Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Direct Color Systems 1024uvmvp

-

Page 1: Getting Started

Getting Started Guide _Getting_Started_Guide_1.2_030314 DCS_Direct_Jet_1024UVMVP... - Page 2 You will be prompted to put in a user name and password. (If you are not prompted then double click on a file) Passwords are as follows and are case sensitive: Login: dcs Password: dcsftp Corporate Direct Color Systems® 99 Hammer Mill Rd Rocky Hill, CT 06067 T: 860-829-2244 F: 860-829-2255 Email: info@directcolorsystems.com...

- Page 3 Equipment Certificate of Compliance Printing Edition 1.2 – March 2014 History Driver installation instructions updated Printed in the USA © Copyright 2014, Direct Color, LLC. All rights reserved. _Getting_Started_Guide_1.2_030314 DCS_Direct_Jet_1024UVMVP...

-

Page 4: Table Of Contents

Turning the Printer on for the First Time LCD Touch Screen Control Screen Main Menu Screen Information Screen Using the 1024UVMVP Understanding Functionality Preparing the Media Table Loading Substrates onto the Media Table Filling the Bulk Ink System Filling or Refilling... - Page 5 The Direct Jet 1024UVMVP accepts material up to 6" (152 mm) thick. Optional heights fully adjustable to 10" (254mm) or 15" (381mm). • The Direct Jet 1024UVMVP model accepts substrates up to 13" (330 mm) x 24" (610 mm) in size and has a printable area of 10" (254mm) x 24" (610 mm). •...

-

Page 6: Safety And Precautions

Go to table of contents Safety and Precautions • Please read these guidelines before operating your Direct Jet printer. • Keep all inks, solvents and lubricants out of the reach of children. • Use only approved cleaning agents and solvents and then only for the purposes specified in this guide. -

Page 7: Getting Started With The Hardware

Go to table of contents Getting Started With the Hardware _Getting_Started_Guide_1.2_030314 P a g e DCS_Direct_Jet_1024UVMVP... -

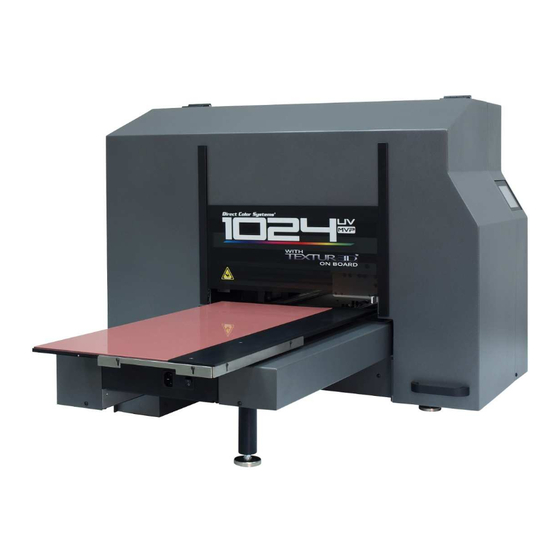

Page 8: Front View

Go to table of contents The 1024UVMVP Below you will find diagrams of the printer and its parts. Be sure to familiarize yourself with all the individual parts and descriptions of the printer as they will be referred to later in this guide. -

Page 9: Rear View

Go to table of contents Rear View Bulk Ink System _Getting_Started_Guide_1.2_030314 P a g e DCS_Direct_Jet_1024UVMVP... -

Page 10: Choosing A Location

Go to table of contents Choosing a Location Position the Direct Jet printer on a stable, level surface platform that doesn't move when the printer is in operation. It is critical that the platform be stable. An unstable platform will significantly impact the graphic printing capability of the printer. - Page 11 DO NOT attempt to use the unit. Contact your dealer/representative or Direct Color Systems directly. The Ink Level screen will appear on the LCD Touch Screen. Silence the alarm by hitting any of the LOW ink lights.

-

Page 12: Lcd Touch Screen

Go to table of contents LCD Touch Screen HMI Version #HM140220 PLC Version #PL140218 _Getting_Started_Guide_1.2_030314 12 | P a g e DCS_Direct_Jet_1024UVMVP... -

Page 13: Control Screen

Go to table of contents Control Screen Your 1024UVMVP is equipped with a 3.5” (89mm) color LCD touch screen display which provides interactive feedback, on-demand printer status, and ink levels. Switching the Main Power on will bring up the Main Control Screen. - Page 14 Go to table of contents raise the print engine and height sensor so when new media is place on the media table, it will clear the sensor when the table moves forward. Lower Print Engine Pressing this button when the power is on will move the print engine down. When you have an object under the height sensor, the print engine will stop once the height sensor has detected the object.

-

Page 15: Main Menu Screen

Go to table of contents Main Menu Screen The Main Menu Screen can be accessed by pressing the icon at any time. Ink Levels This screen displays the current ink level for each color within the Bulk Ink System. The FULL and LOW indicator lights will illuminate to display the current level of ink within each tank. -

Page 16: Information Screen

Go to table of contents Extended Maintenance The Bulk Ink System is equipped with an automatic and programmable white ink circulation system. When the main power is on, the white ink circulation system will automatically circulate the white ink for 120 seconds every 28 minutes. - Page 17 Go to table of contents Control Panel Configuration Button descriptions are available on the Control Panel Configuration screen. Press any button on this screen for more information. Version Information This screen displays the current version of your LCD touch screen software. Initial Calibration Before proceeding with the Getting Started Guide, please refer to the...

-

Page 18: Using The 1024Uvmvp

Go to table of contents Using the 1024UVMVP _Getting_Started_Guide_1.2_030314 18 | P a g e DCS_Direct_Jet_1024UVMVP... -

Page 19: Understanding Functionality

Go to table of contents Understanding Functionality Turn on print engine by pressing . Amber light will turn off. When green light is solid, print engine is powered on and ready. With print engine at max height, test basic functions of printer movement. Press and hold to move media table all the way to the right. - Page 20 Go to table of contents Press and hold until there is sufficient space between the table and the print head to accommodate the thickness of the substrate being loaded. Place the top left edge of the substrate flush with the top left corner of the table using the guides to assure proper placement.

-

Page 21: Filling The Bulk Ink System

Go to table of contents Filling the Bulk Ink System™ _Getting_Started_Guide_1.2_030314 21 | P a g e DCS_Direct_Jet_1024UVMVP... -

Page 22: Filling Or Refilling

Ensure each cap is properly installed on each tank by matching the sticker on the cap to the sticker on the tank. Do not tighten these caps as they will be removed when filling begins. See the assembly instructions found with the 1024UVMVP Refill Kit (PT-1320-K025) for proper refill bottle assembly prior to filling your system. -

Page 23: Priming The System

Guide folder on the orange security device. The Direct Jet 1024UVMVP printer ships with a USB cable for connection between the printer and computer. Connect one end of the USB cable to the USB Connector on the printer and connect the other end to an available USB port on the computer. - Page 24 Go to table of contents Perform six initial charges. After the sixth initial charge is complete run a nozzle check on the provided vellum paper by right clicking on the nozzle check file in the nozzle check queue (tab) and selecting print. If the nozzle check is missing nozzles, run an additional initial charge.

-

Page 25: Difficult To Print To Substrates

Go to table of contents Difficult to Print to Substrates _Getting_Started_Guide_1.2_030314 25 | P a g e DCS_Direct_Jet_1024UVMVP... -

Page 26: Printing Onto Reflective, Shiny And/Or Mirrored Surfaces

Go to table of contents For difficult to print to surfaces such as glass and stainless steel, use our adhesion promoter (I-UV-ADHPR2-200). Apply the promoter to the part of the substrate to be printed to and in normal use, immediately wipe off. Printing can be done with adhesion promoter wet or dry. - Page 27 Go to table of contents is not flat, it will refract light in all directions and you risk curing the inks in the nozzles and on the nozzle plate, which could damage the print head. 3. Angle your RSM substrate slightly so that it slopes downhill away from the capping station as described below.

-

Page 28: Printing Onto Thin Or Low-Melt Point Plastics (E.g. Pvc)

Go to table of contents Printing onto thin or low melt-point plastics (e.g. PVC) If you are using a thin material, the UV Lamp intensity may need to be adjusted so that the material does not warp and scrape against the print head. There is a dial which can be used to adjust the intensity of the lamp to accommodate varying substrates.

Need help?

Do you have a question about the 1024uvmvp and is the answer not in the manual?

Questions and answers