Table of Contents

Summary of Contents for Endress+Hauser FTL64 Series

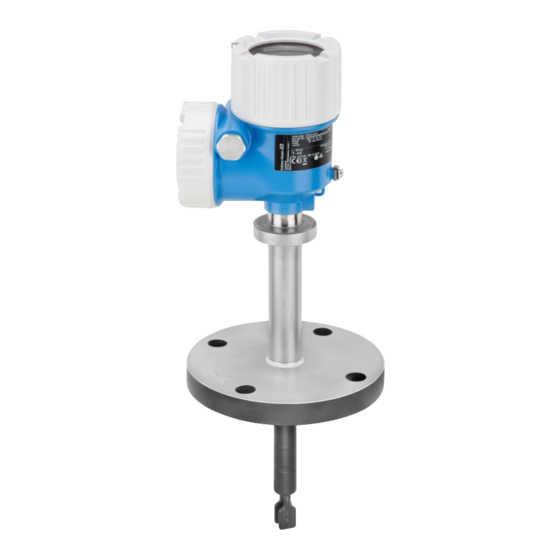

- Page 1 Products Solutions Services FY01023F/00/EN/01.20 71491961 2020-09-28 Valid as of version 01.01.zz (Device firmware) 01.00.zz (Device hardware) Functional Safety Manual Liquiphant FTL64 with electronic insert FEL67 Vibronic Using with FTL325P...

- Page 2 Liquiphant FTL64 with electronic insert FEL67 Order code: XXXXX-XXXXXX Ser. no.: XXXXXXXXXXXX Ext. ord. cd.: XXX.XXXX.XX Serial number www.endress.com/deviceviewer Endress+Hauser Operations App A0023555 Endress+Hauser...

-

Page 3: Table Of Contents

Appendix ..... . 18 Structure of the measuring system ..18 Version history ..... 21 Endress+Hauser... -

Page 4: Declaration Of Conformity

This declaration of conformity is exclusively valid for the customer listed in the cover letter of the respective Endress+Hauser sales center and for the listed products and accessories in delivery status. Maulburg, 31-July-2020 Endress+Hauser SE+Co. -

Page 5: Safety-Related Characteristic Values

For continuous operation at ambient temperature close to +60 °C (+140 °F), a factor of 1.5 should be applied PTC = Proof Test Coverage All diagnostic functions are performed at least once within the diagnostic test interval Maximum time between error recognition and error response A0042187 Endress+Hauser... -

Page 6: About This Document

This symbol contains information on procedures and other facts which do not result in personal injury. 2.2.2 Symbols for certain types of information and graphics Tip Indicates additional information Reference to documentation Reference to graphic Notice or individual step to be observed Series of steps Result of a step Endress+Hauser... -

Page 7: Supplementary Device Documentation

• W@M Device Viewer (www.endress.com/deviceviewer): Enter the serial number from nameplate • Endress+Hauser Operations App: Enter the serial number from the nameplate or scan the 2D matrix code (QR code) on the nameplate The following documentation types are available in the Downloads section of the Endress+Hauser website (www.endress.com/downloads):... -

Page 8: Design

Version: all Feature: 050 "Electrical connection" Version: all Feature: 060 "Application" Version: all Feature: 080 "Surface finish" Version: all Feature: 085 "Probe design" Version: all Feature: 090 "Sensor length, material" Version: all Feature: 105 "Process connection, sealing surface" Version: all Endress+Hauser... -

Page 9: Identification Marking

• if the switch position is > 0.5 the density must be over 0.5 g/cm³ (e.g., liquefied gas, isopentane, petroleum ether). • The gas phase above the liquid may not exceed a maximum permitted density value. The maximum possible gas density depends on the temperature and the device. Endress+Hauser... - Page 10 Buildup (only for MIN detection) The device may only be used in media that do not tend to cause buildup. Buildup is considered to be any deposits with a thickness of over 0.5 mm (0.02 in). Buildup can have the effect that Endress+Hauser...

- Page 11 (acceleration spectral density >1 (m/s²)²/Hz) or ultrasound with cavitation, the safety function must be verified by simulating a demand mode prior to operation. Accidental switchings may sporadically occur if a strong frequency from an external source is superimposed on the frequency of the tuning fork. Endress+Hauser...

-

Page 12: Useful Lifetime Of Electric Components

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the following requirements: ‣ Trained, qualified specialists must have a relevant qualification for this specific function and task. ‣ Personnel must be authorized by the plant owner/operator. ‣ Be familiar with federal/national regulations. Endress+Hauser... -

Page 13: Installation

NOTICE The protective function can be impaired After commissioning the measuring system, changes to the settings can impact the protective function ‣ After changing the settings, perform a proof test to ensure that the safety function is working correctly Endress+Hauser... - Page 14 – >0,7 >0,5 U= 0 V A0039189 3 Selection of density mode Default setting (density >0.7 g/cm³); always use this setting where possible Special setting (density >0.5 g/cm³); extremely light liquids (e.g., liquefied natural gas, isopentane, petroleum ether) Endress+Hauser...

-

Page 15: Operation

Declaration of Conformity. • To monitor the safety-related output signal, it is sufficient to evaluate the response of downstream components of the safety function. If the different states are correctly identified there, the test steps are passed. Endress+Hauser... -

Page 16: Basic Test Sequence

Maintenance instructions and instructions regarding recalibration may be found in the Operating Instructions pertaining to the device. Alternative monitoring measures must be taken to ensure process safety during configuration, proof-testing and maintenance work on the device. Repair Repair means restoring functional integrity by replacing defective components. Endress+Hauser... -

Page 17: Modification

Repair and error handling Components may be repaired/replaced by the customer' s technical staff if genuine spare parts from Endress+Hauser are used (they can be ordered by the end user) and the appropriate installation instructions are followed. A proof test must always be performed after every repair Spare parts are grouped into logical kits with the associated replacement instructions. -

Page 18: Battery Disposal

• In some countries, the end user is legally obliged to return used batteries. • The end user can return old batteries or electronic assemblies containing these batteries free of charge to Endress+Hauser. In accordance with German law regulating the use of batteries (BattG §17 Para Number 3), this symbol is used to denote electronic assemblies that must not be disposed of as municipal waste. - Page 19 OK status. If the tuning fork is covered, the device assumes the safe state and signals the demand mode. 8.1.4 Versions The components Liquiphant FTL64 with electronic insert FEL67 and Nivotester FTL325P may be operated in the versions described in the Functional Safety Manual for the Nivotester FTL325P (FY01006F). Endress+Hauser...

- Page 20 Appendix Liquiphant FTL64 with electronic insert FEL67 Version I, without the Nivotester, may not be used as a safety function in accordance with IEC 61508. Endress+Hauser...

-

Page 21: Version History

Liquiphant FTL64 with electronic insert FEL67 Appendix Version history FY01023F • Version: 01.20 • Valid as of firmware version: 01.01.zz • Valid as of hardware version: 01.00.zz • Changes: First version Endress+Hauser... - Page 24 *71491961* 71491961 www.addresses.endress.com...