Table of Contents

Advertisement

Quick Links

Instructions

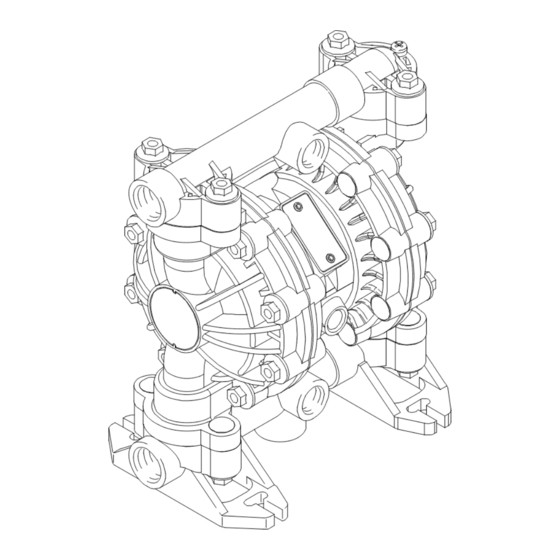

Air-Operated

Diaphragm Pumps

For fluid transfer applications. For professional use only. Only models marked with (*) are

approved for use in European explosive atmosphere locations.

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

ACETAL*, POLYPROPYLENE, AND PVDF

Husky™ 515

Model No. D 5 1 _ _ _ Acetal NPT Pumps

Model No. D 5 2 _ _ _ Polypropylene Pumps

Model No. D 5 5 _ _ _ PVDF NPT Pumps

Model No. D 5 A _ _ _ Acetal BSPT Pumps

Model No. D 5 B _ _ _ Polypropylene BSPT Pumps

Model No. D 5 E _ _ _ PVDF BSPT Pumps

Model No. D 9 1 _ _ _ Acetal NPT Pumps

Model No. D 9 A _ _ _ Acetal BSPT Pumps

For Additional Models, see Table of Contents

ALUMINUM* AND STAINLESS STEEL*

Husky™ 716

Model No. D 4 D _ _ _ Stainless Steel BSPT Pumps, Remote

Model No. D 5 3 _ _ _ Aluminum NPT Pumps

Model No. D 5 4 _ _ _ Stainless Steel NPT Pumps

Model No. D 5 C _ _ _ Aluminum BSPT Pumps

Model No. D 5 D _ _ _ Stainless Steel BSPT Pumps

Model No. D 9 4 _ _ _ Stainless Steel NPT Pumps

Model No. D 9 D _ _ _ Stainless Steel BSPT Pumps

For Additional Models, see Table of Contents

*These models are certified:

II 2 GD

Ex h IIC 66°C...135°C Gb

Ex h IIIC T135°C Db

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Refer to the Pump Matrix on page 23 to determine

the model number of your pump.

ATEX T-code rating is dependent on the temperature

of the fluid being pumped. Fluid temperature is

limited by the materials of the pump interior wetted

parts. See Technical Data for the maximum fluid

operating temperature for your specific pump model.

308981ZBB

EN

9065A

Husky 515

9246A

Husky 716

Advertisement

Table of Contents

Summary of Contents for Graco D51

- Page 1 Instructions Air-Operated Diaphragm Pumps 308981ZBB For fluid transfer applications. For professional use only. Only models marked with (*) are approved for use in European explosive atmosphere locations. 100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure 100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure ACETAL*, POLYPROPYLENE, AND PVDF Husky™...

-

Page 2: Table Of Contents

Husky 515 and 716 Performance Charts ..38 Graco Standard Warranty ....40 WARNING EQUIPMENT MISUSE HAZARD Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury. - Page 3 WARNING TOXIC FLUID HAZARD Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or swallowed. • Know the specific hazards of the fluid you are using. • Do not lift a pump under pressure. If dropped, the fluid section may rupture. Always follow the •...

-

Page 4: Installation

These pumps can be used in a variety of selecting and installing system components. installations. Be sure the mounting surface can Contact your Graco distributor for assistance in support the weight of the pump, hoses, and planning a system to suit your needs. - Page 5 3. Connect remaining ends of tubes to external air sig- ardous fluids. nal, such as Graco’s Cycleflo (P/N 195264) or Cycle- CAUTION flo II (P/N195265) controllers. NOTE: the air pressure at the connectors must be at The pump exhaust air may contain contaminants.

- Page 6 Installation Fluid Pressure Relief Valve Air Exhaust Ventilation CAUTION Read TOXIC FLUID HAZARD on page 3. Some systems may require installation of a pressure relief valve at the pump outlet to prevent overpressur- Read FIRE AND EXPLOSION ization and rupture of the pump or hose. See Fig. 1. HAZARD on page 3.

- Page 7 Installation ABOVE-GROUND TRANSFER INSTALLATION A Pump B Bleed-type master air valve (required for pump) C Electrically conductive air supply line D Air line quick disconnect E Master air valve (for accessories) F Air line filter G Pump air regulator H Fluid drain valve (required) Fluid regulator (optional) K Electrically conductive fluid supply hose L Fluid suction line...

- Page 8 Installation Grounding Ground all of this equipment: • Pump: The metal pump has a grounding strip in WARNING front of the center housing. The acetal pump has a grounding screw on the top manifold. Connect the FIRE AND EXPLOSION HAZARD non-clamp end of the ground wire to the grounding strip or grounding screw, and connect the clamp This pump must be grounded.

- Page 9 Installation Changing the Orientation of the Fluid Inlet Torque to 80 to 90 in-lb (9 to 10 NSm). See and Outlet Ports (Husky 515) Torque Sequence, page 32. You can change the orientation of the fluid inlet and outlet outlet ports by repositioning the manifolds. For Husky 515, see Fig.

- Page 10 Install Reed Switch 1. Shut off air to pump and remove valve cover (A). 2. Remove lower carriage and replace with new car- riage assembly (2), so magnet faces end of valve chamber. 3. Replace valve cover. Torque to 80 to 100 in-lb (9.0 to 13.6 N•m).

-

Page 11: Operation

Operation Pressure Relief Procedure 6. Place the end of the fluid hose (K) into an appropriate container. WARNING 7. Close the fluid drain valve (H). PRESSURIZED EQUIPMENT HAZARD 8. With the pump air regulator (G) closed, open all The equipment stays pressurized until pressure is bleed-type master air valves (B, E). -

Page 12: Maintenance

Maintenance Lubrication Tightening Threaded Connections The air valve is lubricated at the factory to operate with- Before each use, check all hoses for wear or damage out additional lubrication. If you want to provide addi- and replace as necessary. Check to be sure all tional lubrication, remove the hose from the pump air threaded connections are tight and leak-free. -

Page 13: Troubleshooting

Troubleshooting Read Pressure Relief Procedure on page 11, and relieve the pressure before you check or service the equipment. Check all possible problems and causes before disassembling the pump. PROBLEM CAUSE SOLUTION Pump will not cycle, or cycles once and Air valve is stuck or dirty. -

Page 14: Service

Service Air Valve (Husky 515 and Husky 716 pumps without reed switch) NOTE: Air Valve Repair Kit 241657 is available. Parts included in the kit are marked with a dagger (†) in Fig. 6 and in the Parts Drawings and Lists. A tube of general purpose grease 111920 is supplied in the kit. Service the air valve as follows. - Page 15 Air Valve (Husky 515 and Husky 716 pumps with reed switch) NOTE: Air Valve Repair Kit 25C469 is available. Parts included in the kit are marked with a dagger (†) in Fig. 7 and in the Parts Drawings and Lists. A tube of general purpose grease 111920 is supplied in the kit. Service the air valve as follows.

- Page 16 Service Air Section (Husky 515 and 716) Fig. 10 and Fig. NOTE: Air Section Repair Kit 25U241 is available. Parts included with the kit are marked with an asterisk (*) in Fig. 10 and Fig. 11 . General purpose grease 111920 is supplied in the kit. Service the air section as follows. See Disassembly 4.

- Page 17 Service Ball or Duckbill Check Valves Inlet and Outlet for Pumps with Duckbill Check Valves NOTE: Fluid Section Repair Kit D05XXX is available. See page 27 to order the correct kit for your pump. Pumps with duckbill check valves are shipped with the Adhesive 113500 is supplied in the kit.

- Page 18 Service Husky 515 Husky 716 Torque to 80 to 90 in-lb (9 to 10 N-m). See Torque Sequence, page 32. 9067A Fig. 8 Torque to 80 to 90 in-lb (9 to 10 N-m). See Torque Sequence, page 32. Fig. 9 9081A 18 308981...

- Page 19 Service Diaphragms (Husky 515) NOTE: Fluid Section Repair Kit D05XXX is available. See page 23 to order the correct kit for your pump. Service the diaphragms as follows. See Fig. 10. Disassembly 2. Repeat step 1 for the other end of the diaphragm shaft (15).

- Page 20 Service Diaphragms (Husky 515) 416* HD Overmolded Diaphragm The words “AIR SIDE” on diaphragms (and on backup diaphragms required on PTFE models) must face toward diaphragm shaft (15). Flat side of air-side diaphragm plate must face toward diaphragm shaft (15). Apply medium-strength (blue) thread locker to threads, and torque to 80 to 90 in-lb (9 to 10 N-m) at 100 rpm maximum.

- Page 21 Service Diaphragms (Husky 716) NOTE: Fluid Section Repair Kit D05XXX is available. See page 23 to order the correct kit for your pump. Adhesive 113500 is sup- Fig. 11 plied in the kit. Service the diaphragms as follows. See Disassembly 2.

- Page 22 Service Diaphragms (Husky 716) The words “AIR SIDE” on diaphragms (and on backup diaphragms used on PTFE models) must face toward diaphragm shaft (15). HD Overmolded Diaphragm Flat side of the air-side diaphragm plate must face toward diaphragm shaft (15). Apply medium-strength (blue) thread locker to threads, and torque to 80 to 90 in-lb (9 to 10 N-m) at 100 rpm maximum.

-

Page 23: Husky 515 And Husky 716 Pump Matrix

Husky 515 and Husky 716 Pump Matrix Your Model No. is marked on the pump’s serial plate. To determine a pump Model No. from the following matrix, select the six digits that describe the pump, working from left to right. The first digit is always D, designating Husky diaphragm pumps. - Page 24 Additional Husky 515 and Husky 716 Pumps Model Pump Same As: Except for: 241564 D51211 Has open downward port. Use inlet manifold 241558. 26C021 D52966 Has split inlets/outlets. 26D862 D52966 Has manifolds rotated 180°. 241565 D52911 Has open downward port. Use inlet manifold 241557. 26C022 D52911 Has split inlets/outlets.

-

Page 25: Husky 515 And Husky 716 Repair Kits

Part Description 16M001 PLATE, air side - - - - - not used - - - - - not used - - - - - not used 16H679 DIAPHRAGM, HD, overmolded, PTFE/EPDM, with setscrew - - - - - not used Husky 515 and Husky 716 Repair Kits NOTE: Order Repair Kits separately. -

Page 26: Husky 515 And Husky 716 Common Parts

Husky 515 and Husky 716 Common Parts See the Pump Matrix on page 23 for an explanation of the Matrix Column and the Digit. Air Motor Parts List (Matrix Column 2) Guide Kits (Matrix Column 4) Digit Ref. Part Description Qty. - Page 27 Complete Fluid Section Repair Kits Kit No. Description Qty. Kit descriptions appear in the following order: Pump D05931 515/716 IN, PP,SS,PT,FKP model, seat material, ball material, diaphragm material, D05961 515/716 IN, PP,SP,PT,FKP gasket material. For example, 515/716 IN, SS,SS,FK,FKP. D05916 515/716 IN, PP,PT,SP,FKP Kit No.

- Page 28 Husky 515 Parts Drawing † Included in Air Valve Repair Kit 241657 or 25C469 These parts are unique to the remote operated air motor. grounding screw (acetal pump only) 9064B 28 308981...

- Page 29 Husky 515 Fluid Section Parts List See the Pump Matrix on page 23 for an explanation of the Matrix Column and the Digit. See page 26 for Air Motor Parts List (Matrix Column 2) Husky 515 Fluid Section Parts List (Matrix Column 3) Ref.

-

Page 30: Husky 716 Parts Drawing

Husky 716 Parts Drawing † Included in Air Valve Repair Kit 241657 * These parts are unique to the remote operated air motor. Grounding Detail 9070A 30 308981... - Page 31 Husky 716 Fluid Section Parts List See the Pump Matrix on page 23 for an explanation of the Matrix Column and the Digit. See page 26 for Air Motor Parts List (Matrix Column 2) Husky 716 Fluid Section Parts List (Matrix Column 3) Ref.

-

Page 32: Torque Sequence

Torque Sequence Husky 716 Always follow torque sequence when instructed to torque fasteners. 1. Left/Right Fluid Covers Husky 515 Torque bolts to 80-90 in-lb (9-10 N•m) 1. Left/Right Fluid Covers Torque bolts to 80-90 in-lb (9-10 N•m) 1 1 1 1 FRONT VIEW 2. -

Page 33: Husky 515 Technical Data

PVDF pumps..............8.5 lb (3.9 kg) *These temperatures are based onmechanical stress only andmay be altered significantly by pumping certain chemicals. Consult engineering guides for chemical compatibilities and temperature limits, or contact your Graco distributor. -

Page 34: Husky 515 Dimensions

Husky 515 Dimensions FRONT VIEW 1/2 npt(f) or bspt(f) Fluid Outlet * 4.70 in. 5.01 in. (119 mm) (127 mm) 1/4 npt(f) Air Inlet * Pumps with duckbill check valves are shipped with the inlet manifold on top and the outlet manifold on the bottom. -

Page 35: Husky 716 Technical Data

Stainless steel pumps ............18 lb (8.2 kg) *These temperatures are based on mechanical stress only and may be altered significantly by pumping certain chemicals. Consult engineering guides for chemical compatibilities and temperature limits, or contact your Graco distributor. -

Page 36: Reed Switch Technical Data

Reed Switch Technical Data Contact Ratings State ................Normally open Voltage . -

Page 37: Husky 716 Dimensions

Husky 716 Dimensions FRONT VIEW 4.25 in. 4.44 in. * Pumps with duckbill 3/4 npt(f), bspt(f) or (108.0 mm) (112.8 mm) bspp(f) check valves are shipped with the inlet manifold on top and the outlet manifold 1/4 npt(f) on the bottom. To make Air Inlet the inlet manifold on the bottom and the outlet... -

Page 38: Husky 515 And 716 Performance Charts

Husky 515 and 716 Performance Charts Fluid Outlet Pressure Test Conditions: Pump tested in water with inlet submerged. (0.7, 7) Fluid Pressure Curves A at 100 psi (0.7 MPa, 7 bar) air pressure B at 70 psi (0.48 MPa, 4.8 bar) air pressure C at 40 psi (0.28 MPa, 2.8 bar) air pressure (0.55, 5.5) (0.41, 4.1) - Page 39 Husky 515 and 716 Performance Charts Air Consumption Test Conditions: Pump tested in water with inlet submerged. Air Consumption Curves (0.84) A at 100 psi (0.7 MPa, 7 bar) air pressure B at 70 psi (0.48 MPa, 4.8 bar) air pressure C at 40 psi (0.28 MPa, 2.8 bar) air pressure (0.70) (0.56)

-

Page 40: Graco Standard Warranty

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.