Table of Contents

Advertisement

Quick Links

KHLDV SERIES

DIRECT VENT GAS FIREPLACE

INSTALLATION AND

OPERATING INSTRUCTIONS

MODELS: KHLDV400 & KHLDV500

WARNING

IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT

FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY

RESULT CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

–

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

–

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fi re

department.

–

Installation and service must be performed by a qualifi ed

installer, service agency or the gas supplier.

WARNING: Improper installation, adjustment, alteration,

services or maintenance can cause injury or property

damage. Refer to this manual. For assistance or additional

information consult a qualifi ed installer, service agency

or the gas supplier.

This appliance may be installed in an aftermarket*,

permanently located, manufactured home (USA only) or

mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated

on the rating plate. This appliance is not convertible for

use with other gases, unless a certifi ed kit is used.

* Aftermarket: Completion of sale, not for purpose of resale, from the

manufacturer.

READ BEFORE INSTALLING. SAVE THESE INSTRUCTIONS

D U E TO H I G H T E M P E R AT U R E S , T H E

APPLIANCE SHOULD BE LOCATED OUT OF

TRAFFIC AND AWAY FROM FURNITURE AND

DRAPERIES.

CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF HIGH

SURFACE TEMPERATURE AND SHOULD

STAY AWAY TO AVOID BURNS OR CLOTHING

IGNITION.

YOUNG CHILDREN SHOULD BE SUPERVISED

WHEN THEY ARE IN THE SAME ROOM AS THE

APPLIANCE.

C L O T H I N G O R O T H E R F L A M M A B L E

MATERIAL SHOULD NOT BE PLACED ON

OR NEAR THE APPLIANCE.

K E E P T H E R O O M A R E A C L E A R A N D

FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE, AND OTHER FLAMMABLE

VAPORS AND LIQUIDS.

Advertisement

Table of Contents

Summary of Contents for Monessen Hearth Direct Vent Gas Fireplace KHLDV SERIES

-

Page 1: Installation And Operating Instructions

KHLDV SERIES DIRECT VENT GAS FIREPLACE INSTALLATION AND OPERATING INSTRUCTIONS MODELS: KHLDV400 & KHLDV500 WARNING IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. –... -

Page 2: Table Of Contents

CONTENTS Important Safety Information ... 3 Product Features ... 5 Code Approval ... 5 Pre-Installation Information Installing Above 2000 Feet ... 6 Orifi ce Sizes, Pressures and BTUs ... 6 Before You Start ... 6 Fireplace Framing ... 7 Fireplace Dimensions... 8 Fireplace Location ... -

Page 3: Important Safety Information

INSTALLER Please leave these instructions with the appliance. • Read this owner’s manual carefully and completely before trying to assemble, operate, or service this fi replace. • Any change to this fi replace or its controls can be dangerous. • Improper installation or use of this fi replace can cause serious injury or death from fi... - Page 4 IMPORTANT SAFETY INFORMATION Continued from page 3 12. Do not use this fireplace to cook food or burn paper or other objects. 13. Never place anything on top of fireplace. 14. Do not use any solid fuels (wood, coal, paper, cardboard, etc.) in this fireplace.

-

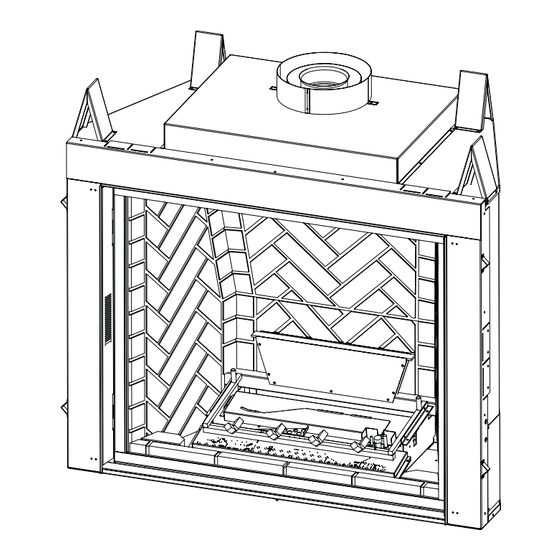

Page 5: Product Features

PRODUCT SPECIFICATIONS Figure 1 - KHLDV Series Fireplace • This appliance is mobile home approved. • The appliance must be properly connected to a venting system. • The appliance is not approved for closet or recessed installations. The efficiency rating of this appliance is a product thermal efficiency rating determined under continuous operating condi- tions and was determined independently of any installed system. -

Page 6: Pre-Installation Information

PRE-INSTALLATION INFORMATION INSTALLING ABOVE 2000 FEET • In the USA, the appliance must be derated 4% for every 1,000 ft above 2,000 ft elevations. Where the heating value of the gas has been reduced, these rules do not apply. • In Canada, these appliances are certified for altitudes of 0 –... -

Page 7: Fireplace Framing

FIREBOX FRAMING Firebox framing can be built before or after the appliance is set in place. Construct firebox framing following Figure 2 and the chart below for your specific installation require- ments. See Figure 3 on page 8 for firebox dimensions. The framing headers may rest on the top of the firebox standoffs. -

Page 8: Fireplace Dimensions

PRE-INSTALLATION INFORMATION FIREPLACE DIMENSIONS DESCRIPTION Overall Front Width Inside Width Glass Width CTR Pipe Rear Width Glass Height Chassis Height Depth Height to Standoffs CTR Height Top Face Side Face Bottom Face Finish Hearth Rise Figure 3 - Fireplace Dimensions Key Letter KHLDV400 KHLDV500... -

Page 9: Cold Climate Insulation

COLD CLIMATE INSULATION If you live in a cold climate, seal all cracks around your appliance, and wherever cold air could enter the room, with noncombustible material. It is especially important to insulate the outside chase cavity between the studs and under the floor on which the appliance rests, if the floor is above ground level. -

Page 10: Mantel Clearances

CLEARANCES CLEARANCES TO COMBUSTIBLES Follow these instructions carefully to ensure safe installation. Failure to follow in struc tions exactly can create a fi re hazard. The appliance cannot be installed on a carpet, tile or other combustible material other than wood fl ooring. If installed on carpet or vinyl fl ooring, the appliance shall be installed on a metal, wood or noncombustible material panel ex tend ing full width and depth of the appliance. -

Page 11: Securing Fireplace To Floor Or Framing

The fireplace must be secured to the floor and/or to framing studs as shown in Figure 6. Use two (2) wood screws or masonry/ concrete screws to secure fireplace to the floor. Use four (4) screws to attach fireplace to framing. The side nailing flanges are 1/2"... -

Page 12: Installation Information

INSTALLATION INFORMATION FINISHING MATERIAL NOTE: Any remote wiring (i.e. remote control, wall switch, and optional fan) must be done prior to fi nal fi nishing to avoid costly reconstruction. Only noncombustible materials (i.e. brick, tile, slate, steel, or other materials with a UL fire rating of Zero) may be used to cover the black painted face of the appliance. -

Page 13: Vent Installation

Horizontal sections of this vent system require a minimum of 3" clearances to combustibles at the top of the fl ue and 1" clearance at the sides and bottom until the fl ue penetrates the outside wall. A minimum 1" clearance all around the fl ue is acceptable at this point of penetration. -

Page 14: Installation Planning

VENT INSTALLATION INSTALLATION PLANNING There are two basic types of direct-vent installation: • Horizontal Termination • Vertical Termination It is important to select the proper length of vent pipe for the type of termination you choose. It is also important to note the wall thickness. - Page 15 FOR HORIZONTAL TERMINATION Vent Terminal Figure 8 - Horizontal Vent Termination Location MINIMUM DISTANCES A = Clearance above the grade, a veranda, porch, deck, or balcony [*12" (305mm) minimum]. B = Clearance to window or door that may be opened [*12" (305mm) minimum]. C = Clearance to permanently closed window [*minimum 12"...

-

Page 16: How To Use The Vent Graph

VENT INSTALLATION TERMINATION CLEARANCES FOR BUILDINGS WITH COMBUSTIBLE AND NONCOMBUSTIBLE EXTERIORS G=6" (152mm) Combustible – 6" (152 mm) Noncombustible – 2" (51mm) Inside Corner G = Combustible 24"(610mm) Noncombustible 18"(457mm) Balcony with No Side Wall HOW TO USE THE VENT GRAPH The Vent Graph should be read in conjunction with the following vent installation instructions to determine the relationship between the vertical and horizontal dimensions of the vent system. -

Page 17: Vertical/Horizontal Termination

VERTICAL/HORIZONTAL TERMINATION CONFIGURATIONS Since it is very important that the venting system maintain its balance between the combustion air intake and the flue gas exhaust, certain limitations as to vent configurations apply and must be strictly adhered to. The Vent Graph, showing the relationship between vertical and horizontal side wall venting, will help to determine the vari- ous dimensions allowable. - Page 18 VENT INSTALLATION VERTICAL/HORIZONTAL TERMINATION CONFIGURATIONS (continued) • If a 90° elbow is used in the horizontal vent run (level height maintained) the horizontal vent length is reduced by 36". See Figures 11 and 12, page 17. This does not apply if the 90°...

-

Page 19: Below Grade Installation

BELOW GRADE INSTALLATIONS When it is not possible to meet the required vent terminal clearances of 12" above grade level, a snorkel kit is recommended. It allows installation depth down to 7" (178mm) below grade level. The 7" (178mm) is measured from the center of the horizontal vent pipe as it penetrates through the wall. -

Page 20: Vertical Through-The-Roof Applications

VENT INSTALLATION VERTICAL (THROUGH-THE-ROOF) APPLICATIONS This gas fireplace has been approved for, • Vertical installations up to 40' (12m) in height. Up to a 10' (3m) horizontal vent run can be installed within the vent system using a maximum of two 90° elbows. See Figure NOTE: Horizontal sections of this vent system require a minimum of 3"... -

Page 21: Installation For Vertical Termination

INSTALLATION FOR VERTICAL TERMINATION 1. Determine the route your vertical venting will take. If ceiling joist, roof rafters or other framing will obstruct the venting system, consider an offset. See Figure 20 to avoid cutting load bearing members. For optimal flame appearance, a restrictor disk is necessary on straight vertical runs of 10' of more. - Page 22 VENT INSTALLATION 3. Cut a hole in the roof using the locating hole as a center point. (Cover any exposed open vent pipes before cutting hole 1/ 2 in roof). The 10 "x10 " (241mm x 241mm) hole must be measured on the horizontal. Actual length may be larger depending on the pitch of the roof.

-

Page 23: Fireplace Installation

CHECK GAS TYPE Use proper gas type for the fireplace you are installing. If you have conflicting gas type, do not install fireplace. See dealer where you purchased the fireplace for proper fireplace for your gas type or conversion kit. INSTALLING GAS PIPING TO FIREPLACE / BURNER SYSTEM LOCATION For propane/LP units, never connect fi... - Page 24 FIREPLACE INSTALLATION Only persons licensed to work with gas piping may make the necessary gas connections to this appliance. NOTE : The gas line connection may be made using some municipalities have additional local codes it is always best to consult your local authorities and the current edition of the National Fuel Gas Code ANSI.Z223.1, NFPA54.

-

Page 25: Checking Gas Pressure

CHECKING GAS PRES SURE 1. Check gas type. The gas supply must be the same as stated on the appliance’s rating decal. If the gas supply is different from the fireplace, STOP! Do not install the appliance. Contact your dealer immediately. 2. -

Page 26: Remote Wall Switch Installation

REMOTE WALL SWITCH INSTALLATION REMOTE WALL MOUNTED SWITCH A remote wall switch and up to fifteen (15) feet of 18 Ga. wire may be used with this appliance. Attach the wall switch in a junction box at the desired location on the wall. See Figure 26. - Page 27 JUNCTION BOX Figure 27 - Junction Box Wiring Diagram 7. Remove the access covers on the right and left side walls of the firebox toward the front by unfastening the screws. NOTE: The access covers are not identical. See Figure 28 8.

- Page 28 OPTIONAL FAN/BLOWER SYSTEM Figure 28 - Blower Access Plates Figure 29 - Blower Access Plates Figure 30 - Assembling Blowers to Access Plates. Figure 31 - Replacing Side Panels 73D0024...

-

Page 29: Glass Removal

GLASS FRAME REMOVAL 1. Remove the plate located in front of the glass at the bottom. 2. Remove rod provided for screen assembly located beneath the cover plate. 3. Rotate the access doors on the right and left side of the glass toward the glass. 4. -

Page 30: Final Installation

FINAL INSTALLATION BRICK, LIGHT BULB, AND LENS PLACEMENT 1. Remove the trapezoidal light shroud located at the back of the firebox by unfastening the three screws. 2. Disassemble the trapezoidal light shroud by unfastening the four screws which secure the front to the back. Set lens with the orange painted surface toward the bottom. -

Page 31: Log Placement

LOG PLACEMENT 1. Place the rear log over the grate toward the back by positioning the holes over the large pins located at the right and left. When the log is in place, the back surface of the log will come in contact with the light trapezoid deflector. 2. - Page 32 FINAL INSTALLATION 5. Place the upper left log at angle over the rear and the middle logs by matching the indentation on the bottom of the log with protrusion on the rear log. Set the pointed end of the log over the flat surface of the middle log. When this log is in place the pointed end will come in contact with the back of the pilot log placed in step #2.

-

Page 33: Operating Instructions (Milli-Volt)

FOR YOUR SAFETY READ BEFORE LIGHTING A. This appliance is equipped with a pilot which must be lit with built-in piezo ignitor while following these instructions exactly. B. BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on the floor. -

Page 34: Lighting Pilot

OPERATING INSTRUCTIONS (MILLI-VOLT) LIGHTING PILOT FOR THE FIRST TIME APPROVED LEAK TESTING METHOD You may check for gas leaks with the following methods only: • Soap and water solution • An approved leak testing spray • Electronic sniffer Never check for gas leak with open fl ame! Check for gas leaks in each of the following locations: •... -

Page 35: Lighting Burner

OPERATING INSTRUCTIONS (MILLI-VOLT) LIGHTING BURNER MAIN BURNER SWITCH The “ON/OFF/RS” switch for the main burner can be found behind door of the fireplace. This switch allows you to turn on and to turn off the main burner without using the gas valve knob. Make sure the button is in the “ON” position to light the main burner. -

Page 36: Cleaning And Maintenance

CLEANING AND MAINTENANCE Turn off gas before servicing fi replace. It is recommended that a qualifi ed service technician perform these check-ups at the beginning of each heating season BURNER, PILOT AND CONTROL COMPARTMENT Keep the control compartment, logs, and burner areas surrounding the logs clean by vacuuming or brushing at least twice a year. -

Page 37: Vent System

VENT SYSTEM The fireplace and venting system should be inspected before initial use and at least annually by a qualified field service person. Inspect the external vent cap on a regular basis to make sure that no debris is interfering with the airflow. Inspect entire venting system to ensure proper function. -

Page 38: Troubleshooting

TROUBLESHOOTING STANDING PILOT IGNITION SYMPTOM POSSIBLE CAUSE 1. Spark ignitor will A. Wire disconnected. not light pilot after repeated triggering of B. Defective ignitor. piezo. C. No gas or low gas pressure. D. No Propane/LPG in tank 2. Pilot will not stay lit A. - Page 39 STANDING PILOT IGNITION SYMPTOM POSSIBLE CAUSE 4. Frequent pilot outage A. Pilot flame may be too high or problem. too low, causing pilot safety to drop out 5. The pilot and main A. Inner vent pipe leaking burner extinguish exhaust gases back into while in operation system B.

-

Page 40: Illustrated Parts Lists

ILLUSTRATED PARTS LISTS FIREBOX COMPONENTS AND ACCESSORIES 73D0024... - Page 41 FIREBOX COMPONENTS AND ACCESSORIES Description Standard Features Bulb Bulb Socket Glass Frame Assembly Junction Block Junction Box Assembly (not shown) Light Lens Panel, Access, Clean 10 Cottage Clay Firebrick Set 10 Cottage Red Firebrick Set 11 Vintage Brown Herringbone Firebrick Set Accessories/Field Installed Options Panel, Access, w/Louvers (used with blower) T-stat Blower with Speed Control...

-

Page 42: Standing Pilot Millivolt Control

ILLUSTRATED PARTS LISTS STANDING PILOT — MILLIVOLT CONTROL 11,12,13, 14 73D0024... - Page 43 STANDING PILOT – MILLIVOLT CONTROL Item Description Gas Valve Assembly Pilot Assembly 2C Replacement Thermocouple Replacement Igniter and Wire Replacement Thermopile Tube, Rear, Venturi Tube, Front, Venturi Tube, Rear, Through-Wall Tube, Front, Through-Wall Flexhose w/ Shutoff Valve Rocker Switch Piezo Igniter Rear Injector Front Injector Rear Burner Assembly...

-

Page 44: Illustrated Parts List

ILLUSTRATED PARTS LIST VENT COMPONENTS FOR 5" Qty/ Item Box Description Horizontal High Wind Termination Cap Horizontal Termination Cap with Built-In Vinyl Siding Standoff, Heat Deflector, Firestop and Adjustable Pipe 7" to 11" Horizontal Termination Cap Built-In Vinyl Siding Standoff, Heat Deflector, Firestop, 90°... -

Page 45: Logs

LOGS 73D0024 Item Description Qty KHLDV400 Log #1 73D0532 Log #2 73D0533 Log #3 73D0534 Log #4 73D0535 Log #5 73D0536 Log #6 73D0537 Log #7 73D0538 ILLUSTRATED PARTS LISTS KHLDV500 73D0134 73D0135 73D0136 73D0137 73D0138 73D0139 73D0140... -

Page 46: Massachusetts Residents Only

MASSACHUSETTS RESIDENTS ONLY: NOTES PLEASE READ AND FOLLOW THESE SPECIAL REQUIREMENTS NOTE REGARDING VENTED PRODUCTS This product must be installed by a licensed plumber or gas fi tter when installed within the Commonwealth of Massachu- setts. Any residence with a direct vent product must have a CO detector installed in the residence. Installation of the fi... - Page 47 2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certifi ed. 3. SIGNAGE. A metal or plastic identifi cation plate shall be permanently mounted to the exterior of the building at a minimum height of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment.

- Page 48 NOTES 73D0024...

- Page 49 NOTES 73D0024...

- Page 50 NOTES 73D0024...

- Page 51 NOTES 73D0024...

-

Page 52: Technical Services

BASIC WARRANTY Monessen Hearth Systems (MHS) warrants the components and materials in your gas appliance to be free from manufacturing and material defects for a period of two years from date of installation. After installation, if any of the components manu- factured by MHS in the appliance are found to be defective in materials or workmanship, MHS will, at its option, replace or repair the defective components at no charge to the original owner.

Need help?

Do you have a question about the Direct Vent Gas Fireplace KHLDV SERIES and is the answer not in the manual?

Questions and answers