the following Operating mode adjustments can be made: Adjustment range:...

-

Page 27: Troubleshooting

BS/3 D e lt a S o l ® 5. Troubleshooting fuse In the case of an error, a message is shown on the display of the controller: Warning symbols Operating control lamp VBus ® terminals sensor terminals load terminals ground terminals power supply... -

Page 28: Various

BS/3 D e lt a S o l ® 5.1 Various: Pump is overheated, but no heat transfer from the Pump starts for a short moment, switches off, switches collector to the tank, flow and return have the same tem- on again, etc. - Page 29 BS/3 D e lt a S o l ® Tanks cool down at night Control the non-return Further pumps which are valve in warm water cir- connected to the solar culation - o.k. tank must also be che- cked. Collector circuit pump runs during the night? Check controller: Manual operation active?

-

Page 30: Accessories

RESOL SD3 (unit °F) Article no.: 180 007 77 Large Display GA3 The RESOL Large Display GA3 is designed for simple connection to RESOL controllers via the RESOL VBus ® . It is used for visualizing the data issued by the controller: collector and store temperature as well as heat quantity produced in the solar system. - Page 31 PC network or router. It enables easy access to the controller via the local network of the owner. Thus, controller access and data charting can be effected from every workstation of the network. A full version of the RESOL ServiceCenter software is included. RESOL VBus / LAN interface adapter Article no.: 180 008 80...

-

Page 32: Impressum

As faults can never be excluded, please note: Your own calculations and plans, under con sider- the approval of RESOL - Elektronische Regelungen GmbH. ation of the current standards should only be basis for your This especially applies for copies, translations, micro- projects.

Need help?

Do you have a question about the DeltaSol BS/3 and is the answer not in the manual?

Questions and answers