Table of Contents

Advertisement

O

PERATOR'S

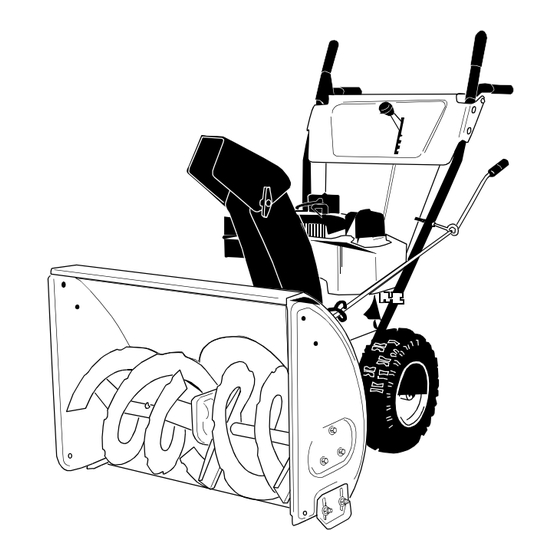

Model Style 4 Shown

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

M

ANUAL

Model Numbers

E602E,E642E,

E642F, E662E,

E662H, 614E,

E644E, E664F,

E6A4E

FORM NO. 770-10003B

6/99

Advertisement

Table of Contents

Summary of Contents for MTD E602E, E642E, E642F, E662E, E662H, 614E, E644E, E644F, E6A4E

- Page 1 Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722. MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722 PRINTED IN U.S.A.

-

Page 2: Section 1: Finding Your Model Number

Operator’s Manual. The information on the model plate is very important if you need help from your dealer or the MTD customer support department. • Every snow thrower has a model plate. You can locate it by standing behind the unit in the operating position and looking down at the rear frame below the engine. -

Page 3: Section 3: Important Safe Operation Practices

SECTION 3: IMPORTANT SAFE OPERATION PRACTICES WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR SNOW THROWER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. -

Page 4: Maintenance And Storage

• If the snow thrower should start to vibrate abnormally, stop the engine and check immediately for the cause. Vibration is generally a warning of trouble. • Stop engine whenever you leave the operating position, before unclogging the collector/impeller housing or discharge guide, and making any repairs, adjustments, or inspections. -

Page 5: Section 4: Contents Of Hardware Pack

SECTION 4: CONTENTS OF HARDWARE PACK Lay out the hardware according to the illustration for identification purposes. Parts are illustrated approximately one-half size. Part numbers are shown in parentheses. (Hardware pack may contain extra items which are not used on your unit.) ATTACHING THE HANDLE ASSEMBLY Hex Bolts 5/16-18 x 1-3/4"... -

Page 6: Section 5: Assembly Instructions

SECTION 5: ASSEMBLY INSTRUCTIONS This operator’s manual covers various models of snow throwers. The units illustrated may vary slightly from your unit. Follow only those instructions which pertain to your model snow thrower. IMPORTANT: After assembly, service engine with gasoline, and check oil level as instructed in the separate engine manual packed with your unit. - Page 7 Auger Control Grip Figure 5 4. Place the auger control grip on top of the left handle. The triangular metal tab must be between the handle and the grip bracket. See Figure 6. Triangle Metal Tab Auger Control Grip Left Left Grip Bracket Handle Spacer...

- Page 8 Cable Roller Hex Bolt Handle Guide 3/4” Long Bolt 1-3/4” Long Figure 9 ATTACHING SHIFT ROD (Hardware D) 1. Place the shift lever in the fastest forward speed position. 2. Models 602, 642, 662: Rotate the shift arm assembly counter clockwise, as far as it will go. Insert the shift rod through the shift arm assembly.

- Page 9 “Z” Cable is Straight Figure 12 4. When correct adjustment is reached, tighten the hex nut against the cable to lock it in position. ATTACHING THE CHUTE ASSEMBLY (Hardware B) 1. Place chute assembly over chute opening, with the opening in the chute assembly facing the front of the unit.

-

Page 10: Final Adjustments

6. Check to make sure all nuts and bolts on the control panel and all four bolts which secure the handles to the frame are tight. LAMP WIRING (If Equipped) Lamp Wire Alternator Lead Right Handle Figure 17 1. Wrap the wire from the lamp down the right handle until the wire can be plugged into the alternator lead wire under the fuel tank. -

Page 11: Section 6: Controls

SECTION 6: CONTROLS THROTTLE CONTROL The throttle control is located on the engine. It regu- lates the speed of the engine. See Figure 20. SAFETY IGNITION SWITCH The ignition key must be inserted in the switch before the unit will start. Remove the ignition key when snow thrower is not in use. -

Page 12: Section 7: Operation

SECTION 7: OPERATION BEFORE STARTING WARNING: Observe all Warning Labels on the snow thrower prior to use. See Figure 2. Your snow thrower is shipped with oil; however, you must check the oil level before operating. Be careful not to overfill. The spark plug wire was disconnected for safety. -

Page 13: To Stop Engine

6. When engine starts, release starter button, and move choke gradually to OFF. If engine falters, move choke immediately to FULL and then gradually to OFF. 7. Repeat steps 6 and 7 until engine starts. If engine fails to start, repeat steps 5, 6, and 7 until engine starts. -

Page 14: Section 8: Adjustments

• Set the skid shoes 1/4" below the scraper bar for normal usage. The skid shoes may be adjusted upward for hard-packed snow. Adjust downward when using on gravel or crushed rock. SECTION 8: ADJUSTMENTS WARNING: Never attempt to clean chute or make any adjustments while engine is running. -

Page 15: Section 9: Lubrication Warning

ADJUSTING SHIFT ROD 1. Remove the hairpin clip and flat washer from the ferrule and remove the ferrule from the shift lever. Place the shift lever in the fastest forward speed position. Models 602, 642, 662: 2. Push up on the shift arm assembly as far as it will go. -

Page 16: Section 10: Maintenance

Shear Bolts Bearings Figure 27 SPROCKET SHAFT Lubricate the sprocket shaft with a light oil at least once a season or after every 25 hours of operation. IMPORTANT: Keep all grease and oil off of the rubber friction wheel and aluminum drive plate. DRIVE AND SHIFTING MECHANISM At least once a season or after every 25 hours of operation, remove the bottom frame cover. -

Page 17: Drive Belt

Rear Auger Belt Engine Pulley Idler Idler Pulley Pulley Figure 29 NOTE: It may be necessary to loosen the six hex nuts that fasten the frame to the auger housing to aid in belt removal. 5. Roll the front and rear auger belts off the engine pulley. -

Page 18: Section 11: Off-Season Storage

5. Using a 7/8" wrench to hold the shaft, loosen, but do not completely remove, the hex nut and bell washer on the left end of gear shaft. See Figure 6. Lightly tap the hex nut to dislodge the ball bearing from the right side of frame. -

Page 19: Section 12: Trouble Shooting Guide

SECTION 12: TROUBLE SHOOTING GUIDE Trouble Possible Cause(s) Engine fails to start Fuel tank empty, or stale fuel. Blocked fuel line. Choke not in ON position Faulty spark plug. Key not in switch on engine. Spark plug wire disconnected. Primer button not depressed. Fuel shut-off valve closed (if so equipped). -

Page 20: Blower Housing

Blower Housing E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F AND E6A4E... - Page 21 Blower Housing E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F AND E6A4E REF. PART DESCRIPTION 712-0116 Lock Jam Nut 3/8-24 756-0178 Flat Idler 784-5632A Auger Idler Arm 710-0459A Hex Cap Screw 3/8-24 x 1.50 741-0475 Bushing 736-0242 Bell Washer 712-3010 Hex Nut 5/16-18 712-0324 Hex Lock Nut 1/4-20...

-

Page 22: Handle Assembly

Handle Assembly E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F AND E6A4E... - Page 23 Handle Assembly E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F AND E6A4E REF. PART DESCRIPTION 712-0116 Jam Lock Nut 3/8-24 732-0193 Compression Spring 736-0105 Bell Washer 784-5619A Shift Handle 710-0459A Hex Cap Screw 3/8-24 736-0275 Flat Washer 714-0104 Cotter Pin 720-0232 Shift Knob 711-0677...

-

Page 24: Frame Assembly

Frame Assembly E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F AND E6A4E Blower Housing Drive Clutch Cable Auger Clutch Cable 16” Wheels 13” or 15” Wheels Auger Clutch Cable... - Page 25 Frame Assembly E602E, E642E, E642F, E662E, E662H, 614E, E644E, E664F AND E6A4E REF. PART 710-1652 Hex Screw 784-5688 Drive Cable Guide Bracket 784-5687A Auger Clutch Cable Bracket 756-0625 Roller Cable 738-0924 Hex Screw 1/4-28 684-0030 Frame Assembly 741-0563 Ball Bearing 736-0105 Bell Washer 712-0116...

- Page 26 Engine and V-Belts E602E, 614E REF. PART 710-1652 Hex Washer Screw 1/4-20 x.5 731-1324 Belt Cover 732-0339 Extension Spring 710-0627 Hex Screw 5/16-24 x .75 710-3005 Hex Cap Screw 3/8-16 x 1.25 05896A Drive Clutch Bracket 748-0234 Shoulder Spacer 756-0985 Pulley Half 754-0343 V-Belt...

- Page 27 Engine and V-Belts E642E, E642F, E662E, E662H, 614E, E644E, E664F AND E6A4E REF. PART 710-1652 Hex Washer Screw 1/4-20 x .50 731-1324 Belt Cover 710-3005 Hex Cap Screw 3/8-16 x 1.25 732-0710 Spring Extension 710-0627 Hex Screw 5/16-24 x .75 05896A Drive Clutch Idler Bracket 748-0234...

- Page 28 The limited warranty set forth below is given by MTD PRODUCTS INC (“MTD”) with respect to new merchan- dise purchased and used in the United States, its posses- sions and territories. MTD warrants this product against defects in material and...

Need help?

Do you have a question about the E602E, E642E, E642F, E662E, E662H, 614E, E644E, E644F, E6A4E and is the answer not in the manual?

Questions and answers

MTD Yard machine Model E644E #317E644E129, serial #1J016B10326 leaking oil trying to remove engine

The manual does not provide specific information about oil leaks when removing the engine. However, oil may leak from the MTD Yard Machine Model E644E during engine removal if the unit is tilted, the oil drain plug or dipstick is not sealed, or if the engine is not fully drained before removal.

This answer is automatically generated