Table of Contents

Advertisement

Quick Links

Operator's Manual

PRECISION TIG

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code:

(ex: 10859)

Serial:

(ex: U1060512345)

IM936

| Issue D ate 12-Feb

© Lincoln Global, Inc. All Rights Reserved.

375 ROHS

®

For use with machines having Code Numbers:

11163

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Lincoln Electric PRECISION TIG 375 ROHS

- Page 1 Operator’s Manual PRECISION TIG 375 ROHS ® For use with machines having Code Numbers: 11163 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM936 | Issue D ate 12-Feb ©...

- Page 2 Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

- Page 3 SAFETY ARC RAYS can burn. ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits 4.a. Use a shield with the proper filter and cover are electrically “hot” when the welder is on. plates to protect your eyes from sparks and Do not touch these “hot”...

- Page 4 SAFETY WELDING and CUTTING CYLINDER may explode SPARKS can if damaged. cause fire or explosion. 7.a. Use only compressed cylinders 6.a. Remove fire hazards from the welding area. containing the correct shielding gas for the If this is not possible, cover them to prevent process used properly...

- Page 5 SAFETY PRÉCAUTIONS DE SÛRETÉ 6. Eloigner les matériaux inflammables ou les recouvrir afin de prévenir tout risque dʼincendie dû aux étincelles. Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce 7.

- Page 6 We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page. Installation ......................Section A Technical Specifications ..................A-1,A-2 Safety Precautions ..............................Select Suitable Location ..................A-3 Grinding .........................A-3 Stacking .........................A-3 Undercarriage Lifting and Moving .................A-3 Tilting ........................A-3 Environmental Rating ....................A-3 Machine Grounding and High F ....A-3, A-4 REQUENCY NTERFERENCE ROTECTION... -

Page 8: Installation

INSTALLATION ® TECHNICAL SPECIFICATIONS-Precision TIG 375 (K2623-1 Export-50/60Hz) RATED INPUT - SINGLE PHASE ONLY Duty Cycle-Applications Voltage + 10% Max. Amps With Power Factor Capacitor 119/69/63 AC/DC Stick / Balance TIG 118/68/62 Unbalance (70% Penetration ) AC TIG 110/64/59 AC/DC Stick / Balance TIG 97/56/52 Unbalance (70% Penetration ) AC TIG... - Page 9 INSTALLATION RECOMMENDED INPUT WIRE AND FUSE SIZES For all Stick, DC TIG, and Balanced AC TIG Welding For Unbalanced AC TIG Welding Above 275 Amps: at 375A/40% Duty Cycle with out Standard Power 350A/40% Duty Cycle, Auto-Balance Penetration with Factor Correction Capacitors out Standard Power Factor Correction Capacitors Based on the 1999 U.S.

-

Page 10: Safety Precautions

INSTALLATION SAFETY PRECAUTIONS ENVIRONMENTAL RATING Read entire installation section before starting Precision TIG ® 375 power sources carry an IP21S installation. Environmental rating. They are rated for use in damp, dirty rain-sheltered environments. WARNING MACHINE GROUNDING AND HIGH FRE- ELECTRIC SHOCK can kill. QUENCY INTERFERENCE PROTECTION •... -

Page 11: Input And Grounding Connections

INSTALLATION 3. Be sure the torch and work cable rubber coverings INPUT and GROUNDING CONNECTIONS are free of cuts and cracks that allow high frequen- WARNING cy leakage. Cables with high natural rubber content, such as Lincoln Stable-Arc ® , better resist high fre- ELECTRIC SHOCK can kill. -

Page 12: Output Cable, Connections And Limitations

INSTALLATION Welders are shipped connected for the highest input Recommended Cable Sizes for Combined Lengths of voltage as listed on the rating plate. To change this Copper Work and Electrode Cables using 75 C Wire: connection, designations on the reconnect panel LOW, MID, and HIGH correspond to the name plated input Machine Rating 0 to 100 Ft. -

Page 13: Tig Torch Connection

INSTALLATION FIGURE A.2 TIG TORCH REMOTE CONNECTION CONTROL P ANEL RECEPTACLE STICK STICK WORK WORK WORK STICK ELECTRODE STUD STUD (Shown without hinged stud cover) FIGURE A CABLE STRAIN RELIEF HOLES TIG TORCH CONNECTION CYLINDER could explode if damaged. ® The Precision TIG torch connection box, located on •... -

Page 14: Auxiliary Power Connections

INSTALLATION FIGURE A.3 OUTPUT (front) Panel INPUT (back) Panel Air Cooled Torch Torch Adapter For Gas Supply COOLANT OUT GAS INPUT 5/8-18 LH 5/8-18 RH hose with 5/8 - 18RH Two - Cable K2166-2 (Opt.) (PTA-9,-7,-26) Male 7/8-14 ?-13 1/2-13 Stud STUD M-LH... -

Page 15: Robotic Interface Connection

INSTALLATION ROBOTIC INTERFACE CONNECTION Robotic interface can be made at the Remote Receptacle (See Operation Section B-2). The machine is shipped with the remote receptacle circuit internally connected to receptacle J5 of the Control board for standard Amptrol operation. In order to enable the remote receptacle for robotic interface its connection plug must be moved from J5 to J5A on the Control board. -

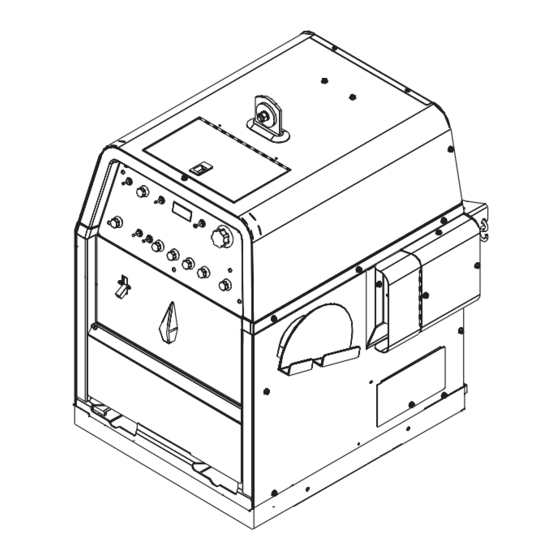

Page 16: Peration

OPERATION SAFETY PRECAUTIONS PRODUCT DESCRIPTION Read and understand this entire section before operat- The Precision TIG 375 is part of a family of industrial ® ing the machine. arc welding power sources providing constant current, single range square wave AC/DC TIG (GTAW) with WARNING patented MicroStart™... -

Page 17: Recommended Processes And Equipment

OPERATION RECOMMENDED PROCESSES AND EQUIPMENT LIMITATIONS The Precision TIG ® machines are protected from over- EQUIPMENT loads beyond the electrical ratings and duty cycles, per the Specifications Section A-1, A-2, with Thermostat protection of the primary and secondary transformer coils. RECOMMENDED PROCESSES The Precision TIG ®... -

Page 18: Controls And Settings

OPERATION CONTROLS AND SETTINGS The Front Control Panel contains the knobs and switches necessary for adjusting the operation of the Precision 375, with function indicator lights and an electronic display for volts and amps. The components are ® described below: FIGURE B.1 - CONTROL PANEL 1. - Page 19 OPERATION • When the Polarity Switch is set to DC (- or +), the • With the Current Control switch to REMOTE posi- TIG mode provides high frequency only for starting. tion, this knob sets the maximum welding level that the Peak output can be set with the remote Amptrol.

- Page 20 OPERATION 7a MENU BUTTON AND DISPLAY SWITCH – TIG Mode Menu (with Advanced Control Panel installed): Pressing and holding the (Menu) Button for about 5 Setting: Description: seconds enters the menu display which allows: Selection 4: HS (TIG Hot Start % of output setting) (Only setting for SS0, above.) •...

- Page 21 OPERATION 8. DIGITAL METER AND DISPLAY SWITCH– A (3- • When the Current Control Switch is in either LOCAL digit) LED meter is used to monitor the preset and or REMOTE positions the arc start switch functions actual welding procedure based on the Display when connected to the Remote receptacle.

- Page 22 OPERATION • In 4-Step position allows welding without continu- ously holding the start switch trigger. The arc start 15. PULSE % ON / SPOT TIME CONTROL –This switch functions in the following manner: knob sets the time for Pulse or Spot modes: 1.

-

Page 23: Internal Set Up Controls

OPERATION INTERNAL SET UP CONTROLS TIG WELDING FEATURES Precision TIG ® 375 Advanced Panel has the following The following DIP switch feature selections function additional control features which are set up using the only when the Precision TIG ® is set to TIG mode (See DIP Switch (S1) provided on the internal panel of this Item 3): option. - Page 24 OPERATION FIGURE B.3 (With DIP Switch #2 OFF) (With DIP Switch #2 ON, As Shipped) PRECISION TIG ®...

- Page 25 B-10 B-10 OPERATION FIGURE B.4 (With DIP Switch #3 ON) (With DIP Switch #3 OFF, As Shipped) PRECISION TIG ®...

-

Page 26: Setup Guidelines For Tig Welding With An Amptrol

B-11 B-11 OPERATION TIG WELD CYCLE CHART SEE ITEM 12 SEE ITEM 12 SEE ITEM 12 SEE ITEM 12 SEE ITEM 7a SEE ITEM 6 SEE ITEM 6 & 7 SEE ITEM 7 SEE ITEM 15 SEE ITEM 14 SEE ITEM 7 SEE ITEM 15 SEE ITEM 7a SEE ITEM 9... - Page 27 B-12 B-12 OPERATION FIGURE B.6 Setup for TIG Amptrol Welding Standard Controls Power Switch Mode Switch Polarity Switch AC Balance AUTO Set: for alum.oxide " Cleaning" More + w/o "Spitting" or " wetting" loss. Balanced for equal + and - current. More - for higher "...

-

Page 28: Making A Tig Weld With An Amptrol

B-13 B-13 OPERATION MAKING A TIG WELD WITH AN AMPTROL Close the arc start switch. This opens the gas valve to automatically purge air from the hose and torch, then shields the arc strike area. After the 0.5 sec- 1. Install welding equipment per Section A-5. ond preflow time, the high frequency becomes available to strike the arc. -

Page 29: Accessories

ACCESSORIES OPTIONAL EQUIPMENT • Magnum ® PTA and PTW Series Torches All Air Cooled or Water-Cooled Magnum ® Torches may be used with the Precision TIG ® 375. FACTORY INSTALLED OPTIONS Connection adapters are only required for Air-Cooled Torches (Refer to Diagrams on A-7): The basic Precision TIG 375 machine is factory ®... -

Page 30: Maintenance

MAINTENANCE SAFETY PRECAUTIONS OVERLOAD PROTECTION FAN-AS-NEEDED (F.A.N.) WARNING The Precision TIG ® 375 has the F.A.N. circuit feature, ELECTRIC SHOCK can kill. which means the cooling fan will operate only while • Only qualified personnel should welding; then for about 8 minutes after welding has perform this maintenance. -

Page 31: Under-Cooler Service

MAINTENANCE SERVICE PROCEDURES FIGURE C.1 SPARK GAP Operation of the Precision TIG should be trouble-free for the life of the machine. Should a malfunction occur, however, the following procedures will be useful to .015 Spark Gap trained service personnel with experience in repairing arc welding equipment: COMPONENT ACCESS Note: In highly dirty environments where there is an... -

Page 32: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 33: Troubleshooting

TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS COURSE OF ACTION OUTPUT PROBLEMS Thermal light comes on 1. Thermal shut down. Dirt and dust may have clogged the cooling channels inside machine; air intake and exhaust louvers may be blocked.;... - Page 34 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS COURSE OF ACTION METER PROBLEMS Meter does not light up 1. Bad meter or its connection. 2. Bad connection at P8 of Control PC board. If all recommended possible areas misadjustment have...

- Page 35 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS COURSE OF ACTION HI-FREQ PROBLEMS No hi-freq 1. Circuit breaker CB1 open 2. Bad connection at P12 of Control PC board 3. Spark gaps shorted 4.

- Page 36 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS COURSE OF ACTION PRESET & OUTPUT CONTROL PROBLEMS Meter does not display preset 1. Faulty potentiometer R1 or its con- nection 2. Bad connection at P9 of Control PC board 3.

- Page 37 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS COURSE OF ACTION STICK WELDING PROBLEMS Stick electrode "blast off" when arc 1. Current may be set too high for is struck electrode size 2.

- Page 38 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS COURSE OF ACTION TIG PROBLEMS Arc "pulsates" in AC polarity, DC 1.Micro switch S2A on polarity switch polarity is o.k. does not open in AC polarity Black area along weld bead 1.

-

Page 39: Wiring Diagrams

WIRING DIAGRAM PRECISION TIG ®... -

Page 40: Dimension Prints

DIMENSION PRINT PRECISION TIG ®... - Page 41 NOTES PRECISION TIG ®...

- Page 42 Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. Insulate yourself from work and ground. Spanish No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE bajo carga con la piel o ropa moja-...

- Page 43 Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. WARNING remove fumes from breathing zone. Spanish Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o AVISO DE...

- Page 44 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...