Summary of Contents for Miller Electric 172 M-10 Gun

- Page 1 Millermatic Challenger 172 Visit our website at www.MillerWelds.com OM-1318 March 2000 Processes Description Wire Feeder And M-10 Gun 187923F MIG (GMAW) Flux Cored (FCAW)

- Page 2 ISO 9001 Quality System Standard. service information for your particular model are also provided. Miller Electric manufactures a full line of welders and welding related equipment. For information on other quality Miller products, contact your local Miller distributor to receive the latest full line catalog or individual catalog sheets.

-

Page 3: Table Of Contents

SECTION 1 – SAFETY PRECAUTIONS - READ BEFORE USING 1-1. Symbol Usage 1-2. Arc Welding Hazards 1-3. Additional Symbols For Installation, Operation, And Maintenance 1-4. Principal Safety Standards WARNING 1-5. EMF Information SECTION 1 – CONSIGNES DE SECURITE – LIRE AVANT UTILISATION This product, when used for welding or cutting, 1-1. -

Page 5: Section 1 - Safety Precautions - Read Before Using

SECTION 1 – SAFETY PRECAUTIONS - READ BEFORE USING 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. Y Marks a special safety message. Means “Note”; not safety related. 1-2. - Page 6 D Do not use welder to thaw frozen pipes. D Remove stick electrode from holder or cut off welding wire at contact tip when not in use.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. D Do not install or place unit on, over, or near combustible surfaces. D Do not install unit near flammables. D Do not overload building wiring – be sure power supply system is properly sized, rated, and protected to handle this unit. -

Page 8: Emf Information

1-5. EMF Information Considerations About Welding And The Effects Of Low Frequency Electric And Magnetic Fields Welding current, as it flows through welding cables, will cause electro- magnetic fields. There has been and still is some concern about such fields. However, after examining more than 500 studies spanning 17 years of research, a special blue ribbon committee of the National Research Council concluded that: “The body of evidence, in the committee’... -

Page 9: Section 1 - Consignes De Securite - Lire Avant Utilisation

SECTION 1 – CONSIGNES DE SECURITE – LIRE AVANT 1-1. Signification des symboles Signifie Mise en garde ! Soyez vigilant ! Cette procédure présente des risques de danger ! Ceux-ci sont identifiés par des symboles adjacents aux directives. Y Identifie un message de sécurité particulier. Signifie NOTA ;... - Page 10 LES RAYONS DE L’ARC peuvent pro- voquer des brûlures dans les yeux et sur la peau. Le rayonnement de l’arc du procédé de soudage génère des rayons visibles et invisibles intenses (ultraviolets et infrarouges) susceptibles de provoquer des brûlures dans les yeux et sur la peau. Des étincelles sont projetées pendant le soudage.

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

1-3. Dangers supplémentaires en relation avec l’installation, le fonctionnement et la maintenance Risque D’INCENDIE OU D’EXPLOSION. D Ne pas placer l’appareil sur, au-dessus ou à proxi- mité de surfaces infllammables. D Ne pas installer l’appareil à proximité de produits inflammables D Ne pas surcharger l’installation électrique –... -

Page 12: Principales Normes De Sécurité

1-4. Principales normes de sécurité Safety in Welding and Cutting, norme ANSI Z49.1, de l’American Wel- ding Society, 550 N.W. Lejeune Rd, Miami FL 33126 Safety and Health Sandards, OSHA 29 CFR 1910, du Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402. -

Page 13: Section 2 - Specifications

SECTION 2 – SPECIFICATIONS 2-1. Specifications Rated Welding Amperage Output Range 130 A @ 20 Volts 40 – 170 DC, 30% Duty Cycle Wire Type Solid/ And Dia Stainless .023 – .035 in (0.6 – 0.9 mm) * While idling 2-2. -

Page 14: Welding Power Source Duty Cycle And Overheating

2-3. Welding Power Source Duty Cycle And Overheating 3 Minutes Welding Overheating 2-4. Welding Gun Duty Cycle And Overheating CAUTION WELDING LONGER THAN RATED DUTY CYCLE can damage gun and void warranty. Do not weld at rated load longer than shown below. Using gasless flux cored wire reduces gun duty cycle. -

Page 15: Section 3 - Installation

SECTION 3 – INSTALLATION 3-1. Installing Work Clamp Tools Needed: 3/8, 7/16 in 3-2. Installing Welding Gun And Changing Polarity Tools Needed: Follow wire manufacturer’s recommendation. 5/16 in Flux Cored Wires (FCAW–Without Gas) Straight Polarity Solid Steel Or Aluminum Wires (GMAW–With Gas) Reverse Polarity DCEN... -

Page 16: Installing Gas Supply

3-3. Installing Gas Supply OM-1318 Page 12 Tools Needed: 5/8, 1-1/8 in Argon Gas Obtain gas cylinder and chain to running gear, wall, or other station- ary support so cylinder cannot fall and break off valve. Cylinder Valve Remove cap, stand to side of valve, and open valve slightly. -

Page 17: Electrical Service Guide

3-4. Electrical Service Guide Input Voltage Input Amperes At Rated Output Max Recommended Standard Fuse Or Circuit Breaker Rating In Amperes Min Input Conductor Size In AWG/Kcmil Max Recommended Input Conductor Length In Feet (Meters) Min Grounding Conductor Size In AWG/Kcmil Reference: 1999 National Electrical Code (NEC) 1 Choose a circuit breaker with time-current curves comparable to a Time Delay Fuse. -

Page 18: Installing Wire Spool And Adjusting Hub Tension

3-6. Installing Wire Spool And Adjusting Hub Tension 1 Lb Wire Spool Standard Wire Spool Standard Wire Reel Part No. 135 615 Part No. 183 312 When a slight force is needed to turn spool, tension is set. Tools Needed: 15/16 in S-0499 OM-1318 Page 14... -

Page 19: Installing Drive Roll, Wire Guide And Threading Welding Wire

3-7. Installing Drive Roll, Wire Guide And Threading Welding Wire Open pressure assembly. Close and tighten pressure assembly, and let go of wire. Press gun trigger until wire comes out of gun. Tools Needed: 6 in (150 mm) Push wire thru guides into gun; Pull and hold wire;... -

Page 20: Weld Parameter

3-8. Weld Parameter Wire Type, Wire Operator Shielding Gas, Diameter Controls And Flow Rate (inch) Voltage Tap* .023 Wire Speed Voltage Tap* E70S-6 .030 20 cfh+ Wire Speed Voltage Tap* .035 Wire Speed Voltage Tap* .023 Wire Speed E70S-6 Voltage Tap* 75% Argon 75% Argon .030... -

Page 21: Section 4 - Operation

SECTION 4 – OPERATION 4-1. Controls Wire Speed Control Use control to select a wire feed speed. As Voltage switch setting in- creases, wire speed range also in- creases (see weld setting label in welding power source). Voltage Switch Switch must “click” into detent position 1, 2, 3, or 4 for proper contact. -

Page 22: Section 5 - Maintenance &Troubleshooting

SECTION 5 – MAINTENANCE &TROUBLESHOOTING 5-1. Routine Maintenance 3 Months Replace unreadable labels. 6 Months Blow out or vacuum inside. during heavy service, clean monthly. 5-2. Drive Motor Fuse F1 Tools Needed: 3/8 in 5-3. Short Circuit Shutdown If contact tip is shorted and sticks to workpiece, the unit shuts down, but fan runs. To resume operation, release gun trigger, turn Off unit, and remove contact tip from workpiece. -

Page 23: Cleaning Or Repairing Drive Assembly

5-4. Cleaning Or Repairing Drive Assembly 5-5. Replacing Gun Contact Tip Tools Needed: Tools Needed: 5/64 in Y Turn power before cleaning or repairing drive assembly. Wire Spool Nozzle Cut welding wire off at nozzle. Re- tract wire onto spool and secure. Pressure Roll Arm Cotter Pin Screw... -

Page 24: Cleaning Or Replacing Gun Liner

5-6. Cleaning Or Replacing Gun Liner 1/2 in Lay gun cable out straight before installing new liner. OM-1318 Page 20 Y Disconnect gun from unit. Head Tube Remove nozzle, contact tip, adapter, gas diffuser, and wire outlet guide. Blow out gun casing. Tools Needed: 3/8 in Remove liner. -

Page 25: Replacing Switch And/Or Head Tube

5-7. Replacing Switch And/Or Head Tube Remove handle locking nut. Secure head tube in vice. Install existing shock washer onto new head tube. Hand-tighten head tube into connector cable. Tools Needed: 3/4 in Y Disconnect gun first. Remove switch housing. Note: If installing new switch, push switch lead connectors onto terminal of new switch (polarity is not important). -

Page 26: Troubleshooting Table

5-8. Troubleshooting Table Trouble No weld output; wire does not feed; fan Secure power cord plug in receptacle (see Section 3-5). does not run. Replace building line fuse or reset circuit breaker if open (see Section 3-5). Secure gun trigger plug in receptacle (see Section 3-2). Place Power switch in On position (see Section 4-1). -

Page 27: Section 6 - Electrical Diagram

SECTION 6 – ELECTRICAL DIAGRAM SB-210 034 Figure 6-1. Circuit Diagram OM-1316 Page 23... -

Page 28: Section 7 - Mig Welding (Gmaw) Guidelines

SECTION 7 – MIG WELDING (GMAW) GUIDELINES 7-1. Typical MIG Process Connections Regulator/ Flowmeter Shielding Gas OM-1318 Page 24 Wire Feeder/ Power Source Work Clamp Y Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a vehicle. -

Page 29: Typical Mig Process Control Settings

7-2. Typical MIG Process Control Settings NOTE These settings are guidelines only. Material and wire type, joint design, fitup, position, shielding gas, etc. affect settings. Test welds to be sure they comply to specifications. Material thickness determines weld parameters. .035 in Wire Recommendation Size... -

Page 30: Holding And Positioning Welding Gun

7-3. Holding And Positioning Welding Gun NOTE Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle, and tip of wire is positioned correctly on seam. End View Of Work Angle End View Of Work Angle OM-1318 Page 26... -

Page 31: Conditions That Affect Weld Bead Shape

7-4. Conditions That Affect Weld Bead Shape NOTE Weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base metal, wire feed speed (weld current), and voltage. Short Short FILLET WELD ELECTRODE EXTENSIONS (STICKOUT) Slow Push Perpendicular... -

Page 32: Gun Movement During Welding

7-5. Gun Movement During Welding NOTE Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads works better. 7-6. Poor Weld Bead Characteristics 7-7. -

Page 33: Troubleshooting - Excessive Spatter

7-8. Troubleshooting – Excessive Spatter Possible Causes Wire feed speed too high. Voltage too high. Electrode extension (stickout) too long. Workpiece dirty. Insufficient shielding gas at welding arc. Dirty welding wire. 7-9. Troubleshooting – Porosity Possible Causes Insufficient shielding gas at welding arc. Wrong gas. -

Page 34: 7-11.Troubleshooting - Lack Of Penetration

7-11. Troubleshooting – Lack Of Penetration Lack of Penetration Good Penetration Possible Causes Improper joint preparation. Improper weld technique. Insufficient heat input. 7-12. Troubleshooting – Incomplete Fusion Possible Causes Workpiece dirty. Insufficient heat input. Improper welding technique. 7-13. Troubleshooting – Burn-Through Possible Causes Excessive heat input. -

Page 35: 7-14.Troubleshooting - Waviness Of Bead

7-14. Troubleshooting – Waviness Of Bead Possible Causes Welding wire extends too far out of nozzle. Unsteady hand. 7-15. Troubleshooting – Distortion Base metal moves in the direction of the weld bead. Possible Causes Excessive heat input. Waviness Of Bead – weld metal that is not parallel and does not cover joint formed by base metal. -

Page 36: Common Mig Shielding Gases

7-16. Common MIG Shielding Gases This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been developed over the years. The most commonly used shielding gases are listed in the following table. - Page 37 Notes OM-1318 Page 33...

-

Page 38: Section 8 – Parts List

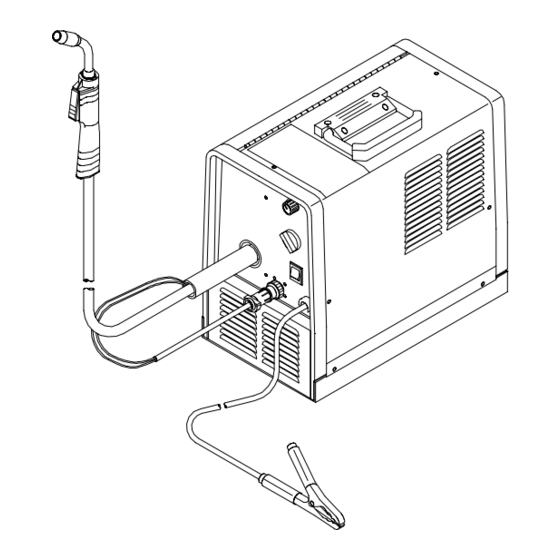

SECTION 8 – PARTS LIST Hardware is common and not available unless listed. ST-801 996-A Figure 8-1.Complete Assembly OM-1318 Page 34... - Page 39 Item Dia. Part Mkgs. Figure 8-1. Complete Assembly ....126 838 DRIVE ASSEMBLY, wire (consisting of) ....090 416 .

- Page 40 Item Dia. Part Mkgs. Figure 8-1. Complete Assembly ....026 843 INSULATOR, vinyl ....111 644 BUSHING, strain relief .370/.430 ID .

- Page 41 Item Part ..169 715 NOZZLE, slip type .500 orf flush ..087 299 TIP, contact scr .023 wire x 1.125 ..000 067 TIP, contact scr .030 wire x 1.125 .

- Page 43 Warranty Questions? Call LIMITED WARRANTY – Subject to the terms and conditions below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants 1-800-4-A-MILLER to its original retail purchaser that new Miller equipment sold for your local after the effective date of this limited warranty is free of defects in material and workmanship at the time it is shipped by Miller.

-

Page 44: Owner's Record

Parts) Circuit Diagrams Welding Process Handbooks File a claim for loss or damage during shipment. 2000 Miller Electric Mfg. Co. 6/00 Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters–USA USA Phone: 920-735-4505 Auto-Attended USA &...

Need help?

Do you have a question about the 172 M-10 Gun and is the answer not in the manual?

Questions and answers

the wire feed motor won't work - what is the problem

If the wire feed motor on a Miller Electric 172 M-10 Gun won't work, possible issues include:

1. No weld output, wire does not feed, and fan does not run:

- Ensure the power cord plug is securely in the receptacle.

- Replace the building line fuse or reset the circuit breaker.

- Secure the gun trigger plug in the receptacle.

- Turn the power switch to the "On" position.

2. No weld output, wire does not feed, but fan motor continues to run:

- Ensure the Voltage control knob is in a proper detent position (1, 2, 3, or 4).

- If the unit has overheated, allow the fan to run until the thermostat resets.

- Check and replace the motor fuse (F1) if necessary.

- Have a Factory Authorized Service Agent inspect board connections and the PC1 board.

These steps should help diagnose and resolve the issue with the wire feed motor.

This answer is automatically generated