Table of Contents

Advertisement

Quick Links

Repair - - Parts List

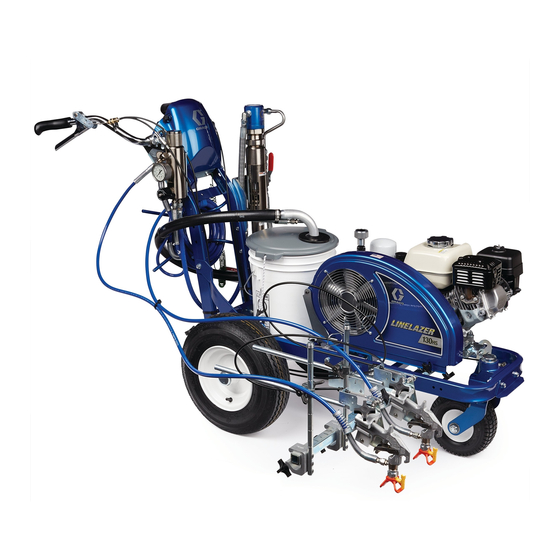

LineLazert 130

Airless Paint Striper

Chinese Patent ZL03801904.3; Australian Patent No. 2005319204; Russian Patent No. 2398927;

U.S. Patent 6,913,417; 7,654,771; Europe Patent No. 1841310; Ukraine Registration No. 90886

- For the application of line striping materials -

3300 psi (228 bar, 22.8 MPa) Maximum Working Pressure

257780

287025

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

n

n

n

n

HS

n

ti13901a

313776C

ENG

313775

311845

311254

309055

Advertisement

Table of Contents

Summary of Contents for Graco LineLazert 130HS

- Page 1 Repair - - Parts List LineLazert 130 Airless Paint Striper Chinese Patent ZL03801904.3; Australian Patent No. 2005319204; Russian Patent No. 2398927; 313776C U.S. Patent 6,913,417; 7,654,771; Europe Patent No. 1841310; Ukraine Registration No. 90886 - For the application of line striping materials - 3300 psi (228 bar, 22.8 MPa) Maximum Working Pressure 313775 257780...

-

Page 2: Table Of Contents

......Graco Warranty ....... -

Page 3: Warnings

Warnings The following Warnings are for the safe setup, use, grounding, maintenance and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbols refer to procedure- -specific risks. Refer back to these Warnings. - Page 4 D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. Call your Graco distributor for information. D Route the hoses away from the traffic areas, sharp edges, moving parts, and hot surfaces.

-

Page 5: Spray Tip Selection Table

Tip Selection (cm) (cm) (cm) (cm) LL5213* 2 (5) LL5215* 2 (5) LL5217 4 (10) LL5219 4 (10) LL5315 4 (10) LL5317 4 (10) LL5319 4 (10) LL5321 4 (10) LL5323 4 (10) LL5325 4 (10) LL5327 4 (10) LL5329 4 (10) LL5331 4 (10) -

Page 6: General Repair Information

General Repair Information SAE O-Ring Installation 1. Unscrew lock nut to touch fitting. 1. Keep all screws, nuts, washers, gaskets, and electrical fittings removed during repair proce- dures. These parts are not normally provided with 2. Lubricate o-ring (A). replacement assemblies. 2. -

Page 7: Maintenance

VERY SLOWLY YEARLY OR 2000 HOURS: loosen tip guard retaining nut or hose end coupling to Replace hydraulic oil and filter element with Graco relieve pressure gradually, then loosen completely. hydraulic oil 169236 (5 gallon/18.9 liter) or 207428 (1 Now clear tip or hose. -

Page 8: Troubleshooting

Set pump valve OFF. Turn pressure down. Turn engine OFF. Pry rod up or down until hy- draulic motor shifts. *Check hydraulic fluid level often. Do not allow it to become too low. Use only Graco approved hydraulic fluid, page 7. 313776... - Page 9 Troubleshooting PROBLEM CAUSE SOLUTION Displacement pump oper- Piston ball is not seating Service piston ball. Manual 311845. ates, but output is low on up- stroke Piston packings are worn or damaged Replace packings. Manual 311845. Displacement pump oper- Strainer (34e) is clogged Clean strainer.

- Page 10 Intake line to pump inlet is not tight Tighten Hydraulic motor is worn or damaged Bring sprayer to Graco distributor for repair Large pressure drop in fluid hose Use larger diameter or shorter hose The sprayer overheats...

-

Page 11: Hydraulic Pump

11. Install drain plug (195); torque to 110 in-lb (12.4 N·m). Install oil filter (199); tighten 3/4 turn 12. Remove eight screws (184) and washers (101), after gasket contacts base. Fill with Graco hydrau- reservoir cover (237), filter assembly (A) and lic oil, page 7. - Page 12 ti13902a Fig. 2 313776...

-

Page 13: Fan Belt

Fan Belt Removal Installation 1. Thread belt (143) around fan pulley (87a) and fan pulley (86). 1. Relieve pressure; page 7. 2. Fig. 3. Loosen belt guard knob (241). 2. Lower engine (185) to put tension on belt. 3. Rotate belt guard (24) up. 4. -

Page 14: Engine

Engine Removal Installation 1. Install rocker plate (87c), dampeners (59) and washers (170), washers (114) on engine (185) with four screws (189), washers (170) and nuts 1. Relieve pressure; page 7. (118); torque to 20 ft-lb (27.1 N·m). 2. Do Fan Belt, Removal; page 13. 3. -

Page 15: Hydraulic Motor Yoke

6. Unscrew and remove hydraulic motor cap (25). 6. Start engine and operate pump for 30 seconds. Turn engine OFF. Check hydraulic oil level and fill 7. Slide piston rod/hydraulic motor cap assembly (A) from hydraulic motor cylinder. with Graco hydraulic oil, page 7. 313776... - Page 16 test hole ti13918a Fig. 5 313776...

-

Page 17: Oil/Filter Change

1. Install drain plug (195). Apply a light coat of oil to oil filter gasket and install oil filter (199). Tighten oil filter 3/4 turn after gasket contacts base. 2. Fill with1.25 gallons (4.73 liters) of Graco hydraulic oil 169236 (5 gallon/20 liter) or 207428 (1 gal- lon/3.8 liter) ti2271a Fig. -

Page 18: Displacement Pump

Fig. 8. Push pin (249) into hole. Push retaining spring (194) into groove. ti13905a Fig. 8 ti13908a Fig. 11 5. Fig. 9. Loosen jam nut. Unscrew pump. Fig. 12. Fill packing nut with Graco TSL. ti13809a ti13906a Fig. 12 Fig. 9 313776... -

Page 19: Parts

Parts - - LineLazer IV Parts Page 34 Parts Page 30 Parts Page 34 Parts Page 28 Parts Page 36 Parts Page 26 ti13917a Parts Page 28 313776... - Page 20 Parts - - LineLazer IV ti13910a 313776...

- Page 21 Parts - - LineLazer IV Ref. Ref. Part No. Description Qty. Part No. Description Qty. 237686 CLAMP, grounding assy 111145 KNOB, pronged 245225 HOSE, 3/8 in. X 50 ft 110837 SCREW, flange, hex 287623 FRAME, linestriper 255162 WHEEL, pneumatic 287417 HANDLE 111040 NUT, lock, insert, nylock, 5/16...

- Page 22 Parts - - LineLazer IV 130 ti6494a Detail 8 ti13911a 313776...

- Page 23 Parts - - LineLazer IV 130 Ref. Ref. Part No. Description Qty. Part No. Description Qty. 224052 BRACKET, support gun 15F637 LABEL, skin injection 248157 GUN, flex, basic, includes guard & tip 1 15A644 LABEL, trigger 287570 KIT, holder, gun 15F624 NUT, cable, gun 287569...

- Page 24 Parts - - LineLazer IV 130 (Engine Control Wiring Diagram) 185a ti13916a TO ENGINE GROUND ENGINE OFF SWITCH ti13912a 34 Ref 313776...

- Page 25 Parts - - LineLazer IV 130 Ref. Ref. Part No. Description Qty. Part No. Description Qty. 245103 VALVE, drain 196178 ADAPTER, nipple 3/8 in. x 3/8 in. 193709 SEAT, valve 196181 FITTING, nipple 1/4 in. x 1/4 in. 193710 SEAT, valve 104813 PLUG, pipe 116424...

- Page 26 Parts - - LineLazer IV 130 ti13914a 313776...

- Page 27 15H953 MANIFOLD, adapter 246176 SLEEVE, hydraulic cylinder, 15B063 LABEL, includes 213 107210 SCREW, cap, socket head 193031 NUT, retaining 15B804 LABEL, Graco Logo 117441 VALVE, ball 178179 WASHER, sealing 101566 NUT, lock 178207 BEARING, piston 15F911 GUARD, pump rod 178226...

- Page 28 Parts - - LineLazer IV 130 181 188 Detail 34 313776...

- Page 29 Parts - - LineLazer IV 130 Ref. Ref. Part No. Description Qty. Part No. Description Qty. 288261 RAIL, belt 100084 BALL, metallic 248973 GUARD, belt, includes: 162, 193, 214, 102040 NUT, lock 224, and 228 107188 O--RING 15E476 BRACKET, retainer, motor 156401 O--RING 287175...

- Page 30 Parts - - LineLazer IV 130 ti6492b Detail A Detail A 313776...

-

Page 31: Technical Data

..... 104 (27.5) leather, tungsten carbide, stainless steel, chrome plating, nickel-plated carbon steel, ceramic, Accessories Must be purchased separately. GRACO- -APPROVED HYDRAULIC OIL 169236 5 Gallons (19 liters) 207428 1 Gallon (3.8 liters) 313776... -

Page 32: Graco Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.