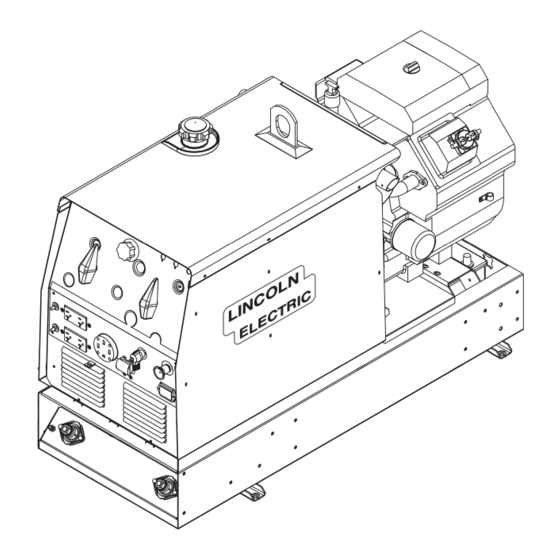

Lincoln Electric RANGER 10,000 PLUS Operator's Manual

Hide thumbs

Also See for RANGER 10,000 PLUS:

- Operator's manual (37 pages) ,

- Specification sheet (168 pages) ,

- Service manual (112 pages)

Table of Contents

Advertisement

RANGER 10,000 PLUS

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

®

AND RANGER 10,000

For Machines with Code Number 11394, 11395, 11398

RETURN TO MAIN MENU

R

C

US

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

Copyright © 2007 Lincoln Global Inc.

IM925

January, 2007

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric RANGER 10,000 PLUS

- Page 1 IM925 RANGER 10,000 PLUS ® January, 2007 AND RANGER 10,000 For Machines with Code Number 11394, 11395, 11398 RETURN TO MAIN MENU Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ...

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

SAFETY ARC RAYS can burn. ELECTRIC SHOCK can 4.a. Use a shield with the proper filter and cover kill. plates to protect your eyes from sparks and 3.a. The electrode and work (or ground) circuits the rays of the arc when welding or observing are electrically “hot”... - Page 4 SAFETY WELDING SPARKS can CYLINDER may explode cause fire or explosion. if damaged. 6.a. Remove fire hazards from the welding area. 7.a. Use only compressed gas cylinders If this is not possible, cover them to prevent containing the correct shielding gas for the the welding sparks from starting a fire.

- Page 5 SAFETY PRÉCAUTIONS DE SÛRETÉ 6. Eloigner les matériaux inflammables ou les recouvrir afin de prévenir tout risque d’incendie dû aux étincelles. Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce 7.

- Page 6 Electric for advice or information about their use of our products. We respond to our customers based on the best information in our posses- sion at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such infor- mation or advice.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page Installation........................Section A Technical Specifications .......................A-1 Safety Precautions ......................A-2 Machine Grounding .......................A-2 Spark Arrester .......................A-2 Towing, Vehicle Mounting .....................A-2 Pre-Operation Engine Service....................A-3 Fuel, Oil .........................A-3 Battery Connections ......................A-3 Welding Cable Connections ..................A-4 Angle of Operation ......................A-4 Lifting, Additional Safety Precautions................A-4 High Altitude Operation ....................A-4 Muffler Relocation ......................A-4 Location and Ventilation ....................A-5... -

Page 8: Installation

INSTALLATION TECHNICAL SPECIFICATIONS - RANGER 10,000 PLUS (K1419-5 ), (K2468-2) RANGER 10,000 (K2160-4) INPUT - GASOLINE ENGINE Description Operating Displacement Capacities Make/Model Starting Horsepower Speed (RPM) cu. in. System (cu.cm.) 41(674) Fuel: (K1419-5) 23 HP @ Kohler 9 Gal (34 L) Kohler 3600 RPM Lubricating Oil:... -

Page 9: Safety Precautions

INSTALLATION SAFETY PRECAUTIONS When this welder is mounted on a truck or trailer, it’s frame must be electrically bonded to the metal frame of the vehicle. Use a #8 or larger copper wire connect- WARNING ed between the machine grounding stud and the Do not attempt to use this equipment until you frame of the vehicle. -

Page 10: Pre-Operation Engine Service

INSTALLATION 3. Proper placement of the equipment on the trailer to FUEL insure stability side to side and front to back when being moved and when standing by itself while being operated or serviced. Fill the fuel tank with clean, fresh, lead-free gasoline. Observe fuel gauge while filling to prevent overfilling. -

Page 11: Angle Of Operation

INSTALLATION WELDING OUTPUT CABLES WARNING • Lift only with equipment of ade- With the engine off, connect the electrode and work cables quate lifting capacity. to the studs provided. These connections should be • Be sure machine is stable when checked periodically and tightened if necessary. -

Page 12: Location And Ventilation

LN-25 with built-in contactor is used. If the cannot be stacked. output “CONTROL” is set below “3”, the LN-25 contactor may not pull in. CONNECTION OF LINCOLN ELECTRIC CONNECTION OF K930-2 TIG MODULE TO THE RANGER 10,000. WARNING... - Page 13 INSTALLATION AUXILIARY POWER The RANGER 10,000 PLUS can provide up to 9,000 watts of 120/240 volts AC, single phase 60Hz power for continuous use and up to 10,500 watts peak. The RANGER 10,000 (Honda 20 HP model) provides 10,000 watts peak. The front of the machine includes three receptacles for connecting the AC power plugs;...

- Page 14 NOT USE THESE DEVICES WITH A RANGER 10,000 PLUS & RANGER 10,000 The Lincoln Electric Company is not responsible for any damage to electrical components improperly connect- ed to the RANGER 10,000 PLUS AND RANGER 10,000. RANGER 10,000 PLUS AND RANGER 10,000...

- Page 15 INSTALLATION 1. Install a double pole, double throw switch between AUXILIARY POWER WHILE WELDING the power company meter and the premises dis- connect. Simultaneous welding and power loads are permitted by following Table I. The permissible currents shown Switch rating must be the same or greater than the assume that current is being drawn from either the customer’s premises disconnect and service over- 120V or 240V supply (not both at the same time).

-

Page 16: Premises Wiring

INSTALLATION Figure 1 CONNECTION OF RANGER 10,000 PLUS OR RANGER 10,000 TO PREMISES WIRING 240 VOLT GROUNDED CONDUCTOR POWER 240 Volt 120 VOLT 60 Hz. COMPANY 3-Wire 120 VOLT Service METER NEUTRAL LOAD DOUBLE POLE DOUBLE THROW SWITCH RATING TO BE THE SAME AS OR GREATER THAN PREMISES SERVICE OVERCURRENT PROTECTION. -

Page 17: Operation

OPERATION SAFETY PRECAUTIONS WELDER CONTROLS - FUNCTION AND OPERATION Do not attempt to use this equipment until you have thoroughly read the engine manufacturer’s manual supplied with your welder. It includes ENGINE SWITCH important safety precautions, detailed engine The engine switch is used to Start the Engine, Select starting, operating and maintenance instructions, High Idle or Auto Idle while the engine is running, and and parts lists. - Page 18 OPERATION “ RANGE” SWITCH The “Range” switch is used to select one of three amperage ranges with generous overlap for Stick/TIG welding, or one Wire Feed welding range. Process Range Setting Current Range STICK/TIG 90 Max. 40 to 90 Amps (constant current) 145 Max.

-

Page 19: Start In/Shutdown Instructions

OPERATION STARTING/SHUTDOWN INSTRUCTIONS After running at high engine speed for 10-14 seconds, the engine will go to low idle. STARTING THE ENGINE Allow the engine to warm up by letting it run at low idle for a few minutes. WARNING STOPPING THE ENGINE •... -

Page 20: Welding Process

OPERATION WELDING PROCESS SETTINGS FOR 1% THORIATED TUNGSTEN For any electrodes the procedures should be kept within TUNGSTEN RANGE SWITCH APPROXIMATE DIAMETER (in.) SETTINGS CURRENT RANGE the rating of the machine. For electrode information see the appropriate Lincoln publication. 90, 145, or 210 80 - 225 Amps 3/32 90 or 145... -

Page 21: Summary Of Welding Processes

OPERATION SUMMARY OF WELDING PROCESSES CONTROL ELECTRODE CABLE IDLE WHEN NOT TO START PROCESS USED MODE WELDING WELDING STICK AUTO Touch electrode to work. Welding starts immediately and engine goes to high idle. WIRE FEED, LN-25 WITH AUTO Cold Press gun trigger, LN-25 INTERNAL CONTACTOR contactor closes. -

Page 22: Accessories

ACCESSORIES K1690-1 GFCI RECEPTACLE KIT - Includes one UL OPTIONAL EQUIPMENT (Field Installed) approved120V ground fault circuit interrupter duplex type receptacle with cover and installation instructions. K957-1 HEAVY DUTY, TWO WHEEL TRAILER FOR Replaces the factory installed 120V duplex receptacle. SMALL WELDERS - For road, off-road and in-plant Each receptacle of the GFCI Duplex is rated at 20 Amps, and yard towing. -

Page 23: Recommended Equipment

ACCESSORIES RECOMMENDED EQUIPMENT PLASMA CUTTING: K1580-1 Pro-Cut 55 STICK Cuts mild steel using the 3-phase AC generator power from the engine driven welder. Accepts 3-phase or 1- K704 ACCESSORY SET - Includes 35 ft. (10m) of phase input power. Requires the K1816-1 Full KVA adapter kit, if connected for 1-phase input power. -

Page 24: Maintenance

MAINTENANCE SAFETY PRECAUTIONS CAUTION WARNING Make certain that the oil filler cap is securely tight- ened after checking or adding oil. If the cap is not Have qualified personnel do the maintenance tight, oil consumption can increase significantly work. Turn the engine off before working inside which may be evidenced by white smoke coming the machine. -

Page 25: Air Cleaner And Other Maintenance

MAINTENANCE AIR CLEANER AND OTHER MAINTENANCE Use 4-stroke motor oil that meets or exceeds the requirements for API service classification SG or SH. • Air Cleaner - With normal operating conditions, the Always check the API SERVICE label on the oil con- maintenance schedule for cleaning and re-oiling tainer to be sure it includes the letters SG or SH. -

Page 26: Engine Adjustments

MAINTENANCE ENGINE ADJUSTMENTS WARNING GASES FROM BATTERY can explode. OVERSPEED IS HAZARDOUS • Keep sparks, flame and cigarettes away from battery. To prevent EXPLOSION when: WARNING • INSTALLING A NEW BATTERY - disconnect negative cable from old battery first and connect to new battery last. -

Page 27: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 28 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION No welder or output power. Open in miscellaneous leads. Open lead in flashing or field circuit. Faulty rotor. Faulty Potentiometer (R1). Faulty stator Field winding. Faulty Field rectifier (D2).

- Page 29 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Engine will not go to high idle when No voltage signal from the using auxiliary power. current sensor. Auxiliary power load less than 100 to 150 watts.

- Page 30 DIAGRAMS Enhanced Diagram RANGER 10,000 PLUS AND RANGER 10,000...

- Page 31 DIAGRAMS Enhanced Diagram RANGER 10,000 PLUS AND RANGER 10,000...

- Page 32 DIAGRAMS RANGER 10,000 PLUS AND RANGER 10,000...

- Page 33 DIAGRAMS RANGER 10,000 PLUS AND RANGER 10,000...

- Page 34 NOTES RANGER 10,000 PLUS AND RANGER 10,000...

- Page 35 ● ● ● WARNING ● Spanish ● ● ● AVISO DE PRECAUCION ● French ● ● ● ATTENTION ● ● German ● ● WARNUNG ● Portuguese ● ● ● ATENÇÃO ● Japanese Chinese Korean Arabic...

- Page 36 ● ● ● ● WARNING ● Spanish ● ● AVISO DE ● PRECAUCION French ● ● ● ● ATTENTION ● ● ● German WARNUNG ● Portuguese ● ● ● ● ● ATENÇÃO ● ● Japanese Chinese Korean Arabic...

- Page 37 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...