Table of Contents

Advertisement

Operator's Manual

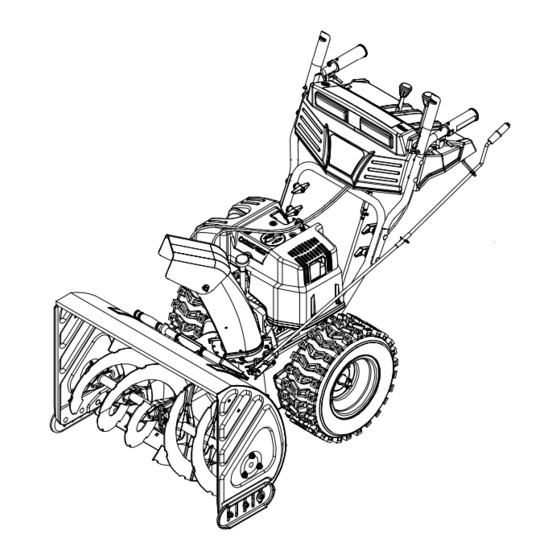

Snow Thrower

Model 10030

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

. 769-00376.fm

FORM NO

(6/2002)

Advertisement

Table of Contents

Summary of Contents for Troy-Bilt 10030

-

Page 1: Snow Thrower

Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019. TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 PRINTED IN U.S.A. -

Page 2: Table Of Contents

. A sample model plate is explained below. For future reference, please copy the model number and the serial number of the equipment in the space below. TROY-BILT LLC P. O. BOX 3 6 1 1 3 1 www.troybilt.com... -

Page 3: Important Safe Operation Practices

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. - Page 4 Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas. Do not operate machine while under the influence of alcohol or drugs. Muffler and engine become hot and can cause a burn. Do not touch.

-

Page 5: Assembling Your Snow Thrower

SECTION 2: ASSEMBLING YOUR SNOW THROWER Unpacking • Remove staples from the top, sides, and ends of the shipping crate. • Set panels aside to avoid tire punctures or personal injury. • Remove and discard plastic bag that covers unit. •... -

Page 6: Final Adjustments

Cable Discharge Chute Figure 3 • Unwrap the headlight wire which is attached to the headlight, beneath the handle panel. Wind the headlight wire around the lower right handle until excess slack is removed. See Figure 4. • Plug the wire from the headlight into the alternator lead coming from the right side of the engine underneath the fuel tank. -

Page 7: Know Your Snow Thrower

Auger Control Z-End Jam Nut Auger Control Cable Figure 5 SECTION 3: KNOWING YOUR SNOW THROWER WARNING: Be familiar with all the controls on the snow thrower and their proper operation. Know how to stop the machine and disengage them quickly. •... - Page 8 Traction Control / Auger Control Lock The traction control is located on the right handle. Squeeze the traction control to engage the wheel drive. Release to stop. This same lever also locks the auger control so you can operate the chute crank without interrupting the snow throwing process.

-

Page 9: Operating Your Snow Thrower

SECTION 4: OPERATING YOUR SNOW THROWER Before Starting Read and understand all instructions and warnings on the machine and in this manual before operating. Gas & Oil Fill-Up • Service the engine with gasoline and oil as instructed in the engine manual shipped with the snow thrower. -

Page 10: Operating Tips

Recoil Starter: With engine running, pull starter rope with a rapid, continuous full arm stroke three or four times. Pulling the starter rope will produce a loud clattering sound, which is normal. • Move throttle control to “stop” or “off” position. •... -

Page 11: Making Adjustments

SECTION 5: MAKING ADJUSTMENTS WARNING: NEVER attempt to clean chute or make any adjustments while engine is running. Shift Rod Hairpin Clip Flat Washer Shift Figure 8 • Remove the hairpin clip and flat washer from the shift handle under the handle panel. See Figure 8. •... -

Page 12: Skid Shoe

Skid Shoe The space between the shave plate and the ground can be adjusted by raising or lowering the skid shoes. For close snow removal, as when using on a smooth concrete or asphalt driveway, place the skid shoes in the low position. -

Page 13: Maintaining Your Snow Thrower

SECTION 6: MAINTAINING YOUR SNOW THROWER WARNING: Before lubricating, repairing, or inspecting, disengage all clutch levers and stop engine. Wait until all moving parts have come to a complete stop. Disconnect the spark plug wire and ground it against the engine to prevent unintended starting. - Page 14 Lube under chute base Figure 15 Traction Control / Auger Control Lock The cams on the ends of the control rods which interlock the traction drive and auger drive clutches must be lubricated at least once a season or every 25 hours of operation using a multi-purpose automotive grease.

-

Page 15: Servicing Your Snow Thrower

SECTION 7: SERVICING YOUR SNOW THROWER WARNING: Before servicing, repairing, or inspecting, disengage all clutch levers and stop engine. Wait until all moving parts have come to a complete stop. Disconnect spark plug wire and ground it against the engine to prevent unintended starting. -

Page 16: Changing Friction Wheel Rubber

Auger Pulley Idler Pulley Figure 19 • Lift the rear auger belt from the auger pulley, and slip the belt between the support bracket and the auger pulley. Repeat for the front auger belt. See Figure 20. • Replace both auger drive belts by following instructions in reverse order. -

Page 17: Off-Season Storage

Shift Rod Assembly Gear Shaft Drive Shaft Figure 23 • Lift the friction wheel assembly out between the axle shaft and the drive shaft assemblies. • Remove the four screws from the friction wheel assembly. Remove the friction wheel rubber from between the friction wheel plates. -

Page 18: Troubleshooting

SECTION 9: TROUBLESHOOTING Problem Engine fails to start. Fuel tank empty, or stale fuel. Blocked fuel line. Choke not in ON position Faulty spark plug. Safety key not in ignition switch on engine. Spark plug wire disconnected. Primer button not being used properly. Engine runs erratic. - Page 19 DO NOT UNCLOG DISCHARGE CHUTE WHILE ENGINE IS RUNNING. SHUT OFF ENGINE AND REMAIN BEHIND HANDLES UNTIL ALL MOVING PARTS HAVE STOPPED BEFORE UNCLOGGING. D00056 777D06573 10030 D06573 751T64141769 751T641393 AVERTISSEMENT POUR VOTRE PROTECTION VEUILLEZ LIRE ATTENTIVEMENT LES DIRECTIVES SUR LA SECURITE ET L'ENTRETIEN...

-

Page 20: Parts List

SECTION 10: PARTS LIST FOR MODEL 10030... - Page 21 Model 10030 Ref. Part No. Part Description 05931A Bearing Housing 684-0065 Impeller Assembly 705-5226 Chute Reinforcement 710-0451 Carriage Bolt 710-0459A Hex Bolt 3/8-24 x 1.5” 710-0604A TT Screw 5/16-18 x 0.625” 710-0703 Carriage Screw 1/4-20 x 0.75” 710-0890A Shear Bolt...

- Page 22 Model 10030...

- Page 23 Model 10030 Ref. Part No. Part Description 618-0043 Dogg Assembly RH 618-0044 Dogg Assembly LH 618-0575 Drive Shaft 656-0012A Friction Wheel Disc Assembly 684-0014B Shift Rod Assembly 684-0042C Friction Wheel Assembly (includes items 58 to 62) 684-0131A Support Bracket 710-0599 TT screw 1/4-20 x 0.5”...

- Page 24 Model 10030 Harness Assembly Connector B, C, L1, L2 Switch and Light 1 and 2 D, E F indicates fuse; G indicates grounding wire. Plugs to: Alternator lead from engine Heated Grips of handles...

- Page 25 Model 10030 Ref. Part No. Part Description 684-0008A Shift Arm Assembly 684-0053B Chute Crank assembly 705-5266 Chut Crank Bracket 710-0449 Carriage Screw 5/16-18 x 2.25” 710-0458 Carriage Bolt 5/16-18 x 1.75” 710-0643 Hex Screw 5/16-18 x 1.0” 710-0788 TT Screw 1/4-20 x 1.0”...

- Page 26 Model 10030 Supplied on engine...

- Page 27 Model 10030 Ref. Part No. 05896A Idler Bracket: Drive Clutch 710-1245B Hex Bolt 5/16-24 x .875” 710-0230 Hex Screw 1/4-28 x .50” 710-0627 Hex Screw 5/16-24 x .750” 710-0654A TT Screw 3/8-16 x 1.0” 710-0696 Hex Screw 3/8-24 x .875”...

- Page 28 Model 10030 Ref. Part No. Description 710-04071 Carriage Bolt 5/16-18 x 1.0” 710-0262 Carriage Bolt 5/16-18 x 1.5” 710-0805 Hex Bolt 5/16-18 x 1.5” 710-0896 Hex AB Screw 1/4-14 x .625” 710-3015 Hex Screw 1/4-20 x .75” 712-0429 Hex Lock Nut...

- Page 29 MANUFACTURER’S LIMITED WARRANTY FOR: The limited warranty set forth below is given by Troy-Bilt LLC with respect to new merchandise purchased and used in the United States, its possessions and territories. Troy-Bilt LLC warrants this product against defects for a...