Table of Contents

Advertisement

Quick Links

INSTRUCTIONS - PARTS LIST

684-021

Revision A

This manual contains IMPORTANT

WARNINGS and INSTRUCTIONS

READ AND RETAIN FOR REFERENCE

DIVORCED DESIGN

®

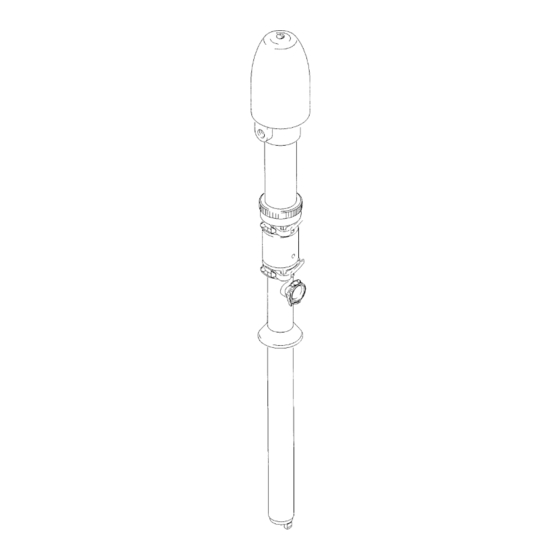

1:1 Ratio Standard

Sanitary Pump

180 PSI (12.6 bar) MAXIMUM FLUID WORKING PRESSURE

180 PSI (12.6 bar) MAXIMUM AIR INPUT PRESSURE

Model: 946-964

TABLE of CONTENTS

Symbols ................................................ 2

Safety Warnings ................................... 2, 3

Installation ............................................. 4, 5

Operation .............................................. 6

Maintenance ......................................... 7

Troubleshooting .................................... 8

Service .................................................. 9

Technical Data ...................................... 10

Warranty ............................................... 12

GRACO INC. - EAS P.O. Box 1441 MINNEAPOLIS, MN 55440-1441

© COPYRIGHT 1997, GRACO INC.

Advertisement

Table of Contents

Summary of Contents for Graco Standard 946-964

-

Page 1: Table Of Contents

Safety Warnings ........2, 3 Installation ..........4, 5 Operation ..........6 Maintenance ......... 7 Troubleshooting ........8 Service ..........9 Technical Data ........10 Warranty ..........12 GRACO INC. - EAS P.O. Box 1441 MINNEAPOLIS, MN 55440-1441 © COPYRIGHT 1997, GRACO INC. -

Page 2: Symbols

This equipment is for professional use only. Read all instruction manuals, tags, and labels before operating the equipment Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. Do not alter or modify this equipment. - Page 3 WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury. Ground the equipment. Refer to Grounding. If there is any static sparking or you feel an electric shock while using this equipment, stop dispensing immediately.

-

Page 4: Installation

1. Pump: use a ground wire and clamp. See the figures and the parts drawing. Figure 1. Loosen the grounding lug locknut (W) and washer (X). Insert one NOTE: Always use Genuine Graco Parts and Accessories, available from your Graco end of the ground wire (Y) into the slot in distributor. - Page 5 Installation 3/8 npt Air Inlet M Bung-Mounted Sanitary Pump B 3/4 npt Exhaust Air Outlet G Air Line Drain Pipe and Valve N Dispensing Valve Air Exhaust Hose C Air Line Filter/Regulator H 1-1/2” Tube Size Flanged Fluid Outlet P Sensing Device D Bleed-Type Master Valve...

-

Page 6: Operation

Operation Allow the pump to cycle slowly until all air is Pressure Relief Procedure pushed out of the lines (the fluid will be flowing in a steady stream from the fluid outlet) and the pump is primed. PRESSURIZED EQUIPMENT HAZARD With the air supply turned on, the pump will The system pressure must be manually relieved to prevent the system from starting or spraying... -

Page 7: Maintenance

Maintenance 4. Wash all the pump parts with an alkaline IMPORTANT NOTE: detergent manufacturer’s recommended temperature The following instructions show a basic procedure for cleaning a sanitary system. concentration, using either a brush or However, be sure to clean the pump and other C.O.P. -

Page 8: Troubleshooting

Troubleshooting 1. Relieve the pressure. 2. Check possible remedies Troubleshooting Chart before To reduce the risk of serious injury whenever you disassembling the pump. are instructed to relieve pressure, always follow the Pressure Relief Procedure. Problem Cause Solution Pump fails to operate Restricted air line or inadequate Clean air line or increase air air supply... -

Page 9: Service

Service Displacement Pump Disassembly Displacement Pump Assembly NOTE: Repair Kit 218-741 is available. Use NOTE: Lubricate the o-rings, throat packings, all parts in the kit for the best results. and piston seals with waterproof approved sanitary lubricant when reassembling. 1. Remove the pump from the fluid container. 1. -

Page 10: Technical Data

Technical Data Category Data Maximum fluid working pressure 180 psi (12.6 bar) Maximum air input pressure 180 psi (12.6 bar) Ratio Pump cycles per gallon (3.8 liters) Fluid flow at 60 cycles per minute 2.3 gallons (8.7 liters) Air consumption approximately 8 scfm (0.224 m³/minute) per gallon (3.8 liters) at 100 psi (7 bar) air Minimum air hose size... - Page 11 NOTES: 684-021...

-

Page 12: Warranty

Graco. These items sold, but not manufactured by Graco (such as electric motor, switches, hose, etc.) are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.