Mitsubishi S16R Operating Instructions Manual

Hide thumbs

Also See for S16R:

- Operation & maintenance manual (112 pages) ,

- Operation & maintenance manual (216 pages) ,

- Service manual (380 pages)

Table of Contents

Advertisement

Quick Links

OPERATION &

MAINTENANCE MANUAL

1

The operator and supervisor are requested to read this Oper-

ation and Maintenance Manual carefully before operating the

engine or conducting inspection and maintenance.

Never operate the engine or conduct maintenance work with-

out completely understanding this manual.

January 2011

Pub. No. 99240-36160

Advertisement

Table of Contents

Summary of Contents for Mitsubishi S16R

- Page 1 OPERATION & MAINTENANCE MANUAL The operator and supervisor are requested to read this Oper- ation and Maintenance Manual carefully before operating the engine or conducting inspection and maintenance. Never operate the engine or conduct maintenance work with- out completely understanding this manual. January 2011 Pub.

- Page 3 FOREWORD This operation and maintenance manual contains detailed operation, inspection and maintenance information for engines from Mitsubishi Heavy Industries, Ltd. Please be forewarned that there are contents which are overlapping between the chapters. Please read this manual thoroughly before proceeding with operation, inspection, and maintenance work for correct use and servicing.

-

Page 4: Limited Warranty

FOREWORD LIMITED WARRANTY If Mitsubishi Heavy Industries, Ltd. examines the returned parts and any failure at manufacturing is found, Mitsubi- shi Heavy Industries, Ltd. shall repair or exchange the parts. Mitsubishi Heavy Industries, Ltd.'s warranty is limited to the compensation work of repair or replacement of parts. - Page 5 Protection Agency. Warranty overage Mitsubishi Heavy Industries, Ltd. warrants to the first owner and each subsequent purchaser of a new non-road die- sel engine that the emission control system of your engine: is designed, built and equipped so as to conform at the time of sales with all applicable regulation of the U.S. Envi- ronmental Protection Agency.

- Page 6 Manufacurer's warranty coverage: The 2011 and later heavy-duty off-road engines are warranted for the warranty period. If any emission-related part on your engine is defective, the part will be repaired or replaced by Mitsubishi Heavy Industries, Ltd. Owner's warranty responsiblities As the heavy-duty off-road engine owner, you are responsible for the performance of the required maintenance...

- Page 7 Subsection (e) shall be warranted for the warranty period defined in Subsection (b) (2). If any such part fails during the period of warranty coverage, it shall be repaired or replaced by Mitsubishi Heavy Industries, Ltd. according to Subsection (4) below. Any such part repaired or replaced under the war- ranty shall be warranted for the remaining warranty period.

- Page 8 (11) The Air Resources Board may request and, in such case, Mitsubishi Heavy Industries, Ltd. shall provide, any documents which describe that Mitsubishi Heavy Industries, Ltd.'s warranty procedures or policies.

- Page 9 (F) Any other part with the primary purpose of reducing emissions or that can increase emission during fail- ure without significantly degrading engine performance. (e) Mitsubishi Heavy Industries, Ltd. shall furnish with each new engine written instructions for the maintenance and use of the engine by the owner.

-

Page 10: Important Information

If you lost or damaged this manual, obtain a new copy at a dealer of Mitsubishi Heavy Industries, Ltd. as soon as possible. Mitsubishi Heavy Industries, Ltd. recommends the engine owner to install an hour meter on the engine due to monitor correct running intervals and to per- form the maintenance at the appropriate timing. - Page 11 FOREWORD WARNING INDICATION The following means are used to call the attention of the operators and maintenance personnel to potential dangers of the engine. Warning statements in the manual Warning labels affixed on the engine Warning tatements The warning statements in this manual describe potential danger in operating, inspecting or maintaining the engine, using the following five classifications to indicate the degree of potential hazard.

- Page 12 FOREWORD Measurements are based on the International System of Units (SI), and they are converted to the metric system units in this manual using the following conversion rates. Pressure :1 MPa = 10.197 kgf/cm Torque:1 N•m = 0.10197 kgf•m Force:1 N = 0.10197 kgf Horsepower:1 kW = 1.341 HP = 1.3596 PS Meter of mercury:1 kPa = 0.75 cmHg Meter of water:1 kPa = 10.197 cmH...

-

Page 13: Table Of Contents

CONTENTS Do Not Add Coolant Immediately After a Sudden Chapter 1 Stop Due to Overheating........1-5 BASIC SAFETY PRECAUTIONS Stop Operation Immediately If You Notice Any Fire and Explosions ......1-1 Unusual Symptoms .......... 1-5 Keep Flames Away .......... 1-1 Avoid Immediate Restart After Abnormal Stop. 1-5 Always Swich the Water Heater ON Avoid Continuous Engine Operation at Low Oil (Emergency generator with water heater).. - Page 14 CONTENTS Oil Filter Alarm Switch........2-4 Chapter 5 Revolution Detection Pickup ......2-5 ENGINE OIL Air Cleaner Indicator ........2-5 Recommended Engine Oil ....5-1 Using Turning Gear ......2-6 Engine Oil Grade ........ 5-1 Engine Oil Specification ...... 5-2 Chapter 3 Selection of Oil Viscosity.....

- Page 15 Gauze Filter - Clean ......... 8-8 General Precautions ......11-1 Fuel Filter - Replace......... 8-9 Contact a Dealer of Mitsubishi Heavy Industries, Fuel Control Link Ball Joint - Inspect....8-10 Ltd. for Repair Service ........11-1 Fuel Pipe - Inspect ......... 8-11 Considerations Before Work ......

- Page 16 CONTENTS Fig. 3-18 Thermo label of damper ......3-12 List of illustrations Fig. 1-1 Warning labels........1-9 Fig. 3-19 Manual Stop Lever ......3-15 Fig. 2-1 Engine Left Side View ......2-1 Fig. 5-1 Engine Oil Grade........5-1 Fig. 2-2 Engine Right Side View ....... 2-1 Fig.

- Page 17 CONTENTS Fig. 8-30 Battery Electrolyte Level - Inspect ..8-23 List of tables Fig. 8-31 Specific Gravity of Battery Electrolyte Table 3-1 Inspection During Operation....3-14 - Check ..........8-23 Table 4-1 Recommended Fuel ........4-1 Fig. 8-32 Starter - Inspect........8-24 Table 4-2 Recommended Limit and Use Limit of Fig.

-

Page 19: Basic Safety Precautions Fire And Explosions

Chapter 1 BASIC SAFETY PRECAUTIONS Fire and Explosions Keep Flames Away Do Not Open Side Cover Until Engine Cools Do not use flames near the engine (in the engine room). Fuel gas vapor or Do not attempt to open the side cover of the crank- other gas can catch fire and produce case before the engine cools down. -

Page 20: Stay Clear Of All Rotating And Moving Parts

Chapter 1 BASIC SAFETY PRECAUTIONS Stay Clear of All Rotating and Moving Parts Install Protective Covers Lockout and Tagout Around Rotating Parts Be sure to lockout and tagout before starting inspec- Make sure the protective covers of tion and maintenance. the engine are correctly installed. -

Page 21: Be Careful Of Exhaust Fume Poisoning1-3

Chapter 1 BASIC SAFETY PRECAUTIONS Be Careful of Exhaust Be Careful of Falling Fume Poisoning Down Operate Engine in a Well-venti- Lift Engine Carefully lated Area To lift the engine, use slings capable of supporting the weight of the Check the exhaust pipes and where engine. -

Page 22: Be Careful Of Burns

Chapter 1 BASIC SAFETY PRECAUTIONS Be Careful of Burns Do Not Touch the Engine Dur- Be Careful of Opening and ing or Immediately After Opera- Closing Radiator Cap tion Never open the radiator cap while the engine is run- To avoid burns, do not touch the ning or immediately after the engine is stopped. -

Page 23: Be Careful When Handling Fuel, Engine Oil Or Llc

Chapter 1 BASIC SAFETY PRECAUTIONS Be Careful When Handling When Abnormality Occurs Fuel, Engine Oil or LLC Do Not Add Coolant Immedi- ately After a Sudden Stop Due Use Only Specified Fuel, to Overheating Engine Oil and LLC If the engine stops suddenly or if you have no choice Use fuel, oil and LLC specified in this manual, and but stop the engine suddenly due to overheating, do handle them carefully. -

Page 24: Battery

Chapter 1 BASIC SAFETY PRECAUTIONS Battery Handle the Battery Correctly Never use flames or allow sparks to generate near the battery. The bat- tery releases flammable hydrogen gas and oxygen gas. Any flames or sparks in the vicinity could cause an explosion. -

Page 25: Other Cautions

If there is a need to modify the engine, contact a Failure to conduct the specified inspections may dealer of Mitsubishi Heavy Industries, Ltd. cause various engine problems, damage to parts, and Observe Safety Rules at Work serious accidents. -

Page 26: Conduct Cooling Operation Before Stopping The Engine

Chapter 1 BASIC SAFETY PRECAUTIONS Conduct Cooling Operation Use of Tools Optimum for Each Before Stopping the Engine Work Before stopping the engine, idle the engine in low gear Always keep in mind to select most appropriate tools for 5 to 6 minutes to cool down. for the work to be performed and use them correctly. -

Page 27: Warning Labels

If any engine part on which a warning label is attached is replaced with a new one, attach a new identical warning label to the new part. To obtain new warning labels, contact a dealer of Mitsubishi Heavy Industries, Ltd. Fig. 1-1 Warning labels... -

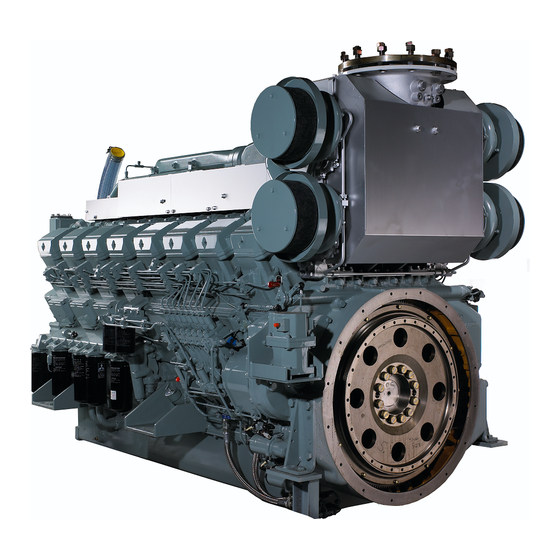

Page 29: Name Of Parts

Chapter 2 NAME OF PARTS Engine External Diagrams Left Side Rear hanger Fuel filter Front hanger Turbocharger Breather Fuel injection pump Front Rear Governor actuator Coolant drain cock Damper Fuel feed pump Starter Bypass oil filter Oil cooler Oil filler Fuel return port Oil filter Oil level gauge... -

Page 30: Equipment And Instrument

Chapter 2 NAME OF PARTS Equipment and Instrument The installed equipment and shapes differ on the engine type. Start and Stop Instrument Start Switch When the start switch on the operation panel is pressed, starting system operates to crank the engine. START STOP Stop Switch... -

Page 31: Instruments

Chapter 2 NAME OF PARTS Instruments This section describes about devices which transmit signals to necessary instruments of the engine operation. Read carefully and understand functions of each device. Oil Pressure Unit Indicate the oil pressure. Oil pressure unit Fig. 2-6 Oil Pressure Unit Thermo Unit Always detect the coolant temperature of engine. -

Page 32: Engine Protection Devices

If the cause of the problem is unknown, contact a dealer of Mitsubishi Heavy Industries, Ltd. Protection devices installed on the engine and their types (setting values) and shapes vary depending on the engine specifications. -

Page 33: Revolution Detection Pickup

Chapter 2 NAME OF PARTS Revolution Detection Pickup The overrun detection pickup generates an alarm when the engine speed becomes high and reaches the specified engine speed. Fig. 2-12 Revolution Detection Pickup Air Cleaner Indicator If the element is clogged, the intake air is decreased and the red signal mark will be displayed. -

Page 34: Using Turning Gear

Chapter 2 NAME OF PARTS Using Turning Gear Before starting the engine, make sure that the manual turning gear is pulled out in the original position. S tarting the engine with the turning gear pushed in not only damages the ring gear but also may result in personal injury. 1. -

Page 35: Operational Environment

Chapter 3 OPERATION Operational Environment Check that the following contents are performed before the engine is operated. Failure to do so may c a use various problems and will shorten the service life of the engine. Prevent from spreading water (especially, seawater or rainwater) and entering foreign materials to the air inlet opening. -

Page 36: Fig. 3-1 Priming Pump - Handle

Chapter 3 OPERATION Fuel System - Bleed Air [Unlock] [Priming] [Lock] When fuel overflow from the air vent plug, wipe thor- oughly. Spilled fuel causes fire hazard. Turn left Move up After bleeding, lock the priming pump securely. If the Hold and and down turn right... -

Page 37: Fig. 3-4 Priming Pump Tightening Method

Chapter 3 OPERATION Priming Pump Tightening Method ° ± ° Position where Never fail to tighten the priming pump to the speci- hand-tightening becomes suddenly fied angle. If the priming pump is not firmly tightened, Priming pump heavy internal thread will be worn due to engine vibration, resulting in sudden ejection of the cap to cause fuel Head can be damaged flow-out. -

Page 38: Preparation Of Lubrication System

Chapter 3 OPERATION Preparation of Lubrication System Engine Oil - Refill Oil level gauge Refilling engine oil must be specified level. If the refilling oil goes over the high marks on the oil level gauge, engine oil may blow out. And also, the engine Improper component parts are adversely affected by increas- High... -

Page 39: Preparation Of Cooling System

Chapter 3 OPERATION Preparation of Cooling System Radiator Cap - Open/Close Stand the lever to Turn the cap about When using the engine with radiator cooling system, the upright position half a turn remove the radiator cap only after the engine has cooled to the room temperature. -

Page 40: Preparation Of Electrical System

Chapter 3 OPERATION Preparation of Electrical System Battery - Check If battery electrolyte is spilled on your skin or clothes, flush immediately with plenty of water. If battery electrolyte get into your eyes, flush them immediately with plenty of water and then get medical attention. Do not use open flames or other fire hazards near the battery. -

Page 41: Test Operation

Chapter 3 OPERATION Test Operation To conduct a test operation, follow the procedures below. Always switch the water heater ON (automatic mode) through a whole year. If the switch is not ON (automatic mode), each cylinder varies considerably in combustion at the starting up the engine. -

Page 42: Normal Engine Operation

2. Check the whole engine for leaks of fuel, engine oil or coolant. If leaks are found, repair the leak, or contact a dealer of Mitsubishi Heavy Industries, Ltd. 3. Visually check bolts and nuts for looseness. -

Page 43: Fuel Tank Oil Level - Check

Chapter 3 OPERATION Fuel Tank Oil Level - Check When working around fuel, make sure there are no open flames, heaters or other fire hazards. Wipe off any spilled fuel completely. Spilled fuel can ignite and cause a fire. Do not remove the strainer when filling the fuel tank. If the engine has a float switch and the fuel level is higher the "LOW"... -

Page 44: Coolant Level - Check

Chapter 3 OPERATION Coolant Level - Check Always use the coolant having the same concentration. If the coolant level is low, add coolant to the specified level. Note: Determine the quantities of LLC based on the coolant capacity and the LLC concentration chart. For the coolant, refer to "COOLANT"... -

Page 45: Air Tank Air Pressure - Check

5E-50 5E-50 5E-50 5E-50 If the abnormality of temperature alteration is found, consult a dealer of Mitsubishi Heavy Industries, Ltd. Fig. 3-18 Thermo label of damper Note: For damper temperature limit and inspection, re- fer to "Damper - Inspect" (8-4). -

Page 46: Start

Chapter 3 OPERATION Start The starting method varies depending on the application and specifications. Start the engine according to the spec- ified procedure. Before starting the engine, check to make sure no one is near the engine and that tools are not left on or near the engine. -

Page 47: Run

Chapter 3 OPERATION Cautions During Operation Inspection During Operation Check for abnormal engine noises or vibrations such as knocking or the exterior of engine such as piping Do not approach rotating parts during operation. joints for leaks. Entanglement by rotating parts can result in serious Carefully check the following items whether there is injury. -

Page 48: Stop

Fig. 3-19 Manual Stop Lever Inspection After Stopping Inspect the engine for fuel, oil or coolant leaks. If any leak is found, repair the leak or contact a dealer of Mitsubishi Heavy Industries, Ltd. 3-14... -

Page 49: Recommended Fuel

Chapter 4 FUEL Recommended Fuel Use a fuel specified in this manual only . Do not refill the fuel tank more than the specified level. Otherwise, fire may result. Use fuel that meets the values specified in the following Table 4-1 of "Recommended Fuel"... -

Page 50: Fuel Specification

Chapter 4 FUEL Fuel Specification Use fuel which meets the requirements specified in the table below. Table 4-2 Recommended Limit and Use Limit of Fuel Property Item Recommended limit Use limit Test method JIS K 2265 :2007 50°C [122°F] or higher Flash point ISO 3769 (In accordance with the regulation) - Page 51 Chapter 4 FUEL Table 4-2 Recommended Limit and Use Limit of Fuel Property Item Recommended limit Use limit Test method Foreign substances JIS B 9931 :2000 (foreign materials at engine fuel 5.0 mg/liter or less ISO 4405 inlet) Lubricity: MWSD (Measured mean 460 µm [0.02 in.] or less Wear Scar Diameter) by HFRR (calculated wear scar diame-...

-

Page 53: Engine Oil

Chapter 5 ENGINE OIL Recommended Engine Oil Use the engine oils recommended in this manual only. Never use oil other than that specified in this manual. The use of inappropriate or inferior oils will result in sticking of piston rings, seizure between piston and cy linder, or premature wear of bearings and moving parts, and significantly shortens the service life of the engine. -

Page 54: Engine Oil Specification

Chapter 5 ENGINE OIL Engine Oil Specification Use engine oil which meets the requirements specified in the table below. Table 5-1 Table of Recommended Limit of Engine Oil Properties Item Unit Recommended limit Test method API/JASO CF class *1 SAE viscosity 15W-40 JIS K 2580 Color ASTM... -

Page 55: Selection Of Oil Viscosity

Chapter 5 ENGINE OIL Table 5-1 Table of Recommended Limit of Engine Oil Properties Item Unit Recommended limit Test method 10/0 Bubbling test JIS K 2518 30/0 ISO 6247 10/0 300°C 140 or lower [572°F] Panel caulking test FED791-3462 325°C 300 or lower [617°F] *1 It must have been certified API service classification CF by 2009. -

Page 56: Service Limits Of Engine Oil

Chapter 5 ENGINE OIL Service Limits of Engine Oil Engine oil degrades through the use and by lapse of time. The quality of engine oil and fuel, and the operating condition of the engine affect the deterioration of the engine oil. Replace the engine oil in accordance with Chapter 7 MAINTENACE SCHEDULE. -

Page 57: Definition Of Properties Of Engine Oil

Chapter 5 ENGINE OIL Definition of Properties of Engine Oil Kinetic Viscosity Water Content Kinetic viscosity is a basic physical property of engine Water in oil promotes corrosion/wear, and decreases oil and is considered as the most important aspect lubricity in sliding parts. when evaluating oil. -

Page 58: Engine Oil Analysis Service

Chapter 5 ENGINE OIL Engine Oil Analysis Service For a long term service life of engine, it is recommended to get an engine oil analysis service. It is a system to understand the availability of the engine oil using in your engine by sampling it with the special sam- pling tools. -

Page 59: Recommended Water For Coolant

Be sure to use Mitsubishi Heavy Industries, Ltd. genuine long life coolant (LLC) "GLASSY long life coolant (Ethyl- ene glycol type)" or "PG GLASSY long life coolant (Non-amine type)" as coolant. When using other brand LLCs by necessity, be sure to use the non-amine type LLC that meets the specification in Mitsubishi Heavy Industries, Ltd. -

Page 60: Other Brand Llcs

Heavy Industries, Ltd. genuine LLC. use of LLC that does not meet the following specifica- When using LLC other than Mitsubishi Heavy Indus- tion. tries, Ltd. genuine long life coolant (LLC) "GLASSY long life coolant (Ethylene glycol type)" or "PG... -

Page 61: Llc Specification

Chapter 6 COOLANT LLC Specification LLC shall be examined according to JIS K2234, Section 7 (Test method), and satisfy this requirements. General matters and the specimen sampling shall comply with JIS K2234. Table 6-2 LLC Specification Property Standard Appearance No precipitation Minimum 1.112 g/cm [69.4199 lb/ft... - Page 62 Chapter 6 COOLANT Table 6-2 LLC Specification Property Standard Aluminum, Cast Mass iron, Steel, Brass, ±0.30 mg/cm change Solder, Copper Metal specimen No visible signs of corrosion on the surface Appearance of the specimen excluding the area contacting to spacer. Circulation metal- after testing However, discoloration is acceptable.

- Page 63 Chapter 6 COOLANT Table 6-2 LLC Specification Property Standard Storage stability vol % (30 vol %, room temperature, 6 Hr) 0.3 or less...

-

Page 64: Maintenance Of Llc

Note: (a) If the outside air temperature is -30°C [-22°F] or lower, use "GLASSY." (b) The concentration above is based on Mitsubishi Heavy Industries, Ltd. genuine LLC "GLASSY long life coolant (Ethylene glycol type)" or "PG GLASSY long life coolant (Non-amine type)."... -

Page 65: Importance Of Llc

Chapter 6 COOLANT Importance of LLC Examples of Abnormali- Today's trend is toward smaller and lighter engines ties Caused by LLC offering greater output, lower fuel consumption and (Amine Type) lower exhaust emission levels. Conditions to which engine coolant is subjected, Pitting of Iron Parts therefore, are becoming severer due to longer operat- Amines are generally effective in suppressing the rust-... -

Page 67: Maintenance Schedule

Check the operating record of the engine to determine the most ap propriate service intervals. (Feel free to consult a dealer of Mitsubishi Heavy Industries, Ltd. regarding service intervals.) Service the items at multiples of the original requirement. For example, at 1000 service hours, also service those items listed under every 250 service hours and every 50 service hours. -

Page 68: General Definition Of Engine

Chapter 7 MAINTENANCE SCHEDULE General Definition of Engine General Definition of Regular Use Engine An engine operated with a constant base load for the purpose of generating electric power, which is used indepen- dently or in combination with commercial power supply. An engine operated under a fluctuating load throughout a day for supplying rated electric power in lieu of commercial power. -

Page 69: Periodic Maintenance Chart For Regular Use Engine

Periodic Maintenance Chart for Regular Use Engine Table 7-1 Periodic Maintenance Chart for Regular Use Engine Refer- Interval and Service item ence page Fuel Tank - Drain Water*1 Every 50 service hours or every month Water Separator - Drain Water*1 Bolts and Nuts on the Engine - Retighten First 50 service hours for Engine Oil, Oil Filter and Bypass Oil Filter - Replace... - Page 70 Couplings - Inspect or Replace *1 Inspecting the Vibration-isolating Rubber *1 *1 If it is not a item supplied from Mitsubishi Heavy Industries, maintain the part following the manufacture's opera- tion manual as required. *2 Items require special tools or large equipment. For the servicing of those items, contact a dealer of Mitsubishi...

-

Page 71: Fig. 3-11 Battery Electrolyte Level - Inspect

Chapter 7 MAINTENANCE SCHEDULE Periodic Maintenance Chart for Emergency Engine Table 7-2 Periodic Maintenance Chart for Emergency Engine Refer- Interval and service item ence page Engine External - Inspect (Check for leakage of fuel, oil and coolant) Fuel Tank Oil Level - Check Engine Oil Level - Check Coolant Level - Check 3-10... -

Page 72: Engine

Chapter 7 MAINTENANCE SCHEDULE Table 7-2 Periodic Maintenance Chart for Emergency Engine Refer- Interval and service item ence page Belt and Belt Tension - Inspect and Adjust Bolts and Nuts on the Engine - Check and Retighten Damper - Inspect Valve Clearance - Inspect and Adjust Basic engine (Check valve mechanism at the same time.) - Page 73 Chapter 7 MAINTENANCE SCHEDULE Table 7-2 Periodic Maintenance Chart for Emergency Engine Refer- Interval and service item ence page Water Pump - Inspect Solenoid Valve and Pressure Reducing Valve of the Cool- ing System - Inspect, Disassemble and Clean *1 Strainer (Including With Ball Tap) of Cooling Water - Cooling system Inspect, Disassemble and Clean *1...

- Page 74 Ball Tap of Water Tank - Repair or Replace *1 Other Consumables - Replace *1 If it is not a item supplied from Mitsubishi Heavy Industries, maintain the part following the manufacture's opera- tion manual as required. *2 Items require special tools or large equipment. For the servicing of those items, contact a dealer of Mitsubishi...

-

Page 75: Periodic Maintenance Chart For General Purpose Engine

Chapter 7 MAINTENANCE SCHEDULE Periodic Maintenance Chart for General Purpose Engine Table 7-3 Periodic Maintenance Chart for General Purpose Engine Refer- Interval and service item ence page Fuel Control Link Ball Joint - Inspect 8-10 Every 50 service hours or Air Strainer - Drain Water and Clean (Air motor type or direct inlet type) 8-25... - Page 76 Air Cleaner Element - Clean, Check and Replace 8-21 *1 If it is not a item supplied from Mitsubishi Heavy Industries, maintain the part following the manufacture's opera- tion manual as required. *2 Items require special tools or large equipment. For the servicing of those items, contact a dealer of Mitsubishi Heavy Industries, Ltd.

-

Page 77: Periodic Inspection And Maintenance Procedures

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Basic Engine Engine External - Inspect Be sure to keep combustible materials away from the engine, especially from the hot engine parts such as exhaust manifolds, or the battery. Check for fuel and oil leaks. Remove dust from the top surface of the battery. A fire can be caused by combustible materials placed near hot engine parts. -

Page 78: Belt And Belt Tension - Inspect And Adjust

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Belt and Belt Tension - Inspect and Adjust If defects such as cuts or surface separations are found during inspection, replace the belt. Keep oil and grease away from the belt. They may cause the belt to slip and shorten the service life. Excessive belt tension can cause rapid wear of the alternator bearing and shorten the service life of the belt. -

Page 79: Table 8-1 Ribbed Belt Tension Force

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Table 8-1 Ribbed Belt Tension Force Belt direct distance (mm) Num- Item ber of 300 or more 400 or more 500 or more Up to 300 600 or more ribs Up to 400 Up to 500 Up to 600 74 N {7.55 kgf }... -

Page 80: Damper - Inspect

For making damper function well, heat of damper must be dissipated from its surface to prevent excessive damper heating. Mitsubishi inspects each engine before shipment to ensure proper operating temperature of the vibration damper. However, the vibration damper temperature varies depending on ambient conditions. Therefore, observe the following suggestions and provide sufficient ventilation for the vibration damper and equipment. -

Page 81: Table 8-3 Thermo Label For Temperature

(b) If the temperature indication of thermo label comes close to the limit temperature of damper or the abnor- mality is found in change of temperature, contact a dealer of Mitsubishi Heavy Industries, Ltd. (c) For damper temperature limit and inspection, refer to "Damper - Inspect"... -

Page 82: Fuel System

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Fuel System Fuel System - Inspect When handling fuel, make sure there are no open flames or other fire hazards near the engine. Wipe off any spilled fuel completely. Spilled fuel can ignite and cause a fire. Fuel Tank - Clean For fuel to be used, refer to "FUEL"... -

Page 83: Water Separator - Drain Water

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Water Separator - Drain Water 1. Prepare a plate, and place it under the drain cock of water separator. 2. Open the drain cock, and drain water in the water separator. 3. Close the all drain cocks after draining. Note: If the specification of water separator differs from the contents of this operation manual, follow the manufacturer's operation manual. -

Page 84: Gauze Filter - Clean

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Gauze Filter - Clean If the gauze filter is clogged, the fuel supply becomes insufficient, resulting in decrease in power output or engine stall. Gauze filter 1. Remove the eye bolt at the inlet port of fuel feed pump. -

Page 85: Fuel Filter - Replace

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Fuel Filter - Replace 1. Clean the area around the fuel filters. 2. Prepare a drip pan, and place it under the fuel fil- ters. 3. Using a filter wrench, remove the fuel filters. 4. -

Page 86: Fuel Control Link Ball Joint - Inspect

0.1 mm [0.004 in.] If the sealed ball joints are found loosened, contact a dealer of Mitsubishi Heavy Industries, Ltd. If the seal on the ball joint is broken, the warranty is invalidated. Lever If the ball joints are integrated in the control link, replace the control link when the ball joints have loos- ened. -

Page 87: Fuel Pipe - Inspect

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Fuel Pipe - Inspect High Pressure Fuel Injection Pipe and Clamp Seat - Inspect and Replace Visual Inspection in Every 2000 Service Hours Check clamp seat cracks and wear, or high pressure fuel injection pipe wear. If defective, replace the clamp seat with a new one. -

Page 88: Lubricating System

When draining oil or changing the oil filter, wear gloves. Hot engine oil and parts may cause burns. Do not dump waste oil. It is forbidden by law. For disposal of waste oil, consult a dealer of Mitsubishi Heavy Indus- tries, Ltd. - Page 89 Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Engine Oil - Refill Oil level gauge Refilling engine oil must be specified level. If the refilling oil goes over the high marks on the oil level gauge, engine oil may blow out. Improper High 1.

-

Page 90: Engine Oil For Mixing Of Fuel And Water - Inspect

If water is mixed with the engine oil, the oil will be milky white. If fuel or water is detected in the engine oil, find the cause of the problem, and repair. If the problem cannot be cor- rected easily, contact a dealer of Mitsubishi Heavy Industries, Ltd. 8-14... -

Page 91: Governor Oil Filter - Change

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Governor Oil Filter - Change Air vent plug When draining oil or changing the oil filter, wear gloves. Hot engine oil and parts may cause burns. 1. Prepare a drip pan and place it under the governor oil filter. -

Page 92: Cooling System

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Cooling System Coolant - Change The service life of LLC is 2 years. Be sure to change coolant at least once every 2 years. Radiator Cap - Open/Close Stand the lever to Turn the cap about When using the engine with radiator cooling system, the upright position half a turn... - Page 93 Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Cooling System - Clean Clean the cooling system when operating the engine or heat exchange equipment first time, or restarting the engine after storage with coolant drained. 1. Close coolant drain cocks and plugs. 2.

-

Page 94: Radiator Fins - Check And Clean

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Radiator Fins - Check and Clean When handling compressed air, wear safety goggles, a hardhat, gloves and other necessary protective gear. Working without wearing proper protective gear could result in serious injuries. Check the radiator fins for holes and cracks. To clean the radiator fins, blow compressed air from the opposite direction of the normal air flow. -

Page 95: Inlet And Exhaust Systems

Replace the turbocharger if any abnormal movement is found. Note: When removing an d inspecting turbocharger, contact a dealer of Mitsubishi Heavy Indu stries, Ltd. Also, inspect that there is any disc oloration or damage on the compressor wheel fins. -

Page 96: Air Cleaner - Check For Clogging

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Air Cleaner - Check for Clogging 1. Check the air cleaner indicator for the element Reset button clogging. 2. If the element is clogged, the red signal mark will Signal (red) be displayed. 3. -

Page 97: Air Cleaner Element - Clean, Check And Replace

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Air Cleaner Element - Clean, Check and Replace When handling compressed air, wear safety goggles, a dust mask, a hardhat, gloves and other necessary protec- tive gear. Working without wearing proper protective gear could result in serious injuries. Never perform maintenance on the air cleaner while the engine is running. - Page 98 Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES 8. After cleaning or replacing the air cleaner element, press the reset button to reset the indicator. Reset button Note: If the specification of air cleaner differs from the Signal (red) contents of this opera tion manual, follow the manufacturer's operation manual.

-

Page 99: Electrical System

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Electrical System Battery - Check If battery electrolyte is spilled on your skin or clothes, flush immediately with plenty of water. If battery electrolyte get into your eyes, flush them immediately with plenty of water and then get medical attention. Do not use open flames or other fire hazards near the battery. -

Page 100: Starter - Inspect

Visually check the alternator for damage. Alternator Remove the belt, and turn the pulley by hand to make sure that it rotates smoothly. Note: If the alternator is defectiv e, consult a dealer of Mitsubishi Heavy Industries, Ltd. Fig. 8-33 Alternator - Inspect 8-24... -

Page 101: Air Starter System

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES Air Starter System Air Strainer - Drain Water and Clean When opening the drain valve of air strainer, open it Starting air Starting air slowly. High pressured air is in the pipe only even if outlet inlet the air tank valve is closed. -

Page 102: Air Tank - Inspect Safety Valve Operation

Safety valve operating pressure (close): 2.84 MPa {29 kgf/cm } [412 psi] 4. If defective in safety valve operation, contact a dealer of Mitsubishi Heavy Industries, Ltd. Note: If the s pecification of air tank differs from the contents of this opera tion manual, follow the manufacturer's operation manual. -

Page 103: Long-Term Storage

Chapter 9 LONG-TERM STORAGE If the engine has been left unattended for 3 months or more, the internal engine parts can rust, and that may cause damage to the engine. When storing the engine for an extended period of time, be sure to follow the steps below. Storing the Engine in an Inoperable Condition for 3 Months or More Preparation for Storage... -

Page 104: Using The Engine After Storage

Chapter 9 LONG-TERM STORAGE Using the Engine After Storage 1. Remove the cover from the engine. 2. Connect a fully charged battery. 3. Remove the cover from the starter and alternator. 4. Adjust the belt tension. Note: Refer to "Belt and Belt Tension - Inspect and Adjust" (8-2) for belt tension adjustment. -

Page 105: Lifting The Engine

Chapter 10 TRANSPORTATION Lifting the Engine Rear hanger To lift the engine, use wire ropes, shackles and slings Front hanger capable of supporting the weight of the engine. Attach the wire rope to the hangers provided on the engine using a correct sling. Keep the engine balanced during lifting by consider- ing the engine's center of gravity. -

Page 107: Troubleshooting

When repairing malfunctioning engine, contact a Cautions Regarding Parts Han- dealer of Mitsubishi Heavy Industries, Ltd. dling Considerations Before Work Handle parts carefully. Before troubleshooting, consider possible causes of... -

Page 108: Case Of Problems, And Conceivable Causes And Remedies

Consult a dealer of Mitsubishi Heavy Industries, Ltd. Basic engine locked Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 109: The Starter Cranks, But The Engine Does Not Start

Consult a dealer of Mitsubishi Heavy Industries, Ltd. Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 110: Output Decrease

Faulty governor control system Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 111: Exhaust Smoke Is White Or Blue

Consult a dealer of Mitsubishi Heavy Industries, Ltd. Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 112: Exhaust Smoke Is Black Or Charcoal

Consult a dealer of Mitsubishi Heavy Industries, Ltd. Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 113: Fuel Consumption Is High

Consult a dealer of Mitsubishi Heavy Industries, Ltd. Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 114: Engine Oil Consumption Is High

Consult a dealer of Mitsubishi Heavy Industries, Ltd. Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 115: Overheating

Consult a dealer of Mitsubishi Heavy Industries, Ltd. Note: The table above also include the parts Mitsubishi He avy Industries, Ltd. does not supply. For the parts Mitsub- ishi Heavy Industries, Ltd. does not supply, inspect and maintain them following the manufacturer's operation manual. -

Page 116: When Fuel Has Run Out

Chapter 11 TROUBLESHOOTING When Fuel has Run Out When fuel runs out while engine is running and the engine has stopped, restart the engine as described below. 1. Return the starter switch to the "OFF" position. 2. Add fuel to the fuel tank. For filling fuel tank, refer to "Fuel Tank Oil Level - Check"... -

Page 117: Main Specifications

Starter 24V DC - 7.5 kW × 2 Alternator DC 24 V - 30 A Turbocharger Mitsubishi TD10 or TD13 Flywheel Equivalent of SAE. 21in Flywheel housing Equivalent of SAE. No.00 Note: (a) The specification above are subject to change without prior notice.

Need help?

Do you have a question about the S16R and is the answer not in the manual?

Questions and answers