Table of Contents

Advertisement

Quick Links

Instructions

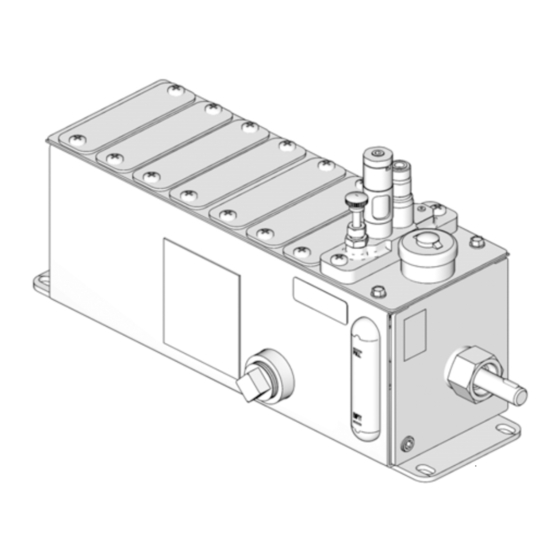

Modular Box

Lubricator

Fluid container used with GBL7500 Suction Fed, Gravity Fed or Pressure Fed Box

Lubricator Pumps used for dispensing non-corrosive and non-abrasive oils and lubricants.

For professional use only.

See Technical Data, page 13 for maximum outlet pressures per pump station.

Important Safety Instructions

Read all warnings and instructions in

this manual and your pump instruction

manual. Save all instructions.

See page 2 for part number information.

3A2100K

EN

ti17757

Advertisement

Table of Contents

Summary of Contents for Graco GBL7500

- Page 1 Modular Box Lubricator 3A2100K Fluid container used with GBL7500 Suction Fed, Gravity Fed or Pressure Fed Box Lubricator Pumps used for dispensing non-corrosive and non-abrasive oils and lubricants. For professional use only. See Technical Data, page 13 for maximum outlet pressures per pump station.

- Page 2 Number are provided in the tables below. For example, MBB1DE is a Modular Box; 6 pint reservoir, (maximum of 3 pumping sta- tions and no motor mount base); 3/16 suction fed pump; 3 pumps; and a direct end rotary drive. NOTE: Some pump configurations are not available. Contact Graco Customer Service or your local Graco distributor for assis- tance.

- Page 3 Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

- Page 4 Warnings WARNING EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system com- ponent.

-

Page 5: Component Identification

The lubricator must be connected to a ground Mounting screw source. *The GBL7500 Box Lubricator Pump and GBL Shaft Rota- 2. Install reservoir to the mounting surface. See tion/Low Level Alarm Pump are available from Graco. See mounting hole layout in the Reservoir and Mounting Accessories/Other Accessories, page 12 for information about Dimension section of this manual, page 14. - Page 6 Refer to pump instruction manual for pump Pressure Relief Procedure in your pump manual installation and priming instructions. (See when you stop dispensing and before cleaning, page 12 for Graco pump model information.) checking, or servicing the equipment. Drive Mechanism 1. Stop lube pump.

- Page 7 Installation 4. Clean lubricator periodically to eliminate contami- nation that may have occurred in the oil. To accom- plish this: a. Drain reservoir by removing drain plug (C) (F 1). Dispose of oil according to all applicable safety regulations. b. Remove all pumping units. c.

-

Page 8: Troubleshooting

Troubleshooting Troubleshooting Problem Cause Solution Low oil level in reservoir Add oil. See Refilling the Reservoir, page 6. Sight well pumps dry Pump issue Refer to the Troubleshooting Section of your pump instruction manual. Low oil level in reservoir Add oil. See Refilling the Reservoir, page 6. - Page 9 Bare Box Parts Bare Box Parts Model: MBD0AA Shown Torque to 110 in. lbs + 10 in. lbs. (12.43 N.m + 1.13 N.m) Ref Part No. Description Ref Part No. Description 556368 KEY, #5 USA 405 Woodruff RESERVOIR 17▲16G243 LABEL, warning, CE & Atex Models COVER, assembly 16P808 LABEL, warning, not CE or Atex GASKET, reservoir, cover...

- Page 10 Accessories Accessories Modular box lubricators are not approved for use in hazardous locations or explosive atmospheres unless all accessories, components and wiring meet all local and national codes. Pumps* - CE and ATEX certified Part No. Description Special Features / Notes 24J391 3/16 in.

- Page 11 Accessories Motors Part Horse Special Power RPM Voltage Hertz Phase Insulation Type Duty Enclosure Frame Features NEMA B Ball 557270 1725 230/460 Class B Polyphase Continuous TENV Bearings Capacitor NEMA B Ball 557271 1725 115/230 Class B Continuous TEFC Start Bearings NEMA B Ball Capacitor...

-

Page 12: Electric Heaters

Accessories Electric Heaters Hazardous Reservoir Number of Part Thermostat Temperature Watt Area Size: pints Heaters Voltage Watts Voltage Range Density Rating (liters) Required 4 (1.89) N/A* 6 (2.84) 8 (3.79) -100°F to 500°F Class 1 12 (5.68) 564058 115/230 20w/in (38°C to 260°C) Group D 16 (7.57) -

Page 13: Technical Data

Technical Data Technical Data Modular Box Lubricator Metric Pump Size Maximum Outlet Maximum Outlet Pressure Pressure 3/16” 7500 psi 51.71 MPa 517.1 bar 1/4” 6000 psi 41.37 MPa 413.7 bar 3/8” 2500 psi 17.24 MPa 172.4 bar Temperature Operating Temperature Range (-29°C to 60°C) -20°F to 140°F Fluid Viscosity... - Page 14 Reservoir and Mounting Dimensions Reservoir and Mounting Dimensions Dimensions are shown in inches (mm). DIM A 5.5 (139.7) 6.1 (154.94) .13 (3.31) 4X SLOTS .438 X .688 (11.13 X 17.48) DIM B .875 (22.23) 3.75 (95.25) Dimensions: All Reservoirs Option A Reservoir Size Dimension A Dimension B...

- Page 15 Drive Options and Dimensions Drive Options and Dimensions Dimensions are shown in inches (mm). Refer to the Part Number Key, page 2 to determine your specific drive. Direct End Rotary Option D, Code A or E (page 2) - Option D, Code A shown. 2.25 (57.15) 2.375 (60.33) FROM C/L OF SLOT...

- Page 16 Drive Options and Dimensions End Rotary Ratchet Option D, Code C, D, G, or H (page 2) - Option D, Code C or D shown Max Input Code Ratio Speed C or G 37.5:1 800 rpm D or H 75:1 800 rpm 1.94 (49.28) 2.375 (60.33)

- Page 17 Drive Options and Dimensions Angle Rotary Drive Option D, Code P - T and Z (page 2) Code Ratio 25:1 50:1 S or Z 188:1 375:1 Right Hand Rear Drive Option D, Code P-T Shown 6.735 (171.07) 2.85 (72.39) FROM C/L OF SLOT .50 (12.7) 1.35 (34.37) FROM C/L OF SLOT...

-

Page 18: Gear Reducer

Drive Options and Dimensions Gear Reducer Option D, Code U - Y (page 2) - Option D, Code U-Y shown Code Ratio 100:1 150:1 200:1 300:1 400:1 4.95 (125.73) 11.75 (298.45) 5.75 (146.05) 3A2100K... - Page 19 Motor Mounting Bases and Dimensions Motor Mounting Bases and Dimensions Dimensions are shown in inches (mm). Refer to the Part Number Key, page 2 to determine your specific mounting base. Motor Mounting Bases Option A, Code J - N (page 2) - These selections may only be used with double reduction end rotary type drives, Option D, Code J - N.

- Page 20 Motor Mounting Bases and Dimensions Motor Mounting Bases Option A, Code P - S (page 2) - These selections may only be used with gear reducer type drives, Option D, Code U-Y. 14.0 (355.6) 12.0 (304.8) 10.0 (251.46) .563 15.0 (381.0) 11.75 (298.45) 2.74 (69.60) .63 (16.00)

- Page 21 Level Controller Dimensions Level Controller Dimensions Dimensions are shown in inches (mm). Refer to part number key, page 2 to determine your specific level controller. RENS Level Controller Option B, Code 4 - 6 (page 2) - Automatic fill option. Does not require a pump station for mounting. Mounted only on the front of the reservoir.

- Page 22 Level Controller Dimensions GARZO Level Controller Option B, Code 7 - 9 (page 2) - Automatic fill option. Mounts on the front of the reservoir. Requires a 0 - 70 psi (0- 0.48 MPa, 0 - 4.82 bar) inlet supply. Switch actuates when a 1/2 to 3/4 loss of oil level occurs in the controller. ELECTRICAL DATA Contacts: Single Pole, Double-Throw Contact Rating: 15 amps at 115/230 or 480 VAC...

- Page 23 Notes Notes 3A2100K...

-

Page 24: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.