SATO S84-ex Operator's Manual

Hide thumbs

Also See for S84-ex:

- Programming reference manual (452 pages) ,

- Operator's manual (380 pages) ,

- Configuration manual (2 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for SATO S84-ex

- Page 1 Operator Manual For printer model:...

- Page 2 Specifications and contents in this document are subject to change without notice. Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card.

-

Page 3: Table Of Contents

2.2 Installation Space....................26 2.2.1 Front View (S84-ex/S86-ex) ..................26 2.2.2 Rear View (S84-ex/S86-ex) ..................27 2.2.3 Media Dispensed View (S84-ex) ................27 2.2.4 Top View (S84-ex) ....................28 2.2.5 Media Dispensed View (S86-ex) ................29 2.2.6 Top View (S86-ex) ....................30 2.3 Installing the Product onto a Support Structure/Applicator ...... - Page 4 4.2.17 Test Print Mode ....................190 4.2.18 Default Setting Mode ................... 193 4.2.19 Download Mode....................196 4.2.20 Upload Mode ....................... 201 4.2.21 Hidden Setting Mode ................... 203 4.2.22 Wireless LAN Certificate Download Mode............204 4.2.23 Site Survey Mode ....................206 S84-ex/S86-ex Operator Manual...

- Page 5 6.1.4 More about the Media Stop Position ..............264 6.1.5 Limitation on Base Reference Point Adjustment ........... 265 6.2 Adjusting the Print Quality................266 6.2.1 Adjusting the Print Darkness ................. 266 6.2.2 Adjusting the Print Speed ..................267 S84-ex/S86-ex Operator Manual...

- Page 6 8.4 Troubleshooting Table ................... 312 8.4.1 No Power/Nothing on the Screen ................312 8.4.2 Cannot Feed the Media ..................312 8.4.3 Can Feed the Media but Cannot Print ..............313 8.4.4 Bad Print Quality....................314 8.4.5 Incorrect Print Position ..................314 S84-ex/S86-ex Operator Manual...

- Page 7 9.6 Notification Function ..................345 9.7 Media Motion of the Product Operation ............347 9.7.1 Feed Motion......................347 9.7.2 Paper End......................347 9.7.3 Sensor Error ......................351 9.7.4 Ribbon Error ......................352 9.8 Print Speed and Media Size ................353 S84-ex/S86-ex Operator Manual...

- Page 8 9.12.1 USB Interface ...................... 379 9.12.2 LAN Ethernet Interface ..................380 9.12.3 RS-232C Interface....................382 9.12.4 IEEE1284 Interface ..................... 384 9.12.5 External Signal Interface (EXT) ................386 9.12.6 Bluetooth Interface ....................399 9.12.7 Wireless LAN Interface..................400 S84-ex/S86-ex Operator Manual...

-

Page 9: Before You Start

• New designed sensor cover with nonstick surface that can be easily removed and cleaned without any tools. • Easily upload/download data to/from an SD card or USB memory, or by using the SATO All-In-One Tool application. • Supports remote product setting through the SATO All-In-One Tool application or a Web browser. - Page 10 Do not set on an unstable area your SATO reseller or technical support. • Do not set the product on an unstable Using the product in one of these...

- Page 11 Doing so could result in a fire or electric immediately power it off, and contact shock. your SATO reseller or technical support. • Do not splash water on the power cord or Using the product in this condition could get it wet. Doing so could result in result in a fire or electric shock.

- Page 12 If a child accidentally drinks the fluid, product. Doing so could result in a fire or immediately consult with a physician. electric shock. Ask your SATO reseller or technical support to conduct internal inspections, adjustments, and repairs. S84-ex/S86-ex Operator Manual...

- Page 13 Operator Manual does not contain this procedure, avoid trying to replace it on Do not place the product in areas with high your own terms, and contact your SATO humidity reseller or technical support. • Do not place this product in an area with •...

- Page 14 (the combination of media and ribbon), and the product settings (the print speed, the print darkness, etc.). Please sufficiently test the product in your usage environment, and use it with the optimal combination. If anything is unclear, or if you have any questions, contact your SATO reseller or technical support center. S84-ex/S86-ex Operator Manual...

- Page 15 • Remove the certificate label (serial number seal) affixed to this product. Use of this product near microwave and/or other wireless LAN equipment, or where static electricity or radio interference is present, may shorten the communication distance, or even disable communication. S84-ex/S86-ex Operator Manual...

- Page 16 Diese Einrichtung kann im Wohnbereich Funkstörungen verursachen. In diesem Fall kann vom Betreiber verlangt werden, angemessene Maßnahmen durchzuführen. Das Gerät ist nicht für die Benutzung im unmittelbaren Gesichtsfeld am Bildschirmarbeitsplatz vorgesehen. Um störende Reflexionen am Bildschirmarbeitsplatz zu vermeiden, darf dieses Produkt nicht im unmittelbaren Gesichtsfeld platziert werden. S84-ex/S86-ex Operator Manual...

- Page 17 Before You Start (Pb) (Hg) (Cd) (Cr6+) (PBB) (PBDE) ABS PC SJ/T 11364 GB/T 26572 GB/T 26572 2006 2 28 SJ/T11364 S84-ex/S86-ex Operator Manual...

- Page 18 Access the following site and select your country from the list. Check the information on the shown page. www.satoworldwide.com/service-and-support.aspx Warranty Period for Consumables For information on the warranty period for print heads and platen rollers, refer to the SATO Global Warranty Program. www.satoworldwide.com/global-warranty-program.aspx...

-

Page 19: Basic Information

Basic Information 1.1 Checking the Bundled Accessories After unpacking the product, make sure that you have all the bundled accessories. If there are missing items, contact the SATO reseller where you purchased the product. User documents (Quick guide, Safety instructions, Global Warranty Program leaflet, etc.) -

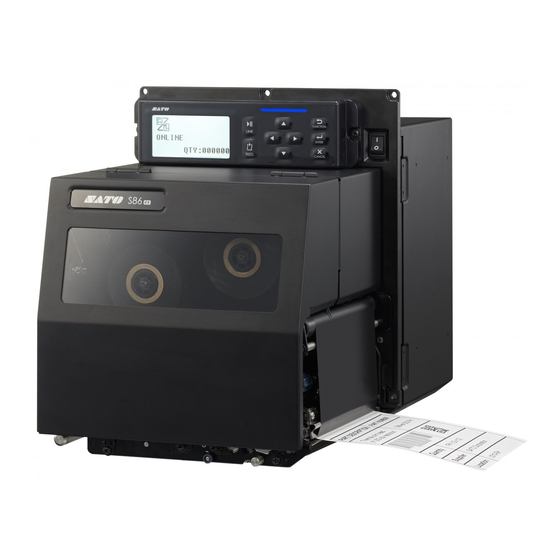

Page 20: Product Orientation

Europe/Asia: Left Hand Europe/Asia: Right Hand Note The pictures in this manual show the S84-ex (Americas: Standard/Right Hand, Europe/Asia: Left Hand), unless otherwise stated. When using the right hand (Americas: Opposite/Left Hand, Europe/Asia: Right Hand) model, the picture on the right shows a symmetrical opposite view of your product. -

Page 21: Parts Identification Of The Product

1.3 Parts Identification of the Product 1.3.1 Front View Operator panel Top cover Power (I/O) switch Press this switch to power on (I) or power off (O) the product. Media discharge outlet S84-ex/S86-ex Operator Manual... -

Page 22: Rear View

Be sure to perform a virus check on the SD card AC input terminal before connecting it to the product. SATO Supplies power to the product through the Corporation shall not be held responsible for any inserted power cord. -

Page 23: Internal View

Pressure roller release tab CAUTION Used to release the pressure plate. Be sure to perform a virus check on the USB memory before connecting it to the product. SATO Ribbon rewind spindle Corporation shall not be held responsible for any ... -

Page 24: Parts On The Operator Panel

Returns to the setting mode menu from the product is in normal mode. setting screens. ENTER button Enter the setting mode menu when the product is in offline mode. Confirm the selected item or setting value when the product is in setting mode. S84-ex/S86-ex Operator Manual... -

Page 25: Led Indicator

Error detected (For example, when a machine error is detected) Error detected (For example, when the ribbon runs out) Flashes at intervals of two seconds. Blue and Error detected (For example, when a communication error has occurred) Alternately flashes blue and red. S84-ex/S86-ex Operator Manual... - Page 26 1 Basic Information This page is intentionally left blank. S84-ex/S86-ex Operator Manual...

-

Page 27: Installing The Product

• A location with high temperature and humidity. • A dusty location. • A location exposed to direct sunlight. • A location with a lot of electrical noise. • A location with a large fluctuation in power. S84-ex/S86-ex Operator Manual... -

Page 28: Installation Space

The illustrations in this section show the product from different angles, providing dimensions and spatial requirements. 2.2.1 Front View (S84-ex/S86-ex) 245 mm (9.6”) 117.5 mm 117.5 mm (4.6”) (4.6”) -

Page 29: Mm (1.7")

5 positions 11 mm (0.4”) 223 mm (8.8”) 11 mm (0.4”) Americas: Standard/Right Hand Europe/Asia: Left Hand 2.2.3 Media Dispensed View (S84-ex) 43 mm (1.7”) Americas: Standard/Right Hand Europe/Asia: Left Hand 150 mm (5.9”) 131 mm (5.15”) 189 mm (7.4”) -

Page 30: Top View (S84-Ex)

2 Installing the Product 2.2.4 Top View (S84-ex) 150 mm (5.9”) 174 mm (6.85”) 223 mm (8.8”) 174 mm (6.85”) 150 mm (5.9”) 10 mm (0.4”) Americas: Standard/Right Hand 230 mm (9.1”) Europe/Asia: Left Hand S84-ex/S86-ex Operator Manual... - Page 31 2 Installing the Product 2.2.5 Media Dispensed View (S86-ex) 43 mm (1.7”) Americas: Standard/Right Hand Europe/Asia: Left Hand 150 mm (5.9”) 131 mm (5.15”) 243 mm (9.6”) S84-ex/S86-ex Operator Manual...

-

Page 32: Americas: Standard/Right Hand

2 Installing the Product 2.2.6 Top View (S86-ex) 150 mm (5.9”) 174 mm (6.85”) 223 mm (8.8”) 174 mm (6.85”) 150 mm (5.9”) 10 mm (0.4”) Americas: Standard/Right Hand Europe/Asia: Left Hand 230 mm (9.1”) S84-ex/S86-ex Operator Manual... -

Page 33: Installing The Product Onto A Support Structure/Applicator

If you do not install the product correctly, it could fall out of the support structure. This may cause injury. The picture below shows the installation of the product onto the support structure. Note This picture is for an instructional display purpose only and is not to be interpreted as a precise example. S84-ex/S86-ex Operator Manual... -

Page 34: Connecting The Interface Cable

Connect the product to a host computer with one or more of the available interface connections. Use a cable that is compatible with the standard of the interface board as stated in Section 9.12 Interface Specifications. Check the orientation of the connector before you make the connection. S84-ex/S86-ex Operator Manual... -

Page 35: Interface Settings

* You cannot select the interface that has already been set for the DATA PORT. Note The main port and sub port cannot simultaneously use the same interface. Data port - SBPL command (Print data) - Product status Sub port - Product status S84-ex/S86-ex Operator Manual... -

Page 36: Interface Combination

LAN adapter, the configured interface setting is changed from WLAN to USB. When USB is configured as the data port or sub port, but the wireless LAN adapter is connected, the configured interface setting is changed from USB to WLAN. S84-ex/S86-ex Operator Manual... -

Page 37: Connecting The Power Cord

AC 100-240 V, 50-60 Hz. If your local voltage is not in the stated range, contact your SATO reseller or technical support center. *The shape of the power plug varies depending on the region in which it was purchased. -

Page 38: Power On/Off The Product

Make sure that the product is in offline mode before you power off. If ONLINE shows on the screen, press the LINE button to change to offline mode. Press the power switch on the operator panel to “O” position. S84-ex/S86-ex Operator Manual... -

Page 39: Installing Optional Memory Storage

Contact your SATO reseller or service center for the recommended SD card or USB memory. CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card. -

Page 40: Removing The Optional Sd Card

Open the top cover. Insert the optional USB memory into the USB connector (Type A) on the front of the product. Contact your SATO reseller for the recommended USB memory. Close the top cover. To remove the USB memory from the... -

Page 41: Loading The Ribbon And Media

If there is a mark on the media, the ink is coated on the outer side of the ribbon. The ink is coated on the inner side. (Face-in ribbon) The ink is coated on the outer side. (Face-out ribbon) S84-ex/S86-ex Operator Manual... -

Page 42: Loading The Ribbon

Note You can also refer to the routing path sticker located on the inner side of the top cover. Open the top cover . CAUTION Open the top cover fully to prevent accidental drop of the cover. S84-ex/S86-ex Operator Manual... - Page 43 Make sure that the ink side of the ribbon is facing down when passing it below the print head. Load an empty ribbon core onto the ribbon rewind spindle . Insert the core all the way in. S84-ex/S86-ex Operator Manual...

- Page 44 If the media is already loaded, turn the head lock lever counterclockwise to lock the print head. If the media is not loaded, continue with Section 3.5 Loading Media. Close the top cover. S84-ex/S86-ex Operator Manual...

-

Page 45: Removing The Ribbon

. Pull to remove the empty core from the ribbon supply spindle . You can use this empty core again when you load a new ribbon roll. Load this empty core onto the ribbon rewind spindle. S84-ex/S86-ex Operator Manual... -

Page 46: Usable Media

The position of the gap sensor is adjustable. You can adjust the gap sensor position in the following range. S84-ex: 5 mm to 66 mm (0.2” to 2.6”) measured from the product’s center frame. S86-ex: 5 mm to 81 mm (0.2” to 3.2”) measured from the product’s center frame. -

Page 47: Loading Media

When loading the media, make sure that the print side is facing Platen roller Label Feed roller and media sensor assembly. Pressure Media shaft roller Label Liner Media shaft Open the top cover. CAUTION Open the top cover fully to prevent accidental drop of the cover. S84-ex/S86-ex Operator Manual... - Page 48 Push the media until the innermost edge of the media lightly touches the product’s center frame. Pull the label out from the discharge outlet. Remove about 30 cm (11.8”) of labels from the liner . S84-ex/S86-ex Operator Manual...

- Page 49 Refer to Section 4.2.17 Test Print Mode for details on how to perform a test print. CAUTION When closing the top cover, be careful not to pinch your fingers. S84-ex/S86-ex Operator Manual...

-

Page 50: Loading Media Without Using Dispenser

Refer to Section 4.2.17 Test Print Mode for details on how to perform a test print. CAUTION When closing the top cover, be careful not to pinch your fingers. S84-ex/S86-ex Operator Manual... -

Page 51: Display And Operation

Shows when the product is in test print mode and hex dump print mode. Shows when the product is in download mode. Shows when the product is in upload mode. Shows when the product is in memory mode. S84-ex/S86-ex Operator Manual... -

Page 52: Operation And Configuration

Always shows when the product is not connected. Shows when the product is not connected to an access point. Not used • Bluetooth connection status Icon Description Shows when Bluetooth is connected. Shows when Bluetooth is disconnected. S84-ex/S86-ex Operator Manual... - Page 53 Shows when a label “near end” is detected. Shows when a command error is detected. Shows when a receive buffer “near full” is detected. Shows when print head damage is detected. Shows when an incompatible print head is detected. S84-ex/S86-ex Operator Manual...

- Page 54 • These icons do not show when the product is in an error mode. • These icons do not show when the trace mode is enabled. • These icons do not show when the ESC+IM command (for specifying LCD display) is in use. S84-ex/S86-ex Operator Manual...

-

Page 55: Setting Mode Menu And Icons

* Shows only if you have installed the optional RFID kit and enabled the RFID mode. The product enters the product information mode. The product enters the loaded emulation mode. * Shows only if you have loaded with the selected emulation firmware module. S84-ex/S86-ex Operator Manual... -

Page 56: Error Display And Icons

Receive buffer over is detected. Item No. error or BCC error is detected. Memory card is not accessible or there is no free space in the memory card. Writing to the ROM failed or kanji data error is detected. S84-ex/S86-ex Operator Manual... -

Page 57: Setting Display

Save the setting and go to the next screen. Returns to the previous screen Setting item Setting contents Valid arrow Select an item using the without saving display display buttons display the setting. buttons. S84-ex/S86-ex Operator Manual... - Page 58 Returns to the previous screen without saving Setting item Setting contents Valid arrow Move the cursor Change the value of the setting. display display buttons the highlighted cursor using the display buttons. using the buttons. S84-ex/S86-ex Operator Manual...

-

Page 59: Operating Modes

Hex Dump Mode • RFID User Mode • Information Mode • Test Print Mode • Default Setting Mode • Download Mode • Upload Mode • Hidden Setting Mode • Wireless LAN Certificate Download Mode • Site Survey Mode S84-ex/S86-ex Operator Manual... - Page 60 * Shows only if you have button RFID User installed the optional RFID RFID user Mode kit and enabled RFID mode. mode button button Information Information Mode mode More operations are shown on the next page. S84-ex/S86-ex Operator Manual...

- Page 61 Power on Download Mode mode Upload Power on Upload Mode mode Power on Hidden Hidden setting Setting Mode mode Wireless LAN Power on WLAN certificate Certificate download mode Download Mode Site Survey Power on Site survey Mode mode S84-ex/S86-ex Operator Manual...

-

Page 62: Online Mode/Pause Mode/Offline Mode

Enters the setting mode menu. Cancel the print job. Shows the remaining Enters online Feed a Adjust the Press simultaneously print job. mode or pause piece of display for one second to enter mode. media. brightness. adjustment mode. S84-ex/S86-ex Operator Manual... -

Page 63: Adjusting The Display Brightness

The buzzer volume icon is shown on the top right corner of the screen. Pressing the button will cycle through the volume level and the buzzer will beep according to the volume. S84-ex/S86-ex Operator Manual... -

Page 64: Canceling The Print Job

• ALL: Cancel all the print jobs in product’s memory. Press the ENTER button to confirm. CANCEL PRINT JOB COMPLETED shows and three beeps will sound. The product will then enter offline mode. The selected print jobs will be cleared from memory. S84-ex/S86-ex Operator Manual... -

Page 65: Adjustment Mode

'-' to move the stop position in the feed direction. The setting value is adjustable by 0.25 mm (0.01”) regardless of the print resolution. The setting range is from -3.75 mm (-0.15”) to +3.75 mm (+0.15”). S84-ex/S86-ex Operator Manual... - Page 66 CANCEL button before pressing the ENTER button will not save the adjustment. Perform a test print after completing the adjustments to make sure that the settings are correct. Refer to Section 4.2.17 Test Print Mode for details. S84-ex/S86-ex Operator Manual...

-

Page 67: Work Shift Setting Mode

Select the work shift number to store the work shift setting. You can select the work shift number from 1 to 3. Note If you select EXIT and press the ENTER button, the product returns to the online screen. S84-ex/S86-ex Operator Manual... - Page 68 The number of characters you can enter depends on the character size set in the HOW MANY CHR? screen. Press the buttons to shift the cursor and press the buttons to set the character. Press the ENTER button to save the work shift name. S84-ex/S86-ex Operator Manual...

-

Page 69: Simple Standalone Mode

Select NO + button button Shows only if there is variable data. button button button Select YES button button Shows only if there is sequential data. button button button button button button S84-ex/S86-ex Operator Manual... - Page 70 4 Operation and Configuration CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card.

- Page 71 Three beeps will sound if the product fails to copy the received data. The product returns to the STANDALONE MODE screen. SAVE COMPLETED. This screen shows when the received data is saved to a specified file. Press the ENTER button to return to the STANDALONE MODE screen. S84-ex/S86-ex Operator Manual...

- Page 72 DIGIT is the digit number of the selected cursor. The screen may be decimal or hexadecimal according to the read data. The maximum number of DIGIT is 99. Note Shows only if there is sequential data. S84-ex/S86-ex Operator Manual...

- Page 73 4 Operation and Configuration OUTPUT LABEL This screen allows you to specify the print number. Move the cursor using the buttons, change the value using buttons and then press the ENTER button. S84-ex/S86-ex Operator Manual...

-

Page 74: Setting Mode Menu

The product changes to the setting mode menu. Select the setting mode using the buttons. The selected setting mode shows on the screen and the icon is highlighted by inverting its colors. Press the ENTER button to enter the selected mode. S84-ex/S86-ex Operator Manual... - Page 75 The functions of the buttons in the setting mode menu are shown as below. Enters offline mode. Enters the selected setting mode. Enters offline mode. Selected Selected icon Navigate to Valid arrow buttons setting highlighted select the for selection. mode. with inverted setting mode. colors. S84-ex/S86-ex Operator Manual...

-

Page 76: User Mode

Shows only if the PASSWORD input is enabled button button button/ button button button button button button button button button button button button button button button button button button Shows only if GB18030 is selected button button Proceed to S84-ex/S86-ex Operator Manual... - Page 77 The setting values of the adjustment mode are shown. • PITCH: Shows the print position offset value. • OFFSET: Shows the stop position offset value. • DARKNESS: Shows the darkness setting value. You can change these values in Adjustment Mode Test Print Mode. S84-ex/S86-ex Operator Manual...

- Page 78 4 Operation and Configuration PRINT SPEED The setting range varies depending on the model. • S84-ex (203 dpi): 4 to 16 ips (inches/sec) • S86-ex (203 dpi): 4 to 14 ips (inches/sec) • S84-ex (305 dpi): 4 to 14 ips (inches/sec) •...

- Page 79 • CHANGE HEAD: Notify when to perform replacement of the print head. • CHANGE BELT (G): Notify when to perform replacement of the gear box timing belt. • CHANGE BELT (R): Notify when to perform replacement of the ribbon timing belt. S84-ex/S86-ex Operator Manual...

- Page 80 CHANGE TIMING BELT (GEAR BOX) Set the notification distance for changing the gear box timing belt. The setting range is from 000 to 300 km. Note The notification function will be disabled if the distance is set to 0. S84-ex/S86-ex Operator Manual...

- Page 81 The notification function will be disabled if the distance is set to 0. SETTING FINISH? Confirm to complete the setting. • YES: Returns to the user mode screen. • NO: Returns to the NOTICE FUNCTION screen to select an item. S84-ex/S86-ex Operator Manual...

-

Page 82: Interface Mode

Select “USB”/ “LAN”/ “RS-232C”/ “IEEE1284” /“Bluetooth”/“WLAN”+ button Setting contents vary depending on the interface. To the USB setting To the IEEE1284 setting To the LAN/WLAN setting To the Bluetooth setting To the RS-232C setting Proceed to S84-ex/S86-ex Operator Manual... - Page 83 Select DISABLE + button Shows only for LAN button interface if SNTP Select IPv6 FUNCTION is enabled. button Select IPv4 button button button button button button (IPv4) button (IPv6) button button button Proceed to S84-ex/S86-ex Operator Manual...

- Page 84 SNMP FUNCTION is enabled. button SNMP TRAP SET+ button SNMP SETTING+ button button button button button To the SNMP v1/v2c button To the SNMP v3 Proceed to NO + button YES + button button button button button S84-ex/S86-ex Operator Manual...

- Page 85 INTERFACE MODE menu. button button button button button button NONE + button button MD5/SHA-1 + button button button button NONE + button DES/AES + button button button button button S84-ex/S86-ex Operator Manual...

- Page 86 TYPE SELECT is set to SNMPv1/SNMPv2c. to SNMPv3. button button button button NONE+ (SNMPv1/v2c) button button (SNMPv3) MD5/SHA-1 + button button button button NONE+ button DES/AES + button button button IPv6+ button IPv4+ button button button button button S84-ex/S86-ex Operator Manual...

- Page 87 • NO: Enter the IGNORE CR/LF screen. PORT SELECT Select the port used for the connected interface. • DATA PORT: For receiving various SBPL commands and executing print operations. • SUB PORT: For monitoring the product status and connecting to external devices. S84-ex/S86-ex Operator Manual...

- Page 88 • The setting will be effective after you power on the product again. IGNORE CR/LF Ignore or acknowledge the CR/LF code of the received data. • YES: Ignore the CR/LF code. • NO: Do not ignore the CR/LF code. Note Shows only if the DATA PORT is selected. S84-ex/S86-ex Operator Manual...

- Page 89 Shows only if LAN interface is selected and the SNTP function is enabled. NTP IPv4 ADDRESS Set the IPv4 address for NTP server. The setting range is from 0.0.0.0 to 255.255.255.255. Note Shows only if LAN interface is selected and the SNTP function is enabled. S84-ex/S86-ex Operator Manual...

- Page 90 Set the SNMP function. • ENABLE: Enables the SNMP function and goes to “SNMP setting select” screen. • DISABLE: Disables the SNMP function and goes to “Interface select screen. Note Shows only if LAN or wireless LAN interface is selected. S84-ex/S86-ex Operator Manual...

- Page 91 Select the trap number of SNMP from 1 to 3. • TRAP [1] • TRAP [2] • TRAP [3] TRAP TYPE SELECT Select SNMP trap type. • SNMPv1 • SNMPv2c • SNMPv3 Note The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 92 Note • Up to 32 alphanumeric characters and symbols (from 20H to 7EH) can be set. • Specify “ ” to input a space. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 93 • The setting will be effective after you power on the product again. PRIVACY PROTOCOL Select SNMP privacy protocol. The options are as follows: • NONE • DES • AES Note The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 94 Writing possible OID are sysContact, sysName, and sysLocation. TRAP Set the SNMP trap. • ENABLE: Allows the SNMP trap. • DISABLE: Does not allow the SNMP trap. Note The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 95 • The setting will be effective after you power on the product again. AUTH PROTOCOL Select SNMP trap authentication protocol. The options are as follows: • NONE • MD5 • SHA-1 Note The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 96 • Up to 32 alphanumeric characters and symbols (from 20H to 7EH) can be set. • Specify “ ” to input a space. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 97 • ENABLE: Enable the FTP function. • DISABLE: Disable the FTP function. Note • Shows only if the LAN or wireless LAN interface is selected. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 98 • ENABLE: Enable the TELNET function. • DISABLE: Disable the TELNET function. Note • Shows only if the LAN or wireless LAN interface is selected. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 99 • STATUS5: When selected, the product will proceed to the ITEM NO. CHECK screen. ITEM NO. CHECK Set the item number check function. • ENABLE: Enable the item number check function. • DISABLE: Disable the item number check function. Note Shows only if PROTOCOL is set to STATUS5. S84-ex/S86-ex Operator Manual...

- Page 100 4 Operation and Configuration BCC CHECK Set the BCC check function. • ENABLE: Enable the BCC check function. • DISABLE: Disable the BCC check function. Note Shows only if PROTOCOL is set to STATUS5. S84-ex/S86-ex Operator Manual...

- Page 101 (DHCP DISABLE) (DHCP ENABLE) button Shows only if LAN interface is selected. Select “DHCP” or “AUTO” + button button (“DHCP” or “AUTO” selected) Select “MANUAL” button button button button button button button button button Proceed to S84-ex/S86-ex Operator Manual...

- Page 102 Shows only if wireless LAN interface is selected. button button button button button button button button Shows only if STATUS5 is selected. button button button button Shows only if STATUS4 is selected. button button button Proceed to S84-ex/S86-ex Operator Manual...

- Page 103 Set the IPv4 gateway address. The setting range is from 0.0.0.0 to 255.255.255.255. The default value is 000.000.000.000 for LAN and 192.168.001.002 for WLAN. Note The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 104 Shows only if LAN interface is selected and “MANUAL” is selected at “IPv6 RESOLUTION” screen. DEFAULT ROUTER Set the default router of IPv6. Note Shows only if LAN interface is selected and “MANUAL” is selected at “IPv6 RESOLUTION” screen. S84-ex/S86-ex Operator Manual...

- Page 105 You can enter a maximum of thirty-two characters including alphabet (upper case and lower case), numbers and symbols. Note • Shows only if wireless LAN interface is selected. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 106 Shows only if PROTOCOL is set to STATUS5. BCC CHECK Set the BCC check function. • ENABLE: Enable the BCC check function. • DISABLE: Disable the BCC check function. Note Shows only if PROTOCOL is set to STATUS5. S84-ex/S86-ex Operator Manual...

- Page 107 • ENQ: Returns a status after receiving a Status Request (ENQ), which has been sent from the host. • CYCLE: Returns a status from the product to the host at an interval of 500 ms. Note Shows only if PROTOCOL is set to STATUS4. S84-ex/S86-ex Operator Manual...

- Page 108 00H 00H 00H 1CH 00H 00H 1CH Status5 ENABLE DISABLE (Default) ENQ (05H) prefix: 4 bytes prefix: 0 byte response 00H 00H 00H 16H Note This setting does not have to be changed when using the S84-ex/S86-ex printer driver. S84-ex/S86-ex Operator Manual...

- Page 109 Select READY/BUSY or XON/XOFF button Select STATUS2, STATUS3 or STATUS4 button Select STATUS5 button button button Shows only if Shows only if READY/BUSY STATUS5 is or XON/XOFF is selected selected button button button button Proceed to S84-ex/S86-ex Operator Manual...

- Page 110 Set the RS-232C stop bit. The following options are available: • 1BIT • 2BIT Note • Shows only if the RS-232C interface is selected. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 111 The setting will be effective after you power on the product again. ITEM NO. CHECK Set the item number check function. • ENABLE: Enable the item number check function. • DISABLE: Disable the item number check function. Note Shows only if PROTOCOL is set to STATUS5. S84-ex/S86-ex Operator Manual...

- Page 112 Shows only if PROTOCOL is set to STATUS5. RECEIVE BUFFER Set the receive buffer type. • MULTI: Multiple receive buffers. • 1ITEM: A single receive buffer. Note Shows only if PROTOCOL is set to READY/BUSY or XON/XOFF. S84-ex/S86-ex Operator Manual...

- Page 113 INTERFACE MODE menu. button button Shows only if STATUS5 is selected button button button button Shows only if STATUS4 is selected button button Shows only if RECEIVE BUFFER is set to 1ITEM. button Proceed to S84-ex/S86-ex Operator Manual...

- Page 114 • DISABLE: Disable the BCC check function. Note Shows only if PROTOCOL is set to STATUS5. RECEIVE BUFFER Set the receive buffer type. • MULTI: Multiple receive buffers. • 1ITEM: A single receive buffer. Note Shows only if PROTOCOL is set to STATUS4. S84-ex/S86-ex Operator Manual...

- Page 115 Set the width of the IEEE1284 ACK signal. The setting range is from 00.5 µs to 12.0 µs, and is adjustable in 0.1 µs steps. Note Shows only if the IEEE1284 interface is selected and RECEIVE BUFFER is set to 1ITEM. S84-ex/S86-ex Operator Manual...

- Page 116 INTERFACE MODE menu. button button button button button button button button Shows only if ENABLE is selected button button button button button button button button button button button Proceed to S84-ex/S86-ex Operator Manual...

- Page 117 • ENABLE: Enable the Bluetooth detection response. • DISABLE: Disable the Bluetooth detection response. Note • Shows only if the Bluetooth interface is selected. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 118 • Shows only if the Bluetooth interface is selected. • You cannot set the PSW value if it is greater than the PSI value. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 119 The following options are available: • STATUS3 • STATUS4 CRC CHECK Set the CRC check function. • ENABLE: Enable the CRC check function. • DISABLE: Disable the CRC check function. Note Shows only if the Bluetooth interface is selected. S84-ex/S86-ex Operator Manual...

-

Page 120: Memory Mode

CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card. - Page 121 Select “FORMAT” CONTENT” + button button Select “MEMORY SIZE” button button button button button button button button button button Select “NO” button Select “YES” button or Select “NO” + button button Select “YES” button button button button S84-ex/S86-ex Operator Manual...

- Page 122 Select whether or not to set the memory storage allocation for use with the Memory card command <CC>. • YES: Proceed to change the storage allocation for the memory slot. • NO: No change to the memory slot. Note Refer to the Programming Reference for details on the command. S84-ex/S86-ex Operator Manual...

- Page 123 Select the memory you want to perform the settings. The following options are available: • SD CARD • USB MEMORY • ROM Note Shows only if MEMORY MODE is set to MEMORY SIZE, STORED CONTENTS or FORMAT. S84-ex/S86-ex Operator Manual...

- Page 124 • FORMAT • GRAPHIC • BMP FILE • TTF FILE MEMORY INFORMATION Shows the number of files and total size of the selected type of information registered in the memory. The maximum number of files is 999. S84-ex/S86-ex Operator Manual...

- Page 125 ENTER button, the screen returns to PLEASE SELECT MEMORY. MEMORY FORMAT Select whether or not to format the memory. • YES: Format the memory. • NO: Do not format the memory. Note If you select NO, the screen returns to MEMORY CARD MODE. S84-ex/S86-ex Operator Manual...

- Page 126 The following options are available: • SD CARD • USB MEMORY Note • Shows only if MEMORY MODE is set to SETTING SAVE. • The setting information of the wireless LAN is saved only if the wireless LAN is connected. S84-ex/S86-ex Operator Manual...

- Page 127 After three beeps, the screen returns to MEMORY CARD MODE. SELECT MEMORY ORIGIN Select the memory to copy the setting information. The following options are available: • SD CARD • USB MEMORY Note Shows only if MEMORY MODE is set to SETTING UPLOAD. S84-ex/S86-ex Operator Manual...

- Page 128 PRINTER SETTING COMPLETED Shows when the setting information has been uploaded to the product. Note • Three beeps will sound when the upload is completed. • The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

-

Page 129: Service Mode

PASSWORD input is enabled button SERVICE MODE Select one from the three service setting modes. • SENSOR LEVEL: Adjust the sensor level. • SETTING: Set the various function settings of the product. • COUNTER CLEAR: Clear various counter value. S84-ex/S86-ex Operator Manual... - Page 130 When I-MARK is selected When GAP is selected button button button Calibration succeed. Calibration failed. button button button Select RETRY button button button Select EXIT CALIBRATION button button button button S84-ex/S86-ex Operator Manual...

- Page 131 This screen shows the instruction to place the media for I-mark sensor adjustment. Shows only if GAP is selected in the SENSOR SELECT screen. After placing the media, press the ENTER button to start the automatic sensor adjustment. S84-ex/S86-ex Operator Manual...

- Page 132 Shows the current level (Reception) of the I-mark sensor on the upper part of the screen. This offset determines how soon the sensor will respond to an incoming I-mark. The adjustment range is from 0 to 127 and is shown on the bottom line of the screen. S84-ex/S86-ex Operator Manual...

- Page 133 0.1 V) Note • The slice level is set automatically by the firmware when the value is set to 0.0 V. • In the case of automatic calculation, the calculated value will be shown automatically after printing. S84-ex/S86-ex Operator Manual...

- Page 134 REPRINT, or CONTINUOUS PRINT is set to ENABLE. button button button button button button Shows only if EXT 9PIN SELECT is set to MODE3. button button Shows only if you have installed the optional RFID kit and enabled the RFID mode. button Proceed to S84-ex/S86-ex Operator Manual...

- Page 135 Shows for the thermal transfer model only. button button button button Select ON button button button Select OFF button button button button Shows for the S86-ex series models only. 203 dpi: NORMAL/M8460Se/M8485Se 305 dpi: NORMAL/M8465Se button Proceed to S84-ex/S86-ex Operator Manual...

- Page 136 Shows only if SAVE PRINT LOG is set to ENABLE. button button button button button button Shows only for the thermal transfer model. button button button Proceed to S84-ex/S86-ex Operator Manual...

- Page 137 305 dpi Shows for the S86-ex series models only. button button button button Select YES + button and when there are changes in printer settings. button button Select NO + button button Waiting to be powered off. S84-ex/S86-ex Operator Manual...

- Page 138 Enable or disable the reprint function using the FEED button. If this function is enabled, you can reprint the last print job by pressing the FEED button in online mode. • YES: Enable the reprint function. • NO: Disable the reprint function. S84-ex/S86-ex Operator Manual...

- Page 139 ONLINE pin: Outputs the signal whether if the product is in online or offline mode. PRN READY pin: Outputs the signal whether if the product has remaining print data or not. Note Refer to the Timing Chart of the EXT Output Signal (Online) for details. S84-ex/S86-ex Operator Manual...

- Page 140 Shows only if you have installed the optional RFID kit and enabled the RFID mode. BACKFEED SPEED Specify the backfeed speed. • FAST: Set to a speed of six inches per second. • NORMAL: Set to a speed of four inches per second. S84-ex/S86-ex Operator Manual...

- Page 141 Enable or disable the detection of the ribbon near end. • ENABLE: Detect and notify when the ribbon is about to run out. • DISABLE: Do not detect the ribbon near end. Note Shows for the thermal transfer model only. S84-ex/S86-ex Operator Manual...

- Page 142 • ON: Keep the compatibility with the product operation of existing models. • OFF: Disable the compatibility with the product operation of existing models. Note For details on the legacy command support, refer to Section 9.3 About Legacy Command Support. S84-ex/S86-ex Operator Manual...

- Page 143 Section 9.3.2 Compatible Mode - Print Head Width (only for S86-ex) for details on the affected items. COMPATIBLE MODE DARKNESS Enable or disable the system command Print Darkness <#E>. • ENABLE: Enable you to execute the Print Darkness <#E>. • DISABLE: Ignore the Print Darkness <#E>. S84-ex/S86-ex Operator Manual...

- Page 144 • Shows only if COMPATIBLE MODE DARKNESS is set to ENABLE. • This table explains that the system accepts the legacy Print Darkness setting command and does not guarantee that the printed darkness of the succeeding model will be the same as the older model. S84-ex/S86-ex Operator Manual...

- Page 145 The setting range varies depending on the following models: Model Name Setting Range Default (mm) Value (mm) S84-ex (203 dpi) 0 - 2500 2500 S84-ex (305 dpi) 0 - 1500 1500 S84-ex (609 dpi) 0 - 400...

- Page 146 CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card.

- Page 147 The product may not operate with the FAST setting, depending on the operating environment. FEED OFFSET Set the feed distance in LINERLESS mode. The setting range is from 000 to 250 mm. Note Shows only if PRINTER TYPE in ADVANCED MODE is set to LINERLESS. S84-ex/S86-ex Operator Manual...

- Page 148 Enable or disable the Plug and play function of the product. • ENABLE: Enable the Plug and play function. • DISABLE: Disable the Plug and play function. Note This function will affect the IEEE1284 interface connectivity because it uses the DEVICE ID response of the IEEE1284. S84-ex/S86-ex Operator Manual...

- Page 149 • If “0000ms” is selected, the product sends an ENQ response with no delay. • If status 4 is set as the cyclic response mode, the product sends an ENQ response with no delay for cycle response or ENQ command. S84-ex/S86-ex Operator Manual...

- Page 150 The printable maximum size of the TrueType font varies depending on the following settings: GB18030 BIG5 KSX1001 Available TrueType font size (MB) 10.6 10.7 10.8 11.7 Note When the product tries to print a TrueType font that is bigger than the maximum size, a command error occurs. S84-ex/S86-ex Operator Manual...

- Page 151 The product can be initialized to this setting at a later time. Refer to Section 4.2.18 Default Setting Mode. DEFAULT SETTING COMPLETED Shows when the product settings have been saved completely. Note The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

- Page 152 • BELT (RIBBON): Clear the counter of ribbon timing belt. CONFIRM COUNTER CLEAR HEAD Select whether to clear the head counter or not. • YES: Clear the head counter. • NO: Does not clear the head counter. S84-ex/S86-ex Operator Manual...

- Page 153 CONFIRM COUNTER CLEAR BELT (R) Select whether to clear the counter of ribbon timing belt or not. • YES: Clear the counter of ribbon timing belt. • NO: Does not clear the counter of ribbon timing belt. S84-ex/S86-ex Operator Manual...

-

Page 154: Advanced Mode

PASSWORD input is enabled button button DISPENSER + button button (CONTINUOUS or LINERLESS) button button button (CONTINUOUS) button (DISPENSER) button button (DISPENSER) button (LINERLESS) ENABLE + DISABLE + button (CONTINUOUS) button (LINERLESS) (CONTINUOUS) (DISPENSER) button button Proceed to S84-ex/S86-ex Operator Manual... - Page 155 “CHECK PAGE”. button button YES + button NO + Shows only if CONTINUOUS is DISABLE + selected. button button button button button button button button Shows only if EXTERNAL REPRINT is enabled. button Proceed to Proceed to S84-ex/S86-ex Operator Manual...

- Page 156 “MODE3” is selected in “EXT 9PIN SELECT” in Service mode. button button Power on the product again . YES + NO + NO + button button YES + Power on the product again. button Proceed to S84-ex/S86-ex Operator Manual...

- Page 157 12 dots/mm and legacy command support is selected. button button Shows only if the button YES + calendar IC is installed button button NO + button button NO + YES + button button button button button button button button Proceed to S84-ex/S86-ex Operator Manual...

- Page 158 Select 0 button button button (0) button button (other than 0) button button button button Shows only if button PAPER END is GAP. button button button button button button Returns to the ADVANCED button MODE screen. S84-ex/S86-ex Operator Manual...

- Page 159 • DIRECT: Print using direct thermal paper. PITCH SENSOR Enable or disable the pitch sensor. • ENABLE: Enable the pitch sensor. • DISABLE: Disable the pitch sensor. Note Shows only if PRINTER TYPE is set to CONTINUOUS. S84-ex/S86-ex Operator Manual...

- Page 160 CAUTION Head check is a reference for checking for a filament disconnection of the print head. This function does not guarantee barcode readability. Note Shows only if the head check function is enabled. S84-ex/S86-ex Operator Manual...

- Page 161 • NO: Proceed to the ZERO SLASH screen. EXTERNAL SIGNAL Enable or disable the external signal (EXT) function. • ENABLE: Enable the external signal (EXT) function. • DISABLE: Disable the external signal (EXT) function. Note Shows only if PRINTER TYPE is set to CONTINUOUS. S84-ex/S86-ex Operator Manual...

- Page 162 The product will not reprint if a command error occurs. CONTINUOUS PRINT Set the reprint function by the print start signal (PRIN) from an external signal. • ENABLE: Enable the continuous print when no print quantity is remaining. • DISABLE: Disable the continuous print. S84-ex/S86-ex Operator Manual...

- Page 163 Shows only if EXTERNAL REPRINT is enabled. I/O SIGNAL SETTING Select whether or not to set the pin number for the input/output signal. • YES: Proceed to the INPUT SIGNAL screen. • NO: Proceed to the I/O SIGNALS INITIALIZE screen. S84-ex/S86-ex Operator Manual...

- Page 164 MODE3 is selected. Note • DISPENSE IN and HOME POS. are available only if CONTROLED is selected in BACKFEED MOTION. • For details, refer to Section 9.5 Input/Output Signal of the External Signal. S84-ex/S86-ex Operator Manual...

- Page 165 Refer to the default value of the pin number in INPUT SIGNAL/OUTPUT SIGNAL. INITIALIZED SETTING This screen shows that the pin number for the input/output signal has been initialized. Power on the product again to make the setting effective. S84-ex/S86-ex Operator Manual...

- Page 166 ‘-’ to move to the right side of the product (when facing the front of the product). The setting range varies depending on the following models: Model Name V (dot) H (dot) S84-ex (203 dpi) ±0-9999 ±0-832 S84-ex (305 dpi) ±0-9999 ±0-1248 S84-ex (609 dpi) ±0-9999...

- Page 167 Toggle the head dot density from 12 dots/mm to 6 dots/mm and vice versa. The following options are available: • 100: Approximately four inches. Effective for S84-ex only. • 150: Approximately six inches. Effective for S84-ex and S86-ex. • 300: Approximately twelve inches. Effective for S84-ex and S86-ex. Note...

- Page 168 MAY, F-JUNE, G-JULY, H-AUGUST, J-SEPTEMBER, K-OCTOBER, L-NOVEMBER, M-DECEMBER. Select the month using the buttons, select the month code using buttons, then press the ENTER button to confirm the month code. Note Shows only if YES is selected in the SET CALENDAR screen. S84-ex/S86-ex Operator Manual...

- Page 169 • STANDARD: Use a standard code. • NON-STANDARD: Use a non-standard code. Note To set the non-standard code, send the user download command <LD> in normal mode. For more details on the <LD> command, refer to the Programming Reference. S84-ex/S86-ex Operator Manual...

- Page 170 MODE SELECT Set the communication command mode for analysis. • XML: Use for supporting Oracle and SAP mode. • SBPL: Use SBPL (SATO Barcode Printer Language) for the printer commands. Note The setting will be effective after you power on the product again.

- Page 171 Specify the width of the label for rotation. The setting range varies depending on the following models: Model Name Setting Range Default Value Step (dot) (dot) S84-ex (203 dpi) 0000-0832 0832 S84-ex (305 dpi) 0000-1248 1248 S84-ex (609 dpi) 0000-2496...

- Page 172 LABEL SIZE ADJ HEIGHT Specify the height of the label for rotation. The setting range varies depending on the following models: Model Name Setting Range Default Value (dot) (dot) S84-ex (203 dpi) 00000-20000 20000 S84-ex (305 dpi) 00000-18000 18000 S84-ex (609 dpi)

- Page 173 • OFF: The LED indicator is always off. ERROR INDICATION Set the LCD backlight for indicating an error. • NONE: No change to the LCD backlight. • ON: The LCD backlight lights orange. • BLINKS: The LCD backlight flashes orange. S84-ex/S86-ex Operator Manual...

-

Page 174: Hex Dump Mode

CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card. - Page 175 For internal buffer Hex dump icon is shown if INTERNAL printing and internal buffer data DATA is selected. printing, the screen automatically icon is shown if RECEIVE changes to normal mode after BUFFER is selected. issuing the media. S84-ex/S86-ex Operator Manual...

- Page 176 • SAVE: Save and print the received data. HEX DUMP Set the print width of the hex dump. • NORMAL: Print the received data with sixteen bytes in one line. • HALF: Print the received data with eight bytes in one line. S84-ex/S86-ex Operator Manual...

- Page 177 ONLINE This screen shows an online status icon if RECEIVE DATA is selected. HEX DUMP PRINT HEX DUMP SAVE OFFLINE This screen shows an offline status icon if RECEIVE DATA or INTERNAL DATA is selected. S84-ex/S86-ex Operator Manual...

- Page 178 This screen shows while the product is transmitting the “SEND BACK DATA”. SEND BACK DATA COMPLETED This screen shows that the product has completed the transmission of “SEND BACK DATA”. Note The product returns to the HEX DUMP MODE screen after three beeps. S84-ex/S86-ex Operator Manual...

-

Page 179: Rfid User Mode

USER MODE menu. button button Shows only if the PASSWORD input is enabled button button button button button button button button button button button button button Select LEVEL button Select PULSE button button button button button Proceed to S84-ex/S86-ex Operator Manual... - Page 180 USER MODE menu. button When reading is When reading collected error occurs Select YES button Select CONTINUE button Select RETRY button or Select NO button button button button button button button button button button button button button button S84-ex/S86-ex Operator Manual...

- Page 181 • YES: Proceed to clear the RFID write numbers (SUCCESS, FAILURE and TOTAL). • NO: Do not clear the RFID counter. Note The total accumulated number of RFID write in the RFID LIFE COUNT is not cleared. S84-ex/S86-ex Operator Manual...

- Page 182 Select whether or not to print a slash on a tag when an RFID tag error occurred. • YES: Prints a slash at the time of RFID tag error. • NO: Do not print a slash at the time of RFID tag error. Only RFID TAG ERROR is printed. S84-ex/S86-ex Operator Manual...

- Page 183 Press the buttons to select the reading area from EPC, TID, USER and PC. • YES: The product reads and shows the data. • NO: Do not read the data and proceed to the next screen. S84-ex/S86-ex Operator Manual...

- Page 184 The setting range is from 0 to 240 mm. To release this function, set the value to 0 mm. WRITE POWER Set the write power of the antenna, referring to the “S84-ex UHF Inlay Placement & Configuration Table” in the S84-ex UHF RFID Configuration Guide.

- Page 185 4 Operation and Configuration READ POWER Set the read power of the antenna, referring to the “S84-ex UHF Inlay Placement & Configuration Table” in the S84-ex UHF RFID Configuration Guide. The measurement unit is in dBm, and it is adjustable with 0.1 dBm.

-

Page 186: Information Mode

Shows only if the PASSWORD input is enabled button button button button button Select Select Select Select LIFE Select HEAD DISPENSE BELT BELT button button button (GEAR BOX) (RIBBON) Select button button button Select NONE button button Proceed to S84-ex/S86-ex Operator Manual... - Page 187 Manual setting: DISABLE Auto settings (not confirmed): ----- button Auto settings (confirmed): IEEE1284/RS-232C/LAN/ USB/WLAN/Bluetooth Version Shows the model name and firmware version of this product. SERIAL NO. Shows the serial number of the control board in this product. S84-ex/S86-ex Operator Manual...

- Page 188 The default selection is NONE. LIFE COUNTER Shows the life count value saved in the product. HEAD COUNTER Shows the head count value saved in the product. DISPENSE COUNTER Shows the dispense count value saved in the product. S84-ex/S86-ex Operator Manual...

- Page 189 LAN IPv6 ADDRESS Shows the IPv6 address of the LAN. Note If the IP address is not acquired from DHCP, it will be shown as “----:----:----:----:----:----:----:----”. LAN IPv6 ROUTER Shows the IPv6 router information for the LAN. S84-ex/S86-ex Operator Manual...

- Page 190 • When the product fails to acquire the IP address or DHCP is disabled, the static IP address will be shown. WLAN MAC ADDRESS Shows the MAC address of the wireless LAN. Note This screen shows only if a wireless LAN unit is installed. BD ADDRESS Shows the BD address. S84-ex/S86-ex Operator Manual...

- Page 191 Shows the interface auto detection status. Note • “-----” shows when the interface is not detected. • DISABLE shows that the INTERFACE AUTO SELECT function is disabled (manual setting). • IEEE1284, RS-232C, LAN, USB, WLAN or Bluetooth shows the detected interface. S84-ex/S86-ex Operator Manual...

-

Page 192: Test Print Mode

Make sure that the EXTERNAL SIGNAL is set to DISABLE before perform test print. • When RFID mode is enabled, RFID related information is printed on the second page of the CONFIGURATION test print. S84-ex/S86-ex Operator Manual... - Page 193 Select the width of the test print from LARGE or SMALL. The available width varies depending on the following models: Model Name LARGE (cm) SMALL (cm) S84-ex S86-ex Note Shows only if TEST PRINT MODE is set to FACTORY or WLAN. S84-ex/S86-ex Operator Manual...

- Page 194 ENTER button to start the test print. TEST PRINT PRESS ENTER KEY The test print is in progress. Press the ENTER button while printing to pause the test print operation. Press the ENTER button again to continue. S84-ex/S86-ex Operator Manual...

-

Page 195: Default Setting Mode

Select the item to be initialized. • PRINTER SETTING: Initialize the settings of the product. • ALT. PROTOCOL: Initialize the protocol code. • WLAN SETTING: Initialize the WLAN setting. Note WLAN SETTING shows only if a wireless LAN unit is installed. S84-ex/S86-ex Operator Manual... - Page 196 DEFAULT WLAN SETTING Select whether or not to initialize the WLAN setting. • YES: Initialize the WLAN setting. • NO: Cancel and return to the DEFAULT MODE screen. Note Shows only if DEFAULT MODE is set to WLAN SETTING. S84-ex/S86-ex Operator Manual...

- Page 197 4 Operation and Configuration DEFAULT SETTING COMPLETED Shows when the initialization has been completed. Note The setting will be effective after you power on the product again. S84-ex/S86-ex Operator Manual...

-

Page 198: Download Mode

CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card. - Page 199 When downloading the font for the first time, it goes to the RECEIVING… screen. When overwriting or deleting existing font data, it goes to the DELETING… screen. Note Shows only if INTERFACE SELECT is set to INTERFACE. S84-ex/S86-ex Operator Manual...

- Page 200 The bar on the lower portion of the screen indicates the data verification progress. After verifying the firmware data, it goes to the PROGRAM DOWNLOAD COMPLETED screen. Note Shows only if INTERFACE SELECT is set to INTERFACE. S84-ex/S86-ex Operator Manual...

- Page 201 • 2 BYTE FONTS: Download “2 byte fonts” and “Outline font”. • CONFIG: Download product configurations. • FONT/LOGO: Download font/logo data. • ALL: Download all data. Note Shows only if INTERFACE SELECT is set to SD CARD or USB MEMORY. S84-ex/S86-ex Operator Manual...

- Page 202 XX/XX shows the file number being verified and total number of files. After verifying the data, it goes to the PROGRAM DOWNLOAD COMPLETED screen. Note Shows only if INTERFACE SELECT is set to SD CARD or USB MEMORY. S84-ex/S86-ex Operator Manual...

-

Page 203: Upload Mode

CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card. - Page 204 WRITING. . . XX/XX (UPLOAD) The product is writing the uploaded data. The bar on the lower portion of the screen indicates the data writing progress. XX/XX shows the file number being written and total number of files. S84-ex/S86-ex Operator Manual...

-

Page 205: Hidden Setting Mode

Enable or disable the work shift setting mode. • YES: Enable the work shift setting mode. • NO: Disable the work shift setting mode. Note For details on the work shift setting mode, refer to Section 4.2.6 Work Shift Setting Mode. S84-ex/S86-ex Operator Manual... -

Page 206: Wireless Lan Certificate Download Mode

The table describes each setting screen in detail. CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card. - Page 207 The setting will be effective after you power on the product again. CERT DOWNLOAD FAILED This screen shows when the certification data download has failed. Power on the product and try again. Note Make sure that there are certification files in the SD card or USB memory. S84-ex/S86-ex Operator Manual...

-

Page 208: Site Survey Mode

* In Site survey mode, the product prints only one label. After the print completion or error release, the Print completion product returns to the list screen. Site survey mode stops when powered off. S84-ex/S86-ex Operator Manual... - Page 209 Infrastructure. Ad Hoc mode NO SEARCHING This is a warning screen when the site survey mode is started if the WIRELESS MODE of the WLAN interface setting is set to Ad Hoc. Power on the product again. S84-ex/S86-ex Operator Manual...

- Page 210 • LARGE: Print the information with a width of 10 cm. • SMALL: Print the information with a width of 4 cm. AP PRINT PRESS ENTER KEY The product is ready to perform printing. Press the ENTER button to start the test print of the site survey. S84-ex/S86-ex Operator Manual...

- Page 211 AP PRINT PRINTING The test print of the site survey is in progress. Note In site survey mode, the product prints only one label. After the print completion or error release, the product returns to the list screen. S84-ex/S86-ex Operator Manual...

-

Page 212: Web Configuration

However, login is required to view Printer Configuration pages such as Adjustment mode and etc. 4.3.1 Information Information is the default page of Web configuration. The Information page is shown as follows. Refer to Section 4.2.16 Information Mode. S84-ex/S86-ex Operator Manual... -

Page 213: External Signal Status

4 Operation and Configuration 4.3.2 External Signal Status The External signal Status page is shown as follows. Refer to Section 9.5 Input/Output Signal of the External Signal. S84-ex/S86-ex Operator Manual... -

Page 214: Sensor Level

4 Operation and Configuration 4.3.3 Sensor Level The Sensor level page is shown as follows. Refer to Sensor Level Adjustments on page 128. S84-ex/S86-ex Operator Manual... -

Page 215: Adjustment Mode

Login is required to view this page. Enter the correct user name and password to log in. The default user name and password are as follows: User Name:admin Password:admin After logging in, the Adjustment mode page is shown as follows. Refer to Section 4.2.5 Adjustment Mode. S84-ex/S86-ex Operator Manual... -

Page 216: User Mode

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the User mode page is shown as follows. Refer to Section 4.2.9 User Mode. S84-ex/S86-ex Operator Manual... -

Page 217: Interface Mode

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the Interface mode page is shown as follows. Refer to Section 4.2.10 Interface Mode. S84-ex/S86-ex Operator Manual... -

Page 218: Interface Mode (Snmp)

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the Interface mode (SNMP) page is shown as follows (continued to the next page). Refer to SNMP FUNCTION on page S84-ex/S86-ex Operator Manual... - Page 219 4 Operation and Configuration S84-ex/S86-ex Operator Manual...

-

Page 220: Wlan Setting

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the WLAN Setting page is shown as follows (continued to the next page). Refer to Section 9.1.14 Wireless LAN Setting. S84-ex/S86-ex Operator Manual... - Page 221 4 Operation and Configuration S84-ex/S86-ex Operator Manual...

-

Page 222: Wlan Certificate

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the WLAN Certificate page is shown as follows. Refer to Section 4.2.22 Wireless LAN Certificate Download Mode. S84-ex/S86-ex Operator Manual... -

Page 223: Memory Mode

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the Memory mode page is shown as follows. Refer to Section 4.2.11 Memory Mode. S84-ex/S86-ex Operator Manual... -

Page 224: Service Mode

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the Service mode page is shown as follows (continued to the next page). Refer to Section 4.2.12 Service Mode. S84-ex/S86-ex Operator Manual... - Page 225 4 Operation and Configuration S84-ex/S86-ex Operator Manual...

-

Page 226: Advanced Mode

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the Advanced mode page is shown as follows (continued to the next two pages). Refer to Section 4.2.13 Advanced Mode. S84-ex/S86-ex Operator Manual... - Page 227 4 Operation and Configuration S84-ex/S86-ex Operator Manual...

- Page 228 4 Operation and Configuration S84-ex/S86-ex Operator Manual...

-

Page 229: Rfid Mode

Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the RFID mode page is shown as follows. Refer to Section 2.1.4 RFID Mode of the S84-ex/S86-ex service manual. S84-ex/S86-ex Operator Manual... -

Page 230: Emulation Mode

Section 4.3.4 Adjustment Mode. After logging in, the Emulation mode page is shown as follows (continued to the next page). Refer to Section 5.2 SZPL Emulation Mode, Section 5.3 SDPL Emulation Mode Section 5.4 SIPL Emulation Mode. S84-ex/S86-ex Operator Manual... - Page 231 4 Operation and Configuration S84-ex/S86-ex Operator Manual...

-

Page 232: Printer Configuration (Read)

Click reload button to refresh the data in the text box. To export the current product configurations, select all the text in the text box and save it as text file. S84-ex/S86-ex Operator Manual... -

Page 233: Printer Configuration (Write)

Click Choose file button and select a product configuration file. Then click Submit button to import the selected product configuration to the product. Note While writing is in progress, do not switch to other pages. The page shows “Setting Successfully Completed” when the setting is completed. S84-ex/S86-ex Operator Manual... -

Page 234: Firmware Download

4.3.17 Firmware Download Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the Firmware Download page is shown as follows. S84-ex/S86-ex Operator Manual... -

Page 235: System/Others

4 Operation and Configuration 4.3.18 System/Others Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the System/Others page is shown as follows. S84-ex/S86-ex Operator Manual... -

Page 236: Test Print

4 Operation and Configuration 4.3.19 Test Print Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the page is shown as follows. S84-ex/S86-ex Operator Manual... -

Page 237: Restart Product

4 Operation and Configuration 4.3.20 Restart Product Login is required to view this page. Enter the correct user name and password to log in as shown in Section 4.3.4 Adjustment Mode. After logging in, the page is shown as follows. S84-ex/S86-ex Operator Manual... - Page 238 4 Operation and Configuration This page is intentionally left blank. S84-ex/S86-ex Operator Manual...

-

Page 239: Emulation Mode

• LOAD: Load the standard firmware or emulation firmware. • DELETE: Delete the selected emulation module. • DOWNLOAD: Download the emulation firmware to the product. Note If there is no emulation module downloaded to the memory of product you cannot select the DELETE function. S84-ex/S86-ex Operator Manual... -

Page 240: Loading The Emulation Module

• STD FIRMWARE: Load the standard firmware. • SZPL (XX.XXX): Load the downloaded SZPL emulation firmware. • SDPL (XX.XXX): Load the downloaded SDPL emulation firmware. • SIPL (XX.XXX): Load the downloaded SIPL emulation firmware. Note The XX.XXX is the module version information. S84-ex/S86-ex Operator Manual... - Page 241 MODULE SETTING SAVE COMPLETED This screen shows the completion of saving the module setting and three beeps will sound. REBOOT PRINTER NOW... This screen shows the product starts rebooting and start up the product with the selected firmware loaded. S84-ex/S86-ex Operator Manual...

-

Page 242: Deleting The Emulation Module

• ALL: Delete all the downloaded emulation firmware. • SZPL (XX.XXX): Delete the downloaded SZPL emulation firmware. • SDPL (XX.XXX): Delete the downloaded SDPL emulation firmware. • SIPL (XX.XXX): Delete the downloaded SIPL emulation firmware. Note The XX.XXX is the module version information. S84-ex/S86-ex Operator Manual... - Page 243 If there is emulation module in the memory of product, the product shows the MODULE DELETE menu. If all the emulation module has been deleted, the product shows the MODULE SETTING menu. S84-ex/S86-ex Operator Manual...

-

Page 244: Downloading The Emulation Module

CAUTION Be sure to perform a virus check on the USB memory or SD card before connecting it to the product. SATO Corporation shall not be held responsible for any product malfunctions caused by a virus spread via USB memory or SD card. - Page 245 The product is writing the module data. The bar on the lower portion of the screen indicates the data writing progress. After writing the module data, it goes to the VERIFYING… screen. Note Shows only if INTERFACE SELECT is set to INTERFACE. S84-ex/S86-ex Operator Manual...

- Page 246 XX/XX shows the file number being read and total number of files. After writing the module data, it goes to the VERIFYING… screen. Note Shows only if INTERFACE SELECT is set to SD CARD or USB MEMORY. S84-ex/S86-ex Operator Manual...

-

Page 247: Emulation Module Error

• Module header error. • Not enough memory space or the module size is too big. When the module download error occurred, • Check the module header information. • Delete the old module. • Delete the unused module. S84-ex/S86-ex Operator Manual... -

Page 248: Szpl Emulation Mode

Shows only if the PASSWORD input is enabled button button button button button button button button button button button Shows only if the LCD is selected in SIZE MODE. button button button button button button button button S84-ex/S86-ex Operator Manual... - Page 249 LABEL SIZE ADJ WIDTH Set the width of the media. The setting range varies depending on the following model: Model Setting Range (dot) S84-ex (203 dpi) 0000 to 0832 S84-ex (305 dpi) 0000 to 1248 S84-ex (609 dpi) 0000 to 2496...

- Page 250 LABEL SIZE ADJ HEIGHT Set the height of the media. The setting range varies depending on the following model: Model Setting Range (dot) S84-ex (203 dpi) 00000 to 20000 S84-ex (305 dpi) 00000 to 18000 S84-ex (609 dpi) 00000 to 09600...

- Page 251 The network is not in used when the ID is set to 000. CONTROL HEADER Set the control header character. The setting range is from 000 (00H) to 255 (FFH). COMMAND HEADER Set the command header character. The setting range is from 000 (00H) to 255 (FFH). S84-ex/S86-ex Operator Manual...

-

Page 252: Auto Emulation Mode Switching Function

The auto emulation mode switching function can be disabled by using the <EMU> command. Note Due to the S84-ex/S86-ex emulation module design, the standard SBPL functionality have been removed and the firmware only support minimum set of commands such as ENQ, SOH commands or Test print commands to work with the AIOT printer management tool continuously. -

Page 253: Sdpl Emulation Mode

Shows only if button CUSTOM is selected in button CTRL CODE TYPE. S84-ex/S86-ex Operator Manual... - Page 254 The setting range is from 00 to FF (hexadecimal). Three beeps will sound, indicating error, if the value is identical with other codes (SOH, STX, CNTBY). Note Shows only if CTRL CODE TYPE is set to CUSTOM. S84-ex/S86-ex Operator Manual...

- Page 255 Set whether to allow the use of TrueType font compatible mode. • ENABLE: Allow the use of TrueType fonts. • DISABLE: Do not allow the use of TrueType fonts. By enabling the TrueType font compatible mode, the bold TrueType font will be printed in smaller pitch. S84-ex/S86-ex Operator Manual...

- Page 256 • DISABLE: Do not ignore <SOH> commands. FORMAT ATTRIBUTE PRIORITY Set the priority of the format attribute. Two options can be selected as follows: • COMMAND: The setting is according to SDPL command. • LCD: The setting is according to FORMAT ATTRIBUTE screen. S84-ex/S86-ex Operator Manual...

- Page 257 Shows only if PAUSE MODE PRIORITY is set to LCD. 1-BYTE CODEPAGE PRIORITY Set the priority of the 1-byte codepage. Two options can be selected as follows: • COMMAND: The setting is according to SDPL command. • LCD: The setting is according to 1-BYTE CODEPAGE screen. S84-ex/S86-ex Operator Manual...

- Page 258 TTF STYLE PRIORITY Set the priority of the TrueType font style. Two options can be selected as follows: • COMMAND: The setting is according to SDPL command. • LCD: The setting is according to BOLD STYLE screen. S84-ex/S86-ex Operator Manual...

- Page 259 Set the priority of printer feedback. Two options can be selected as follows: • COMMAND: The setting is according to <STX>a command. This command is effective until you restart the product • LCD: The setting is according to PRINTER FEEDBACK screen. S84-ex/S86-ex Operator Manual...

- Page 260 • ENABLE: Always send the printer feedback characters to the host. • DISABLE: Do not send the printer feedback characters to the host other than the power reset signal. Note Shows only if PRINTER FEEDBACK PRIORITY is set to LCD. S84-ex/S86-ex Operator Manual...

-

Page 261: Sipl Emulation Mode

The active arrow icons are shown on the screen. * Pressing the button on each screen will revert to the button EMULATION MODE menu. button Shows only if the PASSWORD input is enabled button button button button button button button button button S84-ex/S86-ex Operator Manual... - Page 262 • PROP: Print each character with proportional pitch spacing. CODEPAGE Select the code page to be used from the list. The options are as follows: • 1252 • 1253 • 1254 • 1255 • 1256 • 1257 • 850 • 1250 • 1251 S84-ex/S86-ex Operator Manual...

-

Page 263: Adjusting The Product

The base reference point differs depending on the operation mode or media sensor you use. Continuous Mode I-mark Label Gap Label Print and Print and stop position stop position Dispenser Mode I-mark Label Gap Label Print and Print and dispensing dispensing position position S84-ex/S86-ex Operator Manual... -

Page 264: Adjusting The Print Position

Adjust the print position using the following procedure: Make sure that the product is in online mode or offline mode. Press the buttons for one second to enter the adjustment mode. PITCH POSITION shows on the screen. S84-ex/S86-ex Operator Manual... -

Page 265: Adjusting The Media Stop Position

Adjustment for “+” value adjustment Adjustment for “-” value -3.75 mm (-0.15”) ~ +3.75 mm (+0.15”) Note The above dispensing position for printing indicates the label stop position when the media sensor is set to Gap sensor. S84-ex/S86-ex Operator Manual... -

Page 266: More About The Media Stop Position

6.1.4 More about the Media Stop Position Stop position of the label in dispenser mode. The regular position is to let the label stay about 1 mm (0.04") on the liner. Stop position S84-ex/S86-ex Operator Manual... -

Page 267: Limitation On Base Reference Point Adjustment

Adjusted distance (Max.) Adjustment range of the distance between the print position and the stop position for options: Adjusted Distance Adjusted Distance Types of Options Initial Distance (Min.) (Max.) Dispenser 7.5 mm (0.3”) 15.0 mm (0.6”) 22.5 mm (0.9”) S84-ex/S86-ex Operator Manual... -

Page 268: Adjusting The Print Quality

Press the ENTER button to enter the user mode. OFFSET VOLUME shows on the screen. Note If password function is enabled, PASSWORD is shown on the screen instead. In this case, enter the password first. S84-ex/S86-ex Operator Manual... -

Page 269: Adjusting The Print Speed

LINE button to change the product to offline mode. Press the ENTER button. The product changes to the setting mode menu. Select the USER MODE using the buttons. USER MODE shows on the screen and the icon is highlighted in reverse. S84-ex/S86-ex Operator Manual... - Page 270 Press the ENTER button again until PRINT SPEED shows on the screen. Press the buttons to select a value. Press the ENTER button to save the setting. Press the FUNCTION button to return to the setting mode menu. S84-ex/S86-ex Operator Manual...

-

Page 271: Adjusting The Media Sensors

Enter the password to continue. Select the SENSOR LEVEL using the buttons and then press the ENTER button. SENSOR LEVEL shows on the screen. Select AUTO using the buttons and then press the ENTER button. SENSOR SELECT shows on the screen. S84-ex/S86-ex Operator Manual... - Page 272 Press the media feed and media sensor assembly down to lock it. To get the correct adjustment result, perform the adjustment after you have closed the media sensor assembly. Press the ENTER button to start the sensor adjustment. S84-ex/S86-ex Operator Manual...

- Page 273 If CALIBRATION FAILED shows in step 11, clean the media sensor and repeat the above steps for auto adjustment. Select RETRY in step 13. If the problem persists, adjust the media sensor sensitivity level manually. Refer to the following procedures for manual adjustment. S84-ex/S86-ex Operator Manual...

-

Page 274: Adjusting The I-Mark Sensor Level Manually

I-mark resting over the I-mark sensor I-mark sensor. Press the media feed and media sensor assembly down to lock it. To get the correct adjustment result, close the media sensor assembly before performing the adjustment. S84-ex/S86-ex Operator Manual... - Page 275 If the difference between the “High” and the “Low” level values is less than 1.0 V, repeat the procedure from steps 4 through 12. Criteria for Adjustment: Low level (portion without I-mark): ≤ +1.0 V High level (I-mark position) - Low level: ≥ +1.0 V S84-ex/S86-ex Operator Manual...

- Page 276 Note If you are having difficulties in adjusting the sensor level properly, clean the media sensor portion. If the problem persists, contact your SATO reseller or technical support center to replace the media sensor. Press the buttons to change the SLICE LEVEL and then press the ENTER button.

-

Page 277: Adjusting The Gap Sensor Level Manually

The adjustment range of ADJUST LEVEL is from 0 to 127. Note The ADJUST LEVEL manipulates the potentiometer that will be, therefore, reset to 90, the default value when replacing the PCB or initializing the settings. S84-ex/S86-ex Operator Manual... - Page 278 Note If you are having difficulties in adjusting the sensor level properly, clean the media sensor portion. If the problem persists, contact your SATO reseller or technical support center to replace the media sensor. Press the buttons to change the SLICE LEVEL and then press the ENTER button.

-

Page 279: Adjusting The Paper End Sensor