Advertisement

Quick Links

READ AND SAVE THESE INSTRUCTIONS

®

Installation, Operation and Maintenance Manual

Upon receiving unit, check for any damage and report it immediately to the shipper. Also check to see that all accessory

items are accounted for.

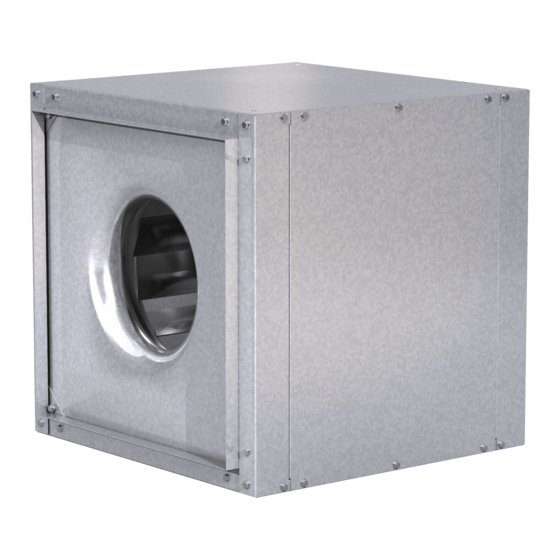

Move fan to desired location and determine position of access panels and motor. Attach the fan to a suitable framework

as specified (hanging or base vibration isolators are recommended). See chart below for dimensions of vibration isolator

centerlines (Fig. 1). See Fig. 2 and 3 for physical dimensions.

The motor's amperage and voltage ratings must be checked for compatibility to supply voltage prior to final electrical

connection. Supply wiring may be routed through knockouts which are provided on the top and bottom of each fan housing.

Provide adequate wiring to permit the access doors to open for servicing. Wiring should be secured inside the fan to prevent

interference with the drive components. All wiring must conform to local and national codes.

Inlet and discharge collars are provided for duct connection. The inlet panel is removable for attaching optional filter box

accessory.

VIBRATION ISOLATOR DIMENSIONAL DATA

Unit Size

A

80

20

3

/

4

90

21

3

/

4

100

23

3

/

4

120

30

1

/

2

150

32

180

37

3

/

8

200

47

3

/

8

M* applies to optional filter box only.

BDF DIMENSIONAL DATA

Fig. 2

BDF Unit

A

B

2

C

I

G

F

J

Unit

A

B

C

Size

80

23

/

18

/

15

/

15

1

1

7

4

2

8

90

24

1

/

21

1

/

18

3

/

4

4

4

100

26

1

/

22

3

/

20

3

/

4

4

4

120

33

27

1

/

22

3

/

4

4

150

34

3

/

32

5

/

27

3

/

4

8

4

180

40

1

/

41

3

/

31

3

/

4

4

4

200

50

1

/

49

1

/

39

3

/

4

4

4

K* is length of fan and filter box combined.

C

M*

22

11

/

26

5

/

16

16

25

5

/

30

1

/

8

2

27

1

/

25

2

/

8

5

31

5

/

30

7

/

8

16

35

27

/

1

8

44

34

15

/

16

51

1

/

36

2

D

E

H

D

E

F

G

/

12

/

9

/

8

/

3

11

3

7

16

16

4

8

18

1

/

15

7

/

12

1

/

10

1

/

4

8

4

2

19

3

/

17

7

/

13

3

/

11

7

/

4

8

4

8

24

1

/

19

7

/

16

13

3

/

8

8

8

28

5

/

23

7

/

19

1

/

16

3

/

1

8

8

8

8

37

1

/

27

7

/

22

1

/

18

7

/

1

2

8

2

8

45

1

/

36

23

1

/

25

1

/

1

8

8

4

Fig. 3

BDF w/ Filter Box

C

Filter

H

I

J

K*

Size

1

5

/

4

/

49

/

16 x 20

3

1

3

8

4

4

1

6

3

/

4

1

/

54

7

/

20 x 25

4

2

8

1

7

3

/

4

1

/

51

7

/

20 x 20

8

2

8

1

7

7

/

5

5

/

63

9

/

12 x 25

8

8

16

1

/

9

7

/

6

3

/

62

1

/

16 x 20

2

8

4

16

1

/

10

1

/

9

5

/

75

3

/

20 x 25

2

2

8

8

1

/

12

1

/

13

85

1

/

16 x 25

2

2

4

Model BDF

Belt Drive Duct Fan

M*

A

C

M*

A

C

K*

B

2

I

G

F

J

Number

Material

of Filters

Thickness (ga.)

2

20

2

20

2

20

4

20

8

20

6

20

12

20

PN 458341

Fig. 1

D

E

H

Approx. Wt. (lbs)

Fan

Filter Box

71

32

92

42

107

52

144

70

223

97

307

134

565

174

Advertisement

Summary of Contents for Greenheck BDF

- Page 1 VIBRATION ISOLATOR DIMENSIONAL DATA Unit Size M* applies to optional filter box only. Fig. 1 BDF DIMENSIONAL DATA Fig. 2 Fig. 3 BDF Unit BDF w/ Filter Box Approx. Wt. (lbs) Unit Filter Number Material Size Size of Filters Thickness (ga.)

- Page 2 (See Fig. 5) For all BDF units, belt tension can be adjusted by loosening four fasteners (marked “R”) on the drive frame. The motor plate slides on the slotted adjusting arms (see Fig. 6). Belt tension should be adjusted to allow 1/64” of deflection per inch of belt span.

-

Page 3: Troubleshooting

MAINTENANCE Belts tend to stretch after a period of time. They should be checked periodically for wear and tightness. When replacing belts, use the same type as supplied with the unit. Matched belts should always be used on units with multigroove pulleys. For belt replacement, loosen the tensioning device far enough to allow removal of the belt by hand. -

Page 4: Parts List

Warranty Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the purchase date. Any units or parts which prove to be defective during the warranty period will be replaced at our option when returned to our factory, transportation prepaid.