Table of Contents

Advertisement

Quick Links

Instruction Manual

D102774X012

July 2020

Type ACE95jr Tank Blanketing Valve

Introduction

▲

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

fire and/or chemical contamination

causing property damage and personal

injury or death.

Fisher™ Tank blanketing valves must

be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations

and Emerson Process Management

Regulator Technologies, Inc.

(Emerson) instructions.

If the valve vents gas or a leak develops

in the system, service to the unit may be

required. Failure to correct trouble could

result in a hazardous condition.

Installation, operation and maintenance

procedures performed by unqualified

personnel may result in improper

adjustment and unsafe operation. Either

condition may result in equipment

damage or personal injury. Use qualified

personnel when installing, operating

and maintaining the Type ACE95jr Tank

Blanketing Valve.

Scope of the Manual

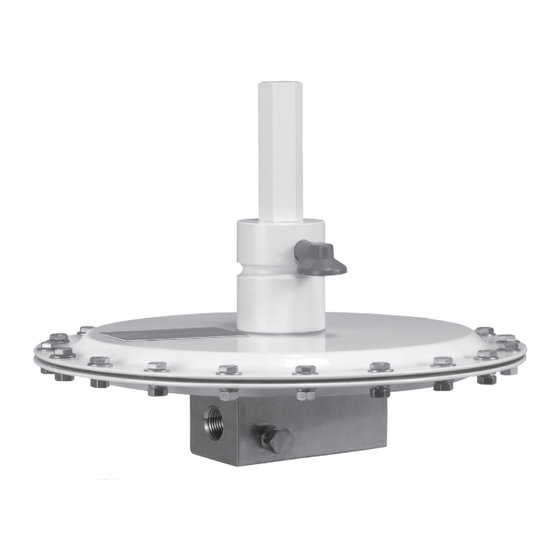

This Instruction Manual provides installation, startup

and maintenance procedures for the Type ACE95jr

tank blanketing valve. See Figure 1.

WARNING

W8157

Figure 1. Type ACE95jr Tank Blanketing Valve

Product Description

The Type ACE95jr tank blanketing valve is an

extension of the Type ACE95 tank blanketing valve

and is intended to handle lesser flows on gas

blanketing systems. The valve prevents a stored

product from vaporizing into the atmosphere, reduces

product combustibility and prevents oxidation or

contamination of the product by reducing its exposure

to air. The Type ACE95jr maintains a slightly positive

pressure and thereby reduces the possibility of tank

wall collapse during pump out operations.

Type ACE95jr

Advertisement

Table of Contents

Summary of Contents for Emerson ACE95jr

- Page 1 This Instruction Manual provides installation, startup to air. The Type ACE95jr maintains a slightly positive and maintenance procedures for the Type ACE95jr pressure and thereby reduces the possibility of tank tank blanketing valve.

-

Page 2: Specifications

Type ACE95jr Specifications This section lists the specifications and ratings for the Type ACE95jr tank blanketing valve. Factory specifications are stamped on a nameplate fastened to the actuator of the valve. Sizes and End Connection Styles Main Valve Flow Characteristic... -

Page 3: Principle Of Operation

TANK PRESSURE Figure 2. Type ACE95jr Operational Schematic Principle of Operation Installation The Type ACE95jr tank blanketing valve controls the ▲ WARNING vapor space pressure over a stored liquid. When liquid is pumped out of the tank or vapors in the tank condense, Personal injury, equipment damage or the pressure in the tank decreases. - Page 4 TANK BLANKETING GAS/VAPOR SPACE E0620 LIQUID Figure 3. Type ACE95jr Tank Blanketing Valve Installation the National Fire Codes of the National certain the body interior is clean and the pipelines Fire Protection Agency or by other are free of foreign material. Apply pipe compound...

-

Page 5: Piping Considerations

Gauges and Shutoff Valves Note Inlet gas shutoff valves are desirable for servicing. If this Type ACE95jr tank blanketing valve was not Piping lengths are best when they are ordered with an inlet pressure gauge, it is advisable to kept short with a minimum number of install a gauge between the inlet shutoff valve and the elbows and fittings. -

Page 6: Monthly Maintenance

Annual Maintenance of local, state and federal regulations. Due to the care Emerson takes in meeting all manufacturing 1. Visually inspect the unit to ensure tight connections, requirements, use only replacement parts manufactured tight seals and safe operation. -

Page 7: Disassembly And Assembly

Type ACE95jr ROLLING DIAPHRAGM (KEY 38) POPPET (STEM) (KEY 42) W8162 CROSS-DRILLED HOLE PISTON O-RING (KEY 37) (KEY 39) CAGE (KEY 52) W8161 Figure 5. Cage Assembly Disassembly and Assembly When performing disassembly or re-assembly operations, refer to Figure 6 for key numbers (unless otherwise directed). - Page 8 5. Remove the range spring (key 8) and spring seat (key 5). A lower range spring (key 162) is used for When assembling the Type ACE95jr tank blanketing negative pressure values only. valve, clean all parts, inspect for unusual wear, lightly 6.

-

Page 9: Parts Ordering

7. Place the diaphragm sub-assembly into the lower actuator case (key 30) with the diaphragm Each Type ACE95jr Tank Blanketing valve is retaining nut (key 13) on top. Take care not to assigned a serial number which can be found on install upside down. -

Page 10: Parts List

Type ACE95jr Parts List Description Part Number Description Part Number Body (C 0.2) 1/2 NPT GC052930X02 Stainless Steel GC053301X02 Steel GC053301X32 NPS 1/2 / DN 15, CL150 RF GC052930X02 1 NPT GC052930X02 Adjusting Screw 0.5 to 5 in. w.c. / 1 to 12 mbar... - Page 11 MAIN VALVE DETAIL GC950201 APPLY LUBRICANT OR SEALANT T = THREAD LOCKER L1 = GENERAL PURPOSE POLYTETRAFLUOROETHYLENE (PTFE) OR LITHIUM GREASE 1. Lubricants must be selected such that they meet the temperature requirements. Figure 6. Type ACE95jr Tank Blanketing Valve Assembly...

- Page 12 Technologies, Inc. All rights reserved. 07/20. Emerson Automation Solutions The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher™ is a mark owned by Fisher Controls International LLC, a...