Summary of Contents for Husqvarna 155

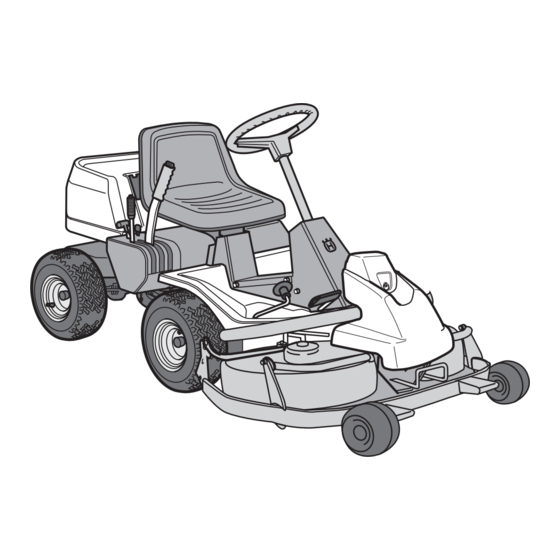

- Page 1 Operator´s manual Rider 155 Please read these instructions carefully and make sure English you understand them before using the machine.

-

Page 3: Table Of Contents

For service measures other than those described in this manual, please contact an authorised dealer that provides parts and service. CONTENTS Operator’s Manual for Rider 155 Replacement of fuel filter ... 27 Replacement of air filter ... 27 Checking the level of the battery acid ... 28 Ignition System ... -

Page 4: Safety Rules For Usa

These instructions are for your safety. Read them carefully. Safe operation practices for ride-on mowers IMPORTANT! This cutting machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety instructions could result in serious injury or death. General operation 1. - Page 5 IV. Service 1. Use extra care in handling gasoline and other fuels. They are flammable and vapours are explosive. a) Use only an approved container. b) Never remove gas cap or add fuel with the engine running. Allow engine to cool before refuelling.

-

Page 6: Introduction

INTRODUCTION Dear customer Thank you for choosing a Husqvarna Rider. Husqvarna Riders are built to a unique design with a front- mounted cutting unit and a patented rear-wheel steering system. Riders are designed for maximum efficiency even in small or confined areas. Collected controls and a hydrostatic transmission controlled by pedals also contribute to the machine’s performance. -

Page 7: Serial Number

SAFETY INSTRUCTIONS Good service Husqvarna products are sold all over the world and only through servicing dealers. This is to ensure that you, the customer, get the best support and service. Before the machine is delivered it undergoes inspection and is adjusted by your dealer. -

Page 8: Explanation Of Symbols

EXPLANATION OF SYMBOLS These symbols are on the machine and in the operator’s manual. Study them carefully so that you know what they mean. Neutral Fast Oil level Cutting height Hydrostatic free wheel Never use the machine if persons, especially children, or animals, are in the vicinity. - Page 9 EXPLANATION OF SYMBOLS Placards 8009-442 English –...

-

Page 10: Safety Instructions

SAFETY INSTRUCTIONS Safety instructions These instructions are for your safety. Read them carefully. WARNING! The inserted symbol means that important safety instructions need to be observed. It applies to your safety. General use • Read all the instructions in this operator’s manual and on the machine before you start it. - Page 11 SAFETY INSTRUCTIONS • Take care when rounding a fixed object, so that the blades do not hit it. Never run the machine over foreign objects. • Only use the machine in daylight or in other well-lit conditions. Keep the machine at a safe distance from holes or other irregularities in the ground.

-

Page 12: Driving On Slopes

SAFETY INSTRUCTIONS Driving on slopes Driving on slopes is one of the operations where the risk of the driver losing control of the machine or of it overturning is the greatest; this can result in serious injury or death. All slopes demand extra care. -

Page 13: Children

SAFETY INSTRUCTIONS Children • Serious accidents may occur if you fail to be on your guard for children in the vicinity of the machine. Children are often attracted to the machine and mowing. Never assume that children will remain where you last saw them. •... - Page 14 SAFETY INSTRUCTIONS • If leaks arise in the fuel system, the engine must not be started until the problem has been resolved. • Store the machine and fuel in such a way that there is no risk that leaking fuel or fumes can cause any damage.

-

Page 15: Transport

SAFETY INSTRUCTIONS • Never use the machine indoors or in spaces lacking proper ventilation. Exhaust fumes contain carbon monoxide, an odourless, poisonous and highly dangerous gas. • Stop and inspect the equipment if you run over or into anything. If necessary, make repairs before starting. -

Page 16: Presentation

Presentation Congratulations on your choice of a top quality product which you will enjoy for many years. These instructions describe the Rider 155. This rider mower is equipped with a 15.5 horsepower Kohler engine. Location of the controls Ignition lock... -

Page 17: Throttle/Choke Lever

Throttle and Choke lever The engine speed is adjusted with the throttle control, and thereby also the rotation speed of the blades. The control is also used to activate the choke function. When the choke is used the engine receives a richer mixture of fuel and air, which simplifies cold start. -

Page 18: Cutting Unit

Cutting unit The Rider 155 can be fitted with four different cutting units. BioClip - 900 mm/36" Combi - 1120 mm/44" Combi - 1030 mm/41" See ”Maintenance \ Checking the Blades” for identification of the cutting unit. Lift lever for the cutting unit The lift lever is used to set the cutting unit in trans- port or cutting position. -

Page 19: Lever For Adjustment Of Cutting Height

Lever for adjustment of cutting height With this lever the cutting height can be adjusted to 9 different positions. Combi, BioClip unit, Seat The seat has a jointed attachment on the front edge and can be tipped forward. The seat can also be adjusted lengthways. Release the knobs under the seat and adjust it forwards or backwards to the required position. -

Page 20: Driving

IMPORTANT INFORMATION The air intake grille in the engine cover behind the driver’s seat must not be blocked by, for example, clothing, leaves, grass or dirt. Impaired cooling of the engine. Risk of major engine damage. Before starting • Read the safety instructions and information on the location and function of the controls before starting (see pages 5-14). - Page 21 Warm engine: 4. Set the throttle control midway between position 1 and 2. 5. Turn the ignition key to start position. IMPORTANT INFORMATION Do not run the starter for more than about 10 seconds at a time. If the engine does not start, wait about 60 seconds before trying again.

-

Page 22: Driving The Machine

Driving the machine 1. Release the parking brake by pressing down the parking brake pedeal and then releasing it. 2. Carefully press down one of the pedals until the correct speed is reached. To drive forwards: press down pedal (1). To reverse: press down pedal (2). -

Page 23: Cutting Tips

4. Push in the lock button on the lift lever and lower down the cutting unit. IMPORTANT INFORMATION The service-life of the drive belts increases considerably if the engine is run at low speed when engaging the blades. For this reason do not increase the throttle until the cutting unit has been lowered to the cutting position. -

Page 24: Stopping The Engine

WARNING! Never drive the machine on ground with a slope of more than 15°. Mow slopes upwards and downwards, never across. Avoid sudden changes in direction. Stopping the engine Preferably allow the engine to idle for a minute to obtain normal working temperature before stopping it if it has been working hard. -

Page 25: Maintenance

The following is a list of the maintenance which should be conducted on the machine. For the items which are not described in these instructions go to an authorised service workshop. Maintenance Check the engine’s oil level Check the engine’s cooling air inlet Check the fuel pump’s air filter Check the steering wires Check the battery... -

Page 26: Dismantling Of The Machine Hoods

Dismantling of the machine hoods Engine hood The engine is accessible for servicing when the engine hood is lifted up. Tilt the seat forward, release the rubber strap under the seat, and tilt the hood backwards. Front hood Release the clip on the front hood and lift off the hood. -

Page 27: Checking And Adjusting The Steering Wires

Checking and adjustment of the steering wires The steering is controlled by means of wires. These can in time become slack, which implies that the adjustment of the steering becomes altered. Check and adjust the steering as follows: 1. Dismantle the frame-plate by releasing the screws (two on each side). -

Page 28: Adjustment Of Throttle Wire

Adjusting the throttle wire If the engine does not respond as it should do when the throttle lever is moved or if the top speed is not reached, the throttle wire may need adjusting. 1. Loosen the clamping screw (by the arrow), and slide the throttle to the choke position. -

Page 29: Replacement Of Fuel Filter

Replacement of the fuel filter Replace the pipe fitted fuel filter every 100 running hours (once per season) or more frequently if it is clogged. Replace the filter as follows: 1. Fold open the engine cover. 2. Move the hose clips away from the filter. Use a pair of flat pliers. -

Page 30: Checking The Level Of The Battery Acid

5. The paper filter may be carefully tapped on a hard surface to remove dust. Do not try to wash or blow it with compressed air. 6. Insert the paper filter and check that it is correct sealed to its seat. Tighten the paper filter wing nut and install the precleaner over the paper filter. -

Page 31: Ignition System

Ignition system The engine is equipped with an electronic ignition system. Only the spark plug requires maintenance. For recommended spark plug, see chapter ”Technical data”. IMPORTANT INFORMATION Fitting the wrong spark plug type can damage the engine. Remove the ignition cable shoe and clean around the spark plug. Remove the spark plug with a 5/8"... -

Page 32: Checking The Safety System

MAINTENANCE Checking the safety system The Rider is equipped with a safety system that prevents starting or driving under the following conditions: The engine should only be possible to start when the cutting unit is in its raised position and the hydrostat pedals are in the neutral position. -

Page 33: Main Fuse

Main fuse The fuse is located in a loose holder under the battery case cover, in front of the battery. Type: Flat-blade mounting, 15 A. Do not use any other type of fuse when replacing. A blown fuse indicates that the mounting has burnt off. -

Page 34: Fitting The Cutting Unit

Fitting the cutting unit 1. Place the Rider on a flat surface and apply the parking brake. Check that the lever for setting the cutting height is in the lowest position. Make sure the support wheels are fitted to the cutting unit (1). -

Page 35: Installing Bioclip 90

Installing BioClip 90 In order to install BioClip 90 the drive belt support wheel must first be removed. 1. Release the tensioning wheel’s spring, see ring in the diagram. 2. Remove the locking pin (1) that is located next to the support wheel. -

Page 36: Adjusting The Parallelism Of The Cutting Unit

Adjusting the parallelism of the cutting unit 1. Remove the front hood and the right-hand fender, as described on page 21. 2. Undo the nuts on the lift strut. 3. Screw out (extend) the stay to raise the rear edge of the cover. Screw in (shorten) the stay to lower the rear edge of the cover. -

Page 37: Replacing The Cutting Unit Belts

Replacing the cutting unit belts Belt replacement on BioClip 90 The BioClip 90 is driven by a toothed belt that synchronises rotation of the blades. The belt is located under the cover of the cutting unit. When changing the belt on a BioClip 90 follow steps 1-7 of the above procedure for version 2. -

Page 38: Service Position For Cutting Unit

Service position for the cutting unit The cutting head can be placed in the service position to provide easy access for cleaning, repairs and servicing. In service position, the cutting unit is raised and locked in the vertical position. Placing in service position 1. - Page 39 4. Fit the support wheels on either side of the rear of the cutting unit. WARNING! Wear protective glasses when dismantling the cutting unit. The spring which tensions up the belt can go off and cause personal injury. 5. Disengage the spring for the drive belt tensioning wheel.

-

Page 40: Restoring From Service Position

WARNING! Observe caution to avoid trapping your hand. 7. Lift off the drive belt (1). Then pull out the pin (2). 8. Pull the frame forwards and refit the pin. 9. Grasp the front edge of the cutting unit, pull out and raise into the service position. -

Page 41: Checking The Blades

Checking the blades To achieve the best mowing results it is important that the blades are undamaged and well-sharpened. Check that the blades’ attachment screws are tight. IMPORTANT INFORMATION Replacing or sharpening the blades should be conducted by an authorised service workshop. -

Page 42: Replacing The Break-Pin (Bioclip 90)

Replacing the break-pin (BioClip 90) The blades are fitted with a break-pin to protect the BioClip unit and its drive when colliding with obstacles. A domed, spring friction washer is fitted to each blade bolt. The washer must always be replaced with a new washer if the blade bolt is loosened. -

Page 43: Lubrication

Check the engine’s oil level Check the oil level in the engine when the Rider stands horizontal with the engine switched off. Fold open the engine cover. Release the dip stick and pull out. Wipe off the oil and insert again. The dip stick must be fully screwed down. -

Page 44: Change Of Oil Filter

Change of oil filter Replace oil filter every 200 operating hours. Drain oil first using the plug on the filter base. Remove the old filter using an oil filter tool. Lightly coat rubber gasket with new oil, then install filter by turning it to the right until hand tight. -

Page 45: Trouble Shooting Schedule

TROUBLE SHOOTING SCHEDULE Problem Engine will not start. Starter does not pull round engine. Engine does not run smoothly. Engine seems to have no power. Engine overheats. Battery does not charge. Machine vibrates. Uneven mowing. Procedure • Fuel tank empty. •... -

Page 46: Storage

Winter storage At the end of the season the machine should immediately be put in order for storage, also if it is going to stand idle for more than 30 days. Fuel which is left to stand for long periods (30 days or more) can leave tacky deposits which can block the carburettor and interfere with the engine. -

Page 47: Technical Data

9 positions, 40-90 mm/1 9/16"-3 9/16", Blade diameter 350 mm/13 3/4" (Side), 420 mm/16 1/2" (Combi 112), TECHNICAL DATA Rider 155 2020 mm/6.61 ft 880 mm/2.89 ft 1060 mm/3.52 ft 247-260 kg/543-572 lb including unit 855 mm/2.8 ft Front 715 mm/2.34 ft, rear 625 mm/2.05 ft 16 x 6.50 x 8... - Page 48 When this product is worn out or no longer used it should be returned to the dealer or other appropriate body for recycling. We reserve the right to change technical specifications without prior notice. Note that no legal claims are valid on the basis of information in this manual. Use only genuine parts for repairs.

-

Page 49: Servicejournal

Work done Pre-delivery service 1. Top up battery with acid and recharge for four hours. 2. Fit steering wheel, seat and any optional equipment. 3. Adjust cutting unit: Adjust the lifting springs (the “weight” of the cutting unit should be 12-15 kg/26.5-33 lbs). Only applies to BioClip. Adjust cutting unit so that rear edge is about 2–4 mm/1/8"... - Page 50 SERVICEJOURNAL Date, mileage, stamp, sign Work done – English ´®z+H-[¶5-¨...

- Page 51 English –...

- Page 52 114 01 35-95 ´®z+H-[¶5-¨ 2004W48...