Advertisement

Quick Links

Advertisement

Summary of Contents for Moffat Versicarte-Pro

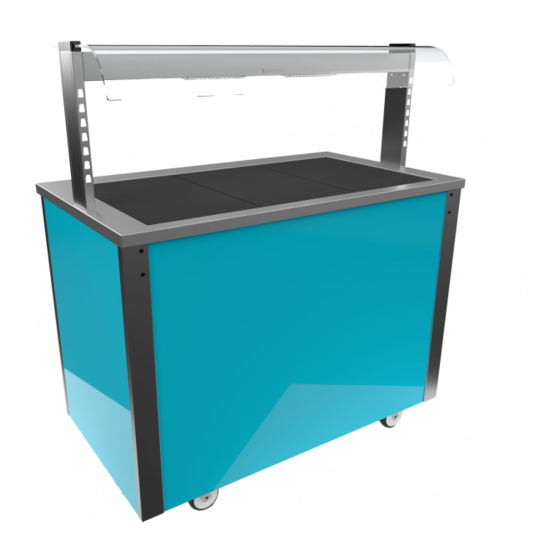

- Page 1 Versicarte-Pro Operating & Service Manual Manual 008 Issue 001 April 2020...

- Page 2 To ensure the best results from this unit please take the time to read and follow all safety, installation and maintenance guidelines carefully before proceeding to install. Keep this manual in a safe place for future consultation. These appliances are CE-marked in compliance with the relevant Low Voltage &...

-

Page 3: Table Of Contents

Contents page Electrical Specification General Installation 6 /7 Refrigerated installation conditions 8 / 9 Refrigerated Display and Refrigerated Well Specification & Operation 10 /11 / 12 Hot Cupboard Specification & Operation Hot Top Specification & Operation Bain-marie Specification & Operation 15 / 16 Heated Display Specification &... -

Page 4: Electrical Specification

1: Electrical Specification This appliance must be earthed and damaged cables must be replaced by a suitably qualified person! 1 Phase Cable 3 Phase Cable Live (L1) Brown Brown Black Grey Neutral Blue Blue Earth Yellow & Green (Striped) Yellow & Green (Striped) A mains cable, type H07RN-F, conforming to code designation 60245 IEC 57, is supplied. -

Page 5: General Installation

2: General Installation Before installation please read the following points: • When placing the counter bodies in position ensure there is adequate access. • These mobile units can simply be butted up together to form a food service counter. • Roll into position and apply the brakes on the operator’s side. - Page 6 3: Refrigeration installation conditions Refrigerated Unit Venting When installing these refrigerated units, allowances must be made for air venting. It is crucial that there is an unrestricted air flow through the under slung compressor and condensing coil. Proper venting must be provided ensuring cool air from the room can be pumped in through the condensing coil and out the other side.

- Page 7 Should conditions exceed the above, the display units may not maintain food temperatures at the required levels. E & R Moffat cannot accept responsibility for the performance of the units being used in extreme conditions. Do not install units where there is high radiated heat,e.g. direct sunlight, room heaters, or bright spot lights.

- Page 8 4: Refrigeration well specification Electrical Power Rating Model Weight Dimensions Power Rating Supply (kg) L X W X H (mm) (kw) with a gantry VC2RW 830 x 680 x 900 13amp 1.22 13amp 1.23 VC3RW 1158 x 660 x 900 13amp VC4RW 1486 x 660 x 900...

- Page 9 Refrigerated Units 4: Refrigeration model operation Refrigerated display units are designed to keep pre-chilled food at a regulated serving temperature and are suitable for the display of most types of cold food. Designed to provide a gentle flow of cold air maintaining a safe and compliant temperature within.

- Page 10 5: Hotcupboard Dimensions Electrical Power Rating Model Weight Supply (kg) L X W X H (mm) (kw) 13amp VC2HC 830 x 680 x 900 VC3HC 1158 x 660 x 900 13amp VC4HC 1486 x 660 x 900 13amp 1814 x 660 x 900 13amp VC5HC Hot storage cupboards are designed for preheating Plates &...

- Page 11 5: Hotcupboard Sahara fan removal & installation Isolate appliance from power supply & allow to cool down before removal. The unit can be easily removed & replaced for cleaning or maintenance, due to a simple IEC type fastening system. • Access to the Plug &...

- Page 12 5: Hotcupboard Hot Cupboard Doors Fig 1 demonstrates the fitting of the cupboard doors; in this case, the rear door (Door A). Hold the door at a slight angle & locate the door fully into the top track. Swing the bottom of the door inwards connecting with the bottom track lower the door into the bottom track, &...

- Page 13 6: Hot Top with hotcupboard Hot plates Electrical Model Dimensions Rating Weight With Gantry (kw) (kw) Supply L X W X H (mm) (kw) (kg) (kw) 2 x 0.18 13amp 1.26 VC2HT 830 x 680 x 900 1.48 3 x 0.18 13amp VC3HT 1158 x 660 x 900...

- Page 14 7: Bain marie with hotcupboard Bainmarie With Gantry Electrical Rating Model Dimensions Weight (kw) (kw) (kw) Supply L X W X H (mm) (kw) (kg) 0.75 1.87 VC2BM 13amp 1.65 830 x 680 x 900 2.34 13amp 1.90 VC3BM 1158 x 660 x 900 2.56 13amp VC4BM...

- Page 15 8: Heated display with storage cupboard Model Weight Dimensions Electrical Power Rating (kg) Supply L X W X H (mm) (kw) VC2GH, VC2GHF, & VC2GHFC 830 x 680 x 1650 13amp VC3GH & VC3GHF, & VC3GHFC 1158 x 680 x 1650 13amp VC2GHSL, VC2GHSLF, &...

- Page 16 8: Heated display with storage cupboard How to Change the Temperature Setting To access the temperature in the controller, Press the L1 key. The display will show 1SP for 1 second • and then the current temperature it is set for Use the L1 and L2 keys to adjust the temperature •...

-

Page 17: Soup Station

9: Neutral display with storage cupboard Model Weight Dimensions Electrical Power Rating (kg) Supply L X W X H (mm) (kw) VC2GA, VC2GAF, & VC2GAFC 830 x 680 x 1650 13amp 0.23 VC3GA & VC3GAF, & VC3GAFC 13amp 1158 x 680 x 1650 0.27 VC2GASL, VC2GASLF, &... - Page 18 10: Soup station These soup kettles are designed to hold ‘pre-cooked’ soups and gravy at serving temperature These units are not designed to heat up cold food. Along with a removable drip tray which aids cleaning, they also come supplied with two 4,5litre stainless steel pots, complete with stainless steel lids.

-

Page 19: Carvery Station

11: Carvery station Bainmarie Electrical Model Dimensions Rating Weight Lights (kw) (kw) Supply (kw) L X W X H (mm) (kg) (kw) 13amp VC4CS, VC4CSSL 830 x 680 x 900 2 x 500 A combined Bain-marie, twin carvery pads, and plate dispenser unit, designed to display and hold carvery type food at serving temperature complete with an inset well fitted with GN1/3 and GN1/6 interchangeable Gastronome type pans, twin spiked carvery pads and a pop up plated dispenser... - Page 20 11: Carvery station In-counter spring-loaded pop-up plate dispensers with a variable spring system to accommodate different plate weights. Ideal for oval, round & square crockery including bowls up to 305mm (12”).Each tube can take a maximum of 65 plates (Depending on type of plate used). Setting the Spring Tension Plates sits on a removable Plate Base Support which in turn rests on a floating platform.

- Page 21 11: Carvery station The ‘Floating Platform’ is supported by an equal amount of tension springs on each corner. The number of springs equates to the size of plate being used. Use the chart below as a starting point; add or remove springs accordingly (in groups of four, one in each corner) until the top plate is at the required serving level).

- Page 22 12: Convection / Regeneration Oven Hot Plates Oven Lights Electrical Model Dimensions Rating Weight (kw) (kw) Supply L X W X H (mm) (kw) (kw) (kg) 2 x 0.18 1 x 0.22 13amp VC2CR, VC2CRSL 830 x 680 x 1350 Note: This unit has a power share feature, during the cook time all power is diverted to the oven the hot top and gantry lights are inhibited.

- Page 23 12: Convection / Regeneration Oven Setting the cook time The Timer is adjustable to a max of 9 hours and 99 minutes. The adjustment is made by pressing either [<<] for reducing time and [>>] for increasing. Exit from the program by pressing the [hand] button or do not use the keypad for 5 seconds.

- Page 24 12: Convection / Regeneration Oven Cook / Freeze Operation Pre-heated for approximately 20 minutes. This is achieved by pressing the switch to the pre-heat position. At the end of this time, the ready light will illuminate, and the internal buzzer will sound. Load the food, evenly spaced through the oven to give a good airflow throughout Set the temperature to 190’C.

-

Page 25: Polar Well

13: Polar Well With Gantry Electrical Model Dimensions Rating Weight Supply (kw) (kw) (kg) L X W X H (mm) 0.23 13amp VC2PW 830 x 680 x 900 0.27 13amp VC3PW 1158 x 660 x 900 0.32 13amp VC4PW 1486 x 660 x 900 0.37 VC5PW 1814 x 660 x 900... -

Page 26: Plate Dispenser

14: Plate Dispenser Electrical Rating Model Weight Dimensions Supply L X W X H (mm) (kw) (kg) 13amp VC2PDH 830 x 680 x 1046 1.20 VC2PDA 830 x 660 x 950 In-counter spring-loaded pop-up plate dispensers Single or twin plate dispensers, in both ambient &... - Page 27 14: Plate Dispenser Setting the plate diameter by using one plate only, set the guides to their correct positions for the size of plate. Plate Diameter Plate Guide position 8” (203mm) 9” (229mm) 10” (254mm) 11” (279mm) 12” (305mm...

- Page 28 14: Plate Dispenser Setting the Spring Tension Plates sits on a removable Plate Base Support which in turn rests on a floating platform. This ‘Floating Platform’ in turn, is supported by several tension springs. The tension springs are fastened symmetrically on two sides. In order to access the tension springs the Plate Base Support needs to be removed.

- Page 29 14: Plate Dispenser The ‘Floating Platform’ is supported by an equal amount of tension springs on each corner. The number of springs equates to the size of plate being used. Use the chart below as a starting point; add or remove springs accordingly (in groups of four, one each corner), until the top plate is at the required serving level) The Springs are held in place using a hook &...

-

Page 30: Crockery Dispenser

15: Universal Crockery Dispenser Electrical Model Dimensions Rating Weight Supply (kw) (kg) L X W X H (mm) 13amp VC2CDH 830 x 680 x 939 1.20 VC2CDA 830 x 660 x 930 In-counter spring-loaded pop-up plate dispensers. Single tube in both ambient & heated formats. - Page 31 16: Quartz Lamp Replacement Ensure appliance is disconnected from mains before servicing. Lamps should not be touched with bare hands, as this may cause premature failure. If lamp is touched, wipe clean with a cloth and alcohol prior to use. Replacement quartz lamps must never exceed the loading specified.

-

Page 32: Cleaning

11: Cleaning 17: Cleaning Before attempting to clean the unit, please ensure that the Unit is isolated from the electric supply and allowed to cool down, with all food plates and other Dishes removed from the unit. Do not use a water jet or pressure spray to clean this appliance. Disconnect trolley from mains and wait until appliance has cooled. - Page 33 Thank you for choosing E&R Moffat! Scan the QR code below to visit the E&R Moffat website for further information: E&R Moffat Ltd. www.ermoffat.co.uk Bonnybridge +44 (0) 1324 812272 FK4 2BS sales@ermoffat.co.uk Scotland...